Professional Documents

Culture Documents

C 2 Quick

Uploaded by

sosatlantiqueOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

C 2 Quick

Uploaded by

sosatlantiqueCopyright:

Available Formats

Version 5.

10 CAESAR II Quick Reference Guide

Copyright 1985-2008 COADE, Inc. All Rights Reserved.

Quick Reference Guide Version 5.10

CAESAR II Quick Reference Guide Version 5.10 The CAESAR II Quick Reference Guide is intended to aid users in quickly identifying needed information and to resolve common questions and problems. This Reference Guide is distributed with each copy of the software and users are urged to copy the Reference Guide as necessary. Comments and suggestions concerning CAESAR II, the User Guide, or the Quick Reference Guide are always welcome. Users with problems, questions, or suggestions can contact the COADE Development/Support staff at: techsupport@coade.com.

CAESAR II Quick Reference Guide Table of Contents CAESAR II Quick Reference Guide Version 5.10.......................................................................1 CAESAR II Software ..............................................................................................2 CAESAR II Pipe Stress Seminars ...........................................................................2 System Requirements ..............................................................................................3 Troubleshooting.......................................................................................................3 CAESAR II Interfaces .............................................................................................3 Piping Codes............................................................................................................4 Restraints .................................................................................................................5 Setup File Directives List ........................................................................................6 List of Materials.....................................................................................................11 CAESAR II Intersection Types .............................................................................12 Code Stresses .........................................................................................................13 Node Locations on Bends......................................................................................24 CAESAR II Quality Assurance Manual ................................................................26 Mechanical Engineering News ..............................................................................26 Additional COADE Software Programs................................................................26

Quick Reference Guide Version 5.10

CAESAR II Software

CAESAR II is an advanced PC based tool for the engineer who designs or analyzes piping systems. CAESAR II uses input spreadsheets, on-line help, graphics, and

extensive error detection procedures to facilitate timely operation and solution. CAESAR II is capable of analyzing large piping models, structural steel models, or combined models, both statically and dynamically. ASME, B31, WRC, and rotating equipment reports combine to provide the analyst with a complete description of the piping systems behavior under the applied loading conditions. Additional technical capabilities such as out-of-core solvers, force spectrum analysis (for water hammer and relief valve solutions), time history, and large rotation rod hangers provide the pipe stress engineer with the most advanced computer based piping program available today. CAESAR II is continuously enhanced to incorporate new technical abilities, to provide additional functionality, and to modify existing computation procedures as the piping codes are updated. A complete list of the most recent changes to CAESAR II can be found in the Chapter 1 of the User Guide. Users wanting software sales are urged to contact the COADE Sales staff at:

Phone:281-890-4566 FAX: 281-890-3301 E-mail: sales@coade.com Web: http://www.coade.com/product_overview.asp?varflag=CAESARII

CAESAR II Pipe Stress Seminars

COADE offers seminars periodically to augment the Engineers knowledge of CAESAR II and Pipe Stress Analysis. The general seminar is held in our Houston

office and covers five days of Statics. Twice yearly we also cover five days of Statics and three days of Dynamics. These seminars emphasize the piping codes, static analysis, dynamic analysis, and problem solving. Custom seminars held at client locations are also available. For additional seminar details, please contact the COADE Support staff at: seminars @coade.com.

Quick Reference Guide Version 5.10

System Requirements

CAESAR II requires Windows 2000, or Windows XP Professional, with a

minimum graphic card capability of 1024x768 resolution. However, for more efficient usage of the software, higher graphics resolutions are necessary. Usually any hardware capable of running these operating systems will be sufficient to run CAESAR II. For effective use of CAESAR II, COADE recommends as a minimum configuration:

2+ Ghz processor 1+ Gbytes of RAM 1280x1024 graphics resolution or better 256+ Mbytes of video RAM Windows 2000 or Windows XP Professional Please note that Windows XP Home Edition, Windows Vista Professional and Windows Vista Home Edition are not supported.

Troubleshooting For troubleshooting and problem solving issues, refer to the CAESAR II Frequently Asked Questions (FAQ) located on the COADE Website. To access the FAQ: (http://www.coade.com/product_faq.asp?varflag=CAESARII&varflagmaster=). CAESAR II Interfaces There are several external interfaces which allow data transfer between CAESAR II and other software packages. Users can access these interfaces via the Tools menu on the CAESAR II Main Menu.

CADWorx requires AUTOCAD

AUTOCAD COMPUTER VISION INTERGRAPH CADPIPE ISOMET PDMS PCF

DXF Output mainframe mainframe requires AUTOCAD mainframe mainframe Alias format

Users interested in these interfaces should contact COADE for further information. We anticipate other interfaces in the future keep users updated via the newsletter or revised documentation.

Quick Reference Guide Version 5.10

Piping Codes The table below displays the Piping Code, publication and/or revision date.

PIPING CODE PUBLICATION REVISION

ANSI B31.1 ANSI B31.3 ANSI B31.4 ANSI B31.4 Chapter IX ANSI B31.5 ANSI B31.8 ANSI B31.8 Chapter VIII ANSI B31.11 ASME SECT III CLASS 2 ASME SECT III CLASS 3 U.S. NAVY 505 CANADIAN Z662 CANADIAN Z662 Ch 11 BS 806 SWEDISH METHOD 1 SWEDISH METHOD 2 ANSI B31.1 STOOMWEZEN RCC-M C RCC-M D CODETI NORWEGIAN FDBR BS7159 UKOOA IGE/TD/12 DnV EN-13480 GPTC/192 PD 8010 Part 1&2

(2004) (2006) (2006) (2006) (2001) (2003) (2003) (2002) (2004) (2004) (1984) (6/2003) (6/2003) 1993, ISSUE 1, SEPTEMBER 1993 2ND EDITION STOCKHOLM 1979 2ND EDITION STOCKHOLM 1979 (1967) (1989) (1988) (1988) (2001) (1999) (1995) (1989) (1994) (2003) (1996) (12/2006) (1998) (2004)

December 15, 2006 May 31, 2007 October 20, 2006 October 20, 2006 May 30, 2005 February 6, 2004 February 6, 2004 May 30, 2003 July 1, 2005 July 1, 2005 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A June 2004 N/A N/A N/A N/A N/A N/A Issue 9 N/A N/A

Quick Reference Guide Version 5.10

Restraints

No. Restraint Type Abbreviation

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Anchor Translational Double Acting Rotational Double Acting Guide, Double Acting Double Acting Limit Stop Translational Double Acting Snubber Translational Directional Rotational Directional Directional Limit Stop Large Rotation Rod Translational Double Acting Bilinear Rotational Double Acting Bilinear Translational Directional Bilinear Rotational Double Acting Bilinear Bottom Out Spring Directional Snubber

A X,Y, or Z RX, RY, or RZ GUI LIM XSNB, YSNB, ZSNB +X, -X, +Y, -Y, +Z, -Z +RX, -RX, +RY, etc. +LIM, -LIM XROD, YROD, ZROD X2, Y2, Z2 RX2, RY2, RZ2 -X2, +Y2, -Y2, etc. -RX2, +RY2, - RY2, etc. XSPR, YSPR, ZSPR +XSNB, -XSNB, +YSNB, etc.

Quick Reference Guide Version 5.10

Setup File Directives List The following list represents the possible directives which can be controlled by the user via the CAESAR II configuration file CAESAR.CFG. These directives can be changed by the user through the use of the CONFIGURE-SETUP program, accessed via Main Menu option #9. Directives are listed in groups corresponding to the configuration program's menu options. Geometry Directives

GEOMETRY DIRECTIVES

CONNECT GEOMETRY THRU CNODES = MIN ALLOWED BEND ANGLE = MAX ALLOWED BEND ANGLE = BEND LENGTH ATTACHMENT PERCENT = MIN ANGLE TO ADJACENT BEND PT = LOOP CLOSURE TOLERANCE = THERMAL BOWING HORIZONTAL TOLERANCE = AUTO NODE NUMBER INCREMENT= Z AXIS UP

YES .5000000E+01 .9500000E+02 .1000000E+01 .5000000E+01 .1000000E+01 .1000000E-03 1000000E+02 NO

34 36 37 38 39 42 92 109 129

Computation Control

COMPUTATION CONTROL

USE PRESSURE STIFFENING = ALPHA TOLERANCE = HANGER DEFAULT RESTRAINT STIFFNESS = DECOMPOSITION SINGULARITY TOLERANCE = BEND AXIAL SHAPE = FRICTION STIFFNESS = FRICTION NORMAL FORCE VARIATION = FRICTION ANGLE VARIATION = FRICTION SLIDE MULTIPLIER = ROD TOLERANCE = ROD INCREMENT =

DEFAULT .5000000E-01 .1000000E+13 .1000000E+11 YES .1000000E+07 .1500000E+00 .1500000E+02 .1000000E+01 .1000000E+01 2000000E+01

65 33 49 50 51 45 47 48 46 59 58

Quick Reference Guide Version 5.10

COMPUTATION CONTROL

INCORE NUMERICAL CHECK = DEFAULT ROTATIONAL RESTRAINT STIFFNESS = IGNORE SPRING HANGER STIFFNESS = MISSING MASS ZPA = MINIMUM WALL MILL TOLERANCE = WRC-107 VERSION = WRC-107 INTERPOLATION = INCLUDE_INSULATION_IN_HYDROTEST= AMBIENT TEMPERATURE = BORDER PRESSURE = COEFFICIENT OF FRICTION = INCLUDE SPRING STIFFNESS IN FREE THERMAL CASES =

NO .1000000E+13 NO EXTRACTED .1200000E+02 LAST VALUE NO 70.00 NONE 0. NO

60 98 99 100 101 107 120 147 135 136 140 141

DEFAULT TRANSLATIONAL RESTRAINT STIFFNESS .1000000E+13

MAR 79 1B1/2B1 119

SIFS and Stresses

SIFS AND STRESSES

REDUCED INTERSECTION = USE WRC329 = NO REDUCED SIF FOR RFT AND WLT B31.1 REDUCED Z FIX = CLASS 1 BRANCH FLEXIBILITY ALL STRESS CASES CORRODED = ADD TORSION IN SL STRESS = ADD F/A IN STRESS = OCCASIONAL LOAD FACTOR = DEFAULT CODE = B31.3 SUSTAINED CASE SIF FACTOR = ALLOW USERS BEND SIF = USE SCHNEIDER = YIELD CRITERION STRESS = USE PD/4T =

B31.1 POST1980 NO NO YES NO NO DEFAULT DEFAULT .000000E+00 B31.3 100000E+01 NO NO NO

32 62 53 54 55 35 66 67 41 43 40 52 63 64

MAX 3D SHEAR 108

Quick Reference Guide Version 5.10

SIFS AND STRESSES

BASE HOOP STRESS ON = EN-13480 use in-plane/out-plane SIF LIBERAL ALLOWANCE = STREE STIFFENING DUE TO PRESS = B31.3 WELDING/CONTOUR TEE MEET B16.9 = IMPLEMENT _B31.3_APPENDIX_P IMPLEMENT_B31.3_CODECASE B31.3 Sec 319.2.3(c), Saxial PRESSURE VARIATION IN EXPANSION CASE DEFAULT =

NO NO YES NO NO NO NO NO DEFAULT

57 133 137 138 139 144 145 146 143

FRP Properties

FRP PROPERTIES

USE FRP SIF = USE FRP FLEXIBILITY = BS 7159 PRESSURE STIFFENING = FRP PROPERTY DATA FILE = AXIAL MODULUS OF ELASTICITY RATIO SHEAR MOD : AXIAL MOD = AXIAL STRAIN : HOOP STRESS FRP LAMINATE TYPE = FRP ALPHA = FRP DENSITY = EXCLUDE F2 FROM BENDING STRESS (UKOOA)

YES YES CAESAR.FRP 3200000E+07 2500000E+00 1527272E+00 THREE .1200000E+02 .6000000E-01 NO

110 11 122 113 114 115 116 117 118 134

DESIGN STRAIN 121

Plot Colors

PLOT COLORS

PIPES HIGHLIGHTS LABELS BACKGROUND AXES

LIGHTCYAN GREEN GREEN BLACK LIGHTRED

1 2 3 5 15

Quick Reference Guide Version 5.10

PLOT COLORS

HANGER/NOZZLES RIGID/BENDS NODES YELLOW STRUCTURE DISPLACED SHAPE STRESS > LEVEL 5 STRESS > LEVEL 4 STRESS > LEVEL 3 STRESS > LEVEL 2 STRESS > LEVEL 1 STRESS < LEVEL 1 STRESS LEVEL 5 STRESS LEVEL 4 STRESS LEVEL 3 STRESS LEVEL 2 STRESS LEVEL 1

BROWN LIGHTGREEN YELLOW LIGHTRED BROWN RED YELLOW GREEN LIGHTCYAN BLUE DARKBLUE .3000000E+05 .2500000E+05 .2000000E+05 .1500000E+05 .1000000E+05

16 17 18 31 30 24 25 26 27 28 29 19 20 21 22 23

Database Definitions

DATABASE DEFINITIONS

STRCT DBASE = VALVE & FLANGE = EXPANSION JT DATABASE = PIPING SIZE SPECIFICATION = DEFAULT SPRING HANGER TABLE = SYSTEM DIRECTORY NAME = UNITS FILE NAME = LOAD CASE TEMPLATE = ENABLE ODBC OUTPUT APPEND RE-RUNS TO EXISTING DATA ODBC DATABASE NAME

AISC89.BIN PATHWAY.JHD ANSI 1 SYSTEM .ENGLISH.FIL .LOAD.TPL NO NO <NONE>

70 91 88 112 123 124 142 128 126 127

CADWORX.VHD 90

10

Quick Reference Guide Version 5.10

Miscellaneous Computations

MISCELLANEOUS COMPUTATIONS

OUTPUT REPORTS BY LOAD CASE DISPLACEMENT NODAL SORTING DYNAMIC INPUT EXAMPLE TEXT TIME HIST ANIMATE OUTPUT TABLE OF CONTENTS INPUT FUNCTION KEYS DISPLAYED MEMORY ALLOCATED USER ID " " DISABLE _UNDO

YES YES MAX YES ON YES 12 NA NO

87 89 94 104 105 106 NA 128

Quick Reference Guide Version 5.10

11

List of Materials The CAESAR II Material Table contains 17 different isotropic materials. Properties and allowed temperature ranges for each isotropic material are listed below.

Material No. Material Name Elastic Modulus Poisson's Ratio Pipe Density (lb./cu.in) Temperature Range (deg. F)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

Low Carbon Steel High Carbon Steel Carbon Moly Steel

29.5 E6 29.3 E6 29.2 E6

0.292 0.289 0.289 0.289 0.289 0.292 0.305 0.305 0.300 0.211 0.315 0.315 0.330 0.330 0.355 0.331 0.330

0.28993 0.28009 0.28935 0.28935 0.28935 0.28930 0.28010 0.28990 0.28070 0.25580 0.31870 0.30610 0.33850 0.10130 0.32270 0.30610 0.31890

-325 -325 -325 -325 -325 -325 -325 -325 -325 70 -325 -325 -325 -325 70 -325 -325

1400 1400 1400 1400 1400 1400 1400 1400 1400 1000 1400 1400 1400 600 400 1200 1200

Low Chrome Moly Steel 29.7 E6 Med Chrome Moly Steel 30.9 E6

Austenitic Stainless Straight Chromium Type 310 Stainless Wrought Iron Grey Cast Iron K-Monel Copper Nickel Aluminum Copper 99.8% Cu Commercial Brass Leaded Tin Bronze 1

28.3 E6 29.2 E6 28. 3 E6 29.5 E6 13.4 E6 26.0 E6 22.0 E6 10.2 E6 16.0 E6 17.0 E6 14.0 E6

Monel 67% Ni/30% Cu 26.0 E6

In addition CAESAR II supports material types 18 or 19 for cut short and cut long cold spring elements. Material number 20 activates the CAESAR II Orthotropic Material Model (i.e., Fiber-glass reinforced plastic pipe); the default coefficient of expansion is 12.0 E-6 in./in./F. Material 21 indicates user-defined properties. Material numbers over 100 are from the Material Database and include the allowable stress and other piping code data.

12

Quick Reference Guide Version 5.10

CAESAR II Intersection Types

CAESAR II Type B31.3 Type Notes Sketch

1 Reinforced

Reinforced Fabricated Tee Used to lower SIFs

Not a fitting Modified pipe

2 Unreinforced

Unreinforced Fabricated Tee

Routine intersection Not a fitting Modified pipe Usually the cheapest

3 Welded Tee

Welding Tee

Usually size-on-size Governed by B16.9 Usually the lowest SIF Usually expensive

4 Sweepolet

Welded-in Contour Insert

Sit-in" fitting Forged fittings on a pipe

5 Weldolet

Branch Welded on Fitting

"Sit-on" fitting Forged fittings on a pipe

6 Extruded

Extruded Welding Tee

Seldom used Used for thick wall manifolds Extruded from straight pipe

Quick Reference Guide Version 5.10

13

Code Stresses Listed below are the Code Stress equations for the actual and allowable stresses used by CAESAR II. For the listed codes, the actual stress is defined by the left hand side of the equation and the allowable stress is defined by the right hand side. The CAESAR II load case label is also listed after the equation. Typically the load case recommendations made by CAESAR II are sufficient for code compliance. However, CAESAR II does not recommend occasional load cases. Occasional loads are unknown in origin and must be specified by the user. US Codes

Longitudinal Pressure Stress - Slp Slp = PD0/4tn Slp = PDi2/(D02 - Di2) S = Slp + Fax/A + Sb < code approximation code exact equation, CAESAR II default NA (OPE)

Operating Stress - unless otherwise specified

B31.1 Sl = Slp + 0.75 i Ma / Z i Mc / Z Slp + 0.75 i Ma / Z + 0.75 i Mb / Z B31.3 Sl = Slp + Fax/A + Sb sqrt (Sb2 + 4 St2) Fax/A + Sb + Slp Sb = [sqrt ( (iiMi)2 + (i0M0)2 )]/Z < < < Sh f [ 1.25 (Sc+Sh) - Sl ] k Sh (SUS) (EXP) (OCC) < < < Sh f [ 1.25 (Sc+Sh) - Sl ] k Sh (SUS) (EXP) (OCC)

ASME SECT III CLASS 2 & 3 < i Mc / Z B1 * Slpmax + B2 * (Ma + Mb) / Z < < 1.5 Sh f (1.25 Sc + 0.25 Sh) + Sh -Sl 1.8 Sh and < 1.5 Sy (SUS) (EXP) (OCC)

14

Quick Reference Guide Version 5.10

B31.1 (1967) and Navy Section 505 Sl = Slp + sqrt (Sb2 + 4 St2) sqrt ( Sb + 4 St )

2 2

< < <

Sh f (1.25Sc + 0.25Sh + (Sh-Sl)) k Sh

(SUS) (EXP) (OCC)

Slp + sqrt (Sb + 4 St )

2 2

B31.4 If FAC = 1.0 (fully restrained pipe) FAC | E dT Fax/A SHOOP| + SHOOP < < 0.9 (Syield) 0.9 (Syield) (OPE) (OPE) If FAC = 0.001 (buried, but soil restraints modeled) SHOOP + Sb + SHOOP (If Slp + Fax/A is compressive) If FAC = 0.0 (fully above ground) Slp + Fax/A + Sb + SHOOP (If Slp + Fax/A is compressive) (Slp + Sb + Fax/A) (1.0 - FAC) sqrt ( Sb + 4 St )

2 2

< < < <

0.9 (Syield) (0.75) (0.72) (Syield) 0.72 (Syield) 0.8 (Syield)

(OPE) (SUS) (EXP) (OCC)

(Slp + Sb + Fax/A) (1.0 - FAC)

B31.4 Chapter IX Hoop Stress: Sh F1 Sy 0.8 Sy 0.9 Sy (OPE, SUS, OCC) (OPE, SUS, OCC) (OPE, SUS, OCC) Longitudinal Stress: |SL| Equivalent Stress: Se Where: Sy = specified minimum yield strength F1 = hoop stress design factor (0.60 or 0.72, see Table A402.3.5(a) of B31.4) Sh = (Pi Pe) D / 2t SL= Sa + Sb or Sa - Sb, whichever results in greater stress value Se = 2[((SL - Sh)/2)2 + St2]1/2

Quick Reference Guide Version 5.10

15

B31.5 Sl = Slp + Fax/A + Sb sqrt (Sb + 4 St )

2 2

< < <

2

Sh f [ 1.25 (Sc+Sh) - Sl ] k Sh

(SUS) (EXP) (OCC)

Fax/A + Sb + Slp Sb = [sqrt ( (iiMi) + (i0M0) )]/Z

2

B31.8 B31.8 For Restrained Pipe (as defined in Section 833.1):

For Straight Pipe:

Max(SL, SC) Max(SL, SC) SL and SC SL = SP + SX + SB

For All Other Components

< 0.9ST < 0.9ST < 0.9ST < ST

(OPE) (SUS) (OCC)* (OCC) *

CAESAR II prints the controlling stress of the two

SL

< 0.9ST B31.8 For Unrestrained Pipe (as defined in Section 833.1):

(OPE, SUS, OCC)

SL SE Where: SL SP SX SB SC MR Mt2] SE ME = SP + SX + SB = 0.3SHoop (for restrained pipe) = 0.5SHoop (for unrestrained pipe) = R/A

< 0.75ST < f[1.25(SC + SH) SL]

(SUS, OCC) (EXP)

= MB/Z (for straight pipe/bends with SIF = 1.0) = MR/Z (for other components) = Max (|SHoop SL|, sqrt[SL2 SLSHoop + SHoop2]) = sqrt[(0.75iiMi)2 + (0.75ioMo)2 + = ME/Z = sqrt[(0.75iiMi)2 + (0.75ioMo)2 + Mt2]

16

Quick Reference Guide Version 5.10

B31.8 For Unrestrained Pipe (as defined in Section 833.1): Continued S T SH SC SU = Specified Minimum Yield Stress = Temperature Derating Factor = 0.33SUT = 0.33SU = Specified Minimum Ultimate Tensile Stress

B31.8 Chapter VIII Hoop Stress: Longitudinal Stress: Equivalent Stress: Where: S = Specified Minimum Yield Strength F1= Hoop Stress Design Factor (0.50 or 0.72, see Table A842.22 of the B31.8 Code) T= Temperature Derating Factor (see Table 841.116A of the B31.8 Code)

Note: The product of S and T (i.e. the yield stress at operating temperature) is required in SH of the CAESAR II Input.

Sh |SL| Se

F1 S T 0.8 S 0.9 S

(OPE, SUS, OCC) (OPE, SUS, OCC) (OPE, SUS, OCC)

Sh= (Pi Pe) D / 2t SL = maximum longitudinal stress (positive tensile, negative compressive) Se = 2[((SL - Sh)/2)2 + Ss2]1/2 Ss = tangential shear stress GPTC Slp + 0.75i Ma/Z Sl = Slp+Sb Se = sqrt(Sb +4St )

2 2

< < <

Syield 0.75(Sy)Ft 0.72 (Syield)

(OPE) (SUS) (EXP)

Note: GPTC is similar to B31.8 with noted changes.

B31.11 If FAC = 1.0 (fully restrained pipe) FAC | E Fax/A dT SHOOP| + SHOOP < < 0.9 (Syield) 0.9 (Syield) (OPE) (OPE) If FAC = 0.001 (buried, but soil restraints modeled) SHOOP + Sb + SHOOP

Quick Reference Guide Version 5.10

17

B31.11 Continued (If Slp + Fax/A is compressive) If FAC = 0.0 (fully above ground) Slp + Fax/A + Sb + SHOOP (If Slp + Fax/A is compressive) (Slp + Sb + Fax/A) (1.0 - FAC) sqrt ( Sb2 + 4 St2 ) (Slp + Sb + Fax/A) (1.0 - FAC) < < < (0.75) (0.72) (Syield) 0.72 (Syield) 0.88 (Syield) (SUS) (EXP) (OCC) < 0.9 (Syield) (OPE)

International Codes

Canadian Z662 If FAC = 1.0 (fully restrained pipe) |E dT Sh| + Sh Sh | + Sb + Sh Sh is compressive) < < < < < < S*T S*F*L*T 0.72 S * T Sh f (1.25 Sc + .25 Sh) + Sh - Sl 1.2 Sh (OPE) (SUS, OCC) (EXP) (SUS) (EXP) (OCC) < < 0.9 S * T S*T (OPE) (OPE) If FAC = 0.001 (buried, but soil restraints modeled) |Fax / A (If Fax / A -

If FAC = 0.0 (fully above ground) |Slp + Fax / A| + Sb + Sh (If Slp + Fax / A is compressive) Sl = 0.5Sh + Sb SE = sqrt [Sb 2 + 4St2] RCC-M C & D Slp + 0.75i Ma/Z iMc/Z Slpmax + 0.75i (Ma + Mb)/Z Stoomwezen Slp + 0.75i Ma/Z < iMc/Z < fe 1.2f f (SUS) (EXP) (OCC)

Slp + 0.75i (Ma + Mb)/Z <

18

Quick Reference Guide Version 5.10

CODETI Sl = Slp + Fax/A + Sb sqrt (Sb + 4St )

2 2

< < <

Sh f [1.25 (Sl + Sh)] - Sl Ksh

(SUS) (EXP) (OCC)

Slp + Fax/A + iMa/Z + iMb/Z Sb = [ Sqrt ((iiMi) + (i0M0) ] /Z

2 2

Norwegian

2 PDi .75Ma SI = + 2 2 Z Eff(D0 D1 )

(SUS)

iMc/Z < Sh + Sr - Sl

(EXP)

.75i (Ma + Mb) PmaxDi2 + 2 -D 2 ) Z Eff(D0 i M = sqrt (Mx2 + My2 + Mz2) Sr= Minimum of 1.25 Sc + 0.25 Sh; FrRs-F2; or Fr (1.25R1 + 0.25R2) The latter applies to temperatures over 370C; 425C for Austenitic stainless steel Fr= Cyclic reduction factor Rs= Permissible extent of stress for 7000 cycles R1= Minimum of Sc and 0.267 Rm R2= Minimum of Sh and 0.367 Rm Rm = Ultimate tensile strength at room temperature

(OCC)

FDBR

Sl = Slp + 0.75 i Ma / Z i Mc / Z Slp + 0.75 i Ma / Z + 0.75 i Mb / Z

< < <

Sh f [ 1.25 (Sc+Sh) - Sl ] k Sh

(SUS) (EXP) (OCC)

Quick Reference Guide Version 5.10

19

BS 7159 If Sx is tensile:

2 2 sqrt (Sx + 4Ss )

<

Sh

(OPE)

and

2 2 sqrt (S + 4Ss )

<

Sh*EH/EA

(OPE)

or, if Sx is compressive:

S + x Sx

<

Sh*EH/EA

(OPE)

and

Sx Sx = P Dm

<

1.25Sh

(OPE)

( ) + [sqrt((i xi Mi ) 2 +(i xo M o )2 )] Z ( 4t )

P Dm

( ) - [sqrt((i xi Mi ) 2 +(i xo M o ) 2 )] - Fx A Z ( 4t )

MP D m

(If Fx/A > P(Dm)/(4t), and it is compressive)

S =

( ) ( 2t )

2 o M o ) )]

for straight pipes

MP D m

( ) [sqrt((i i Mi )2 +(i + Z ( 2t )

for bends

MP D m

( ) + [sqrt((i xi Mi ) 2 +(i xo M o )2 )] Z ( 2t )

for tees

Dm and t are always for the Run Pipe Eff = Ratio of E to Ex

20

Quick Reference Guide Version 5.10

UKOOA ab (f2/r) + PDm/ (4t) < (f1 f2 LTHS) / 2.0 Where: P = design pressure Dm = pipe mean diameter t = pipe wall thickness f1 = factor of safety for 97.5% lower confidence limit, usually 0.85 f2 = system factory of safety, usually 0.67 ab = axial bending stress due to mechanical loads r = a(0:1) / a(2:1) a(0:1) = long term axial tensile strength in absence of pressure load a(2:1) = long term axial tensile strength in under only pressure loading LTHS = long term hydrostatic strength (hoop stress allowable) BS 806 Straight Pipe < fc fs F ft fL Bends < fc fs F ft fs = = = = = sqrt (F2 + 4 fs2) Mt (d + 2t) /4I max (ft, fL) r/I * sqrt[(miFTi)2 + (m0FTo)2] r/I * sqrt[(miFLi)2 + (m0FLo)2] < < SAOPE SASUS SAEXP = = = = = sqrt(F2 + 4fs2) Mt(d + 2t) / 4I max (ft, fL) pd/2t + 0.5p pd2/[4t(d + t)] + (d + 2t)[sqrt(mi2 + mo2)] / 2I < < SAOPE SASUS SAEXP

Quick Reference Guide Version 5.10

21

BS 806 Continued Branch Junctions < fcb fb Fsb q m = = = = q * sqrt[fb2 + 4fsb2] (d + t)*p*m/(2t) + r/I*sqrt[(miFTL)2 + (moFTO)2] Mt (d + 2t) / 4I geometric parameter min[(H*Sproof ambient + H*Sproof design); (H*Sproof ambient + F)] Savg rupture at design temperature min[.8*Sproof, Screep rupture] < < SAOPE SASUS SAEXP

= 1.0 except for operating cases = 5 or .44 bases on d2/d1 ratio in operating cases

EXP SA = OPE SA = SUS SA = Det Norske Veritas (DNV) Hoop Stress: Sh Hoop Stress: Sh ns SMYS nu SMTS n SMYS

Longitudinal Stress: SL Where: Sh ns SMYS nu SMTS SL n Se = = = = = = = =

Equivalent Stress: Se n SMYS (Pi Pe) (D t) / 2t hoop stress yield usage factor Tables C1 and C2 of DNV specified minimum yield strength, at operating temperature hoop stress bursting usage factor Tables C1 and C2 of DNV specified minimum tensile strength, at operating temperature maximum longitudinal stress equivalent stress usage factor Table C4 of DNV [Sh2 + SL2 - ShSL + 3t2]1/2

22

Quick Reference Guide Version 5.10

EN-13480 < < < Kfn fn + fh Kfn (SUS) (EXP) (OCC)

EN-13480 Alternate Option due to primary loads

< < <

Kfn fn + fh Kfn

(SUS) (EXP) (OCC)

due to occasional loads

PD8010 Part 1 Hoop Stress Equivalent Stress Where: Sy e a Sh Se = specified minimum yield strength = weld joint factor = design factor Sh< aeSy Se< 0.9Sy (OPE, SUS, OCC) (OPE, SUS, OCC)

Quick Reference Guide Version 5.10

23

PD8010 Part 1 Continued Shl ST = SL SL for unrestrained piping SL for restrained piping If FAC = 1.0 (fully restrained pipe) FAC | E Fax/A dT - SHOOP| + SHOOP SHOOP + Sb + SHOOP < < 0.9 (Syield) 0.9 (Syield) (OPE) (OPE) If FAC = 0.001 (buried, but soil restraints modeled) (If Slp + Fax/A is compressive) If FAC = 0.0 (fully above ground) Slp + Fax/A + Sb + SHOOP (If Slp + Fax/A is compressive) (Slp + Sb + Fax/A) (1.0 - FAC) sqrt ( Sb2 + 4 St2 ) (Slp + Sb + Fax/A) (1.0 - FAC) PD8010 Part 2 Hoop Stress Equivalent Stress Where: Sy fdh fde Sh= S e= ST = specified minimum yield strength hoop stress design factor (See Table 2) equivalent stress design factor (See Table 2) Sh< fdhSy Se< fdeSy (OPE, SUS, OCC) (OPE, SUS, OCC) < < < (0.75) (0.72) (Syield) 0.72 (Syield) 0.8 (Syield) (SUS) (EXP) (OCC) < 0.9 (Syield) (OPE) Based on restrained/unrestrained status hoop stress using nominal dimensions

24

Quick Reference Guide Version 5.10

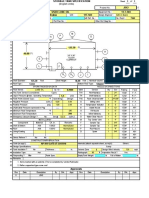

Node Locations on Bends

Bends are defined by the element entering the bend and the element leaving the bend. The actual bend curvature is always physically at the TO end of the element entering the bend. The element leaving a bend must appear immediately after the element defining (entering) the bend. The default bend radius is 1.5 times the pipe nominal OD. For stress and displacement output the TO node of the element entering the bend is located geometrically at the FAR point on the bend. The FAR point is at the weld line of the bend, and adjacent to the straight element leaving the bend. The NEAR point on the bend is at the weld line of the bend, and adjacent to the straight element entering the bend. The FROM point on the element is located at the NEAR point of the bend if the total length of the element as specified in the DX, DY and DZ fields is equal to: Radius * tan( Beta / 2 ) where Beta is the bend angle, and Radius is the bend radius of curvature to the bend centerline. Nodes defined in the Angle # and Node # fields are placed at the given angle on the bend curvature. The angle starts with zero degrees at the NEAR point on the bend and goes to Beta degrees at the FAR point of the bend. Angles are always entered in degrees. By default, nodes on the bend curvature cannot be specified within five (5) degrees of one another or within five degrees of the nearest end point. This and other bend settings may be changed through the Main Menu, Configure-Setup processor. When the FROM node on the element entering the bend is not at the bend NEAR point a node may be placed at the near point of the bend by entering an Angle # on the bend spreadsheet equal to 0.0 degrees. For more information see the following figure. When defining a bend element for the first time in the pipe spreadsheet, nodes are automatically placed at the near and mid point of the bend. The generated midpoint node number is one less than the TO node number on the element, and the generated near point node number is two less than the TO node number on the element. A near point should always be included in the model in tight, highly formed piping systems. The top-left figure below shows the points on the bend as they would be input. The top-right figure shows the actual geometric location of the points on the bend. The bottom-left figure shows the same geometry except that two nodes are defined on the bend curvature at angles of zero and forty-five degrees.

Quick Reference Guide Version 5.10

25

For an animated tutorial on modeling bends, select the ANIMATED TUTORIALS option on the Help menu.

26

Quick Reference Guide Version 5.10

CAESAR II Quality Assurance Manual The CAESAR II Quality Assurance Manual is intended to serve as a publicly available verification document. This manual discusses (briefly) the current industry QA standards, the COADE QA standard, a series of benchmark jobs, and instructions for users implementing QA procedures on their own hardware. The benchmark jobs consist of comparisons to published data by ASME and the NRC. Additional test jobs compare CAESAR II results to other industry programs. For additional information on the Quality Assurance Manual, please contact the sales department at sales@coade.com. Mechanical Engineering News As an aid to the users of COADE software products, COADE publishes Mechanical Engineering News several times a year. This publication contains discussions on recent developments that affect users, and technical features illustrating modeling techniques and software applications. This newsletter is sent to all users of COADE software at the time of publication. Back issues can be acquired by contacting the COADE sales staff. Additional COADE Software Programs

CADWorx Plant - An AutoCAD based plant design/drafting program with a bidirectional data transfer link to CAESAR II. CADWorx allows models to be created in ortho, iso, 2D or 3D modes. CADWorx template specifications, contained with

built in auto routing, auto iso, stress iso, auto dimensioning, complete libraries, center of gravity calculations, and bill of materials, provides the most complete plant design package to designers. CodeCalc - A program for the design or analysis of pressure vessel components. CodeCalc capabilities include: analysis of tubesheets, rectangular vessels, flanges, nozzles, Zick Analysis, and the standard internal/external thickness and pressure computations on heads, shells, and cones. API 579 calculations are also included. PV Elite - A comprehensive program for the design or analysis of vertical and horizontal vessels. Pressure Vessel Codes include ASME VIII-1 and VIII-2, PD:5500 and EN-13445. PVElite includes all of the CodeCalc functionality. TANK - A program for the design or rerating of API-650/653 storage tanks. The program includes API 650 Appendices A, E, F, M, P, and S, as well as API 653 Appendix B. Computations address: winds girders, conical roof design, allowed fluid heights, and remaining corrosion allowance.

Index

Quick Reference Guide Index

A Additional COADE Software Programs 26 ASME SECT III CLASS 2 & 3 13 B B31.1 13 B31.1 (1967) and Navy Section 505 14 B31.11 16, 17 B31.3 13 B31.4 14 B31.4 Chapter IX 14 B31.5 15 B31.8 15 B31.8 Chapter VIII 16 Bends 20 Branch Junctions 21 BS 7159 19 BS 806 20, 21 C CAESAR II Interfaces 3 CAESAR II Intersection Types 12 CAESAR II Pipe Stress Seminars 2 CAESAR II Quality Assurance Manual 26 CAESAR II Quick Reference Guide Version 5.10 1 CAESAR II Software 2 Canadian Z662 17 Code Stresses 13 CODETI 18 Computation Control 6 D Database Definitions 9 Det Norske Veritas (DNV) 21 E EN-13480 22 F FDBR 18 G Geometry Directives 6 GPTC 16 I International Stresses 17 L List of Materials 11 M Mechanical Engineering News 26 Miscellaneous Computations 10 N Node Locations on Bends 24 Norwegian 18 P Piping Codes 4 Plot Colors 8 R RCC-M C & D 17 Restraints 5 S Setup File Directives List 6 SIFS and Stresses 7 Stoomwezen 17 System Requirements 3 T Troubleshooting 3 U UKOOA 20 US Codes 13

COADE Inc. 12777 Jones Road Suite 480 Houston, Texas 77070 Phone: (281)890-4566 Fax: (281)890-3301 Email: sales@coade.com Web: www.coade.com

CAESAR II Quick Reference Guide Version 5.10 Last Revised 111/2007

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- FluidFlow Designer HandbookDocument78 pagesFluidFlow Designer Handbooksosatlantique100% (4)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- UBC 1997 UBC Code StructuralDocument510 pagesUBC 1997 UBC Code Structuralkurokandas83% (6)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Piping Codes PDFDocument47 pagesPiping Codes PDFsosatlantiqueNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- 650 741rev3Document2 pages650 741rev3sosatlantiqueNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Welcome To Presentation On: Pipe Support Systems & Piping FlexibilityDocument67 pagesWelcome To Presentation On: Pipe Support Systems & Piping Flexibilitysids8292% (24)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hilti Calculation ExamplesDocument10 pagesHilti Calculation ExamplesNgoc TruongNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- SampleCalculationspipingB3132008 PDFDocument13 pagesSampleCalculationspipingB3132008 PDFsosatlantiqueNo ratings yet

- SampleCalculationspipingB3132008 PDFDocument13 pagesSampleCalculationspipingB3132008 PDFsosatlantiqueNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- SampleCalculationspipingB3132008 PDFDocument13 pagesSampleCalculationspipingB3132008 PDFsosatlantiqueNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Cadworx 2013 Quick Start GuideDocument17 pagesCadworx 2013 Quick Start GuideEric LyonNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Flexiable AnalysisDocument12 pagesFlexiable AnalysismohamedeliasNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Flexiable AnalysisDocument12 pagesFlexiable AnalysismohamedeliasNo ratings yet

- API 650 Tank Design 1Document5 pagesAPI 650 Tank Design 1robertantoreni100% (9)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Flexiable AnalysisDocument12 pagesFlexiable AnalysismohamedeliasNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Mathcad Tutorial: by Colorado State University StudentDocument51 pagesMathcad Tutorial: by Colorado State University StudentDiana ScodreanuNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)