Professional Documents

Culture Documents

Advance Valves Commenced Manufacturing Industrial Valves Over 25 Years Ago

Advance Valves Commenced Manufacturing Industrial Valves Over 25 Years Ago

Uploaded by

vchajjedCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Advance Valves Commenced Manufacturing Industrial Valves Over 25 Years Ago

Advance Valves Commenced Manufacturing Industrial Valves Over 25 Years Ago

Uploaded by

vchajjedCopyright:

Available Formats

Advance VaIves commenced manufacturing ndustrial Valves over 25 years ago, in 1986.

The Company was

promoted and is presently led by Mr. Uma Shanker, a Gold Medalist in Mechanical Engineering with a Master's

Degree in Business Administration (MBA) and industry experience of over 35 years.

Since then Advance VaIves has established its position among the top 5 quality manufacturers internationally in its

product range. Advance Valves is today considered a pioneer in technology for its Dual Plate Check & Balancing

Valves, and even for its Butterfly Valves, especially in the domestic market.

Advance VaIves has regularly been supplying its products to the Oil and Gas, Refineries and Petrochemical, Power,

Water, Fertiliser, Steel, and HVAC sectors. Today, Advance Valves interacts with all the major clients and EPC's both

in the domestic markets as well as globally.

Advance VaIves is considered by its clients both in the national and international marketplace to be amongst the

top few vendors in its range of products. This is because of its:

O Ability to supply valves of exotic metallurgies, including superior Nickel alloys & Titanium;

O Ability to supply valves of sizes between 2 to 3 metres;

O Ability to supply valves upto # 2500, and AP 6A;

O Ability to meet client's stringent quality requirements, including bubbletight shutoff;

O Ability to manufacture valves for Cryogenic applications down to -196 deg. C;

O Ability to manufacture valves for Fire-Safe applications up to 900 deg C;

O Ability to manufacture valves complying with Fugitive Emission norms;

O Excellent track record of our products.

Advance VaIves specializes in the manufacture of Dual Plate Check Valves (as per AP 594), High Performance

Metal Seated and Soft Seated Butterfly Valves (as per AP 609) in metallurgies suitable for all petrochemical, sour

services, seawater services, power & chemical, mining, power and oxygen sectors, amongst other applications.

These include offerings in Aluminum Bronze, Duplex S.S, Titanium, Hastelloy, Alloy 20, ncolloy amongst other super

alloys. Our Balancing Valves are considered to be a de-facto standard in the ndian HVAC sector.

Advance VaIves products have been widely accepted and repeatedly used in very diverse applications, the energy

and process industries in particular, and others on a wider note.

Soclal responslblllLles

We at Advance VaIves firmly believe that it is vitally important to give back to the communities in which we live and

work.

Corporate Social Responsibility has become an integral part of the Advance Valves' philosophy and is the

cornerstone of our core values for being a good Corporate Citizen.

We define Corporate Social Responsibility (CSR) as making socially responsible products, engaging in socially

responsible employee relations and making a commitment to the community around it.

Our CSR objectives include maintaining top notch ethical and business practices: safety, health and well-being of our

employees and those around us; energy conservation measures, conservation of water, waste management and

community engagement. Undertaking these activities will surely enable a brighter future for our employees and their

families.

We have initiated health care programs for our employees and sponsored education for their children. We also

contribute both money and time to institutions and organizations that serve people all over the world, helping to

enhance the quality of life for everyone in the global community.

Our products have formed part of the Euro V projects undertaken by the various oil refineries, replacing valves with

older and dated technologies.

Our ultimate aim is to do our bit towards making the world a better place to live in

V|s|on 8tatement:

Avl |s corr|lled lo oecor|rg lre |eader |r va|ve App||cal|or 3o|ul|orsl

H|ss|on 8tatement:

0ur r|ss|or |s lo prov|de lre r|grl va|ve lre l|rsl l|re, every l|re, ra||rg us ar |rd|spersao|e parlrer lo lre corpar|es

Wrose ous|ress We supporl

Quality is an integral component in Advance Valve's philosophy. We are an SO 9001-2008 & AP 6D certified

organization having CE PED accreditation as well. Advance Dual Plate Check Valves and Metal Seated Butterfly

Valves have been successfully certified for FireSafe applications (BS 6755, SO 10497) and cryogenic services (BS

6364). We have developed in-house Cryogenic test facilities up to 196 C & Fugitive Emission testing requirements

for Butterfly Valves to suit & meet requirements of LNG & liquid air applications.

Advance Valves is committed to creating value for all its stakeholders in particular and society in general, by

engaging in distinct business areas relating to design, manufacturing, supply and support of products and services

globally.

To achieve this, the organization will ensure sustained deployment of emerging technologies in conformance with

national and international standards, and will continually monitor and improve the effectiveness of quality

management systems for:

O :stomers - by providing total solutions in line with their stated and implied requirements;

O mpIoyees - by empowerment at all levels in safe and conducive work environments;

O $:ppIiers - by equipping them with appropriate tools and technology to meet the quality requirements;

O $areoIders - by enhancing the prestige of the organization through adoption of productive methods and

ethical practices, thereby becoming a respectable Corporate Citizen.

This policy is implemented and maintained at all levels within the organization and will be reviewed to ensure that the

Corporate goals are achieved. The effective operation of the processes are controlled through criteria and methods

communicated to the appropriate level and monitor, measurement wherever applicable and analysis to achieve

planned results and continuous improvement.

PRODU%

Balancing Valves

Dual plate check valves

LLerfly concenLrlc valves

LLerfly doble eccenLrlc valves

LLerfly Lrlple eccenLrlc valves

AcLaLed valves

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Bill of Lading v1 - Master-ComprimidoDocument2 pagesBill of Lading v1 - Master-ComprimidoalexanderNo ratings yet

- Functional Testing E-GuideDocument18 pagesFunctional Testing E-GuidePrathyusha V100% (1)

- Human Resource Training and DevelopmentDocument11 pagesHuman Resource Training and DevelopmentSiti Sarah Zalikha Binti Umar BakiNo ratings yet

- YAHOO! Corporate Governance GuidelinesDocument10 pagesYAHOO! Corporate Governance GuidelinesAli Shafique0% (1)

- Brcode India Reporting - Service Line JR: S Band Primary LocationDocument26 pagesBrcode India Reporting - Service Line JR: S Band Primary LocationVijay KumarNo ratings yet

- Planning: Gas Authority of India (GAIL) - New PlansDocument17 pagesPlanning: Gas Authority of India (GAIL) - New PlansDivjot BatraNo ratings yet

- The Pivotal Factors For Effective External EngagementDocument10 pagesThe Pivotal Factors For Effective External EngagementAbdel AzizNo ratings yet

- Payslip Apr2020Document1 pagePayslip Apr2020Pinki Mitra DasNo ratings yet

- OHS Hazard Physical Hazard Isolation Chemical Hazard Radiation Sharp Edges Ergonomics Work Netiquette Etiquette Flaming SpamDocument2 pagesOHS Hazard Physical Hazard Isolation Chemical Hazard Radiation Sharp Edges Ergonomics Work Netiquette Etiquette Flaming SpamCelNo ratings yet

- Class 12th E-Ship Chapter 8Document8 pagesClass 12th E-Ship Chapter 8Mu saNo ratings yet

- The Global ExpansionDocument17 pagesThe Global Expansionsharaf fahimNo ratings yet

- HTTPSWWW Ws - gov.Taipei001Upload405relfile1828875928c6c8811 F50a 402a b961 C23067fba50c PDFDocument218 pagesHTTPSWWW Ws - gov.Taipei001Upload405relfile1828875928c6c8811 F50a 402a b961 C23067fba50c PDF林聖倫No ratings yet

- SWOT Analysis in Action at SKODADocument3 pagesSWOT Analysis in Action at SKODARashid ShahzadNo ratings yet

- Fa2 Ch-2 Current LiabilitiesDocument82 pagesFa2 Ch-2 Current LiabilitiesTsi AwekeNo ratings yet

- AutoReceipt 2543324021 PDFDocument1 pageAutoReceipt 2543324021 PDFSudhir TanwarNo ratings yet

- Jacob Linstruth Resume 09Document1 pageJacob Linstruth Resume 09api-487675461No ratings yet

- Chapter 1 & 2Document14 pagesChapter 1 & 2Dawit BekeleNo ratings yet

- Human Resource Management Project About IsuzuDocument5 pagesHuman Resource Management Project About IsuzuHilary Fae FigueroaNo ratings yet

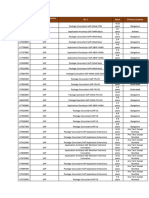

- TransactionDocument12 pagesTransactionutkarshdubey.capNo ratings yet

- Juris Doctor College of Law - Xavier University Ateneo de Cgayan Effective SY 2020-2021 First Year LAW Subject Units Law Subject UnitsDocument1 pageJuris Doctor College of Law - Xavier University Ateneo de Cgayan Effective SY 2020-2021 First Year LAW Subject Units Law Subject UnitsNaiza Mae R. BinayaoNo ratings yet

- Acknowledgement: Saurabh Kushwaha (B.Pharma 8 Semester) Roll - No,-1908720500064Document22 pagesAcknowledgement: Saurabh Kushwaha (B.Pharma 8 Semester) Roll - No,-1908720500064Vivek KushwahaNo ratings yet

- Ethical Leadership Behaviour and Employee Satisfaction: January 2010Document14 pagesEthical Leadership Behaviour and Employee Satisfaction: January 2010Ayele BizunehNo ratings yet

- Test Bank Management Information Systems 5th Edition Effy OzDocument19 pagesTest Bank Management Information Systems 5th Edition Effy OzChristian Perez100% (1)

- How To Write Resume For Business AnalystDocument7 pagesHow To Write Resume For Business Analystsyn0tiwemym3100% (2)

- Business Sustainability and Transformation Strategies 2021 Ebook enDocument10 pagesBusiness Sustainability and Transformation Strategies 2021 Ebook enerdaltekinNo ratings yet

- GDP, GNP, SavDocument108 pagesGDP, GNP, SavAshish ParidaNo ratings yet

- Ca 1 Costing TechniquesDocument6 pagesCa 1 Costing TechniquesORIYOMI KASALINo ratings yet

- Vodafone Idea Limited/Idea Cellular Limited: Manager - Central Product Configurations MAY 2015-JULY 2021Document2 pagesVodafone Idea Limited/Idea Cellular Limited: Manager - Central Product Configurations MAY 2015-JULY 2021nikskujuNo ratings yet

- Passive Attacks: Passive Attacks and Active Attacks. A Passive Attack Attempts To Learn or Make Use of Information FromDocument7 pagesPassive Attacks: Passive Attacks and Active Attacks. A Passive Attack Attempts To Learn or Make Use of Information FromD'Third AnoriNo ratings yet

- Week 3 - Fintech StudyDocument191 pagesWeek 3 - Fintech StudyMohamed RadwanNo ratings yet