Professional Documents

Culture Documents

Gestra NRG16-12-NRG17-12-NRG19-12 - e

Uploaded by

Voicu StaneseOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gestra NRG16-12-NRG17-12-NRG19-12 - e

Uploaded by

Voicu StaneseCopyright:

Available Formats

Issue Date: 3/06

GESTRA Steam Systems

Self-Monitoring Level-Control Electrodes NRG 16-12 NRG 17-12 NRG 19-12

Description

The level electrodes NRG 16-12, NRG 17-12 and NRG 19-12 detect the max. liquid level (high level alarm) in a steam boiler. The operation of the electrode is based on the conductivity measuring principle using the electrical conductivity of water for signalling one liquid level:

High level alarm

Product Range B1 NRG 16-12 NRG 17-12 NRG 19-12

Technical Data

Type approval TV 01-02-0112 Service pressure NRG 16-12: 32 bar at 238 C NRG 17-12: 60 bar at 275 C NRG 19-12: 100 bar at 311 C Connection Srewed " BSP, ISO 228-1 Materials Stem: 1.4571 X6CrNiMoTi17-12-2 Measuring electrode: 1.4401, X5CrNiMo17-12-2 Electrode insulation: PEEK Terminal box: polyamide (PA) Lengths available 500 mm 1000 mm 1500 mm Cell constant C 0.13 cm -1 with measuring surface extension 0.3 cm -1 without measuring surface extension Response sensitivity 10 S/cm at 25 C, cell constant 0.3 cm -1 0.5 S/cm at 25 C, cell constant 0.13 cm -1 Terminal box Four-pin connector, cable gland M 16 (PG 9) Protection IP 65 to EN 60529 Max. admissible ambient temperature Max. 70 C Weight Approx. 1.1 kg

The NRG 1...-12 is designed for use in conjunction with level switch NRS 1-8 as a self-monitoring level limiter with periodic self-checking (SMART) feature. Application in steam and pressurized hot-water plants in accordance with TRD 604, sheet 1 and sheet 2 (24h/72h operation) as well as EN 12952 and EN 12953. The electrical equipment meets the requirements of the Regulations on Protection Circuits DIN VDE 0116.

Function

The water level limiter comprises a level electrode type NRG 1...-12 and a level switch type NRS 1-8. The level electrode NRG 1...12 consists of a pressure-tight measuring electrode. The electrode is insulated with a special plastic seal. The level limiter operation is based on the conductive measuring principle using the electrical conductivity of water for signalling water level. During normal, troublefree operation the level electrode tip is immersed in boiler water and no low level alarm is given. A low level alarm will only be raised if the electrode tip is exposed for more than 3 seconds. A low level alarm will also be activated if the insulating seals placed between the electrodes and the body are no longer pressure tight, allowing water to penetrate into the cavities between the body, tube and stud. However in this instance the alarm is caused by a malfunction of the electrode, and confirmation should always be done by checking if there is water in the gauge glass. The equipment combination NRG 1...-12 and NRS 1-8 provides fail safe protection against a first fault in accordance with TRD 604.

NRG 16 -12 with measuring surface extension (optional)

NRG 17-12

NRG 19-12

System Components

NRS 1-8 Level switch NRS 1-8. Two channel level limiter (redundancy) with periodic self-checking routine to DIN VDE 0116.

Design

NRG 1...-12: Screwed " BSP to ISO 228-1.

Key

Examples of Installation

Flange PN 40, PN 63, PN 160, DN 50, DIN 2501-1 Flange PN 40, PN 63, PN 160, DN 100, DIN 2501-1 " BSP

1 2 3 4 5 6 7 8 9 0

For the approval of the boiler standpipe with connecting flange the relevant regulations must be considered. Vent hole

Provide vent hole as close as possible to the boiler wall!

DN 50

1 2

20

8 4

High water (HW) Electrode rod d = 8 mm Protection tube DN 80 Protection tube DN 100 Electrode distance 14 mm Low water (LW) Reducer DIN 2616, part 2 K-88.9 x 3.2- 42.4 x 2.6 W

20

5 6 9

90

20

Fig. 1

NRG 16-12 / NRG 17-12 installation of high-level alarm electrode inside the boiler

" BSP

" BSP

1 2

3000

DN 100

24.5 24.5

20

20

5 7 8 4 9

90

20

Fig. 2

Combination with internal protection tube

Examples of Installation

Important Notes

Note that screened four-core cable, e.g. I-Y(St)Y 2 x 2 x 0.8 or LIYCY 4 x 0.5 2 is required. Max. cable length 100 m with water conductivity from 10 S/cm.

e.g

. 45

Max. cable length 30 m with water conductivity from 0.5 S/cm. NRG 16-12 NRG 17-12 Max. cable length 15 m with water conductivity from 0.5 S/cm when used in conjunction with inverter URN1 (24 V d.c.). The installation of electrodes inside the boiler is only approved for shell-type boilers. For other boiler types the trouble-free interaction and correct operation of the steam boiler and the low level alarm must be approved by the competent Technical Supervisory Association (in Germany: TV). The electrode shall be installed vertically or with a lateral inclination of 45. DN 50, PN 40 DN 50, PN 63 Installation directly inside the steam boiler is recommended as this provides operational and maintenance cost savings. In this case a protection tube ( DN 80 mm) is required. In pressurized hot-water plants the electrode may also be installed in the feed main ( DN 50) in a position inclined by 45. Combination electrodes must be installed vertically. When the electrode is installed inside the boiler, a protection tube I.D. 100 mm (Water Level 100) must be provided. If the electrode is installed in an external chamber, purging of the chamber is required at regular intervals. For this purpose the GESTRA logic unit for monitoring type SRL 6 is available.

Switching level

Cut L so that the dimension a is 20 mm Dimension b 14 mm (tolerance for centring) L = max. 1000 mm (inclined installation)

DN 80

Fig. 3

Laterally inclined installation of electrode in a rising feed main of a pressurized hot-water plant

Please note

For the approval of the boiler standpipe the relevant

regulations must be considered.

The inclination angle of the electrode must not exeed

45. The max. length of the electrode rod is 1000 mm. Fig. 3

NRG 19-12

NRG 19-11

If the electrode is installed outdoor, it must be provided

with a weather-proof cover supplied by GESTRA.

DN 20

20

4

DN 25, PN 160 Centre distance

DN 50, PN 160

5 9

DN 20

DN 25, PN 160

DN 20

Centre distance

Fig. 4

External chamber type III for installation of a high-level electrode outside of boiler.

Fig. 5

DN 25, PN 160

External chamber type XIII for installation of two electrodes outside of boiler.

Self-Monitoring Level-Control Electrodes NRG 16-12 NRG 17-12 NRG 19-12

Order and Enquiry Specifications

GESTRA self-monitoring level-control electrode for selfmonitoring high water-level limiter according to TRD 604 and TRD 602:

Level-control electrode type NRG 16-12.....................

PN 40, connection ..................................................... Inspection.................................................................. Cell constant C .......................................................... Length .................................................................mm PN 63, connection ..................................................... Inspection.................................................................. Cell constant C .......................................................... Length .................................................................mm PN 160, connection ................................................... Inspection.................................................................. Cell constant C .......................................................... Length .................................................................mm

Level-control electrode type NRG 17-12.....................

Level-control electrode type NRG 19-12.....................

85

165

1500

Ancillary Equipment

Logic unit type SRL 6 for monitoring purging cycles Weather-proof protective cover for outdoor installa-

tion.

ATEX (Atmosphre Explosible)

The equipment constitutes a simple item of electrical equipment as defined in DIN EN 50020 section 5.4. According to the European Directive ATEX 94/9/EC the equipment may only be used in potentially explosive atmospheres if it is provided with approved Zener barriers. Applicable in Ex zones 1, 2 (1999/92/EC). The equipment does not bear an Ex marking. The suitability of the Zener barriers is certified in a separate document.

23

Fig. 6

NRG 16-12 with measuring surface extension (cell constant 0.13) / NRG 17-12 / NRG 19-12.

Supply in accordance with our general terms of business.

GESTRA AG

P. O. Box 10 54 60, D-28054 Bremen Mnchener Str. 77 D-28215 Bremen , Telephone +49 (0) 421 35 03 - 0, Fax +49 (0) 421 35 03-393 E-Mail gestra.ag@flowserve.com, Internet www.gestra.de

818556-00/306cm 1991 GESTRA AG Bremen Printed in Germany

1500

(electrode installed in external measuring pot).

1500

The following test certificates can be issued on request, at extra cost: In accordance with EN 10204-2.1, -2.2 and -3.1B. All inspection requirements have to be stated with the order. After supply of the equipment certification cannot be established. For tests and inspection charges please consult us.

85

272

120

283

You might also like

- Gestra NRGT 26 1 NRGT 26 1sDocument2 pagesGestra NRGT 26 1 NRGT 26 1sVoicu StaneseNo ratings yet

- NivoPress DataSheet 2Document4 pagesNivoPress DataSheet 2Svetlana GabricNo ratings yet

- Audio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsFrom EverandAudio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsNo ratings yet

- Gestra Level ConventionalDocument4 pagesGestra Level ConventionalVoicu StaneseNo ratings yet

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- 818956Document24 pages818956jetiradoNo ratings yet

- Immersion Temperature SensorsDocument4 pagesImmersion Temperature SensorsmansidevNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Installation Instructions 810831-00: Water-Level Limiter / Controller NRS 1-9Document16 pagesInstallation Instructions 810831-00: Water-Level Limiter / Controller NRS 1-9Voicu StaneseNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Pce 28Document3 pagesPce 28Pop-Coman SimionNo ratings yet

- Containing 2 To 12 Valves 2/2 Normally Closed, Direct Operated 1/8Document8 pagesContaining 2 To 12 Valves 2/2 Normally Closed, Direct Operated 1/8Urip S. SetyadjiNo ratings yet

- RAK TR.1000S H DatabladDocument4 pagesRAK TR.1000S H DatabladPhuc HuynhNo ratings yet

- PTCDocument18 pagesPTCRetno_GNo ratings yet

- Lga 52Document11 pagesLga 52caner8948No ratings yet

- gt403 Ce2Document4 pagesgt403 Ce2SodaDrinkNo ratings yet

- Nor GrenDocument5 pagesNor GrenSarlo11No ratings yet

- ADocument2 pagesACharles DanielNo ratings yet

- Temp Sensor ChillerDocument3 pagesTemp Sensor Chillerpradeep_tyagi80No ratings yet

- LGB BControlDocument21 pagesLGB BControlaalfaqiNo ratings yet

- Druck PT Data SheetDocument7 pagesDruck PT Data Sheethits289No ratings yet

- OEM En3-222Document4 pagesOEM En3-222chandushar1604No ratings yet

- Time Control Technique: Timer MK 9906N, On Delayed MinitimerDocument4 pagesTime Control Technique: Timer MK 9906N, On Delayed MinitimerKim Hảo Hoàng NguyễnNo ratings yet

- Oil Burner Controls: Building TechnologiesDocument18 pagesOil Burner Controls: Building TechnologiesThiago FernandesNo ratings yet

- Contact Connection 1-3: 6 (2.5) A, AC 250 V: Building TechnologiesDocument4 pagesContact Connection 1-3: 6 (2.5) A, AC 250 V: Building TechnologiesDavid NguyenNo ratings yet

- Condenserless Liquid ChillersDocument12 pagesCondenserless Liquid ChillersBader ShrbajiNo ratings yet

- Unitrans Universal Pressure Transmitters Type Ut-10, Ut-11: ApplicationsDocument4 pagesUnitrans Universal Pressure Transmitters Type Ut-10, Ut-11: ApplicationsbehnamatgNo ratings yet

- Akocontrol Cat en 2-3Document27 pagesAkocontrol Cat en 2-3Alberto PinhoNo ratings yet

- Installation, Operating & Maintenance Manual. Electronic Level Switch LIDEC 91-92Document22 pagesInstallation, Operating & Maintenance Manual. Electronic Level Switch LIDEC 91-92carlos_sagitarioNo ratings yet

- Wika Il-10Document4 pagesWika Il-10José MelâneoNo ratings yet

- Pressure Transmitter: Principle of OperationDocument4 pagesPressure Transmitter: Principle of OperationAranNo ratings yet

- LG An 7418 en 14032006Document11 pagesLG An 7418 en 14032006Thiago FernandesNo ratings yet

- SensorDocument6 pagesSensorFarhan ZafarNo ratings yet

- Instruction For Installation and Maintenance - VT - ADocument13 pagesInstruction For Installation and Maintenance - VT - AcataconstantinNo ratings yet

- Gas Burned Siemens Landis LGA41Document11 pagesGas Burned Siemens Landis LGA41Abelardo PeironeNo ratings yet

- BN5983Document4 pagesBN5983iyilmaz1No ratings yet

- Sem210 Series: Programmable In-Head Universal Temperature TransmitterDocument5 pagesSem210 Series: Programmable In-Head Universal Temperature TransmitterjhuskanovicNo ratings yet

- 900025Document3 pages900025marci666No ratings yet

- Sondaloop Data Sheet 283 Iss L Measuring Range 10m April 2017Document2 pagesSondaloop Data Sheet 283 Iss L Measuring Range 10m April 2017farruscoprdNo ratings yet

- Instruction Manual: Models 7EF and 7HF ControllersDocument48 pagesInstruction Manual: Models 7EF and 7HF ControllerskmpoulosNo ratings yet

- Samsom - Solenoid Valve TypeDocument12 pagesSamsom - Solenoid Valve TypeWeimarNo ratings yet

- Controlador para Calderetea de Motores Lmo44.255 - 38ld0015Document10 pagesControlador para Calderetea de Motores Lmo44.255 - 38ld0015Pablo AllosiaNo ratings yet

- T500 Elite Manual: (Software Version 3.0.XCSA)Document33 pagesT500 Elite Manual: (Software Version 3.0.XCSA)Fernando OchoaNo ratings yet

- Differential Pressure DetectorsDocument4 pagesDifferential Pressure Detectorskdp_806212786No ratings yet

- Multical 401: Installation and User's GuideDocument20 pagesMultical 401: Installation and User's GuidecmilivojeNo ratings yet

- ADocument2 pagesAAGNALDOJULIONo ratings yet

- System Sensor WFDTNRN Data SheetDocument4 pagesSystem Sensor WFDTNRN Data SheetJMAC SupplyNo ratings yet

- ETT15ENDocument4 pagesETT15ENDiego CordovaNo ratings yet

- RIS DGPTDocument6 pagesRIS DGPTKarin Aca OviNo ratings yet

- SM 592.2 Caja de Control ElectromagneticaDocument6 pagesSM 592.2 Caja de Control ElectromagneticaHectorI.GoCaNo ratings yet

- Over Voltage Under Voltage Relay SUR353Document2 pagesOver Voltage Under Voltage Relay SUR353Yasir AyubNo ratings yet

- Power Supply Systems Surge Arresters - Type 2: SPD Type 2 According To EN 61643-11 SPD Class II According To IEC 61643-1Document3 pagesPower Supply Systems Surge Arresters - Type 2: SPD Type 2 According To EN 61643-11 SPD Class II According To IEC 61643-1Jonathan Quispe TNo ratings yet

- Emp2 Box Pressure TransmitterDocument8 pagesEmp2 Box Pressure TransmitterAsif HameedNo ratings yet

- Next Dx.u.s 052.z2.h6.Dc - Ec FanDocument7 pagesNext Dx.u.s 052.z2.h6.Dc - Ec Fankapten_2008No ratings yet

- Wika Pressure SensorDocument4 pagesWika Pressure SensorPratap ValekarNo ratings yet

- Dell Studio-1558 Service Manual En-UsDocument49 pagesDell Studio-1558 Service Manual En-UsVoicu StaneseNo ratings yet

- Building Automation and Control L System Desi GoDocument52 pagesBuilding Automation and Control L System Desi GoVoicu StaneseNo ratings yet

- 2N3906 General Purpose Transistors: PNP SiliconDocument7 pages2N3906 General Purpose Transistors: PNP SiliconJose G. Cantillo L.No ratings yet

- Manufacturer: Model: Year: Registration: Mileage: Job Number: DateDocument5 pagesManufacturer: Model: Year: Registration: Mileage: Job Number: DateVoicu StaneseNo ratings yet

- Modbus RtuDocument8 pagesModbus RtuVoicu StaneseNo ratings yet

- M-Bus 012Document36 pagesM-Bus 012Voicu StaneseNo ratings yet

- MpBus 02 eDocument30 pagesMpBus 02 eVoicu StaneseNo ratings yet

- MBus 03 eDocument26 pagesMBus 03 eVoicu StaneseNo ratings yet

- Kalorimetar Data Sheet UH50 - UH106 101kDocument15 pagesKalorimetar Data Sheet UH50 - UH106 101kbobesponjakockaloneNo ratings yet

- Distributed Power Generation Using MicroturbinesDocument1 pageDistributed Power Generation Using MicroturbinesVoicu StaneseNo ratings yet

- Appendix BDocument14 pagesAppendix BVoicu StaneseNo ratings yet

- A 60-kW Microturbine Demonstration Facility Phase II: Instrumentation, Website Development, and EvaluationDocument14 pagesA 60-kW Microturbine Demonstration Facility Phase II: Instrumentation, Website Development, and EvaluationVoicu StaneseNo ratings yet

- Performance of The Capstone C30 Microturbine On Biodiesel BlendsDocument11 pagesPerformance of The Capstone C30 Microturbine On Biodiesel BlendsVoicu StaneseNo ratings yet

- Project Proposal - Articulation SessionsDocument8 pagesProject Proposal - Articulation SessionsJhay-are PogoyNo ratings yet

- Memorandum of AgreementDocument6 pagesMemorandum of AgreementJomar JaymeNo ratings yet

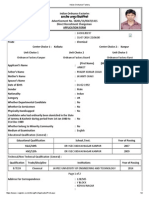

- Indian Ordnance FactoryDocument2 pagesIndian Ordnance FactoryAniket ChakiNo ratings yet

- LIC Form - Intimation of Death Retirement Leaving ServiceDocument1 pageLIC Form - Intimation of Death Retirement Leaving ServicekaustubhNo ratings yet

- Gcse Economics 8136/1: Paper 1 - How Markets WorkDocument19 pagesGcse Economics 8136/1: Paper 1 - How Markets WorkkaruneshnNo ratings yet

- Form DVAT 27A: Intimation of Deposit of Government DuesDocument2 pagesForm DVAT 27A: Intimation of Deposit of Government DueshhhhhhhuuuuuyyuyyyyyNo ratings yet

- BPI vs. Posadas, G.R. No. L - 34583, 1931Document8 pagesBPI vs. Posadas, G.R. No. L - 34583, 1931Nikko AlelojoNo ratings yet

- Accomplishment Report Dictrict Preventive MaintenanceDocument2 pagesAccomplishment Report Dictrict Preventive MaintenanceZenia CapalacNo ratings yet

- MC 10226555 0001Document7 pagesMC 10226555 0001Hema IbraNo ratings yet

- Impact of Wrongful Termination On EmployeesDocument4 pagesImpact of Wrongful Termination On EmployeesAvil HarshNo ratings yet

- On Fracture MechanicsDocument81 pagesOn Fracture MechanicsDEEPAK100% (1)

- User Exits in Validations SubstitutionsDocument3 pagesUser Exits in Validations SubstitutionssandeepNo ratings yet

- 2008 Reverse Logistics Strategies For End-Of-life ProductsDocument22 pages2008 Reverse Logistics Strategies For End-Of-life ProductsValen Ramirez HNo ratings yet

- Questions & Answers On CountersDocument24 pagesQuestions & Answers On Counterskibrom atsbha100% (2)

- SPD eRAN7.0 CSPC Feature Introduction-20140228-A-1.0Document25 pagesSPD eRAN7.0 CSPC Feature Introduction-20140228-A-1.0contact2vikasNo ratings yet

- D.E.I Technical College, Dayalbagh Agra 5 III Semester Electrical Engg. Electrical Circuits and Measurements Question Bank Unit 1Document5 pagesD.E.I Technical College, Dayalbagh Agra 5 III Semester Electrical Engg. Electrical Circuits and Measurements Question Bank Unit 1Pritam Kumar Singh100% (1)

- People V NiellesDocument2 pagesPeople V NiellesRobielyn Kate NerpioNo ratings yet

- Variable Length Subnet MasksDocument4 pagesVariable Length Subnet MaskszelalemNo ratings yet

- Projek Rekabentuk Walkwaybridge 2014 - 15Document6 pagesProjek Rekabentuk Walkwaybridge 2014 - 15HambaliNo ratings yet

- Functions and Uses of CCTV CameraDocument42 pagesFunctions and Uses of CCTV CameraMojere GuardiarioNo ratings yet

- Jicable DAS For Power Industry Applications 2015-A3-4Document6 pagesJicable DAS For Power Industry Applications 2015-A3-4Richard KluthNo ratings yet

- Invoice 1281595768Document3 pagesInvoice 1281595768vikas9849No ratings yet

- Blockchain Unit Wise Question BankDocument3 pagesBlockchain Unit Wise Question BankMeghana50% (4)

- Logbook) Industrial Attachment Brief To Students-3Document6 pagesLogbook) Industrial Attachment Brief To Students-3geybor100% (1)

- REID CatalogDocument54 pagesREID Catalogzhaoye maoNo ratings yet

- Successfully Allocating Risk and Negotiating A PPP ContractDocument12 pagesSuccessfully Allocating Risk and Negotiating A PPP ContractWilliam Tong100% (1)

- Goat Farm ProjectDocument44 pagesGoat Farm ProjectVipin Kushwaha83% (6)

- Universal Marine: Welcome To Our One Stop Marine ServicesDocument8 pagesUniversal Marine: Welcome To Our One Stop Marine Serviceshoangtruongson1111No ratings yet

- Challan FormDocument2 pagesChallan FormSingh KaramvirNo ratings yet

- Point of View Task CardsDocument7 pagesPoint of View Task Cardsapi-660227300No ratings yet