Professional Documents

Culture Documents

Larm Clutched Arm 2011 M BDSM

Uploaded by

Cristian Ágreda AlvarezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Larm Clutched Arm 2011 M BDSM

Uploaded by

Cristian Ágreda AlvarezCopyright:

Available Formats

This article was downloaded by: [Marco Ceccarelli]

On: 11 February 2012, At: 06:49

Publisher: Taylor & Francis

Informa Ltd Registered in England and Wales Registered Number: 1072954 Registered office: Mortimer House,

37-41 Mortimer Street, London W1T 3JH, UK

Mechanics Based Design of Structures and Machines: An

International Journal

Publication details, including instructions for authors and subscription information:

http://www.tandfonline.com/loi/lmbd20

A Multiobjective Optimal Path Planning for a 1-DOF

Clutched ARM

Hao Gu

a

& Marco Ceccarelli

a

a

Laboratory of Robotics and Mechatronics (LARM), Department of Mechanics, Structures,

Environment and Territory (DIMSAT), University of Cassino, Cassino, Italy

Available online: 10 Jan 2012

To cite this article: Hao Gu & Marco Ceccarelli (2012): A Multiobjective Optimal Path Planning for a 1-DOF Clutched ARM,

Mechanics Based Design of Structures and Machines: An International Journal, 40:1, 109-121

To link to this article: http://dx.doi.org/10.1080/15397734.2011.609090

PLEASE SCROLL DOWN FOR ARTICLE

Full terms and conditions of use: http://www.tandfonline.com/page/terms-and-conditions

This article may be used for research, teaching, and private study purposes. Any substantial or systematic

reproduction, redistribution, reselling, loan, sub-licensing, systematic supply, or distribution in any form to

anyone is expressly forbidden.

The publisher does not give any warranty express or implied or make any representation that the contents

will be complete or accurate or up to date. The accuracy of any instructions, formulae, and drug doses should

be independently verified with primary sources. The publisher shall not be liable for any loss, actions, claims,

proceedings, demand, or costs or damages whatsoever or howsoever caused arising directly or indirectly in

connection with or arising out of the use of this material.

Mechanics Based Design of Structures and Machines, 40: 109121, 2012

Copyright Taylor & Francis Group, LLC

ISSN: 1539-7734 print/1539-7742 online

DOI: 10.1080/15397734.2011.609090

Innovative Application Brief

A MULTIOBJECTIVE OPTIMAL PATH PLANNING

FOR A 1-DOF CLUTCHED ARM

#

Hao Gu and Marco Ceccarelli

Laboratory of Robotics and Mechatronics (LARM), Department of Mechanics,

Structures, Environment and Territory (DIMSAT), University of Cassino,

Cassino, Italy

In this paper, a procedure of optimal path planning is proposed for the operation of the

anthropomorphic low-cost easy-operation LARM clutched arm with only one actuator.

An algorithm is proposed for path planning of the arm motion with multiobjective

considerations that take into account of traveling time, energy consumption, and end-

effector performance. Numerical examples and laboratory experiments are reported to

show the feasibility of the proposed path planning and the efciency of the LARM

clutched arm.

Keywords: Clutch systems; Humanoid robots; Robotic arms; Path planning.

INTRODUCTION

Industrial robots are typical examples of robotic arms, which are widely

used in factory today (ABB, 2011; COMAU, 2011; KUKA, 2011). Other popular

examples are the robotic arms in humanoid robots like in ASIMO by Honda (2011),

and ARMAR by University of Karlsrahe (Albers et al., 2007), and the Care-O-

bot by Fraunhofer IPA (Graf et al., 2009). Most of these existing robotic arms are

designed as multiactuator systems, which operate with fast movement and precise

positioning. But they are very expensive and complex systems for no expert users.

Mainly for service applications in home and public places, very precise or

dexterous manipulations are not, in general, required (Morales et al., 2005). Thus,

it is possible to design a robotic arm simpler and cheaper, by reducing the number

of actuators, as attempted in Nakamura et al. (2001), Karbasi et al. (2006), and

Gu et al. (2010). However, the nonholonomic solution in Nakamura et al. (2001)

increases the control complexity; the Chebychev-Pantograph mechanism in Nava

(2006) does not provide a sufcient workspace; the Unidrive Modular Robot system

in Karbasi et al. (2006) is not suitable for robotic arms; and the Armatron (Carroll,

Received April 5, 2011; Accepted July 11, 2011

#

Communicated by P. Larochelle.

Correspondence: Hao Gu, Laboratory of Robotics and Mechatronics (LARM), Department

of Mechanics, Structures, Environment and Territory (DIMSAT), University of Cassino, Via G. Di

Biasio, 43, Cassino 03043, Italy; E-mail: hao.gu@unicas.it

109

D

o

w

n

l

o

a

d

e

d

b

y

[

M

a

r

c

o

C

e

c

c

a

r

e

l

l

i

]

a

t

0

6

:

4

9

1

1

F

e

b

r

u

a

r

y

2

0

1

2

110 GU AND CECCARELLI

2007) is just a toy with no automation built in and no proper payload capability for

practical applications.

At LARM (Laboratory of Robotics and Mechatronics, University of Cassino,

Italy), a new robotic arm named as LARM clutched arm (Gu et al., 2010) has been

proposed with only a single motor by using a clutch system. Such a 1-DOF solution

is still versatile within a 3D workspace. In previous works (Gu et al., 2010; Gu and

Ceccarelli, 2010a), simulations and preliminary experimental tests have validated the

feasibility of the design concept. Recently, a prototype has been built with a proper

control system.

The operation task for LARM clutched arm can be summarized as in two

parts: trajectory planning, in which the arm generates a prescribed trajectory, and

optimal path planning, in which a point-to-point motion is optimized to achieve

certain task objectives. The trajectory-planning task has already been achieved with

an efcient algorithm in Gu and Ceccarelli (2010a). Optimal path planning can

strongly affect the efciency of using its single actuator. Moreover, a proper path

can particularly overcome its natural drawback in terms of operation speed.

A preliminary study on an optimal path-planning task has been carried out

by investigating the planar motion of the limb part in a 2D optimal path planning

in Gu and Ceccarelli (2010b). However, the multiobjective formulation in Gu

and Ceccarelli (2010b) is not completely formulated to evaluate the path-planning

characteristics, and the numerical results in Gu and Ceccarelli (2010b) are not

validated by tests.

The purpose of this paper is to present a proper procedure of optimal

path planning for such a new robotic arm with 1-DOF by using numerical and

experimental results to show its engineering feasibility.

THE LARM CLUTCHED ARM

The conceptual design of the LARM clutched arm consists of a compact

shoulder that can perform required rotations (R

1

to R

3

) for a three-revolute

manipulator. The main idea is to use a proper clutch system to obtain three

submotions from the source motion of a single motor.

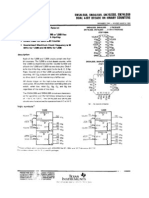

Figure 1 illustrates the mechanical design of the shoulder, which is the key part

to achieve the concept idea into a practical system. This shoulder-centered design

makes the main mass of LARM clutched arm concentrated on the arm xed frame,

and the limb part can be lightweight.

In the scheme of Fig. 1(a), symbols G

ia,b

(i = 16) and B

ia,b

(i = 1, 2)

represent gears and belt wheels, respectively, W

ia

and W

ib

(i = 1, 2) represent

the worm and the worm wheel, respectively. Electromagnetic clutches named as

C

i

(i = 13) are assembled along rotating axes. By changing the states of clutches,

the gearing system can be activated in 2

3

= 8 modes. The self-locking feature of

worm and worm wheel eliminates the need of braking power. Possible operation

modes (OP) for LARM clutched arm are listed in Table 1, where 0 means that a

clutch is deactivated and 1 a clutch is activated. In particular, OP0 is a stationary

mode, with null energy consumption.

A built prototype of LARM clutched arm is illustrated in Fig. 2. It has

dimensions more or less like a human arm, with 3-kg weight and 2-kg payload

capability.

D

o

w

n

l

o

a

d

e

d

b

y

[

M

a

r

c

o

C

e

c

c

a

r

e

l

l

i

]

a

t

0

6

:

4

9

1

1

F

e

b

r

u

a

r

y

2

0

1

2

PATH PLANNING FOR A 1-DOF CLUTCHED ARM 111

Figure 1 The LARM clutch system in the shoulder design: (a) a scheme; (b) a CAD design.

Table 1 The operation modes for LARM clutched arm (Gu and Ceccarelli, 2010a)

Operation mode OP0 OP1 OP2 OP3 OP4 OP5 OP6 OP7

Active rotations None R

1

R

2

R

3

R

1

& R

2

R

1

& R

3

R

2

& R

3

R

1

R

3

C

1

0 1 0 0 1 1 0 1

C

2

0 0 1 0 1 0 1 1

C

3

0 0 0 1 0 1 1 1

A proposed controller for LARM clutched arm consists of a servo amplier

for DC motor, a Programmable Logic Controller (PLC) for electromagnetic

clutches, and a National Instruments (NI) Peripheral Component Interconnect

(PCI) board for communications. The whole system (except PC) requires only a

common 24V DC power supply, which can be an advantage for applying it on

Figure 2 A prototype of LARM clutched arm (Gu and Ceccarelli, 2010a): (a) the overall structure

with the control system; (b) the clutch system in the shoulder.

D

o

w

n

l

o

a

d

e

d

b

y

[

M

a

r

c

o

C

e

c

c

a

r

e

l

l

i

]

a

t

0

6

:

4

9

1

1

F

e

b

r

u

a

r

y

2

0

1

2

112 GU AND CECCARELLI

mobile robots with a commercial battery. A Graphic User Interface (GUI) has been

programmed with LabVIEW, which can control and monitor the arms motion

through suitable virtual instruments.

Summarizing, LARM clutched arm has the following novel characteristics:

- lightweight limb design, with low-cost, low energy consumption, and easy

operation;

- 1-DOF clutched solution with motion capability in a 3D space;

- avoiding overheat of motor, since the motor works only for actuating the arm and

self-locking mechanisms ensure the arm to maintain its posture once the arm is

stationary.

OPERATION CHARACTERISTICS OF LARM CLUTCHED ARM

Operation modes OP1OP7 can be expressed as vectors in the joint space

and combined modes like OP4, OP5, OP6, and OP7 have a constant slope that is

determined by the reduction ratios in the mechanical design. Thus, it is convenient

to search the optimal path in the joint space.

In Fig. 3(a), a typical prescribed task can be given by the start and end points

with several path possibilities given by OP vectors in joint space. For example, the

dashed line in Fig. 3(a) indicates a path that is composed of two segments (SG1

,

SG2

) by means of OP3 and OP2, respectively. Another path is indicated by a solid

line, which has three segments (SG1SG3) with OP2, OP6, and OP3, respectively.

A path segment SGi (i = 1N) contains two kind of information, namely, a

discrete one for the selected operation mode (OP) and a continuous one for the

motor displacement (D). Therefore, a path can be characterized by a sequence of

segments with data for OP and D. For example, the segment sequence in Fig. 3(a)

is given as OP2, OP6, and OP3 with D1, D2, and D3, respectively, and can be used

as a command sequence for the path planner in the controller.

Figure 3 An example of the operation for LARM clutched arm: (a) path possibilities in joint space;

(b) a controlled path generation with the proposed strategy.

D

o

w

n

l

o

a

d

e

d

b

y

[

M

a

r

c

o

C

e

c

c

a

r

e

l

l

i

]

a

t

0

6

:

4

9

1

1

F

e

b

r

u

a

r

y

2

0

1

2

PATH PLANNING FOR A 1-DOF CLUTCHED ARM 113

Figure 3(b) illustrates the proposed control strategy to coordinate the motor

and operation mode for the solid path in Fig. 3(a). The motor is controlled with

a smooth speed to output a desired angular displacement for each segment (SG1

SG3) while clutches only change their states when the motor stops. The transient

dynamics caused by clutch actions can be strongly limited and even avoided with

suitable delay time (t

S

) for motor activation, as indicated in Fig. 3(b). For the

prototype, a t

S

delay of 80msec has been experienced as suitable enough.

Thus, an optimal path-planning task is to seek a proper sequence of segments

with certain operation modes and motor displacements as variables of the path-

planning problem.

For traditional robotic arms, the actuator for each DOF is independent and

in a point-to-point optimal path planning, the main effort is to optimize the motion

of each actuator (Ceccarelli, 2004). For the LARM clutched arm with 1-DOF, the

single actuator is shared by three joints, which are dependent to each other when

they are activated simultaneously. The optimal path planning for LARM clutched

arm concentrates on a proper sequence of OP. The single actuator only serves

the robotic arm to implement the selected OP actions with suitable cooperation to

clutches.

In the block diagram of Fig. 4, the optimal path planning for LARM clutched

arm depends of the three variables OP, D, and N, and outputs command sequences

of OP and D. The controller can interpret such command sequences into control

signals for motor and clutches with a proposed control strategy as in the example

in Fig. 3(b). With a feedback of speed, the motor is controlled to track the desired

smooth motion with a proper PID law.

A cubic function can be chosen for the desired motor speed, in order to

achieve smooth and differentiable features. The motor displacement command in

kth segment is D

k

. A symmetrical speed up and down motion lasts for t

k

with a

speed peak of P

k

. Since the area enveloped by the speed curve is the displacement,

Figure 4 A schematic diagram for the control of LARM clutched arm.

D

o

w

n

l

o

a

d

e

d

b

y

[

M

a

r

c

o

C

e

c

c

a

r

e

l

l

i

]

a

t

0

6

:

4

9

1

1

F

e

b

r

u

a

r

y

2

0

1

2

114 GU AND CECCARELLI

D

k

, t

k

, and P

k

are linked by the relationship

D

k

=

t

k

2

P

k

. (1)

The mean acceleration (o

M

) for speeding up to P

k

can be given by the

expression

P

k

=

t

k

2

tg: =

t

k

2

o

M

. (2)

If the value of o

M

is given, substituting Equation (2) into Equation (1), t

k

can

be obtained as

t

k

= 2

D

k

,o

M

. (3)

Thus, P

k

can be xed by substituting Equation (3) into Equation (2).

Consequently, P

k

and t

k

can be expressed as monadic functions of D

k

. For the

prototype, an o

M

of 2000 deg/sec

2

has been experienced as a suitable value.

In addition, the motor has a limited speed with P

max

, and a large D

k

may cause

P

k

to exceed P

max

. In this case, P

k

and t

k

should be recomputed with the conditions

P

k

= P

max

,

(4)

t

k

=

2D

k

P

k

.

Once P

k

and t

k

are determined, the cubic speed can be formulated by

identifying coefcients in

0

motor

=

l

2

t

2

+ l

3

t

3

, t |0, t

k

,2]

P

k

l

2

(t t

k

,2)

2

l

3

(t t

k

,2)

3

, t |t

k

,2, t

k

],

(5)

with l

2

= 12P

k

,t

2

k

and l

3

= 16P

k

,t

3

k

.

Considering the delay t

S

, the motion period T

k

for kth segment is expressed as

T

k

= t

S

+ t

k

. (6)

Equations (1)(6) summarize the motion generation process for the motor,

which is executed by the controller when it reads a command D

k

in kth segment.

A FORMULATION FOR OPTIMAL PATH PLANNING

An operation with low energy consumption and smooth behavior can be

obtained by using basic criteria for an optimal path planning.

Time is an important issue when a robot serves a human although the

action of anthropomorphic robotic arm is not expected to be as fast as industrial

manipulators. Although the mechanical design of LARM clutched arm gifts energy

saving features, how to use the single motor and clutches properly and efciently

D

o

w

n

l

o

a

d

e

d

b

y

[

M

a

r

c

o

C

e

c

c

a

r

e

l

l

i

]

a

t

0

6

:

4

9

1

1

F

e

b

r

u

a

r

y

2

0

1

2

PATH PLANNING FOR A 1-DOF CLUTCHED ARM 115

is still a question for low energy consumption. Accelerations of the end effector

can directly indicate the motion characteristics. For friendly and safe purposes, the

acceleration o

H

should be minimized during a task of LARM clutched arm.

Thus, an optimal path planning of LARM clutched arm can be formulated

as a multiobjective optimization problem with traveling time T

tra

, consumed energy

E

con

, and maximum acceleration o

H

of the end effector in the form

min ] = ]

T

tra

T

ref

,

E

con

E

ref

,

o

H

o

ref

, (7)

subject to

0

1

|0

1 min

, 0

1 max

],

0

2

|0

2 min

, 0

2 max

],

(8)

0

E

|0

E min

, 0

E max

],

0

motor

|P

max

, P

max

],

where T

ref

, E

ref

, and o

ref

are reference values and 0

1

0

3

are the joint angles with

0

E

= 0

3

0

2

as the elbow angle.

By using weighting sum strategy (The Math Works, 1992), the multiobjective

problem in Equation (7) can be converted into a scalar one in the form

min ] = n

1

T

tra

T

ref

+ n

2

E

con

E

ref

+ n

3

o

H

o

ref

, (9)

in which n

1

n

3

are weighting factors with condition 0 n

i

1 (i = 13) and n

1

+

n

2

+ n

3

= 1.

Since the three criteria in Equation (9) can be competitive to each other, a

weighting factor of the most emphasized criterion can be conveniently considered

as for major effect.

For a path with N segments, the traveling time can be computed as sum of

time segments with Equation (6). The consumed energy E

con

can be computed by

summing the work of the motor (W

motor

) and the work of electromagnetic clutches

(W

clutch

). W

motor

can be computed as

W

motor

=

N

k=1

T

k

0

t

motor

0

motor

dt

, (10)

where t

motor

is the actuating motor torque. Since the power of the selected

electromagnetic clutch in the prototype is given as Pn

clutch

= 7.2 W, W

clutch

can be

computed as

W

clutch

=

N

k=1

(n

OP

T

k

Pn

clutch

), (11)

in which n

OP

is the number of activated clutches depending on the OP mode.

D

o

w

n

l

o

a

d

e

d

b

y

[

M

a

r

c

o

C

e

c

c

a

r

e

l

l

i

]

a

t

0

6

:

4

9

1

1

F

e

b

r

u

a

r

y

2

0

1

2

116 GU AND CECCARELLI

Figure 5 A kinematic model of the LARM clutched arm (Gu and Ceccarelli, 2010a).

Acceleration o

H

can be computed by referring to Cartesian Space coordinates

(x, ,, z) in the form

o

H

= Max(

x

2

+ ,

2

+ z

2

). (12)

Since the LARM clutched arm can achieve any point-to-point task (within its

workspace) with OP1, OP2, and OP3 sequentially, a reference operation mode can

be dened with utmost those three segments to compute T

ref

, E

ref

, and o

ref

.

The computation of W

motor

and o

H

requires evaluation of the arms kinematics

and dynamics. LARM clutched arm can be considered as a two-link planar

manipulator rotating around the Y-axis with dimensions L

1

, L

2

, and L

3

(L

0

is

shoulder size in a trunk body; Fig. 5). The rotating plane for upper arm and forearm

is dened as S-plane with coordinate X

s

Y

s

. The Forward Kinematic Problem (FKP)

and Inverse Kinematic Problem (IKP) of LARM clutched arm can be expressed by

using the model in Fig. 5.

The dynamics of a model with concentrated link masses can be computed to

give the motor torque t

motor

as

t

motor

= C

1

t

1

,K

1

+ C

2

t

2

,K

2

+ C

3

t

3

,K

3

+ t

]

, (13)

in which K

1

, K

2

, and K

3

are reduction ratios for three gear trains; C

i

(i = 13)

indicates the clutch state that equals to 1 or 0; t

i

(i = 13) is the output torque

for each joint. It means that when clutch C

i

is deactivated, the link output torque t

i

do not require motor torque, since the self-locking mechanism ensures the braking

action. t

]

is a torque considering friction and other secondary effects that are

generated in the gear trains. Since it is difcult to formulate accurately a t

]

as in

practical case, it has been convenient to identify t

]

approximately via tests on the

prototype, in which t

]

considers all the dissipative effects as computed by comparing

a numerical result with an experimental test. With a payload of 0.25kg on the arm

D

o

w

n

l

o

a

d

e

d

b

y

[

M

a

r

c

o

C

e

c

c

a

r

e

l

l

i

]

a

t

0

6

:

4

9

1

1

F

e

b

r

u

a

r

y

2

0

1

2

PATH PLANNING FOR A 1-DOF CLUTCHED ARM 117

extremity, t

]

has been measured from 0.167Nm up to 0.271Nm as depending on

the operation mode, with the maximum value when all gear trains are activated.

A NUMERICAL PROCEDURE FOR OPTIMAL PATH PLANNING

Since path generation for LARM clutched arm with OP vectors can be

considered as a 3D robot navigation procedure in joint space, widely used Articial

Intelligence (AI) methods in the optimal path planning can be also properly applied.

Among many approaches in AI area, A* (A star) is one of the most common

and well-known heuristic graph-searching algorithm (Nilsson, 1982). In order to

use A*, a node structure can be dened with information on path-planning

characteristics that are related to ] objective function in Equation (9). Parameter

h is the predict estimate to reach the goal end point, which provides the heuristic

information for the A* search (Nilsson, 1982), as the distance left to the goal with

the expression

h =

(0

1

0

1end

)

2

+ (0

2

0

2end

)

2

+ (0

3

0

3end

)

2

(0

1start

0

1end

)

2

+ (0

2start

0

2end

)

2

+ (0

3start

0

3end

)

2

, (14)

in which (0

1start

, 0

2start

, 0

3start

) and (0

1end

, 0

2end

, 0

3end

) are joint coordinates for start

point and end point, respectively. The cost for a node is a sum of ] and h. A node

with minimal cost will be selected rstly in the path search.

Figure 6(a) illustrates a node expanding process with OPs, where a father node

is a current selected node while son nodes are those expanded from the father node.

The depth information of a node increases by 1, which can indicate the order of

generation for the node. In Fig. 6(b), a more visual scheme for node expansion is

indicated in joint space, where black circles are for father nodes, and white circles

are for son nodes.

One important issue is that each node will remember its father node and

pointers of the son nodes will point to the data address of their father node. In such

a way, once a node is on the goal, the optimal path can be obtained by tracking

back with pointers.

Figure 6 A scheme for node expansion: (a) in the node tree; (b) in the joint space.

D

o

w

n

l

o

a

d

e

d

b

y

[

M

a

r

c

o

C

e

c

c

a

r

e

l

l

i

]

a

t

0

6

:

4

9

1

1

F

e

b

r

u

a

r

y

2

0

1

2

118 GU AND CECCARELLI

When a motion step of motor (A0

motor

) is given, the joint coordinates of the

new expanded nodes can be updated with expressions as

0

i

= 0

i

+ C

i

sign (OP) A0,K

i

, (i = 1, . . . , 3) (15)

where OP can be either positive or negative for forward or backward movement.

NUMERICAL EXAMPLE AND TEST RESULTS

A numerical example is reported as referring to the case with weighting factors

for T

tra

, E

con

, and o

H

with decreasing values n

1

= 0.6, n

2

= 0.3, and n

3

= 0.1,

respectively. A start point in joint space is given as (90

, 90

, 0

), while an end

point is given as (130

, 60

, 40

). A0

motor

is given at 100

. Joints ranges are set

within the arm workspace.

The reference operation with the sequence OP1, OP2, and OP3 is used to

compute T

tra

, E

con

, and o

H

as T

ref

, E

ref

, and o

ref

for the optimal solution. Results for

the optimal path that is obtained with the sequence OP3, OP4, OP1 are reported

in Figs. 79.

The computed traveling time with 5.63sec is shorter than in the reference

operation with 7.24sec; the corresponding values for D1, D2, and D3 are 3000

,

2300

, and 200

; the energy consumption is 73.30J and acceleration is 0.28 (m/sec

2

)

much smaller than in the reference operation. The cost function converges to a value

of 0.90 from the initial value of 1.00 after only 172 iterations. Initial values of ] and

h are 0 and 1, respectively, since in the start point T

tra

, E

con

, and o

H

are zeros while

the predicted estimate to the end point is full. When the robotic arm reaches the end

point, ] and h converges to 0.89, and 0.01, respectively. With an average consuming

power at about 13W (E

con

,T

tra

) and a maximum end-effector acceleration at no

Figure 7 Computed optimal path: (a) in joint space; (b) in Cartesian space (solid line is for optimal

path and dashed line is for reference path).

D

o

w

n

l

o

a

d

e

d

b

y

[

M

a

r

c

o

C

e

c

c

a

r

e

l

l

i

]

a

t

0

6

:

4

9

1

1

F

e

b

r

u

a

r

y

2

0

1

2

PATH PLANNING FOR A 1-DOF CLUTCHED ARM 119

Figure 8 Experimental result of time evolution for motor speed and torque in the optimal operation

(solid line is for optimal operation and dashed line is for reference operation).

more than 0.3 m/sec

2

, the optimal operation can still be considered as energy saving

and gentle behaved.

Experimental tests have been carried out on the prototype with the optimal

path operation whose results are reported in Figs. 8 and 9. Due to the self-

locking gearing systems, the motor torque returns to zero when the operation

task nishes. In Fig. 9, test results of the consumed energy for optimal and

reference operation give 75.13 and 68.73J, respectively. They are close to the

numerical results. In addition, E

con

in the test for the optimal operation increases

with respect to the reference operation, as happened in the numerical case too. In

order to have a further comparison, numerical time evolution of E

con

for optimal

operation has been added in Fig. 9 as a dot-dashed line. It can be observed that

Figure 9 Experimental result of time evolution for energy consumption in the optimal operation (solid

line is for optimal operation, dashed line is for reference operation, and dot-dashed line is for optimal

operation in numerical computation).

D

o

w

n

l

o

a

d

e

d

b

y

[

M

a

r

c

o

C

e

c

c

a

r

e

l

l

i

]

a

t

0

6

:

4

9

1

1

F

e

b

r

u

a

r

y

2

0

1

2

120 GU AND CECCARELLI

test result ts the numerical one with a similar trend shape. Due to the backlash

and insufcient stiffness effects in the rst prototype of LARM clutched arm,

end-effector accelerations in the test are not exactly the same as the numerical ones.

CONCLUSIONS

A novel clutched robotic arm with only one motor has been described

as suitable for anthropomorphic operations. A multiobjective formulation has

been proposed for path planning with a comprehensive consideration of traveling

time, energy consumption, and end-effector behavior. A numerical procedure has

been presented by using an AI algorithm with computationally efcient features.

Numerical examples and test results have shown the engineering feasibility of the

proposed procedure of optimal path planning for 1-DOF LARM clutched arm with

fast movement, low energy consumption, and gentle behaviors.

ACKNOWLEDGMENT

The rst author would like to acknowledge China Scholarship Council (CSC)

for supporting his PhD study and research at LARM in the University of Cassino,

Italy, for the years 20082010.

REFERENCES

ABB (2011). http://www.abb.com/robotics (accessed April 6, 2011).

Albers, A., Brudniok, S., Ottnad, J., Sauter, C., Sedchaicharn, K. (2007). Design of

ARMARIIIA New Humanoid Robot. Proceedings of 16th International Workshop

on Robotics in Alpe-Adria Danube Region, Ljubljana, June 79, 1117.

Carroll, T. (2007). Then and now-robot arms. Servo 8:7982.

Ceccarelli, M. (2004). Fundamentals of Mechanics of Robotic Manipulation.

Dordrecht: Kluwer.

COMAU (2011). http://www.comau.it (accessed April 6, 2011).

Graf, B., Reiser, U., Hgele, M., Mauz, K., Klein, P. (2009). Robotic Home Assistant

Care-O-Bot 3Product Vision and Innovation Platform. Proceedings of the IEEE

Workshop on Advanced Robotics and its Social ImpactsARSO 2009, Tokyo,

November 23, 139144.

Gu, H., Ceccarelli, M. (2010a). Trajectory planning for a 1-dof clutched robotic arm.

Robotica 29(5):745756.

Gu, H., Ceccarelli, M. (2010b). An Optimum Path Planning for LARM Clutched

Arm. Proceeding of the 12th International Symposium on Advances in Robot

Kinematics (ARK 2010), Piran, June 27July 1, 393400.

Gu, H., Ceccarelli, M., Carbone, G. (2010). Design and simulation of a 1-dof

anthropomorphic clutched arm for humanoid robots. International Journal of

Humanoid Robotics 7:157182.

Honda (2011). http://www.honda.co.jp/ASIMO (accessed April 6, 2011).

Karbasi, H., Khajepour, A., Huissoon, J. P. (2006). Unidrive modular robot:

dynamics, control, and experiments. Journal of Dynamic Systems, Measurement, and

Control 128:969975.

D

o

w

n

l

o

a

d

e

d

b

y

[

M

a

r

c

o

C

e

c

c

a

r

e

l

l

i

]

a

t

0

6

:

4

9

1

1

F

e

b

r

u

a

r

y

2

0

1

2

PATH PLANNING FOR A 1-DOF CLUTCHED ARM 121

KUKA (2011). http://www.kuka-robotics.com/en/products (accessed April 6,

2011).

Morales, A., Asfour, T., Osswald, D., Schulz, S., Dillmann, R. (2005). Towards

an Anthropomorphic Manipulator for an Assistant Humanoid Robot. Proceeding

of the Workshop on Humanoid Manipulation, Cambridge, June 11, http://

wwwiaim.ira.uka.de/users/asfour/publications/whm05.pdf (accessed April 6,

2011).

Nakamura, Y., Chung, W., Sordalen, O. J. (2001). Design and control of

the nonholonomic manipulator. IEEE Transactions on Robotics and Automation

17:4859.

Nava, N. E. (2006). Design and Simulation of a New Low-Cost Easy-Operation

Humanoid Robot. PhD thesis. Cassino: University of Cassino, LARM.

Nilsson, N. J. (1982). Principles of Articial Intelligence. New York: Springer-Verlag.

The Math Works (1992). Optimization Toolbox Users Guide. Natick, MA: The Math

Works Inc.

D

o

w

n

l

o

a

d

e

d

b

y

[

M

a

r

c

o

C

e

c

c

a

r

e

l

l

i

]

a

t

0

6

:

4

9

1

1

F

e

b

r

u

a

r

y

2

0

1

2

You might also like

- PLC Micrologix 1100 1763 Pp001 - en PDocument4 pagesPLC Micrologix 1100 1763 Pp001 - en PAscn Frs AbrahamNo ratings yet

- 9324 pp001 - en PDocument12 pages9324 pp001 - en Pparanoid18No ratings yet

- Freelance Version 2015 - Coming SoonDocument4 pagesFreelance Version 2015 - Coming SoonCristian Ágreda AlvarezNo ratings yet

- Panel 800Document3 pagesPanel 800Cristian Ágreda AlvarezNo ratings yet

- Simulation Approach On Step Speed Control of Induction Motor Using Lab ViewDocument6 pagesSimulation Approach On Step Speed Control of Induction Motor Using Lab ViewCristian Ágreda AlvarezNo ratings yet

- Sift GpuDocument5 pagesSift GpuCristian Ágreda AlvarezNo ratings yet

- 05342997Document5 pages05342997Cristian Ágreda AlvarezNo ratings yet

- Festo Pneumatics Basic Workbook TP101Document194 pagesFesto Pneumatics Basic Workbook TP101Dimitar_Garpov_8272No ratings yet

- Festo Pneumatics Basic Workbook TP101Document194 pagesFesto Pneumatics Basic Workbook TP101Dimitar_Garpov_8272No ratings yet

- A Tutorial On Hidden Markov Models and Selected Applications in Speech RecognitionDocument30 pagesA Tutorial On Hidden Markov Models and Selected Applications in Speech Recognitionazizd15No ratings yet

- 74LS69Document7 pages74LS69Cristian Ágreda AlvarezNo ratings yet

- 00 Alcocer 2000 Redes Indice GeneralDocument6 pages00 Alcocer 2000 Redes Indice GeneraladfertelNo ratings yet

- Reading6 1995 Particle SwarmingDocument7 pagesReading6 1995 Particle SwarmingAlfonso BarrigaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 8th ChapterDocument39 pages8th ChapterMasthan BabuNo ratings yet

- Digicoil Parts List: GBC Is An Acco Brands CompanyDocument46 pagesDigicoil Parts List: GBC Is An Acco Brands CompanyMike DonnellyNo ratings yet

- Iron Ore Final Grinding by HPGR and Air ClassificationDocument20 pagesIron Ore Final Grinding by HPGR and Air ClassificationW ZuoNo ratings yet

- Runge Kutta AlgorithmDocument3 pagesRunge Kutta AlgorithmRodrigo AbdoNo ratings yet

- Datos de PresionesDocument3 pagesDatos de PresionesWilson Jaime Saucedo LeonNo ratings yet

- 4kw Solar SystemDocument12 pages4kw Solar Systemsureshn829606No ratings yet

- Steel Conduit Install Guide PDFDocument32 pagesSteel Conduit Install Guide PDFOliver Hermosa100% (1)

- D 2172 - 01 RdixnziDocument13 pagesD 2172 - 01 RdixnziJhony CotaNo ratings yet

- JC-22D Furnace Draft Controller BrochureDocument4 pagesJC-22D Furnace Draft Controller BrochureEli SantosNo ratings yet

- Syntatic Analysis SampleDocument22 pagesSyntatic Analysis SampleSagarNo ratings yet

- Determining Footing Sizes IrcDocument2 pagesDetermining Footing Sizes IrcAiline TriciaNo ratings yet

- DTVault Privacy User's ManualDocument20 pagesDTVault Privacy User's Manualmk777No ratings yet

- B737 MaxDocument4 pagesB737 MaxEmerson Juncom33% (3)

- Proesos Miniitab Six SigmaDocument60 pagesProesos Miniitab Six SigmaEdwin Roger Hernandez MejiaNo ratings yet

- Chemical Engineering Facts at Your Fingertips Guidebook - 2016 PDFDocument14 pagesChemical Engineering Facts at Your Fingertips Guidebook - 2016 PDFKimberly Conley50% (2)

- Bar Design Guide PDFDocument8 pagesBar Design Guide PDFAakash GoliyanNo ratings yet

- CollectionsDocument6 pagesCollectionsiamsonalNo ratings yet

- Model 5216/5916 Steel Carriage House Residential Door Spec SheetDocument1 pageModel 5216/5916 Steel Carriage House Residential Door Spec SheetLuis Felipe Dominguez RuizNo ratings yet

- Vietnam - Introduce Tekla Open APIDocument34 pagesVietnam - Introduce Tekla Open API김성곤No ratings yet

- Rabatex Textile Machinery Manufacturers, Sectional warping machine, Beam storage, cone creel, Beam trollys, Reed cleaning machine, Automatic Tensioning creel Device, motorized beam trolley, poly beamer, Mono Filament Creel, Carbon Creel, Warp Beam Carrier, Cloth Roll Carrier, Beam Pallet TrolleyDocument14 pagesRabatex Textile Machinery Manufacturers, Sectional warping machine, Beam storage, cone creel, Beam trollys, Reed cleaning machine, Automatic Tensioning creel Device, motorized beam trolley, poly beamer, Mono Filament Creel, Carbon Creel, Warp Beam Carrier, Cloth Roll Carrier, Beam Pallet TrolleySALES TEAMNo ratings yet

- Project Pegasus Andy Contextualizes Contemporary Time Travel Research 3-18-10Document2 pagesProject Pegasus Andy Contextualizes Contemporary Time Travel Research 3-18-10Lawrence JonesNo ratings yet

- (CHEVROLET) Manual de Taller Chevrolet Sail 2010Document120 pages(CHEVROLET) Manual de Taller Chevrolet Sail 2010Nader Jimenez79% (14)

- Oracle Fixed AssetsDocument1,204 pagesOracle Fixed AssetsYudha Prayoga100% (1)

- GEMINI II Operating Instructions 06-235975-001 Print 5127 2014-05-08Document120 pagesGEMINI II Operating Instructions 06-235975-001 Print 5127 2014-05-08Nattapong Natt100% (1)

- Livrari Autoturisme Autohtone / Domestic Passenger Car DeliveriesDocument3 pagesLivrari Autoturisme Autohtone / Domestic Passenger Car DeliveriesBogdan PopNo ratings yet

- PenstockDocument7 pagesPenstockmodest_dhuNo ratings yet

- Master Cheat SheetDocument2 pagesMaster Cheat SheetPranab BhattacharjeeNo ratings yet

- An Interview With An Ofw Civil EngineerDocument3 pagesAn Interview With An Ofw Civil EngineerYath DreNo ratings yet

- Oxmoor DCA-2 ManualDocument15 pagesOxmoor DCA-2 Manualridgeback123No ratings yet

- Polyken 930 TapeDocument2 pagesPolyken 930 TapeKyaw Kyaw AungNo ratings yet