Professional Documents

Culture Documents

Lifter Construction Guide: Author: Timothy M. Ventura Date: March 09, 2002

Uploaded by

gbelusicOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lifter Construction Guide: Author: Timothy M. Ventura Date: March 09, 2002

Uploaded by

gbelusicCopyright:

Available Formats

Lifter Construction Guide

Author: Timothy M. Ventura Date: March 09, 2002 Warning Notice: This document is intended for educational use only! The project described in this document uses

extremely high-voltage power-sources, and is intended for readers over 21 years of age who are experienced working with dangerously high-voltages. If you are not a legal adult, or are not proficient working with dangerously high-voltages, do not try to build this project without expert supervision. The author of this document is not responsible for any death, injury, or property damage resulting from or relating to the procedures shown or devices described in this document.

Purpose of this Document: This document provides a step-by-step description of the methods and procedures involved with building a prototype electrokinetic propulsion-device. If properly constructed, this device will generate enough force to levitate itself from a resting surface. Step 1: Obtain Required Materials 2mm by 6mm balsa-wood strips 30-gauge enameled copper magnet-wire Aluminum Foil 1 Tube Super-Glue or Krazy-Glue Brand cyanoacrylate adhesive Sewing Thread 1 hobby knife 1 25,000+ volt DC Power supply 1 Scotch-Brand tape roll NOTE: For more details, please see included Required Materials document. Step 2: Cut Balsa Support-Struts Cut the balsa-wood strips in half to create 2mm by 3mm strips. Cut these into two sets balsa struts 1 set of 3 struts 20 centimeters in length, and a second set of 2 struts 11 centimeters in length. Bevel the edges of each of the 20cm struts to allow it to be glued later at an angle to the 11cm struts. The beveling should be about 30 degrees in slope, and remember to bevel both ends on the same side of the balsa face.

Page 1 of 4

Step 3: Assemble Balsa Struts Mark each of the 11cm struts at the top (to help you remember which end is up) and again at a mark 4cm up from the bottom. Sparingly use super-glue to attach each of the 3 vertical 11cm struts to a 20cm horizontal strut as shown in the picture. In the picture, the beveled ends of the 20cm struts have been glued at right angles at the 4cm mark on the vertical struts.

Step 4: Complete Chassis Assembly Similar to step 3, glue together the 3 pieces of the Lifter frame using super-glue. Glue the unconnected ends of the 20cm struts to the other side of the 4cm mark that you created on the vertical strut in Step 3. Ensure that the ends of the Lifter line up as shown in the picture.

Step 5: Cut Aluminum Foil Strip Cut a strip of aluminum foil 5cm wide and approximately 1 meter in length. This foil strip will be used to surround the bottom-part of the Lifter.

Page 2 of 4

Step 6: Fold Foil Around Chassis Put glue on the 20cm strip and hold it onto the foil until it sets. Notice in the picture how the foil is even with the bottom of the vertical struts. If done correctly, you should have an extra 1-centimeter of foil above the 20cm balsa horizontal strut. Roll the Lifter chassis down the length of the foil, gluing for each side of the chassis as you go. You must have an extra 1cm lip above the horizontal struts to reduce ion-leakage. Step 7: Fold down Foil Edges Cut the corners around the top of the 1 cm lip above the horizontal struts and fold the foil over the top of the strut for each of the 3 Lifter sides. Use a piece of Scotch-tape cut in half lengthwise to hold the folded corners as close to the inside of the foil as possible and reduce leakage.

Step 8: Attach Ground Wire to Foil Poke a small hole through the foil skirt and run the ground-wire through it as shown in the picture. The hole should be behind the strut so that the wire is supported by it. Make sure to strip the ground-wire of its enamel coating before you connect it. The ground wire must have a section of barecopper to contact the foil in order to work. Give yourself about 2 extra feet of wire off the lifter to connect it to your power-supplys ground.

Page 3 of 4

Step 9: Attach Corona Wire Approximately 4 cm up from the top of the foil, or about 2cm from the very top of the vertical support struts, run a length of magnet wire around all three vertical struts. Make sure to loop the wire around each of the vertical struts at least once to ensure that it stays in place, and when you come back to the first vertical strut, tie the wire off so that the corona wire runs around the entire frame of the Lifter. After you have the corona-wire in place, scrape some of the enamel off of the wire. Step 10: Finished Lifter If you have correctly followed the above steps, you should have a Lifter prototype identical to the one shown here. Use the Testing Guide document to assist you with testing the Lifter, and use the Troubleshooting document if you encounter problems while testing.

Page 4 of 4

You might also like

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

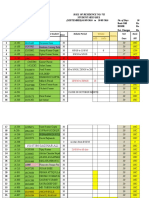

- Pranveer Singh Group of Institutions, Nh-2, Bhauti, Kanpur Bus Route No.1 ONLY Dated .11.11.2018Document2 pagesPranveer Singh Group of Institutions, Nh-2, Bhauti, Kanpur Bus Route No.1 ONLY Dated .11.11.2018daskhagoNo ratings yet

- Cug August PaymentDocument1 pageCug August PaymentdaskhagoNo ratings yet

- Notice: Hostel in From WillDocument1 pageNotice: Hostel in From WilldaskhagoNo ratings yet

- Moonish Crazing PDFDocument1 pageMoonish Crazing PDFdaskhagoNo ratings yet

- SDVSZZSFBDocument10 pagesSDVSZZSFBdaskhagoNo ratings yet

- Dielectric element nodal positions and connectivity for 1V electrodesDocument1 pageDielectric element nodal positions and connectivity for 1V electrodesdaskhagoNo ratings yet

- DcascascDocument16 pagesDcascascdaskhagoNo ratings yet

- Weibull plots for stretch levels of materialDocument3 pagesWeibull plots for stretch levels of materialdaskhagoNo ratings yet

- HALL OF RESIDENCE NO. VII STUDENT MESS BILLDocument379 pagesHALL OF RESIDENCE NO. VII STUDENT MESS BILLdaskhagoNo ratings yet

- SgfbsfbsDocument6 pagesSgfbsfbsdaskhagoNo ratings yet

- New Work 6Document4 pagesNew Work 6daskhagoNo ratings yet

- DVSVVDocument4 pagesDVSVVdaskhagoNo ratings yet

- HALL OF RESIDENCE NO. VII STUDENT MESS BILLDocument379 pagesHALL OF RESIDENCE NO. VII STUDENT MESS BILLdaskhagoNo ratings yet

- HALL OF RESIDENCE NO. VII STUDENT MESS BILLDocument379 pagesHALL OF RESIDENCE NO. VII STUDENT MESS BILLdaskhagoNo ratings yet

- HALL OF RESIDENCE NO. VII STUDENT MESS BILLDocument379 pagesHALL OF RESIDENCE NO. VII STUDENT MESS BILLdaskhagoNo ratings yet

- HALL OF RESIDENCE NO. VII STUDENT MESS BILLDocument379 pagesHALL OF RESIDENCE NO. VII STUDENT MESS BILLdaskhagoNo ratings yet

- Full Length Paper INCAM2015 1Document3 pagesFull Length Paper INCAM2015 1daskhagoNo ratings yet

- HALL OF RESIDENCE NO. VII STUDENT MESS BILLDocument379 pagesHALL OF RESIDENCE NO. VII STUDENT MESS BILLdaskhagoNo ratings yet

- New Work 4Document3 pagesNew Work 4daskhagoNo ratings yet

- HALL OF RESIDENCE NO. VII STUDENT MESS BILLDocument379 pagesHALL OF RESIDENCE NO. VII STUDENT MESS BILLdaskhagoNo ratings yet

- HALL OF RESIDENCE NO. VII STUDENT MESS BILLDocument379 pagesHALL OF RESIDENCE NO. VII STUDENT MESS BILLdaskhagoNo ratings yet

- Application Form Regular Faculty150816111245 PDFDocument7 pagesApplication Form Regular Faculty150816111245 PDFdaskhagoNo ratings yet

- Schematic Diagram Electrode Assembly PDFDocument1 pageSchematic Diagram Electrode Assembly PDFdaskhagoNo ratings yet

- Mess DuesDocument1 pageMess DuesdaskhagoNo ratings yet

- Freely-jointed polymer chain modelDocument6 pagesFreely-jointed polymer chain modelkhayatNo ratings yet

- Marc Mess PaymentDocument1 pageMarc Mess PaymentdaskhagoNo ratings yet

- September Mess Bill-2016Document365 pagesSeptember Mess Bill-2016daskhagoNo ratings yet

- Mess Menu 1 December 2016Document2 pagesMess Menu 1 December 2016daskhagoNo ratings yet

- Paymnet and Receipt Onward June-16..Document31 pagesPaymnet and Receipt Onward June-16..daskhagoNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- MQC Lab Manual 2021-2022-AutonomyDocument39 pagesMQC Lab Manual 2021-2022-AutonomyAniket YadavNo ratings yet

- Grading System The Inconvenient Use of The Computing Grades in PortalDocument5 pagesGrading System The Inconvenient Use of The Computing Grades in PortalJm WhoooNo ratings yet

- Audi Q5: First Generation (Typ 8R 2008-2017)Document19 pagesAudi Q5: First Generation (Typ 8R 2008-2017)roberto100% (1)

- Consumers ' Usage and Adoption of E-Pharmacy in India: Mallika SrivastavaDocument16 pagesConsumers ' Usage and Adoption of E-Pharmacy in India: Mallika SrivastavaSundaravel ElangovanNo ratings yet

- !!!Логос - конференц10.12.21 копіяDocument141 pages!!!Логос - конференц10.12.21 копіяНаталія БондарNo ratings yet

- SBI Sample PaperDocument283 pagesSBI Sample Paperbeintouch1430% (1)

- JM Guide To ATE Flier (c2020)Document2 pagesJM Guide To ATE Flier (c2020)Maged HegabNo ratings yet

- BenchmarkDocument4 pagesBenchmarkKiran KumarNo ratings yet

- Philippine Army BDU BidDocument2 pagesPhilippine Army BDU BidMaria TeresaNo ratings yet

- Steps To Christ AW November 2016 Page Spreaad PDFDocument2 pagesSteps To Christ AW November 2016 Page Spreaad PDFHampson MalekanoNo ratings yet

- HVAC Master Validation PlanDocument51 pagesHVAC Master Validation Plannavas197293% (30)

- Money Laundering in Online Trading RegulationDocument8 pagesMoney Laundering in Online Trading RegulationSiti Rabiah MagfirohNo ratings yet

- MCQ Ch16solDocument4 pagesMCQ Ch16solandiswahlongwa870No ratings yet

- Mobile ApplicationDocument2 pagesMobile Applicationdarebusi1No ratings yet

- H I ĐĂNG Assigment 3 1641Document17 pagesH I ĐĂNG Assigment 3 1641Huynh Ngoc Hai Dang (FGW DN)No ratings yet

- Physioex 9.0 Exercise 1 Act 1Document5 pagesPhysioex 9.0 Exercise 1 Act 1Adela LhuzNo ratings yet

- Technical specifications for JR3 multi-axis force-torque sensor modelsDocument1 pageTechnical specifications for JR3 multi-axis force-torque sensor modelsSAN JUAN BAUTISTANo ratings yet

- A Database of Chromatographic Properties and Mass Spectra of Fatty Acid Methyl Esters From Omega-3 ProductsDocument9 pagesA Database of Chromatographic Properties and Mass Spectra of Fatty Acid Methyl Esters From Omega-3 ProductsmisaelNo ratings yet

- (123doc) - Chapter-24Document6 pages(123doc) - Chapter-24Pháp NguyễnNo ratings yet

- Damcos Mas2600 Installation UsermanualDocument26 pagesDamcos Mas2600 Installation Usermanualair1111No ratings yet

- PHY210 Mechanism Ii and Thermal Physics Lab Report: Faculty of Applied Sciences Uitm Pahang (Jengka Campus)Document13 pagesPHY210 Mechanism Ii and Thermal Physics Lab Report: Faculty of Applied Sciences Uitm Pahang (Jengka Campus)Arissa SyaminaNo ratings yet

- Stroboscopy For Benign Laryngeal Pathology in Evidence Based Health CareDocument5 pagesStroboscopy For Benign Laryngeal Pathology in Evidence Based Health CareDoina RusuNo ratings yet

- Command List-6Document3 pagesCommand List-6Carlos ArbelaezNo ratings yet

- Equilibruim of Forces and How Three Forces Meet at A PointDocument32 pagesEquilibruim of Forces and How Three Forces Meet at A PointSherif Yehia Al MaraghyNo ratings yet

- SiloDocument7 pagesSiloMayr - GeroldingerNo ratings yet

- Bio310 Summary 1-5Document22 pagesBio310 Summary 1-5Syafiqah ArdillaNo ratings yet

- Indian Journal of Natural Products and Resources Vol 1 No 4 Phytochemical pharmacological profile Cassia tora overviewDocument8 pagesIndian Journal of Natural Products and Resources Vol 1 No 4 Phytochemical pharmacological profile Cassia tora overviewPRINCIPAL BHILWARANo ratings yet

- OS LabDocument130 pagesOS LabSourav BadhanNo ratings yet

- Mutual Fund PDFDocument22 pagesMutual Fund PDFRajNo ratings yet

- Meet Joe Black (1998) : A Metaphor of LifeDocument10 pagesMeet Joe Black (1998) : A Metaphor of LifeSara OrsenoNo ratings yet