Professional Documents

Culture Documents

Draglile Mining

Draglile Mining

Uploaded by

Sachin VermaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Draglile Mining

Draglile Mining

Uploaded by

Sachin VermaCopyright:

Available Formats

Boom Point Sheave Bridge support Rope Hoist Rope Mast A Frame Drag Drum Boom Drag Chain

Boom Foot Hoist Chain Dump Rope Dragline Bucket

Shoe

Hoist Drum

Tub

Major component of a dragline

Khanindra Pathaks Lecture

Boom Point Sheave

Boom Hoisting line Bucket

Dumping Line

Drag Cable

Khanindra Pathaks Lecture DRAG LINE

15-200 Hp Hdm Rb Rcr Rdm Rdg th Main Working Parameters of a Dragline

Hb

Khanindra Pathaks Lecture

Hdg

Dragline Faces

End Face (Deep Cut)

End Face (High Cut)

Combination Digging

Khanindra Pathaks Lecture

A B Awd bFS y A1 B 1 2 H h

Hwd

1wd

Khanindra Pathaks Lecture

EXPOSED COAL SEAM HIGHWALL BOOM DIGGING POSITION DRAGLINE POSITION No. 3 PREVIOUS DIGOUT KEY CUT

A

BOOM DUMPING POSITION

DRAGLINE POSITION No. 1 DRAGLINE POSITION No. 2 DRAGLINE POSITION No. 3 NEXT DIGOUT

FLOOR

HIGHWALL DRAGLINE POSITION No. 2 DRAGLINE POSITION No. 1, 3 KEY CUT COAL SEA M PRODUCTION CUT BACKWALL

XXXXXXXXXXXXXX

KEY CUT SPOIL

SPOIL PREVIOUS CUT

SECTION A-A

A TYPICAL DRAGLINE OPERATION

Khanindra Pathaks Lecture 6

Extended Bench Method

This method of face development is applied when effective reach of the dragline is to be extended. This is associated with certain degree of rehandling This method is useful when the overburden depths can not be handled by normal casting It may be necessary when overburden depths are gradually increasing or there is a temporary change in relief.

Dragline Dump Radius

PIT WIDTH

Overburden to be rehandled

Khanindra Pathaks Lecture

Highwall bench to be excavated

At the completion of the previous block, the dragline is located at the end of the bridge. From this position the last of the block of OB can be spoiled directly . To start excavation of the new block, the dragline is walked off the bridge and placed in line with the new high wall at A. This is now ready for providing key cut for the block to be excavated. A

Block to be excavated

Bridge Length

New Pit

Khanindra Pathaks Lecture

At this situation, the key cut is completed. At the start of this cut, the dragline must be far enough along the cut to allow the bucket to be pulled right up to the length of the new block without the drag rope limit switches being activated. As the cut is deepened, the machine walks forward and across the cut to keep in line with the highwall batter at the depth it is digging. The key cut spoil is used to form the bulk of the next bridge.

New bridge being Built from key cut spoil

New Pit

Khanindra Pathaks Lecture

Here the new bridge is completed to the required lenth by part of the highwall bench and the top of the block. Same dragline position is used to excavate the high wall bench as well as the top of the block. Dozr is used to clean up loose bench material while the dragline is digging from the top of the block.

Highwall Bench

New bridge

Top of block

New Pit

Khanindra Pathaks Lecture

10

After completion of the digging of the highwall bench further excavation of the bulk of the block takes place. To directly dump the material , position ofhe dragline will have to be proper.

Start of new spoil pil

Corner of key cut

Khanindra Pathaks Lecture

11

Excavation with DL close to the edge of the working face. Final clean up of top of coal sam is carried out at this stage.

Working Face

Corner of key cut

Khanindra Pathaks Lecture

12

Final stage. Clears the last part of the previous bridge

Corner of key cut

Khanindra Pathaks Lecture

13

Khanindra Pathaks Lecture

14

y 40

Rotation axis of excavator

20 20 0 I -20 II III 40 60

-40

Variation of the angle of inclination of the bucket Pathaks Lecture Khanindra bottom within dragline working zone (I - Rotation axis of excavator)

15

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Guide To Petrophysical InterpretationDocument147 pagesGuide To Petrophysical InterpretationJD JD100% (4)

- Foundation Analysis and Design - Fifth Edition - Joseph BowlesDocument9 pagesFoundation Analysis and Design - Fifth Edition - Joseph BowlesJoão Marcos S. CorrêaNo ratings yet

- Marín, Sierra, 2011 PDFDocument102 pagesMarín, Sierra, 2011 PDFMaria Magdalena HenaoNo ratings yet

- Tunnel Rock Mechanics Presentation by T. Ramamurthy Iit DelhiDocument76 pagesTunnel Rock Mechanics Presentation by T. Ramamurthy Iit DelhiS N satyanarayanaNo ratings yet

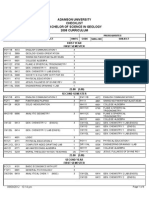

- BS Geology 2008 CurriculumDocument6 pagesBS Geology 2008 CurriculumjotonxNo ratings yet

- Sr. No. Particular Test MethodDocument3 pagesSr. No. Particular Test MethodAakash JadhavNo ratings yet

- Technical Publications: Donald H. GrayDocument7 pagesTechnical Publications: Donald H. Graysayabaik1No ratings yet

- SOALDocument12 pagesSOAL5jx6kym4h5No ratings yet

- Bibliography of The Geology of Indonesia BIG - III - JAVA by J.T. Van GorselDocument127 pagesBibliography of The Geology of Indonesia BIG - III - JAVA by J.T. Van GorselGin Gin Ginanjar100% (1)

- Sandvik ScreensDocument14 pagesSandvik ScreensTamal Tanu RoyNo ratings yet

- Production Logging and Its Implementation: A Technical ReviewDocument11 pagesProduction Logging and Its Implementation: A Technical ReviewTheNourEldenNo ratings yet

- Evidence of A Massive Thermonuclear Explosion On Mars in The Past, The Cydonian Hypothesis, and Fermi's ParadoxDocument23 pagesEvidence of A Massive Thermonuclear Explosion On Mars in The Past, The Cydonian Hypothesis, and Fermi's ParadoxSomeRandomGuyNo ratings yet

- Soal PAT Bing X SMKDocument7 pagesSoal PAT Bing X SMKzuhud0% (1)

- Yang JCAMDocument18 pagesYang JCAMBonn SilvaNo ratings yet

- Course Outline EarthquakeDocument4 pagesCourse Outline EarthquakeDianaAguilarCoroNo ratings yet

- Design Methodology For Underground Ring BlastingDocument17 pagesDesign Methodology For Underground Ring Blastinghnavast100% (5)

- Ecology of South Florida - Spring 2013 - Exam 1Document279 pagesEcology of South Florida - Spring 2013 - Exam 1FLFishermanNo ratings yet

- Mandal-Ekofisk (!) Petroleum System in The Central Graben of The North SeaDocument18 pagesMandal-Ekofisk (!) Petroleum System in The Central Graben of The North SeaJuan Pablo Rea VásquezNo ratings yet

- Mlu Tutorial PDFDocument66 pagesMlu Tutorial PDFManish JhaNo ratings yet

- BorelogsDocument4 pagesBorelogsOrbital PublishingNo ratings yet

- Big Lagoon Bombing RangeDocument227 pagesBig Lagoon Bombing RangeCAP History Library100% (1)

- Lampiran NarrativeDocument16 pagesLampiran NarrativeINDRAKURNIAWANSIRNo ratings yet

- Geo - CH-3Document48 pagesGeo - CH-3mbambuNo ratings yet

- Geol 11 Week 10 - Rock Deformation - Annotated Lecture SlidesDocument12 pagesGeol 11 Week 10 - Rock Deformation - Annotated Lecture SlidesAssignment ForNo ratings yet

- The ISV20 Extension Publication Vietnam, C7Document6 pagesThe ISV20 Extension Publication Vietnam, C7Laurens SmetsNo ratings yet

- Gold Exploration in South AustraliaDocument5 pagesGold Exploration in South AustraliaguitarfrenziNo ratings yet

- Amal-18 Sta DDR#24 06-03-2020Document30 pagesAmal-18 Sta DDR#24 06-03-2020eng7mohamed7hashimNo ratings yet

- Pile Foundation Design and Construction Practice in MalaysiaDocument26 pagesPile Foundation Design and Construction Practice in MalaysiaHanizan Abu Bakar100% (4)

- Razvan Calangiu CV 2021Document3 pagesRazvan Calangiu CV 2021Apostol ArmeanuNo ratings yet

- Faq by Suresh Pandey SirDocument150 pagesFaq by Suresh Pandey Sirdevneeki100% (1)