Professional Documents

Culture Documents

Elec Feeder

Elec Feeder

Uploaded by

Rodrigo Fritis LopezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Elec Feeder

Elec Feeder

Uploaded by

Rodrigo Fritis LopezCopyright:

Available Formats

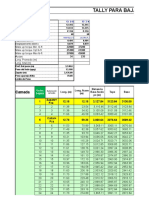

Quantity of Feeders: Weight (lbs.

) per Cubic Foot PCF Moisture Content: %

FMC Technologies, Inc. 2730 Hwy 145 South Saltillo, MS 38866 P: 1.800.356.4899 P: 662.869.5711 F: 662.869.7405 Email: mhsol.info@fmcti.com Name or description of material to be handled: Size of Material (Sieve Analysis) Angle of Repose Material Width Max: deg. Material Length Max: Minimum feed rate (in tons per hour) Belt Loader Trough Slope: deg. down deg. up. Remote Pot TPH Diag. Disc Material Thickness

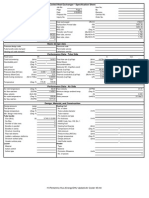

Heavy Duty Electromagnetic and Electromechanical Feeder Data Sheet

Temperature of Material Temperature of Surroundings Maximum feed rate (in tons per hour)

F deg. Max F deg. Max

TPH

Trough Type: (Sketch if other than flat open pan) Flat Open Pan Covered Tubular Down Spout Trough Liners: T1-A 304SS

Dimensions Requested Wide X Long X High None Requested (Provide most economical) Type of Mounting: Base Suspension Drive Position: Under trough in rear Over trough in front AC (Municipal) Power: Voltage Cycle Hz

UHMW

Other

Controller Enclosure: Standard (NEMA+) D.C. Input Load Monitoring Proportional If there are any additional controller requirements please describe: Method of supplying material to Syntron Feeder trough:

Feeder discharges into:

If an existing hopper, provide dimensions and wall slope. Provide additional sketch if necessary. Hopper Transition:

T = H = B = Rear Angle = Front Angle = W = Side Angle =

If there are any unusual operating conditions requiring special construction, please give details.

Customer Type: Company Name: 10204 02-17-10

User

OEM

Resale

Contact: Address: City, State, Zip:

Email: Phone: Fax:

You might also like

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Rig Sizing CalculatorDocument32 pagesRig Sizing CalculatorHorafigNo ratings yet

- Hydraulics CalculationDocument1 pageHydraulics CalculationSudish BhatNo ratings yet

- Drill Pipe Performance DataDocument35 pagesDrill Pipe Performance DatasnatajNo ratings yet

- Design (Imperial) 7.23Document9 pagesDesign (Imperial) 7.23ozgurturunc4No ratings yet

- BELT CONVEYOR - Discharge TrajectoryDocument1 pageBELT CONVEYOR - Discharge TrajectoryEslam FaroukNo ratings yet

- Conveyor Tension and Trajectory CalculationDocument8 pagesConveyor Tension and Trajectory CalculationGregory Nick Toledo Veliz50% (2)

- Conveyor CalculationsDocument3 pagesConveyor Calculationsmishra_1982No ratings yet

- Pipeline Mechanical DesignDocument6 pagesPipeline Mechanical DesignArun Ramu100% (1)

- Design (Imperial) 7.23Document9 pagesDesign (Imperial) 7.23Salih HasNo ratings yet

- Screw ConveyorDocument6 pagesScrew ConveyorJobsonReisNo ratings yet

- Konveyör Hesabı 7.24Document9 pagesKonveyör Hesabı 7.24Salih HasNo ratings yet

- Cyclone SeparatorDocument1 pageCyclone SeparatorDan Toader100% (1)

- 30 Ton Capacity Puller Set: Parts List ForDocument2 pages30 Ton Capacity Puller Set: Parts List ForGuatemalan1979No ratings yet

- Calculation Sheet IEEE80Document3 pagesCalculation Sheet IEEE80Suranga JayaweeraNo ratings yet

- FM200 CalcFlow Mundu R01Document6 pagesFM200 CalcFlow Mundu R01Rahul DevaNo ratings yet

- Solo 2530Document3 pagesSolo 2530Anerol Zoto AicragNo ratings yet

- EvaporadorDocument1 pageEvaporadormelatorNo ratings yet

- Hysys PrintDocument33 pagesHysys PrintmilagrosNo ratings yet

- Input Echo of Support Lug InputDocument1 pageInput Echo of Support Lug InputwhngomjNo ratings yet

- Form - PCS PDFDocument2 pagesForm - PCS PDFBrian WellsNo ratings yet

- Axial Inline Fan 200 CMHDocument1 pageAxial Inline Fan 200 CMHHonka VoxNo ratings yet

- 30 Ton Capacity Puller Set: Parts List ForDocument2 pages30 Ton Capacity Puller Set: Parts List ForGuatemalan1979No ratings yet

- Specification Sheet: Colchester Tornado 100 2 Axis CNC Lathe With Fanuc OT ControlDocument1 pageSpecification Sheet: Colchester Tornado 100 2 Axis CNC Lathe With Fanuc OT ControlMoustaffaNo ratings yet

- AHU Technical Specification & DrawingDocument12 pagesAHU Technical Specification & DrawingADsupermanNo ratings yet

- CM470Document2 pagesCM470kahandawalaNo ratings yet

- Longwise Pocket Bike QuotationDocument1 pageLongwise Pocket Bike QuotationNathan McmenneminNo ratings yet

- Wave Equation ApplicationsDocument26 pagesWave Equation ApplicationsUmdpmg Ursa100% (1)

- Triple Wire Machine Exampl KiwiDocument39 pagesTriple Wire Machine Exampl KiwiVenkatNo ratings yet

- Wong Uma Ure 01-01-03 TechnicalDocument5 pagesWong Uma Ure 01-01-03 TechnicalinquillayNo ratings yet

- Doosan S500LCV Hydraulic ExcavatorDocument3 pagesDoosan S500LCV Hydraulic ExcavatorDidik Hartadi0% (1)

- 13 - 375 Casing Tally PEB - V5 - SAL-18 - 09-05-15Document18 pages13 - 375 Casing Tally PEB - V5 - SAL-18 - 09-05-15Juan AndiaNo ratings yet

- 3.0 Data Vent. 148 PG 900 HP 680 CFMDocument1 page3.0 Data Vent. 148 PG 900 HP 680 CFMRigo McFly Casanova ArmijoNo ratings yet

- Air Cooler 45 Case1 PDFDocument2 pagesAir Cooler 45 Case1 PDFHeny MarthaNo ratings yet

- CT Model NumberDocument1 pageCT Model NumbergiahaoNo ratings yet

- Techincal Data Sheet EPB-Shield For BC-18 Description Specification RemarksDocument4 pagesTechincal Data Sheet EPB-Shield For BC-18 Description Specification Remarkskalpesh86patel9246No ratings yet

- Plate Heat Exchangers: Technical DataDocument15 pagesPlate Heat Exchangers: Technical DataIvanNo ratings yet

- Pullet v4.1Document2 pagesPullet v4.1Kalil RahimanNo ratings yet

- 100 PresentationDocument19 pages100 Presentationapi-253596801No ratings yet

- Luna 30,000 Single Wall Mount Submittal Data SheetDocument2 pagesLuna 30,000 Single Wall Mount Submittal Data Sheetcmorley5057No ratings yet

- Lath Machine (Daulat) Make Welding Machine (Tig-300consists ofDocument5 pagesLath Machine (Daulat) Make Welding Machine (Tig-300consists ofsudhakar84No ratings yet

- Microsoft PowerPoint - PCM Vulcain TMDocument22 pagesMicrosoft PowerPoint - PCM Vulcain TMDouglas A. RuizNo ratings yet

- Calculating Book of Flow Meter: Shan Xi Yi Xin Measurement & Control Meter Co., LTDDocument1 pageCalculating Book of Flow Meter: Shan Xi Yi Xin Measurement & Control Meter Co., LTDShiva Prakasam PernetiNo ratings yet

- Option 3bDocument6 pagesOption 3bdeepakjoyinNo ratings yet

- Casing Summary: Well Name: Sample 11 - Full DataDocument0 pagesCasing Summary: Well Name: Sample 11 - Full DataMohamed SaeedNo ratings yet

- Output Summary: Waruteknikatama Waru77Document1 pageOutput Summary: Waruteknikatama Waru77hudionoNo ratings yet

- MDB Room (Bsmt.1) Rev.3Document5 pagesMDB Room (Bsmt.1) Rev.3arifkhadeerNo ratings yet

- TH-SP 204: Stationary PlanerDocument1 pageTH-SP 204: Stationary PlanerDanOlteanuNo ratings yet

- DS581 Dropdrum UserguideDocument2 pagesDS581 Dropdrum UserguideWilliam RiosNo ratings yet

- HHK 12A DatasheetDocument2 pagesHHK 12A DatasheetFelipe FernandesNo ratings yet

- Plunger LiftDocument6 pagesPlunger LiftAnonymous 7pEAc0lGWNo ratings yet

- K9KEF 2013 - SpecificationDocument1 pageK9KEF 2013 - SpecificationbdthinhNo ratings yet

- Geo Pro Inc Head Loss TablesDocument1 pageGeo Pro Inc Head Loss TablesmarrukhjNo ratings yet

- Centrifugal Pump Process Data SheetDocument2 pagesCentrifugal Pump Process Data Sheetmayukhguha1988No ratings yet

- GSP 31Document4 pagesGSP 31LAKHDARI LarbiNo ratings yet