Professional Documents

Culture Documents

Cavitation in Centrifugal Pumps: Alternative Solutions

Cavitation in Centrifugal Pumps: Alternative Solutions

Uploaded by

Mohammed MorsyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cavitation in Centrifugal Pumps: Alternative Solutions

Cavitation in Centrifugal Pumps: Alternative Solutions

Uploaded by

Mohammed MorsyCopyright:

Available Formats

Cavitation in centrifugal pumps

Cavitation is a common occurrence but is the least understood of all pumping problems. Your pump is cavitating if knocking noises and vibrations can be heard when it is operating. Other signs may be erratic power consumption and fluctuations or reductions in pump output. If you continue to operate your pump when it is cavitating, it will be damaged. Impeller surfaces and pump bowls will pit and wear, eventually leading to mechanical destruction. increase the size of valves and pipework do not allow air into the suction line ensure adequate submergence over the foot valve. The submergence should be at least 5.3 times the suction diameter.

Alternative solutions

One solution may be to reduce the required net positive suction head. This can done by lowering the pump speed. However, this will also result in reduced output from the pump which may not suit your system. If pump suction conditions cannot be improved, you should seek expert assistance. It may be that your pumping system needs to be redesigned.

What is the cause?

When water enters a pump, its velocity increases causing a reduction in pressure within the pumping unit. If this pressure falls too low, some of the water will vaporise, forming bubbles entrained in the liquid. These bubbles collapse violently as they move to areas of higher pressure creating the noise and vibration from the pump. The pressure required to operate a pump without causing cavitation is called net positive suction head (NPSH). Therefore the pressure head available at the pump inlet should exceed the NPSH required. This is specified by the pump manufacturer, and is a function of the pump design

Assistance

Your local office of the Department of Natural Resources and Water may be able to assist you further with this topic or water supply, irrigation or drainage generally. Call them for details of other fact sheets, available services and associated charges. March 2006 W8 For further information phone 13 13 04

How to avoid cavitation

As cavitation relates only to the suction side of the pump all prevention measures should be directed at this area. Suction lifts that are too high will only encourage cavitation. As a general rule, centrifugal pumps located less than 4 metres above the water level should not experience cavitation. The following guidelines should be applied to avoid the problem: minimise the number of valves and bends in the suction line use eccentric reducers, not concentric ensure the straight side of the eccentric reducer is installed along the top of the suction line suction length should be as short as possible suction pipe should be at least the same diameter as the pump inlet connection use long radius bends

www.nrw.qld.gov.au

Water ... securing water for Queenslands future

311662 177902

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Double Paddle MixerDocument118 pagesDouble Paddle MixerArun Kumar80% (5)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Bearing Shaft Fits and Tolerances 1Document9 pagesBearing Shaft Fits and Tolerances 1Arun KumarNo ratings yet

- Industrial Pipe Marking GuideDocument2 pagesIndustrial Pipe Marking GuideArun KumarNo ratings yet

- CapaDocument24 pagesCapaArun KumarNo ratings yet

- Safety Management SystemDocument17 pagesSafety Management SystemPradeep NegiNo ratings yet

- Safety Management SystemDocument17 pagesSafety Management SystemPradeep NegiNo ratings yet

- Ims Iso 9001 Iso 14001 Ohsas 18001 Documentation PackageDocument9 pagesIms Iso 9001 Iso 14001 Ohsas 18001 Documentation PackageArun KumarNo ratings yet

- Ehandbook Process Safety 1309 PDFDocument15 pagesEhandbook Process Safety 1309 PDFArun KumarNo ratings yet

- Glass GlossaryDocument3 pagesGlass GlossaryArun Kumar100% (1)

- Corrective and Preventive Actions: "A Five Step Approach"Document41 pagesCorrective and Preventive Actions: "A Five Step Approach"Arun KumarNo ratings yet

- OISD Standard 244 DraftDocument94 pagesOISD Standard 244 DraftSuresh GanesanNo ratings yet

- Seko Dosing DiaDocument12 pagesSeko Dosing DiaSeptriani LaoliNo ratings yet

- Safety Is Money in The BankDocument3 pagesSafety Is Money in The BankArun KumarNo ratings yet

- Non Veg DishesDocument99 pagesNon Veg DishesArun KumarNo ratings yet

- Veg DishesDocument45 pagesVeg DishesArun KumarNo ratings yet

- Melting Points of MetalsDocument1 pageMelting Points of MetalsArun KumarNo ratings yet

- Pug Mills / Paddle Mixers: Design & Principles of OperationDocument1 pagePug Mills / Paddle Mixers: Design & Principles of OperationArun KumarNo ratings yet

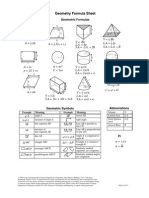

- Geometry Formula SheetDocument1 pageGeometry Formula SheetArun KumarNo ratings yet

- Dust Control in TunnelsDocument27 pagesDust Control in TunnelsrockyminNo ratings yet

- The Explosives Rules, 1983: Preliminary 1. Short Title and CommencementDocument2 pagesThe Explosives Rules, 1983: Preliminary 1. Short Title and CommencementArun KumarNo ratings yet

- List of Youtube Video Clips For Kataline Infraproducts PVT Ltd-IndiaDocument4 pagesList of Youtube Video Clips For Kataline Infraproducts PVT Ltd-IndiaArun KumarNo ratings yet

- Iso 9001 2008 StandardDocument90 pagesIso 9001 2008 StandardArun KumarNo ratings yet