Professional Documents

Culture Documents

Text

Uploaded by

Jamaliah JajaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Text

Uploaded by

Jamaliah JajaCopyright:

Available Formats

CIVE2400 Fluid Mechanics Section 1: Fluid Flow in Pipes CIVE2400 FLUID MECHANICS........................................................ ........................................... 1 SECTION 1: FLUID FLOW IN PIPES....

................................................................................ ...... 1 1. 1.1 1.2 1.3 FLUID FLOW IN PIPES............................................................. ........................................... 2 Pressure loss due to friction in a pipeline. ................................... ................................................................................ 2 Pressure loss during laminar flow in a pipe................................... ..............................................................................4 Pressure loss during turbulent flow in a pipe................................... ...........................................................................4 1.4 Choice of friction factor f ................................................ ................................................................................ ..............6 1.4.1 The value of f for Laminar flow .......................... ................................................................................ ........................7 1.4.2 Blasius equation for f ......................... ................................................................................ .........................................7 1.4.3 Nikuradse ..................... ................................................................................ ...............................................................7 1.4.4 Colebrook -White equation for f .......................................................... ........................................................................8 1.5 Lo cal Head Losses................................................................. ................................................................................ .......10 1.5.1 Losses at Sudden Enlargement.................................... ................................................................................ ..............10 1.5.2 Losses at Sudden Contraction ............................ ................................................................................ .......................12 1.5.3 Other Local Losses.............................. ................................................................................ ......................................12 1.6 1.7 1.8 1.9 Pipeline Analysis ..... ................................................................................ .....................................................................14 Pressure Head, Velocity Head, Potential Head and Total Head in a Pipeline............... .........................................15 Flow in pipes with losses due to fri ction........................................................................... ..........................................17 Reservoir and Pipe Example......... ................................................................................ ..............................................17 1.10 Pipes in series............................................................ ................................................................................ ....................18 1.10.1 Pipes in Series Example .......................... ................................................................................ .............................19 1.11 Pipes in parallel ......................... ................................................................................ ...................................................20 1.11.1 Pipes in Parallel E xample.......................................................................... ...........................................................20 1.11.2 An alternat ive method ..................................................................... .....................................................................22 1.12 Bra nched pipes .................................................................... ................................................................................ .........22 1.12.1 Example of Branched Pipe The Three Reservoir Problem.........

.......................................................................24 1.12.2 Other Pipe Flow Examples....................................................... ............................................................................28 1 .12.2.1 Adding a parallel pipe example ......................................... ..............................................................................28 CIVE 2400: Fluid Mechanics Pipe Flow 1

1. Fluid Flow in Pipes We will be looking here at the flow of real fluid in pipes real meaning a fluid that possesses viscosity hence looses energy due to friction as fluid particles interact with one another and the pipe wall. Recall from Level 1 that the shear stress induced in a fluid flowing near a boundary is given by Newton's law of vi scosity: du dy This ells us ha he shear s ress, , in a fluid is propor ional o he veloci y gradien - he ra e of change of veloci y across he fluid pa h. For a New onian fluid we can wri e: = du dy where he cons an of propor ionali y, , is known as he coefficien of viscosi y (or simply viscosi y). Recall also ha flow can be classified in o one of wo ypes, laminar or urbulen flow (wi h a small ransi ional region be ween hese wo). The non-dimensional number, he Reynolds number, Re, is used o de ermine which ype of flow occurs: Re = ud Re < 2000 For a pipe Laminar flow: Transi ional flow: Turbulen flow: 2000 < Re < 4000 Re > 4000 I is impor an o de ermine he flow ype as his governs how he amoun of ene rgy los o fric ion rela es o he veloci y of he flow. And hence how much ene rgy mus be used o move he fluid. 1.1 Pressure loss due o fric ion in a pipel ine. Consider a cylindrical elemen of incompressible fluid flowing in he pipe, as shown Figure 1: Elemen of fluid in a pipe CIVE 2400: Fluid Mechanics Pipe Flow 2

The pressure a he ups ream end, 1, is p, and a he downs ream end, 2, he pre ssure has fallen by p o (p-p). The driving force due o pressure (F = Pressure x Area) can hen be wri en driving force = Pressure force a 1 - pressure force a 2 pA ( p p) A = p A = p d 2 4 The retarding force is that due to the shear stress by the walls = shear stress area over which it acts = w a ea of pipe wall = wdL

As the flow is in equilibrium, driving force = retarding force p d 2 4 = wdL p = w 4 L d Equa ion 1 Giving an expression for pressure loss in a pipe in erms of he pipe diame er and he shear s ress a he wall on he pipe. The shear s ress will va ry wi h veloci y of flow and hence wi h Re. Many experimen s have been done wi h various fluids measuring he pressure loss a various Reynolds numbers. These r esul s plo ed o show a graph of he rela ionship be ween pressure loss and Re look similar o he figure below: Figure 2: Rela ionship be ween veloci y and pressure loss in pipes CIVE 2400: Fluid Mechanics Pipe Flow 3

laminar urbulen where 1.7 < a < 2.0 p u p u a As hese are empirical rela ionships, hey help in de ermining he pressure loss bu no in finding he magni ude of he shear s ress a he wall w on a par icul ar fluid. If we knew w we could hen use i o give a general equa ion o predic he pressure loss. 1.2 Pressure loss during laminar flow in a pipe In general he shear s ress w. is almos impossible o measure. Bu for laminar flow i is po ssible o calcula e a heore ical value for a given veloci y, fluid and pipe dim ension. (As his was covered in he Level 1 module, only he resul is presen ed here.) The pressure loss in a pipe wi h laminar flow is given by he Hagen-Poise uille equa ion:

32Lu d2 32Lu gd 2 Equa ion 2

1.3 P essu e loss du ing u bulen flow in a pipe In his de iva ion we will con side a gene al bounded flow fluid flowing in a channel we will hen apply his o pipe flow. In gene al i is mos common in enginee ing o have Re > 2000 i.e. u bulen flow in bo h closed (pipes and duc s) and open ( ive s and channe ls). Howeve analy ical exp essions a e no available so empi ical ela ionships a e equi ed ( hose de ived f om expe imen al measu emen s). Conside he elemen of fluid, shown in figu e 3 below, flowing in a channel, i has leng h L and wi h we ed pe ime e P. The flow is s eady and unifo m so ha accele a ion is ze o and he flow a ea a sec ions 1 and 2 is equal o A.

Figu e 3: Elemen of fluid in a channel flowing wi h unifo m flow CIVE 2400: Fluid Mechanics Pipe Flow 4

Whe e hf is known as he head loss due o f ic ion (Remembe means veloci y and is some imes w i en u .)

p = or in hf =

erms of head

he veloci y, u, is

This graph shows ssed as

ha

he rela ionship be ween pressure loss and Re can be expre

p1 A p 2 A w LP + W sin = 0 writing the weight term as gAL and sin = z/L gives A( p1 p 2 ) w LP gAz = 0 his can be rearranged o give

[( p1 p2 ) gz ] L dp * dx o P =0 A

o = m Equa ion 3 whe e m = A/P is known as he hyd aulic mean dep h W i ing piezome i c head loss as p* = ghf, hen shea s ess pe uni leng h is exp essed as o = m gh f dp * =m dx L So we now have a ela ionship of shea s ess a he wall o he a e of change in piezome ic p essu e. To make use of his equa ion an empi ical fac o mus b e in oduced. This is usually in he fo m of a f ic ion fac o f, and w i en o = f whe e u is he mean flow veloci y. Hence u 2 2 dp * u 2 gh f = f = dx 2m L So, fo a gene al bounded flow, head loss due o f ic ion can be w i en hf = fLu 2 2m Equa ion 4 Mo e specifically, fo a ci cula pipe, m = A/P = d /4d = d/4 giving 2 4 fLu 2 hf = 2 gd Equation 5 This is known as the Darcy-Weisbach equation for he ad loss in circular i es (Often referred to as the Darcy equation) This equatio n is equivalent to the Hagen-Poiseuille equation for laminar flow with the exce tion of the em irical friction factor f introduced. It is sometimes useful to wr ite the Darcy equation in terms of discharge Q, (using Q = Au) CIVE 2400: Fluid Mechanics Pi e Flow 5

whe e he fi s e m ep esen s i ing piezome ic head p*)

he piezome ic head loss of he leng h L o (w

u= hf = 4Q d 2 64 fLQ 2 fLQ 2 = 2 g 2 d 5 3.03d 5 Equation 6 Or with a 1% error hf = fLQ 2 3d 5 Equation 7 NOTE On Friction Factor Value The f value shown above is different to that used in American ractice. Their re lationshi is f American = 4 f Sometimes the f is re laced by the Greek letter . where = f American = 4 f Conse uent y great care must be taken when choosing the va ue of f with attentio n taken to the source of that va ue. 1.4 Choice of friction factor f The va ue of f must be chosen with care or e se the head oss wi not be correc t. Assessment of the physics governing the va ue of friction in a f uid has ed to the fo owing re ationships 1. hf L 2. hf v2 3. hf 1/d 4. hf depends on surfa ce roughness of pipes 5. hf depends on f uid density and viscosity 6. hf is inde pendent of pressure Conse uent y f cannot be a constant if it is to give correct head oss va ues from the Darcy e uation. An expression that gives f based on f uid properties and the f ow conditions is re uired. CIVE 2400: F uid Mechanics Pipe F ow 6

1.4.1 The va ue of f for Laminar f ow As mentioned above the e uation derived for head oss in turbu ent f ow is e uiv a ent to that derived for aminar f ow the on y difference being the empirica f . E uation the two e uations for head oss a ows us to derive an expression of f that a ows the Darcy e uation to be app ied to aminar f ow. E uating the Hag en Poiseui e and Darcy Weisbach e uations gives: 32Lu 4 fLu 2 = 2 gd gd 2 16 f = vd 16 f = Re Equa ion 8 1.4.2 Blasius equa ion fo f Blasius, in 1913, was he fi s o give an accu a e empi ical exp ession fo f f o u bulen flow in smoo h pipes, ha is: 0.079 f = Re 0.25 Equa ion 9 This ex p ession is fai ly accu a e, giving head losses +/ 5% of ac ual values fo Re u p o 100000. 1.4.3 Niku adse Niku adse made a g ea con ibu ion o he heo y of pipe flow by diffe en ia in g be ween ough and smoo h pipes. A ough pipe is one whe e he mean heigh of oughness is g ea e han he hickness of he lamina sub laye . Niku adse a if icially oughened pipe by coa ing hem wi h sand. He defined a ela ive oughnes s value ks/d (mean heigh of oughness ove pipe diame e ) and p oduced g aphs o f f agains Re fo a ange of ela ive oughness 1/30 o 1/1014. Figu e 4: Regions on plo of Niku adess da a CIVE 2400: Fluid Mechanics Pipe Flow 7

The egions which can be iden ified a e: 1. Lamina flow (f = 16/Re) 2. T ansi i on f om lamina o u bulen An uns able egion be ween Re = 2000 and 4000. Pipe flow no mally lies ou side his egion 3. Smoo h u bulen The limi ing line of u bulen flow. All values of ela ive oughness end owa d his as Re dec eas es. 4. T ansi ional u bulen The egion which f va ies wi h bo h Re and ela iv e oughness. Mos pipes lie in his egion. 5. Rough u bulen . f emains cons a n fo a given ela ive oughness. I is independen of Re. 1.4.4 Coleb ook Whi e equa ion fo f Coleb ook and Whi e did a la ge numbe of expe imen s on comme cial pipes and h ey also b ough oge he some impo an heo e ical wo k by von Ka man and P and l. This wo k esul ed in an equa ion a ibu ed o hem as he Coleb ook Whi e equa ion: 1 k 1.26 = 4 log10 s + 3.71d Re f f Equa ion 10 I is applicable o he whole of he u bulen egion fo comme cial pipes and u ses an effec ive oughness value (ks) ob ained expe imen ally fo all comme cial pipes. No e a pa icula difficul y wi h his equa ion. f appea s on bo h sides in a squa e oo e m and so canno be calcula ed easily. T ial and e o me ho ds mus be used o ge f once ksRe and d a e known. (In he 1940s when calcula io ns we e done by slide ule his was a ime consuming ask.) Nowadays i is ela ively ivial o solve he equa ion on a p og ammable calcula o o sp eadshee . Moody made a useful con ibu ion o help, he plo ed f agains Re fo comme cia l pipes see he figu e below. This figu e has become known as he Moody Diag am. [No e ha his figu e uses (= 4f) for friction factor rather than f. The shape of the diagram wi not change if f were used instead.] CIVE 2400: F uid Mechanics Pipe F ow 8

A numbe

of dis inc

egions can be iden ified on he diag am.

1 5.1286 k = 4 og10 s + 0.89 f 3.71d Re Equa ion 12 o 5.1286 k f = 1 4 log10 s + 0.89 3.71d Re 2 Equa ion 13 He e he las e m of he Coleb ook Whi e equa ion has been eplaced wi h 5.1286/Re0.89 which p ovides mo e accu a e esul s fo Re > 105. The p obl em wi h hese fo mulas s ill emains ha hese con ain a dependence on ks. Wha value of ks should be used fo any pa icula pipe? Fo una ely pipe manufac u es p ovide values and ypical values can of en be aken simila o hose in abl e 1 below. CIVE 2400: Fluid Mechanics Pipe Flow 9

Figure 5: Moody Diagram. He a so deve oped an e uation based on the Co ebrook Wh ite e uation that made it simp er to ca cu ate f: 200 k 10 6 1 / 3 s f = 0.001375 1 + d + Re Equa ion 11 This equa ion of Moody gives f co ec o +/ 3 < Re < 1 107 and fo ks/d < 0.01. Ba p esen ed an al e na ive explici equa ion fo f in 1975

Pipe Ma e ial B ass, coppe , glass, Pe spex Asbes os cemen W ough i on Galvanised i on Plas ic Bi umen lined duc ile i on Spun conc e e lined duc ile i on Slimed conc e e s ewe Table 1: Typical ks values 1.5 Local Head Losses ks (mm) 0.003 0.03 0.06 0.15 0.03 0.03 0.03 6.0 In addi ion o head loss due o f ic ion he e a e always head losses in pipe li nes due o bends, junc ions, valves e c. (See no es f om Level 1, Sec ion 4 Re al Fluids fo a discussion of ene gy losses in flowing fluids.) Fo comple eness of analysis hese should be aken in o accoun . In p ac ice, in long pipe lines of seve al kilome es hei effec may be negligible fo sho pipeline he los ses may be g ea e han hose fo f ic ion. A gene al heo y fo local losses is no possible, howeve ough u bulen flow is usually assumed which gives he s imple fo mula u2 hL = k L 2g Equa ion 14 Whe e hL is he local head loss and kL is a cons an fo a pa icula fi ing (valve o junc ion e c.) Fo he cases of sudden con ac ion (e.g. flowing ou of a ank in o a pipe) of a sudden enla ge men (e.g. flowing f om a pipe in o a ank) hen a heo e ical value of kL can b e de ived. Fo junc ions bend e c. kL mus be ob ained expe imen ally. 1.5.1 Losses a Sudden Enla gemen Conside he flow in he sudden enla gemen , shown in figu e 6 below, fluid flow s f om sec ion 1 o sec ion 2. The veloci y mus educe and so he p essu e inc eases ( his follows f om Be noulli). A posi ion 1 u bulen eddies occu which give ise o he local head loss. Figu e 6: Sudden Expansion CIVE 2400: Fluid Mechanics Pipe Flow 10

Apply he momen um equa ion be ween posi ions 1 and 2 o give: p1 A1 p2 A2 = Q (u 2 u1 ) Now use he con inui y equa ion o emove Q. (i.e. subs i u e Q = A2u2) p1 A1 p2 A2 = A2u 2 (u 2 u1 ) Rea anging gives p2 p1 u 2 = (u1 u2 ) g g Equa ion 17 Now apply he Be noulli equa ion f om poin 1 o 2, wi h he head lo ss e m hL p1 u12 p u2 + = 2 + 2 + hL g 2 g g 2 g And ea anging gives hL = Combi ning Equa ions 17 and 18 gives hL = hL 2 u12 u 2 u 2 (u1 u 2 ) 2g g 1 2 u12 u2 p2 p1 2g g Equa ion 18 (u = u2 2g ) 2 Equa ion 19 Subs i u ing again fo he con inui y equa ion o ge an exp ession involving he wo a eas, (i.e. u2=u1A1/A2) gives A u2 hL = 1 1 1 A2 2 g 2 Equa ion 20 Compa ing his wi h Equa ion 14 gives kL A k L = 1 1 A2 2 Equa ion 21 When a pipe expands in o a la ge ank A1 << A2 i.e. A1/A2 = 0 so kL = 1. Tha is, he head loss is equal o he veloci y head jus befo e he expan sion in o he ank. CIVE 2400: Fluid Mechanics Pipe Flow 11

1.5.2 Losses a Sudden Con ac ion Figu e 7: Sudden Con ac ion In a sudden con ac ion, flow con ac s f om poin 1 o poin 1 , fo ming a vena con ac ion. F om expe imen i has been shown ha his con ac ion is abou 40% (i.e. A1 = 0.6 A2). I is possible o assume h a ene gy losses f om 1 o 1 a e negligible (no sepa a ion occu s in con ac in g flow) bu ha majo losses occu be ween 1 and 2 as he flow expands again. In his case Equa ion 16 can be used f om poin 1 o 2 o give: (by con inui y u1 = A2u2/A1 = A2u2/0.6A2 = u2/0.6) 0.6 A2 (u 2 / 0.6 )2 hL = 1 A2 2g 2 hL = 0.44 i.e. A a sudden con ac ion kL = 0.44. 1.5.3 O he Local Losses 2 u2 2g Equa ion 22 La ge losses in ene gy in ene gy usually occu only whe e flow expands. The mech anism a wo k in hese si ua ions is ha as veloci y dec eases (by con inui y) so p essu e mus inc ease (by Be noulli). When he p essu e inc eases in he di ec ion of fluid ou side he bounda y laye has enough momen um o ove come his p essu e ha is ying o push i backwa ds. The fluid wi hin he bounda y laye has so li le momen um ha i will ve y quickly be b ough o es , and possi bly eve sed in di ec ion. If his eve sal occu s i lif s he bounda y laye a way f om he su face as shown in Figu e 8. This phenomenon is known as bounda y laye sepa a ion. Figu e 8: Bounda y laye sepa a ion CIVE 2400: Fluid Mechanics Pipe Flow 12

A he edge of he sepa a ed bounda y laye , whe e he veloci ies change di ec i on, a line of vo ices occu (known as a vo ex shee ). This happens because flu id o ei he side is moving in he opposi e di ec ion. This bounda y laye sepa a ion and inc ease in he u bulence because of he vo ices esul s in ve y la ge ene gy losses in he flow. These sepa a ing / dive gen flows a e inhe en ly uns able and fa mo e ene gy is los han in pa allel o conve gen flow. Some c ommon si ua ion whe e significan head losses occu in pipe a e shown in figu e 9

Y Junc ions Bends Figu e 9: Local losses in pipe flow The values of kL fo hese common si ua ions a e shown in Table 2. I gives value ha a e used in p ac ic e. kL value P ac ice 0.10 0.5 0.5 0.4 0.4 1.5 0.25 Bellmou h en y Sha p en y Sha p exi 90 bend 90 ees In line flow B anch o line Ga e value (open) Table 2: kL values CIVE 2400: Fluid Mechanics Pipe Flow 13

A dive gen

duc o diffuse Tee Junc ions

1.6 Pipeline Analysis To analyses he flow in a pipe line we will use Be noullis equa ion. The Be noulli equa ion was in oduced in he Level 1 module, and as a eminde i is p esen ed again he e. Be noullis equa ion is a s a emen of conse va ion of ene gy along a s eamline, by his p inciple he o al ene gy in he sys em does no change, Thus he o al head does no change. So he Be noulli equa ion can be w i en p u2 + + z = H = cons an g 2 g o To al Po en ial Kine ic P essu e ene gy pe + ene gy pe + ene gy pe = ene gy p e uni weigh uni weigh uni weigh uni weigh

veloci y head = u2 2g po en ial head = z o al head = H In his fo m Be noullis equa ion has some es ic ions in i s applicabili y, hey a e: Flow is s eady; Densi y is cons an (i.e . fluid is incomp essible); F ic ion losses a e negligible. The equa ion ela es he s a es a wo poin s along a single s eamline. CIVE 2400: Fluid Mechanics Pipe Flow 14

As all of hese elemen s of he equa ion have uni s of leng h, hey a e of en fe ed o as he following: p essu e head = p g

1.7 P essu e Head, Veloci y Head, Po en ial Head and To al Head in a Pipeline.

Figu e 10: Rese voi feeding a pipe To analyses he flow in he pipe we apply h e Be noulli equa ion along a s eamline f om poin 1 on he su face of he ese voi o poin 2 a he ou le nozzle of he pipe. And we know ha he o al ene gy pe uni weigh o he o al head does no change i is cons an along a s eamline. Bu wha is his value of his cons an ? We have he Be noulli equa ion 2 p1 u12 p2 u2 + +z = H = + +z g 2 g 1 g 2 g 2

We can calcula e he o al head, H, a he ese voi , p1 = 0 as his is a mosphe ic and a mosphe ic gauge p essu e is ze o, he su face is moving ve y slowly co mpa ed o ha in he pipe so u1 = 0 , so all we a e lef wi h is o al head = H = z1 he eleva ion of he ese voi . A useful me hod of analysing he flow is o show he p essu es g aphically on he same diag am as he pipe and ese voi . In he figu e above he o al head line is shown. If we a ached piezome e s a poin s along he pipe, wha would be hei levels when he pipe nozzle was close d? (Piezome e s, as you will emembe , a e simply open ended ve ical ubes fill ed wi h he same liquid whose p essu e hey a e measu ing). To al head line p essu e head H eleva ion Figu e 11: Piezome e levels wi h ze o veloci y As you can see in he above figu e, wi h ze o veloci y all of he levels in he piezome e s a e equal and he sa me as he o al head line. A each poin on he line, when u = 0 CIVE 2400: Fluid Mechanics Pipe Flow 15

By looking a ow hese diffe ing a pipe ha a hill) befo e

he example of en heads ela changes diame falling o i s

he ese voi wi h which feeds a pipe we will see h e o each o he . Conside he ese voi below feed e and ises (in eali y i may have o pass ove final level.

p +z = H g

p . g Wha would happen o he levels in he piezome e s (p essu e heads) if he wa e was flowing wi h veloci y = u? We know f om ea lie examples ha as veloci y i nc eases so p essu e falls veloci y head To al head line p essu e head hyd aulic g ade line H eleva ion Figu e 12: Piezome e levels when fluid is flowing p u2 + +z = H g 2 g u2 We see in his figu e ha he levels have educed by an amoun equal o he veloci y h ead, . Now as 2g he pipe is of cons an diame e we know ha he veloci y is c ons an along he pipe so he veloci y head is cons an and ep esen ed g aphica lly by he ho izon al line shown. ( his line is known as he hyd aulic g ade lin e). Wha would happen if he pipe we e no of cons an diame e ? Look a he fig u e below whe e he pipe f om he example above is eplaced by a pipe of h ee s ec ions wi h he middle sec ion of la ge diame e veloci y head To al head line p essu e head hyd aulic g ade line H eleva ion Figu e 13: Piezome e levels and veloci y heads wi h fluid flowing in va ying di ame e pipes The veloci y head a each poin is now diffe en . This is because he veloci y is diffe en a each poin . By conside ing con inui y we know ha he veloci y is diffe en because he diame e of he pipe is diffe en . Which pi pe has he g ea es diame e ? CIVE 2400: Fluid Mechanics Pipe Flow 16

The level in

he piezome e is he p essu e head and i s value is given by

Pipe 2, because he veloci y, and hence he veloci y head, is he smalles . This g aphical ep esen a ion has he advan age ha we can see a a glance he p es su es in he sys em. Fo example, whe e along he whole line is he lowes p ess u e head? I is whe e he hyd aulic g ade line is nea es o he pipe eleva ion i.e. a he highes poin of he pipe. 1.8 Flow in pipes wi h losses due o f ic ion. In a eal pipe line he e a e ene gy losses due o f ic ion hese mus be ake n in o accoun as hey can be ve y significan . How would he p essu e and hyd a ulic g ade lines change wi h f ic ion? Going back o he cons an diame e pipe, we would have a p essu e si ua ion like his shown below veloci y head To al head line p essu e head hyd aulic g ade line H hf eleva ion Figu e 14: Hyd aulic G ade line and To al head lines fo a cons an diame e pip e wi h f ic ion How can he o al head be changing? We have said ha he o al head o o al ene gy pe uni weigh is cons an . We a e conside ing ene gy conse va ion, so if we allow fo an amoun of ene gy o be los due o f ic ion he o al head will change. Equa ion 19 is he Be noulli equa ion as applied o a pipe line wi h he ene gy loss due o f ic ion w i en as a head and given he symbol h f ( he head loss due o f ic ion) and he local ene gy losses w i en as a head, hL ( he local head loss). p1 u12 p u2 + + z1 = 2 + 2 + z 2 + h f + hL g 2 g g 2 g Equa ion 23 1.9 Rese voi and Pipe Example

CIVE 2400: Fluid Mechanics Pipe Flow 17

Figu e 15: Rese voi

feeding a pipe

Conside

he example of a ese voi

feeding a pipe, as shown in figu e 15.

The pipe diame e is 100mm and has leng h 15m and feeds di ec ly in o he a mosp he e a poin C 4m below he su face of he ese voi (i.e. za zc = 4.0m). The h ighes poin on he pipe is a B which is 1.5m above he su face of he ese voi (i.e. zb za = 1.5m) and 5 m along he pipe measu ed f om he ese voi . Assume he en ance and exi o he pipe o be sha p and he value of f ic ion fac o f o be 0.08. Calcula e a) veloci y of wa e leaving he pipe a poin C, b) p es su e in he pipe a poin B. a) We use he Be noulli equa ion wi h app op ia e l osses f om poin A o C and fo en y loss kL = 0.5 and exi loss kL = 1.0. Fo he local losses f om Table 2 fo a sha p en y kL = 0.5 and fo he sha p exi as i opens in o he a mosphe e wi h no con ac ion he e a e no losses, so u2 hL = 0.5 2g F ic ion losses a e given by he Da cy equa ion 4 fLu 2 hf = 2 gd P essu e a A and C a e bo h a mosphe ic, uA is ve y small so can be se o ze o, giving zA = u2 2g + zC + u2 4 fLu 2 + 0.5 2 gd 2g z A zC = u2 4 fL 1 + 0.5 + d 2g

Subs i u e in he numbe s f om he ques ion 4 0.08 15 u2 4= 1.5 + 2 9.81 0.1 1.26m / s b) To find he p essu e a B apply Be noulli f om poin A o B using he veloci y calcula ed above. The leng h of he pipe is L1 = 5m: 2 pB u u2 4 fL1 u 2 zA = + +z + + 0.5 2g g 2 g B 2 gd pB u 2 4 fL1 z A zB = + 1 + 0.5 + d g 2 g 1.5 = pB 1.26 2 4 0.08 5.0 + 1.5 + 1000 9.81 2 9.81 0.1 p B = 28.58 103 N / m 2

CIVE 2400: Fluid Mechanics Pipe Flow 18

Tha is 28.58 kN/m2 below 1.10 Pipes in se ies When o fo m a pipe line, hey head) will be he sum of ns.

a mosphe ic. pipes of diffe en diame e s a e connec ed end o end a e said o be in se ies. The o al loss of ene gy (o he losses in each pipe plus local losses a connec io

1.10.1 Pipes in Se ies Example Conside he wo ese voi s shown in figu e 16, c onnec ed by a single pipe ha changes diame e ove i s leng h. The su faces of he wo ese voi s have a diffe ence in level of 9m. The pipe has a diame e of 200mm fo he fi s 15m (f om A o C) hen a diame e of 250mm fo he emainin g 45m (f om C o B). Figu e 16: Fo he en ance use kL = 0.5 and he exi kL = 1.0. The join a C is sudden. Fo bo h pipes use f = 0.01. To al head loss fo he sys em H = heigh diffe ence of ese voi s hf1 = head loss fo 200mm diame e sec ion of pipe hf2 = head loss fo 250mm diame e sec ion of pipe hL en y = head loss a en y poi n hL join = head loss a join of he wo pipes hL exi = head loss a exi poin e ms of

hf 1 = hf 2 = 2 fL1Q 2 3d15 fL2Q 2 5 3d 2 hLen y u2 Q2 Q2 1 4Q 2 = 0.5 0.0826 4 = 0.0413 4 = 0 .5 1 = 0 .5 2g d1 d1 2 g d1 hLexi = 1.0 2 u2 Q2 Q2 = 1.0 0.0826 4 = 0.0826 4 2g d2 d2 2 hLjoin = (u 1 u2 2g ) 2

1 1 2 2 2 2 1 4Q d1 d 2 2 1 = 0.0826Q 2 2 = d 2g

Subs i u e hese in o hf1 + hf2 + hL en y + hL join + hL exi = 9 and solve fo Q, o give Q = 0.158 m3/s CIVE 2400: Fluid Mechanics Pipe Flow 19

So H = hf1 + hf2 + hL en y + hL join + hL exi = 9m All losses a e, in Q:

1.11 Pipes in pa allel When wo o mo e pipes in pa allel connec wo ese voi s, as shown in Figu e 17 , fo example, hen he fluid may flow down any of he available pipes a possib le diffe en a es. Bu he head diffe ence ove each pipe will always be he sa me. The o al volume flow a e will be he sum of he flow in each pipe. The ana lysis can be ca ied ou by simply ea ing each pipe individually and summing f low a es a he end. Figu e 17: Pipes in Pa allel 1.11.1 Pipes in Pa allel Example Two pipes connec wo ese voi s (A and B) which have a heigh diffe ence of 10m . Pipe 1 has diame e 50mm and leng h 100m. Pipe 2 has diame e 100mm and leng h 100m. Bo h have en y loss kL = 0.5 and exi loss kL=1.0 and Da cy f of 0.008. Calcula e: a) a e of flow fo each pipe b) he diame e D of a pipe 100m long ha could eplace he wo pipes and p ovide he same flow. a) Apply Be noulli o each pipe sepa a ely. Fo pipe 1: 2 pA u A p u2 u 2 4 flu12 u2 + + z A = B + B + z B + 0.5 1 + + 1.0 1 g 2 g g 2 g 2 g 2 gd1 2g pA and pB a e a mosphe ic, and as he ese voi su face move s slowly uA and uB a e negligible, so u2 4 fl z A z B = 0.5 + + 1.0 1 2g d1 B B

4 0.008 100 u12 10 = 1.0 + 0.05 2 9.81 u1 = 1.731 m / s And flow a e is giv Q1 = u1 d12 4 = 0.0034 m 3 / s For i e 2: 2 2 A uA u2 u 2 4 flu2 u2 + + z A = B + B + z B + 0.5 2 + + 1.0 2 g 2 g g 2 g 2 g 2 gd 2 2g

CIVE 2400: Fluid Mechanics Pipe Flow 20

Again pA and pB a e a mosphe ic, and as nd uB a e negligible, so B B

he

ese voi

su face move s slowly uA a

u2 4 fl z A z B = 0.5 + + 1.0 2 2g d2 2 4 0.008 100 u 2 10 = 1.0 + = 2.42 m / s And flow a e is given by Q2 = u 2 d 22 4 = 0.0190 m 3 / s b) Re lacing the i e, we need Q = Q1 + Q2 = 0.0034 + 0.0190 = 0.0224 m3/s For t his i e, diameter D, velocity u , and making the same assum tions about entry/e xit losses, we have: 2 u 2 4 flu 2 u2 A uA u2 + + z A = B + B + z B + 0.5 + + 1.0 g 2 g g 2 g 2 g 2 gD 2g 2 4 fl u z A z B = 0.5 + + 1.0 D 2g 2 4 0.008 100 u 10 = 1.0 + D 2 2 = 1.0 + u D The veloci y can be ob ained f om Q i.e. D 2 Q = Au = u 4 4Q 0.02852 u = = D2 D 2 So

2 f ( D) = 241212 D 5 1.5D 3.2 f (0.1058) = 0.161 So inc ease D sligh ly, y 0.107m f (0.107) = 0.022 i.e. he solu ion is be ween 0.107m and 0.1058m bu 0.107 if sufficien ly accu a e. CIVE 2400: Fluid Mechanics Pipe Flow 21

3.2 0.02852 196.2 = 1.0 + D D 2 0 = 241212 D 5 1.5D 3.2 which mus vely An app oxima e answe can be ob ained by d opping he second e m: 0 = 2412 12D 5 3.2 D = 5 3.2 W i ing he func ion 241212 D = 0.1058m

be

1.11.2 An al e na ive me hod An al e na ive me hod (al hough based on he same heo y) is shown below using he Da cy equa ion in e ms of Q fLQ 2 hf = 3d 5 And he loss equa ions in e ms of Q: u2 Q2 42 Q 2 Q2 hL = k =k =k = 0.0826 k 4 2g 2 gA2 2 g 2 d 2 d For Pi e 1 10 = hL entry + hf + hL exit Q2 0.008 100Q 2 Q2 10 = 0.0826 0.5 + + 0.0826 1.0 0 .054 3 0.055 0.054 Q = 0.0034 m 3 / s Q = 3.4 litres / s For Pi e 2 10 = hL entry + hf + hL exit 10 = 0.0826 0.5 Q = 0.0188 m 3 / s Q = 18.8 litres / s Q 2 0.008 100Q 2 Q2 + + 0.0826 1.0 4 0.14 3 0.15 0.1 1.12 Branched i es If i es connect three reservoirs, as shown in Figure 17, th en the roblem becomes more com lex. One of the roblems is that it is sometimes difficult to decide which direction fluid will flow. In ractice solutions are now done by com uter techniques that can determine flow direction, however it is useful to examine the techniques necessary to solve this roblem. A B C D Figure 17: The three reservoir roblem For these roblems it is best to use the Darcy equation ex ressed in terms of discharge i.e. equation 7. fLQ 2 hf = 3d 5 When three or more i es meet at a junction then the following basic rinci les a ly: CIVE 2400: Fluid Mechanics Pi e Flow 22

1. The continuity equation must be obeyed i.e. total flow into the junction must equal total flow out of the junction; 2. at any one oint there can only be one value of head, and 3. Darcys equation must be satisfied for each i e. It is usu al to ignore minor losses (entry and exit losses) as ractical hand calculations become im ossible fortunately they are often negligible. One roblem still to b e resolved is that however we calculate friction it will always roduce a ositi ve dro when in reality head loss is in the direction of flow. The direction of flow is often obvious, but when it is not a direction has to be assumed. If the wrong assum tion is made then no hysically ossible solution will be obtained. In the figure above the heads at the reservoir are known but the head at the jun ction D is not. Neither are any of the i e flows known. The flow in i es 1 and 2 are obviously from A to D and D to C res ectively. If one assumes that the fl ow in i e 2 is from D to B then the following relationshi s could be written: z a hD = h f 1 hD z b = h f 2 hD z c = h f 3 Q1 = Q2 + Q3 The hf expressions are functions of Q, so we have 4 e uations with four unknowns , hD, Q1, Q2 and Q3 which we must so ve simu taneous y. CIVE 2400: F uid Mechanics Pipe F ow 23

The a gebraic so ution is rather tedious so a tria and error method is usua y recommended. For examp e this procedure usua y converges to a so ution uick y: 1. estimate a va ue of the head at the junction, hD 2. substitute this into the first three e uations to get an estimate for Q for each pipe. 3. check to see i f continuity is (or is not) satisfied from the fourth e uation 4. if the f ow in to the junction is too high choose a arger hD and vice versa. 5. return to step 2 If the direction of the f ow in pipe 2 was wrong y assumed then no so ution w i be found. If you have made this mistake then switch the direction to obtain these four e uations z a hD = h f 1 z b hD = h f 2 hD z c = h f 3 Q1 + Q2 = Q3 Looking at these two sets of e uations we can see that they are identica if hD = zb. This suggests that a good starting va ue for the iteration is zb then the direction of f ow wi become c ear at the first iteration. 1.12.1 Examp e of Branched Pipe The Three Reservoir Prob em Water f ows from reservoir A through pipe 1, diameter d1 = 120mm, ength L1=120m , to junction D from which the two pipes eave, pipe 2, diameter d2=75mm, ength L2=60m goes to reservoir B, and pipe 3, diameter d3=60mm, ength L3=40m goes to reservoir C. Reservoir B is 16m be ow reservoir A, and reservoir C is 24m be ow reservoir A. A pipes have f = 0.01. (Ignore and entry and exit osses.) We kn ow the f ow is from A to D and from D to C but are never uite sure which way th e f ow is a ong the other pipe either D to B or B to D. We first must assume one direction. If that is not correct there wi not be a sensib e so ution. To kee p the notation from above we can write za = 24, zb = 16 and zc = 0. For f ow A t o D z a hD = h f 1 24 hD = f1 L1Q12 = 16075 Q12 3d15 Assume f ow is D to B hD zb = h f 2 hD 8 = 2 f 2 L2Q2 2 = 84280 Q2 5 3d 2 For f ow is D to C hD zc = h f 3 f 3 L3Q32 = 171468 Q32 5 3d 3 The fina e uation is continuity, wh ich for this chosen direction D to B is hD 0 = Q1 = Q2 + Q3 CIVE 2400: F uid Mechanics Pipe F ow 24

Now it is a matter of systematica y uesting va ues of hD unti continuity is s atisfied. This is best done in a tab e. And it is usua y best to initia y gues s hD = za then reduce its va ue (unti the error in continuity is sma ): hj 24.00 20.00 17.00 17.10 17.20 17.30 17.25 17.24 Q1 0.00000 0.01577 0.02087 0. 02072 0.02057 0.02042 0.02049 0.02051 Q2 0.01378 0.01193 0.01033 0.01039 0.01045 0.01050 0.01048 0.01047 Q3 0.01183 0.01080 0.00996 0.00999 0.01002 0.01004 0.01 003 0.01003 Q1=Q2+Q3 0.02561 0.02273 0.02029 0.02038 0.02046 0.02055 0.02051 0.0 2050 err 0.02561 0.00696 0.00058 0.00034 0.00010 0.00013 0.00001 0.00001 So the so ution is that the head at the junction is 17.24 m, which gives Q1 = 0. 0205m3/s, Q1 = 0.01047m3/s and Q1 = 0.01003m3/s. Had we guessed that the f ow was from B to D, the second e uation wou d have bee n zb hD = h f 2 8 hD = 2 f 2 L2Q2 2 = 84280 Q2 5 3d 2 and continuity wou d have been Q1 + Q2 = Q3 . If you then attempted to so ve thi s you wou d soon see that there is no so ution. CIVE 2400: F uid Mechanics Pipe F ow 25

An a ternative method to so ve the above prob em is shown be ow. It does not so ve the head at the junction, instead direct y so ves for a ve ocity (it may be e asi y amended to so ve for discharge Q) [For this particu ar uestion the method shown above is easier to app y but the method shown be ow cou d be seen as more genera as it produces a function that cou d be so ved by a numerica method an d so may prove more convenient for other simi ar situations.] Again for this we wi assume the f ow wi be from reservoir A to junction D then from D to reser voirs B and C. There are three unknowns u1, u2 and u3 the three e uations we nee d to so ve are obtained from A to B then A to C and from continuity at the junct ion D. F ow from A to B 2 2 pA uA p u2 4 fL2u12 4 fL2u 2 + +z A = B + B +zB + + g 2 g g 2 g 2 gd1 2 gd 2 P u ing pA = pB and aking uA and uB as negligible, gives 2 4 fL2u12 4 fL2u2 + z A zB = 2 gd1 2 gd 2 Pu in he numbe s f om he ques ion 2 4 0.01 120u12 4 0.01 6 0u2 + 16 = 2 g 0.12 2 g 0.075 2 16 = 2.0387u12 + 1.6310u2 (equa ion i) Flow f om A o C 2 2 p u2 pA u A 4 fL2u12 4 fL3u3 + + z A = C + C + zC + + g 2 g g 2 g 2 gd1 2 gd 3 Pu ing pA = pc and aking uA and uc as negligible, gives 2 4 fL2u12 4 fL3u3 + z A zC = 2 gd1 2 gd 3 Pu in he numbe s f om he ques ion 2 4 0.01 120u12 4 0.0 1 40u3 + 24 = 2 g 0.12 2 g 0.060 2 24 = 2.0387u12 + 1.3592u3

d 2 1 4 u1 = d 22 4 u2 + 2 d 32 4 u3 u3 2 d u1 = 2 d 1 wi h numbe s f om he ques ion d u2 + 3 d 1 u1 0.3906u 2 0.25u3 = 0 (equa ion iii) CIVE 2400: Fluid Mechanics Pipe Flow 26

(equa ion ii) F o con inui y a o C Q1 = Q2 + Q3

he junc ion Flow A o D = Flow D

o B + Flow D

he values of u1, u2 and u3 mus be found by solving he simul aneous equa ion i , ii and iii. The echnique o do his is o subs i u e fo equa ions i, and ii in o equa ion iii, hen solve his exp ession. I is usually done by a ial an d e o app oach. i.e. f om i, u 2 = 9.81 1.25u12 f om ii, u3 = 17.657 1.5u12

subs i u ed in iii gives u1 0.3906 9.81 1.25u12 0.25 17.657 1.5u12 = 0 = f (u1 )

Giving u1 = 1.82 m/s, so u2 = 2.38 m/s, u3 = 12.69 m/s Flow a es a e d12 Q1 = u1 = 0.0206 m 3 / s 4 d 2 Q2 = 2 u 2 = 0.0105 m 3 / s 4 d 2 Q3 = 3 u3 = 0.0101 m 3 / s 4 Check for continuity at the junction Q1 = Q2 + Q3 0.0206 = 0.0105 + 0.0101 CIVE 2400: Fluid Mechanics Pi e Flow 27

This able shows some ial and e o solu ions u 1 2 1.8 1.85 1.83 1.82 f(u) 1.14769 0.289789 057

0.03176 0.046606 0.015107 0.00

1.12.2 Other Pi e Flow Exam les 1.12.2.1 Adding a arallel i e exam le A i e joins two reservoirs whose head difference is 10m. The i e is 0.2 m diam eter, 1000m in length and has a f value of 0.008. a) What is the flow in the i eline? b) It is required to increase the flow to the downstream reservoir by 30% . This is to be done adding a second i e of the same diameter that connects at some oint along the old i e and runs down to the lower reservoir. Assuming the diameter and the friction factor are the same as the old i e, how long should the new i e be? 10m Original i e New i e 100 0m a) fLQ 2 3d 5 0.008 1000Q 2 10 = 3 0.25 Q = 0.0346 m 3 / s hf = Q = 34.6 litres / s b) H = 10 = h f 1 + h f 2 = h f 1 + h f 3 hf 2 = hf 3 f LQ f 2 L2Q2 = 3 3 53 5 3d 2 3d 3 as the i es 2 and 3 are the same f, same len gth and the same diameter then Q2 = Q3. 2 2 By continuity Q1 = Q2 + Q3 = 2Q2 = 2Q3 So Q2 = and L2 = 1000 -L1 Then Q1 2 CIVE 2400: Fluid Mechanics Pi e Flow 28

10 = h f 1 + h f 2 2 f1 L1Q12 f 2 L2Q2 + 10 = 2 2d12 2d 2 10 = f1 L1Q12 f 2 (1000 L1 )(Q1 / 2) + 2 2d12 2d 2 2 As f1 = f2, d1 = d2 10 = (1000 L1 ) f1Q12 L + 2 1 3d1 4 The new Q1 is o be 30% g ea e han befo e so Q1 = 1.3 0.034 = 0.442 m3/s Solve fo L o give L1 = 455.6m L2 = 1000 455.6 = 544.4 m CIVE 2400: Fluid Mechanics Pipe Flow 29

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- PUMPSDocument151 pagesPUMPSAZIZ97% (30)

- Chapter 13: Kinetics of A Particle: Force and Acceleration: 13.1 Newton's Laws of MotionDocument5 pagesChapter 13: Kinetics of A Particle: Force and Acceleration: 13.1 Newton's Laws of MotionideepujNo ratings yet

- Emwf - t185 QsDocument6 pagesEmwf - t185 QsSiva KumarNo ratings yet

- General Specification For Mass Flow MeterDocument138 pagesGeneral Specification For Mass Flow MeterRenalyn TorioNo ratings yet

- Matter and Phase Change ReviewDocument4 pagesMatter and Phase Change ReviewZachary NeuNo ratings yet

- 6c Midterm StudyDocument15 pages6c Midterm StudyCote LeBlancNo ratings yet

- LightDocument2 pagesLightelorran0% (2)

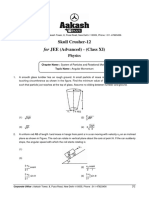

- Skull Crusher-12 - Class XI - JEE (Adv) - PhysicsDocument7 pagesSkull Crusher-12 - Class XI - JEE (Adv) - Physicslootera715No ratings yet

- AE May 2013 04 BS 10Document4 pagesAE May 2013 04 BS 10Amber HarrisNo ratings yet

- Hole Cleaning PDF - 1672150874871Document88 pagesHole Cleaning PDF - 1672150874871Mohamed MamdouhNo ratings yet

- Solutions: 4. Tunnel Diode (8 PTS) 1) 2) F 0Document2 pagesSolutions: 4. Tunnel Diode (8 PTS) 1) 2) F 0Kolisetty SudhakarNo ratings yet

- IGCSE Physics NotesDocument16 pagesIGCSE Physics NotesMhdAboualy84% (32)

- Surge Analysis and Design - Case StudyDocument10 pagesSurge Analysis and Design - Case StudyRaghuveer Rao PallepatiNo ratings yet

- Numerical Study Ofa Tesla TurbineDocument8 pagesNumerical Study Ofa Tesla TurbineRavi ScoobyNo ratings yet

- Chapter 5: The Second Law of Thermodynamics: in A Cyclic ProcessDocument42 pagesChapter 5: The Second Law of Thermodynamics: in A Cyclic Processأحمد صلاح الدينNo ratings yet

- Optical Fiber LossesDocument2 pagesOptical Fiber LossesMedi Srikanth NethaNo ratings yet

- Lug AnalysisDocument15 pagesLug AnalysisAfzalul Karim Nirvick0% (1)

- Grade 7: Module 2, Quarter 3 Lesson 2.1Document29 pagesGrade 7: Module 2, Quarter 3 Lesson 2.1Judy Caroline CatacutanNo ratings yet

- What Is Uniform Circular MotionDocument1 pageWhat Is Uniform Circular MotionSabrina BanociaNo ratings yet

- Experiment # 3: Objective:: Fig: 3.1 (Pelton Wheel Turbine)Document3 pagesExperiment # 3: Objective:: Fig: 3.1 (Pelton Wheel Turbine)waseemjuttNo ratings yet

- AERODYN2 - Part 7 - Climbing FlightDocument32 pagesAERODYN2 - Part 7 - Climbing FlightSecretNo ratings yet

- Unit 2 Variable Stresses, Design of Shafts, Keys and CouplingsDocument134 pagesUnit 2 Variable Stresses, Design of Shafts, Keys and CouplingsDravid PrabaNo ratings yet

- Sediment Erosion in Hydro Turbines 1Document414 pagesSediment Erosion in Hydro Turbines 1Eng Bagaragaza RomualdNo ratings yet

- Electromagnetic Field Theory Lec1Document27 pagesElectromagnetic Field Theory Lec1Sourabh GhoshNo ratings yet

- Betti's Theorem PDFDocument62 pagesBetti's Theorem PDFrigaschNo ratings yet

- Learning Activity Sheet in General Physics 1 Lesson 11: Mechanical Waves and SoundDocument10 pagesLearning Activity Sheet in General Physics 1 Lesson 11: Mechanical Waves and SoundSenica Caydil Jay D.No ratings yet

- Seismic Exploration Technique and ProcessingDocument211 pagesSeismic Exploration Technique and ProcessingDimas PradanaNo ratings yet

- Trigonometry Formulae: sin 2θ=2 sin θ cos θDocument2 pagesTrigonometry Formulae: sin 2θ=2 sin θ cos θMaishNo ratings yet

- Emt 4Document12 pagesEmt 4PMANIKANDANSVNNo ratings yet