Professional Documents

Culture Documents

Sling Chart PDF

Uploaded by

tatonyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sling Chart PDF

Uploaded by

tatonyCopyright:

Available Formats

1819 2nd Avenue N.

P.O. Box 30637

Billings, MT 59107-0637

(406) 248-1151

(800) 488-3754

8989 Roller Coaster Road

Missoula, MT 59808

(406) 543-2982

(800) 775-2794

www.nwisupply.com

Choker Hitch Capacities

When the pull on a choker hitch results in an angle of less than

120o, the work load limit must be adjusted. Determine the angle of

choke and multiply the choker hitch work load limit

by the loss factor to get the reduced work load.

Wire Rope Construction

Core

One Rope Lay

Wire Rope

When wire rope is bent around the load diameter,

the rope strength is decreased. The D/d ratio is the

diameter of the object around which the rope is bent

(D), divided by the diameter (d) of the rope.

%&' (

'

)*

*!"$

!"$

!"#$

Strand

(D/d) Considerations

Sling Load Chart

Wire

Center Wire

This chart illustrates how the stress in a sling

increases as the angle increases (all angles are

measured from the vertical).

When one sling leg lifts 1,000 lbs. at 0o, the sling

stress is also 1,000 lbs. If the sling angle increases

to 45o , the stress actually exerted on the sling

would be 1,414 lbs., an increase of 41.4%.

Should the sling angle be increased to 60o, the

stress would be 2,000 lbs., or a 100% increase. At

o

an 85 angle (highly unlikely), sling stress increases

1,047%. With a load of 1,000 lbs., the sling stress

would be 11,473 lbs.

How to Select a Sling for Use at Any Angle

When calculating for selection of the proper sling,

select the vertical angle in the chart at left. Read the

increase in stress as a percentage factor. Multiply

the actual load weight by this percentage, then add

the answer to the actual load to be lifted. This gives

the rated capacity to look for in selecting the proper

size of sling.

Efciencies of Wire Rope Slings

These gures represent the efciency of the attachment. The approximate percentage of effective rope strength

available with each type of tting depends upon the diameter, construction and grade of rope.

Wire rope sockets - Spelter attachment 100%

Swage sleeve thimble attachment

100%

Swage-sleeve loop attachment

100%

Wedge sockets (depending on design) 80-90%

Clips (number of clips varies w/ rope size) 80%

Thimble Splice: 3/8 to 5/8 diameter

3/4 to 1 1/8 diameter

1 1/4 to 1 1/2 diameter

1 5/8 to 2 diameter

2 1/8 and up

90-95%

85-90%

80-85%

75-80%

70-75%

Loop Splice: The efciency of a loop splice without a thimble is somewhat less than given above for a thimble splice.

Nylon Web Slings

Removal from Service Criteria

for Synthetic Slings

Eye & Eye (EE) & Endless (EN) style slings - 1 & 2 Ply Slings

Rated Capacities in Lbs. based on 9800 lbs webbing.

Design Factor = 5:1 when new.

Polyester Roundslings

Rated Capacities in Lbs.

Design Factor = 5:1 when new.

Slingmax HPF Twin-Path Slings

Rated Capacities in Lbs.

!

"

#

"

"

Design Factor = 5:1 when new.

$!% $ %

"

All slings must be inspected daily or before each shift

in normal service conditions. If conditons are severe

or youre unsure if the sling has been inspected, YOU

NEED TO INSPECT THE SLING BEFORE USING.

Slings shall be removed from service if any of the

following conditions are present :

All Slings

Missing or illegible tag

Holes, tears, cuts, snags, punctures or knots

Acid or alkali burns

Melting, charring or weld splatter

Distortion, pitting, corrosion or other tting damage

Any condition causing doubt as to strength of the sling

Damaged slings must not be used for ANY purpose!

Roundslings and Twin-path Slings

Damage to the cover that exposes yarn

Broken, cut or damaged core yarns

Damage to the cover may indicate a loss of core

yarn strength.

For Slings Equipped With:

Check-Fast: The EWI does not extend past the

sling tag area.

Tattle Tails: One or both of the tails does not extend

past the sling tag area.

Fiber Optics: Light is not transmitted.

Web Slings

Excessive abrasion

Crushed webbing

Ultraviolet light damage

Broken or worn stitching in load bearing splices

Red core yarn if furnished. If there is damage and

the red yarns are not visible, DO NOT USE THE

SLING! Remember, ANY DOUBT, DONT!

Wear Protection for Slings

All slings must be protected from damage by

materials of sufcient strength, thickness and

construction.

The edge of a load need not be razor sharp

to cut slings.

If the load moves across the sling or the sling

across the load, the sling may become

damaged.

There is no such thing as Cut Proof wear

protection. Cut resistant wear protection does

exist.

There is a BIG difference between abrasion

and cutting damage, and the appropriate wear

protection to use for each.

Gloves and cardboard are not wear protection

devises.

Contact us for wear protection that is engineered to withstand tension and compression.

Engineered Wear Protection

Cornermax Sleeves

Cornermax Pad

Magnetic Corner Protectors

Meshguard

Alloy Chain Slings Grade 80/Grade 100

Rated Capacities in Lbs.

Design Factor = 4:1 when new.

Calculating Load Weights

!"

#$

%!&'(

%!&' (

*

*

+

+

,

,-

,-

,-

.

/

/

1

Sling Tension and Weight Distribution

Center of Gravity Centered

Offset Center of Gravity

6 ft. Leg

Proportional

Share of

the Load

x

Load Factor

Sling Tension

.25 Distance

3

=

.75 Share of Load

12

.75 x 55,000 = 41,250

x

L1

6

=

=

1.2

H

5

203

23

23

3

10.5 ft. Leg

Rigging Hardware Capacities

Rated Capacities in Lbs.

Design Factor = 5:1 when new.

,+

+

/ 0

/.

/.

$%

&

&

&

""

&&

!

!%

"!

$!

&&!

$

'!

!&

$

(% $ '

(&

( &! !

% ' $

& $" !&

& $

&

)

*+

49,500 lbs.

.75 Distance

9

=

.25 Share of Load

12

.25 x 55,000 = 13,750

x

L2

10.5

=

=

2.1

H

5

Sling Tension

28,875 lbs.

Proportional

Share of

the Load

x

Load Factor

4)

4

)

Read the Label!

ASME standards

require all slings

to be marked with

manufacturer, stock number and rated loads for

the types of hitches used and the angle upon

which it is based, as well as other information

pertinent to sling type.

- .

+. /

'1

!1

"!

!!

"

"#

!!

%!

&#

&"

%&

&!

&%#

!&

$"

"#

(&

!

! #

"

(&

% "#

$$ '$

&$#

&$#

& ( ! (#

& %" &! %#

Coefcients of Friction

"

1819 2nd Avenue N.

P.O. Box 30637

Billings, MT 59107-0637

(406) 248-1151

(800) 488-3754

8989 Roller Coaster Road

Missoula, MT 59808

(406) 543-2982

(800) 775-2794

www.nwisupply.com

Wire

Rope

Slings

)" -$''

&* .#-/ 1

-/ 2

+$, +0"",

Two Leg

Bridle

Slings

.#

1

"

Four Leg

Bridle

Slings

$%

)'

&' *'

!"#

(

Alloy Links

!""#$#%$&'(

Three Leg

Bridle

Slings

$%

)'

&' *'

!"#

#$

(&

%& )&

!"

'

EIPS IWRC - Extra Improved Plow Steel with Independent Wire Rope Core

Sling Types

Sling Uses

Loop

Thimble

Thimble

& Hook

Choker

Vertical

Vertical

Basket

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Investigations Findings ON Errant Atps: Sam Lim Senior Manager Compliance & Investigation WSH CouncilDocument17 pagesInvestigations Findings ON Errant Atps: Sam Lim Senior Manager Compliance & Investigation WSH CounciltatonyNo ratings yet

- Heat Cold StressDocument34 pagesHeat Cold StresstatonyNo ratings yet

- SUBARUDocument308 pagesSUBARUtatonyNo ratings yet

- Leading and Lagging Indicators PDFDocument35 pagesLeading and Lagging Indicators PDFtatony50% (2)

- Hand Gloves PUB RequirementDocument1 pageHand Gloves PUB RequirementtatonyNo ratings yet

- WSH Manual Marine IndustriesDocument360 pagesWSH Manual Marine IndustriesluiscremaschiNo ratings yet

- SISO Mag - Issue3 - 2014 - v17 - LR PDFDocument32 pagesSISO Mag - Issue3 - 2014 - v17 - LR PDFtatonyNo ratings yet

- 13th SISO Annual WSHO Conference Flyer For EDM v2Document1 page13th SISO Annual WSHO Conference Flyer For EDM v2tatonyNo ratings yet

- 4D Game RulesDocument14 pages4D Game RulestatonyNo ratings yet

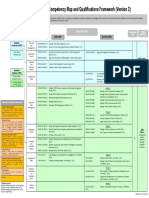

- WSHP Competency MapDocument4 pagesWSHP Competency MaptatonyNo ratings yet

- 226 EHS Inspection ReportDocument5 pages226 EHS Inspection ReporttatonyNo ratings yet

- Process Safety Performance IndicatorsDocument35 pagesProcess Safety Performance Indicatorstatony100% (4)

- Chemical Management GHS TaskforceDocument1 pageChemical Management GHS TaskforcetatonyNo ratings yet

- Certificate of Supervision of Building WorksDocument1 pageCertificate of Supervision of Building WorkstatonyNo ratings yet

- GE Water & Process Technology GS-11010Document16 pagesGE Water & Process Technology GS-11010tatonyNo ratings yet

- Adam Adam Adam Adam Adam Adam Adam Adam Adam AdamDocument1 pageAdam Adam Adam Adam Adam Adam Adam Adam Adam AdamtatonyNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Composition of Superabrasive Grinding WheelsDocument2 pagesComposition of Superabrasive Grinding WheelssekarnttfNo ratings yet

- October 6 - Development of Chemical EngineeringDocument14 pagesOctober 6 - Development of Chemical EngineeringcilovNo ratings yet

- Askeland ChapterDocument84 pagesAskeland ChapterjuegyiNo ratings yet

- Dyeing StylesDocument7 pagesDyeing StylesSushila SahaniNo ratings yet

- Drugs of Biological OriginDocument4 pagesDrugs of Biological OriginIdenyi Daniel Ewa EdeNo ratings yet

- How To Remove Ink From Clothes - 11 Steps - Wikihow PDFDocument8 pagesHow To Remove Ink From Clothes - 11 Steps - Wikihow PDFmilan_lahiruNo ratings yet

- Types of TabletsDocument4 pagesTypes of TabletsDiana MaeNo ratings yet

- Cotton Waste - Gin MotesDocument5 pagesCotton Waste - Gin MotesDilhani pereraNo ratings yet

- Organized Recalls KapsDocument5 pagesOrganized Recalls KapssimbaiNo ratings yet

- 87-88 Actuator - Technical SpecificationsDocument9 pages87-88 Actuator - Technical SpecificationsJose Luis Frias ColoradoNo ratings yet

- Ace InhibitorsDocument15 pagesAce InhibitorsCarolyn Conn EdwardsNo ratings yet

- Exterior FinishesDocument14 pagesExterior Finishespratiksha590No ratings yet

- Bio Degradation of PlasticsDocument24 pagesBio Degradation of PlasticsArchit Gupta100% (1)

- Spec - 2017-02 - A00 - NON-METALLIC MATERIALS - SELECTION AND APPLICATIONDocument25 pagesSpec - 2017-02 - A00 - NON-METALLIC MATERIALS - SELECTION AND APPLICATIONAL Rajhi Zakaria100% (1)

- Daftar Obat Aman Dan Berbahaya Untuk Ibu Hamil Dan MenyusuiDocument17 pagesDaftar Obat Aman Dan Berbahaya Untuk Ibu Hamil Dan MenyusuiFirda LestariNo ratings yet

- Hand Reaming and BroachingDocument25 pagesHand Reaming and Broachingpradeep_i19No ratings yet

- Armflex Rubber Expansion Joint: No. NameDocument1 pageArmflex Rubber Expansion Joint: No. NameAmirNo ratings yet

- H1 - Neural Conduction and Synaptic TransmissionDocument9 pagesH1 - Neural Conduction and Synaptic TransmissionAlexandra Nicole EnriquezNo ratings yet

- GRC SlabDocument10 pagesGRC SlabWayne KentNo ratings yet

- Arkivoc 2018, I, AmidinasDocument44 pagesArkivoc 2018, I, AmidinasgokucharlyNo ratings yet

- Aircraft Panel LinesDocument17 pagesAircraft Panel Linesmav87th-1No ratings yet

- PC3150 PDFDocument8 pagesPC3150 PDFMaffone NumerounoNo ratings yet

- M110-14, M1110-14 Specification SheetDocument6 pagesM110-14, M1110-14 Specification SheetWattsNo ratings yet

- PRPDocument1 pagePRPMONALINo ratings yet

- Hummel PG GlandsDocument7 pagesHummel PG GlandsBob JohnsonNo ratings yet

- Unit - 2 Shoe Room FinishDocument11 pagesUnit - 2 Shoe Room FinishParamasees LambaNo ratings yet

- Aml125 PDFDocument12 pagesAml125 PDF31scribd31No ratings yet

- Chem 332 Exam 1 ReviewDocument6 pagesChem 332 Exam 1 ReviewhddriNo ratings yet

- Assay Ob Borax PDFDocument14 pagesAssay Ob Borax PDFAbram Louies Hanna100% (1)

- Lecture 1Document22 pagesLecture 1Devakan BalaganeshNo ratings yet