Professional Documents

Culture Documents

Alarm Check Valve

Uploaded by

HellenHoaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alarm Check Valve

Uploaded by

HellenHoaCopyright:

Available Formats

March 2, 2007

Wet 20a

TECHNICAL DATA

wET pIpE sprINkLEr sysTEm

The Viking Corporation, 210 N Industrial park Drive, Hastings mI 49058 Telephone: 269-945-9501 Technical services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

1. DEsCrIpTION

A wet pipe sprinkler system is fixed fire protection using piping filled with pressurized water supplied from a dependable source. Closed heat sensitive automatic sprinklers spaced and located in accordance with recognized installation standards are used to detect a fire. Upon operation, the sprinklers distribute the water over a specific area to control or extinguish the fire. As the water flows through the system, an alarm is activated to indicate the system is operating. Only those sprinklers immediately over or adjacent to the fire operate, minimizing water damage. A wet pipe sprinkler system may be installed in any structure not subject to freezing to automatically protect the structure, contents, and/or personnel from loss due to fire. The structure must be substantial enough to support the piping system filled with water. Using water as its extinguishing agent, one wet system may cover as much as 52,000 square feet in a single fire area. The system should be designed by qualified fire protection engineers in conjunction with insuring bodies. Sprinkler systems are engineered to meet the standards of National Fire Protection Association (see N.F.P.A. Pamphlet 13, The Installation of Sprinkler Systems), Factory Mutual (F.M.), Loss Prevention Council (FOC), Assemblee Pleniere, Verband der Sachversicherer or other similar organizations, and also with the provisions of governmental codes, ordinances, and standards where applicable. Small unheated areas of a building may be protected by a wet system if an antifreeze-loop or auxiliary dry system is installed. For rules and limitations, see appropriate codes and standards.

2. AppLICATIONs

Form No. F_041289

Revised page replaces page 1-4 dated January 12, 1990. (Revised format and renumbered page.)

Wet 20b

March 2, 2007

TECHNICAL DATA

wET pIpE sprINkLEr sysTEm

The Viking Corporation, 210 N Industrial park Drive, Hastings mI 49058 Telephone: 269-945-9501 Technical services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

3. wET pIpE sprINkLEr sysTEm wITH VIkING ALArm VALVE

A. sysTEm OpErATION

In the normal set condition, the system piping is filled with water. When a fire occurs, the heat operates a sprinkler allowing the water to flow. The alarm valve clapper is opened by the flow of water allowing pressurized water to enter the alarm port to activate the connected alarm devices. When using variable pressure water supply, the water flowing through the alarm port overcomes the retard chambers drain restriction, filling the retard chamber then activating the connected alarm devices. The alarms will continue to sound until the flow of water is manually turned off.

B. NOrmAL CONDITIONs

1. 2. 3. 4. All water supply control valves open and secured. Alarm test shut-off valve in ALARM position. Water gauge valves open. The water supply pressure gauge (lower gauge) equals that of the known service-line pressure. The system pressure gauge (upper gauge) reading is equal to or greater than the water supply pressure gauge reading. 5. Incoming power to all alarm switches on. 6. Main-drain valve, auxiliary drain valves and inspectors test valves tightly closed. 7. The sprinkler head cabinet contains appropriate replacement sprinklers and wrenches. 8. Temperature maintained above freezing for entire system. 9. If Fire Department connection is used, make sure the automatic drip valve is free, allowing accumulated water to escape. 10. Sprinklers in good condition and unobstructed.

C. sysTEm TEsT

INspECTIONs: It is imperative that the system be inspected and tested on a regular basis. The following recommendations are minimum requirements. The frequency of the inspections may vary due to contaminated or corrosive water supplies and corrosive atmospheres. In addition, the alarm devices or other connected equipment may require more frequent inspections. Refer to the technical data, system description, applicable codes, and the authority having jurisdiction for minimum requirements. Prior to testing the equipment, notify appropriate personnel. 1. Alarm Test: At least quarterly, test all connected alarm devices by opening the remote inspectors test valve. When weather conditions or other circumstances prohibit using the inspectors test valve, the alarms shall be tested by turning the alarm test shut-off valve to the TEST position. When testing is complete return the valve to the ALARM position. 2. riser Flow Test: At least quarterly, perform a riser flow test. Observe and record the supply pressure gauge reading. Open the main drain valve fully. The alarm should sound. Again observe and record the supply pressure gauge reading. Close the main drain valve. If the readings vary significantly from those previously established or from normal, check the main supply line for obstructions or closed valves and correct. 3. General: During all inspections, testing, and maintenance activities the valve, trim, piping, alarm devices, and connected equipment must be visually inspected for physical damage, freezing, corrosion, or other conditions that may inhibit the proper operation of the system.

D. TrOUBLEsHOOTING

1. General a. Alarm fails to sound on test: clean water motor and strainers in the alarm line. Check bell for obstructions. If the alarm still fails, call your Viking representative. b. Water supply pressure gauge drops on the flow test: immediately check roadway valve and post indicator or control valve. If both are open, immediately call your Viking representative, as a line obstruction is indicated. c. Alarm sounds immediately on alarm test: clean orifice tee or retarding chamber drain restriction. 2. Intermittent alarms: bleed air from the high points of the system. If system pressure is seldom, if ever, greater than supply pressure, drain the system and check the alarm valve rubber and by-pass check valve rubber for cold flow and sealing efficiency. Clean valve seats and replace rubbers as necessary. 3. False Alarms: If water pressure surges produce false alarms, check the following: a. Make sure the valve has been trimmed exactly as shown on Viking trim sheets with no deviations. The trim size and fitting arrangement is required for proper operation. b. Air trapped in the sprinkler piping can cause false alarms, the alarms to cycle on and off during testing, and other nuisance problems. To correct, bleed as much air as possible from the trapped high points of system piping. This condition can be minimized by opening the remote inspector test valve and slowly filling the system with water when placing the system in service.

March 2, 2007

Wet 20c

TECHNICAL DATA

wET pIpE sprINkLEr sysTEm

The Viking Corporation, 210 N Industrial park Drive, Hastings mI 49058 Telephone: 269-945-9501 Technical services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

c. d. e. f. Clean drain restriction on retard chamber trim. Clean or replace check valve on external by-pass trim. Clean or replace alarm valve clapper rubber. Add retard chamber and drain restriction if not provided.

E. rEmOVING THE sysTEm FrOm sErVICE

wArNING: The system should be placed out of service only for repairs. The work to be done must be completed in a manner to minimize the time that the system must be out of service. All hazardous activities in the effected area shall be terminated until the system is placed back in service. Any system impairment shall be coordinated with the owner, local authority having jurisdiction, and other related parties. Place a roving fire patrol in the area covered by the system until the system is back in service. Prior to turning off any valves or activating any alarms, notify local security guards and/or central alarm station (if used) so that a false alarm will not be signaled and result in a local fire department response. 1. Close the water supply control valve. 2. Open the main drain valve. 3. Open all auxiliary drain valves and inspectors test valve. 4. System and supply pressure gauges should now read zero. 5. If system will be subject to freezing, drain any trapped water in the system, devices, valve, and trim. 6. Place a system-out-of-service sign in a visible location.

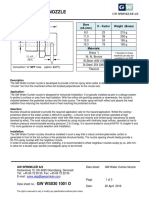

Component A A.1 B.1 B.2 B B.3 B.4 B.5 B.6 B.7 C D C.1 D.1 D.2 D.3 E E.1

Decsription system Valve Alarm Check Valve

part Numbers Various

Corresponding Data pages 26a-g 27a-c

Check Valve Trim including: Check Valve (not shown) Main Drain Valve Side Outlet Valve Water Gauge Restriction Restricted Orifice Restricted Orifice (not shown) Retard Chamber Alarm Pressure Switch Water Motor Alarm Alarm Line Strainer Check Valve Swing Check Valve Various 803a-d 05904B PS101A, PS102A 07862 01489A 38a-b

--

Various

or 28a-c

water Flow Alarm Equipment 711a-d 711a-d

Note: when viewing this data page online, blue text represents hyperlinks and will open the desired data page when clicked.

Wet 20d

March 2, 2007

TECHNICAL DATA

wET pIpE sprINkLEr sysTEm

The Viking Corporation, 210 N Industrial park Drive, Hastings mI 49058 Telephone: 269-945-9501 Technical services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

4. wET pIpE sprINkLEr sysTEm wITH VIkING EAsy rIsEr swING CHECk VALVE AND wATErFLOw INDICATOr

A. sysTEm OpErATION

In the normal set condition, the system piping is filled with water. When a fire occurs, the heat operates a sprinkler allowing the water flow. The waterflow indicator is activated by the water flow. The paddle, which normally lies motionless inside the pipe, is forced up, thereby activating the pneumatic time delay mechanism which closes or opens a microswitch after the preset retard time has elapsed. This action causes an electric alarm to sound. All alarms will continue to sound as long as there is a flow of water in the system. The water will continue to flow until it is shut off manually.

B. NOrmAL CONDITIONs

1. All water supply control valves open and secured. 2. Water gauge valves open. 3. The water supply pressure gauge (lower gauge) equals that of the known service-line pressure. The system pressure gauge (upper gauge) reading is equal to or greater than the water supply pressure gauge reading. 4. Incoming power to all alarm switches on. 5. Main-drain valve, auxiliary drain valves, and inspectors test valves tightly closed. 6. The sprinkler head cabinet contains appropriate replacement sprinklers and wrenches. 7. Temperature maintained above freezing for entire system. 8. If Fire Department connection is used, make sure the automatic drip valve is free, allowing accumulated water to escape. 9. Sprinklers in good condition and unobstructed.

C. sysTEm TEsT

INspECTIONs: It is imperative that the system be inspected and tested on a regular basis. The following recommendations are minimum requirements. The frequency of the inspections may vary due to contaminated or corrosive water supplies and corrosive atmospheres. In addition, the alarm devices or other connected equipment may require more frequent inspections. Refer to the technical data, system description, applicable codes, and the authority having jurisdiction for minimum requirements. Prior to testing the equipment, notify appropriate personnel. 1. Alarm Test: At least quarterly, test all connected alarm devices by opening the remote inspectors test valve 2. riser Flow Test: At least quarterly perform a riser flow test. Observe and record the supply pressure gauge reading. Open the main drain valve fully. Again observe and record the supply pressure gauge reading. Close the main drain valve. If the readings vary significantly from those previously established or from normal, check the main supply line for obstructions or closed valves and correct. 3. General: During all inspections, testing, and maintenance activities, the valve, trim, piping, alarm devices, and connected equipment must be visually inspected for physical damage, freezing, corrosion, or other conditions that may inhibit the proper operation of the system.

D. TrOUBLEsHOOTING

1. General a. Alarm fails to sound on test: Check bell for obstructions. Check power source and wiring. If the alarm still fails, call your Viking representative. b. Water supply pressure gauge drops on the flow test: immediately check roadway valve and post indicator or control valve. If both are open, immediately call your Viking representative, since a line obstruction is indicated. c. Alarm sounds immediately on alarm test: During surges, the paddle will move. The switch mechanism is provided with a pneumatic time delay to prevent closing of the alarm line circuit. The time delay can be adjusted from 0 to 90 seconds (see the waterflow indicator device page). d. Intermittent alarms - bleed air from the high points of the system. If system pressure is seldom, if ever, greater than supply pressure, drain the system and check the check valve rubber for cold flow and sealing efficiency. Clean valve seats and replace rubbers as necessary. 2. False Alarms: If water pressure surges produce false alarms, check the following: a. Air trapped in the sprinkler piping can cause false alarms, the alarms to cycle on and off during testing and other nuisance problems. To correct bleed as much air as possible from the trapped high points of system piping. This condition can be minimized by opening the remote inspector test valve and slowly filling the system with water when placing the system in service.

March 2, 2007

Wet 20e

TECHNICAL DATA

wET pIpE sprINkLEr sysTEm

The Viking Corporation, 210 N Industrial park Drive, Hastings mI 49058 Telephone: 269-945-9501 Technical services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com E. rEmOVING THE sysTEm FrOm sErVICE

wArNING: The system should be placed out of service only for repairs. The work must be completed in a manner to minimize the time that the system must be out of service. All hazardous activities in the effected area shall be terminated until the system is placed back in service. Any system impairment shall be coordinated with the owner, local authority having jurisdiction, and other related parties. Place a roving fire patrol in the area covered by the system until the system is back in service. Prior to turning off any valves or activating any alarms, notify local security guards and/or central alarm station (if used) so that a false alarm will not be signaled and result in a local fire department response. 1. Close the water supply control valve. 2. Open the main drain valve. 3. Open all auxiliary drain valves and inspectors test valve. 4. System and supply pressure gauges should now read zero. 5. If system will be subject to freezing, drain any trapped water in the system, devices, valve, and trim. 6. Place a system-out-of-service sign in a visible location.

Component A B A.1 B.1 B.2 B.3 B.4 C C.1 C.2 C.3 D D.1

Decsription Easy Riser Check Valve Automatic Drip Valve Main Drain Valve Side Outlet Valve Water Gauge

part Numbers system Valve Various

Corresponding Data pages 815a-f

Check Valve Trim including: Various 815a-f

water Flow Alarm Equipment Alarm Pressure Switch or Water Flow Indicator Electric Alarm Bell Check Valve Swing Check Valve Various 803a-d PS101A, PS102A Various --703a-b --

Note: when viewing this data page online, blue text represents hyperlinks and will open the desired data page when clicked.

ThIS PAgE INTENTIONALLy LEFT BLANk

Form No. F_041289

Revised page replaces page 1-4 dated January 12, 1990. (Revised format and renumbered page.)

You might also like

- Wet System ManualDocument38 pagesWet System ManualLalit MalhotraNo ratings yet

- Commissioning Protocol For AFDA SystemDocument7 pagesCommissioning Protocol For AFDA SystemRaj KamalNo ratings yet

- NFPA 13 - 2016 Edition: - Specifically Permit Stainless Steel in Accordance With Schedule 10S or Schedule 40SDocument8 pagesNFPA 13 - 2016 Edition: - Specifically Permit Stainless Steel in Accordance With Schedule 10S or Schedule 40SAhmed Nabil100% (1)

- Viking Main Control ValveDocument3 pagesViking Main Control Valvearf laadeNo ratings yet

- Water Base ProtectionDocument42 pagesWater Base ProtectionandreasbudiNo ratings yet

- Sprinkler System DesignDocument19 pagesSprinkler System DesignRajahi Moahmed100% (1)

- Hose Stream Demands Part-1 PDFDocument4 pagesHose Stream Demands Part-1 PDFHugo Mario Ariza PalacioNo ratings yet

- Fs2011 FullDocument242 pagesFs2011 FullryankckoNo ratings yet

- Inspection, Testing and Maintenance of Fire Protection SystemsDocument126 pagesInspection, Testing and Maintenance of Fire Protection SystemsGee MacawileNo ratings yet

- Et 321 06-23-15Document2 pagesEt 321 06-23-15Shishan AhmadNo ratings yet

- System Design: Total Flooding Extinguishing SystemDocument45 pagesSystem Design: Total Flooding Extinguishing SystemsureshkanuboyinaNo ratings yet

- HydraulicDocument8 pagesHydraulicOsama OmayerNo ratings yet

- Fire Sprinkler Pipe and Fittings NotesDocument6 pagesFire Sprinkler Pipe and Fittings Notesmary joy Panama100% (1)

- Sidewall SprinklerDocument6 pagesSidewall SprinklerAhrian BenaNo ratings yet

- Water Mist Nozzle GW M5 PDFDocument6 pagesWater Mist Nozzle GW M5 PDFZulfi Andrie ZulkiarNo ratings yet

- Hydraulic Calculation For Foam Monitor SystemDocument1 pageHydraulic Calculation For Foam Monitor SystemSyazwan KhairulNo ratings yet

- Isle of Wight Fire & Rescue Service: Record of Fire Safety Equipment Testing Fire Drills & TrainingDocument18 pagesIsle of Wight Fire & Rescue Service: Record of Fire Safety Equipment Testing Fire Drills & TrainingcaptalaaNo ratings yet

- Wet Riser Stage 2 (Above)Document1 pageWet Riser Stage 2 (Above)ZamzuriNo ratings yet

- Key Maintenance SwitchDocument4 pagesKey Maintenance SwitchkuraimundNo ratings yet

- Water Curtain (20.04.16)Document3 pagesWater Curtain (20.04.16)احمد الجزار2007No ratings yet

- Specification For Fire Water MonitorsDocument6 pagesSpecification For Fire Water MonitorsThiru AnanthNo ratings yet

- Fmconfnfpa 45Document39 pagesFmconfnfpa 45M Ahmed LatifNo ratings yet

- Enclosure Integrity Testing For Gas Suppressions - EnglishDocument4 pagesEnclosure Integrity Testing For Gas Suppressions - EnglishSalim Bakhsh100% (1)

- Handbook On Building Fire CodesDocument287 pagesHandbook On Building Fire Codesmz1234567100% (1)

- Jci 2017072Document15 pagesJci 2017072Toretta AdrianNo ratings yet

- Bukel Fire Aircraft - HangarsDocument7 pagesBukel Fire Aircraft - HangarsmukeshsinghtomarNo ratings yet

- Sprinklers PDFDocument43 pagesSprinklers PDFpil7194No ratings yet

- Inergen SpecDocument19 pagesInergen SpecMargaret DaughertyNo ratings yet

- Sprinkler System ComponentsDocument68 pagesSprinkler System Componentsjosediaz141No ratings yet

- Hydraulic Calculations For Small RoomsDocument4 pagesHydraulic Calculations For Small RoomsAnonymous qrSsYuxyoYNo ratings yet

- Comparison of Sprinkler Design Criteria 1. Sprinkler Installation Nfpa 13Document16 pagesComparison of Sprinkler Design Criteria 1. Sprinkler Installation Nfpa 13coolth2No ratings yet

- SprinklersDocument16 pagesSprinklersAdel Suker100% (1)

- Fire Protection General Notes Fire Protection Symbol and Abbreviation ScheduleDocument9 pagesFire Protection General Notes Fire Protection Symbol and Abbreviation ScheduleMaxwellNo ratings yet

- How To Make A Flame DetectorDocument4 pagesHow To Make A Flame DetectorTariq ZuhlufNo ratings yet

- Et 323 07-28-15Document5 pagesEt 323 07-28-15Shishan AhmadNo ratings yet

- Redbook Vol1part1 LPCBDocument755 pagesRedbook Vol1part1 LPCBvbgiri0% (1)

- 04-Sprinkler SystemDocument32 pages04-Sprinkler SystemRavi100% (1)

- Falar CajiligDocument5 pagesFalar CajiligRamil S. ArtatesNo ratings yet

- Stand Pipe System: Prepared BY Homer C. Panganiban Jr. PMEDocument39 pagesStand Pipe System: Prepared BY Homer C. Panganiban Jr. PMEJay Mark CayonteNo ratings yet

- Fire Supression SystemDocument37 pagesFire Supression SystemStephen Odon Fasto100% (1)

- Inert Gas Fire SuppressionDocument3 pagesInert Gas Fire SuppressionTransgulfNo ratings yet

- Fire Sprinkler Flow SwitchDocument8 pagesFire Sprinkler Flow Switchm.sofiqur rahmanNo ratings yet

- Alarmline Linear Heat Detection Power PointDocument27 pagesAlarmline Linear Heat Detection Power PointCris Javicho100% (1)

- Foam CalculationsDocument8 pagesFoam Calculationsahmed salemNo ratings yet

- Product Manual DCP Trolley Mounted 25-50-75 KGDocument6 pagesProduct Manual DCP Trolley Mounted 25-50-75 KGm4l4ysiaNo ratings yet

- Fire Protection Engineering Fall 2001Document35 pagesFire Protection Engineering Fall 2001Hany RifaatNo ratings yet

- NFPA13 - Pt1 - Handout Cambios Nfpa 13Document33 pagesNFPA13 - Pt1 - Handout Cambios Nfpa 13Eden FriasNo ratings yet

- Fire Protection SystemDocument5 pagesFire Protection Systemadilmomin45No ratings yet

- Terms of Reference: Philippine Science High School-Bicol Region CampusDocument16 pagesTerms of Reference: Philippine Science High School-Bicol Region CampusMichael Jorge BernalesNo ratings yet

- Fire Sprinkler For Non-Storage Facilities PPT Presentation PDFDocument62 pagesFire Sprinkler For Non-Storage Facilities PPT Presentation PDFMickoAngeloRamirezAquino100% (2)

- Hydrant DrawingDocument1 pageHydrant DrawingCokroNo ratings yet

- As 4118.1.8-1999 Fire Sprinkler Systems Components - Pressure-Reducing ValvesDocument8 pagesAs 4118.1.8-1999 Fire Sprinkler Systems Components - Pressure-Reducing ValvesSAI Global - APACNo ratings yet

- O&M Fire Hydrant SystemDocument21 pagesO&M Fire Hydrant SystemAHMAD ISLAHINo ratings yet

- Fike - Water Mist Design Machinery SpacesDocument6 pagesFike - Water Mist Design Machinery SpacesminiongskyNo ratings yet

- Ansul R-102Document4 pagesAnsul R-102heliopintoNo ratings yet

- Viking - Preaction System ManualDocument64 pagesViking - Preaction System Manualwetchkrub100% (2)

- Diseño Del Sistema de DiluvioDocument4 pagesDiseño Del Sistema de DiluvioJosé Martín Meza CabillasNo ratings yet

- Deluge Valve HD FireDocument14 pagesDeluge Valve HD FireKeshodbana KeshodNo ratings yet

- Deluge Valve ADocument14 pagesDeluge Valve ASiddharth GupteNo ratings yet

- Fire Alarm ValveDocument2 pagesFire Alarm ValveasdthuNo ratings yet

- CP 83 Construction Computer-Aided Desing (CAD) PDFDocument204 pagesCP 83 Construction Computer-Aided Desing (CAD) PDFHellenHoa80% (5)

- CP 48-2005 Water ServicesDocument57 pagesCP 48-2005 Water ServicesHellenHoa84% (19)

- CP 83 Construction Computer-Aided Desing (CAD) PDFDocument204 pagesCP 83 Construction Computer-Aided Desing (CAD) PDFHellenHoa80% (5)

- ARI - 820-2000 Ice Storage BinsDocument8 pagesARI - 820-2000 Ice Storage BinsHellenHoaNo ratings yet

- Tennis Court Lighting Standards 6-4Document6 pagesTennis Court Lighting Standards 6-4HellenHoaNo ratings yet

- En 10263-1Document30 pagesEn 10263-1Mogos PaulNo ratings yet

- Siltech E50Document4 pagesSiltech E50Rajesh ChowdhuryNo ratings yet

- Biodegradable Wastes: Hospital WasteDocument4 pagesBiodegradable Wastes: Hospital WasteFAIZA A PASCUALNo ratings yet

- Lectureone Introduction To BioChE - 2Document20 pagesLectureone Introduction To BioChE - 2desalegn abera100% (1)

- NESC Diploma - MillwrightDocument2 pagesNESC Diploma - MillwrightjamesNo ratings yet

- The Big Picture: EnzymesDocument54 pagesThe Big Picture: EnzymesSoumiya SrinivasanNo ratings yet

- Heat Capacity Lab ReportDocument8 pagesHeat Capacity Lab ReportLiHong Khaw100% (1)

- Panchakanya Structural SteelDocument5 pagesPanchakanya Structural Steelkabira12No ratings yet

- Brochures WSM2-Y PDFDocument16 pagesBrochures WSM2-Y PDFkunkzNo ratings yet

- Manual On Pavement Design PDFDocument31 pagesManual On Pavement Design PDFAnil Kumsr T B100% (3)

- MMU 0102, MMA 0204, MMB 0207 - Professional: Vishay BeyschlagDocument13 pagesMMU 0102, MMA 0204, MMB 0207 - Professional: Vishay BeyschlagJan KowalskiNo ratings yet

- Accumulatore Charg InstructionsDocument11 pagesAccumulatore Charg InstructionsBrad BergNo ratings yet

- YLAA InstallationDocument62 pagesYLAA InstallationJoe YoungNo ratings yet

- MetalCoat 470 480 Brochure enDocument9 pagesMetalCoat 470 480 Brochure endanceNo ratings yet

- Sum11 Pharma PDFDocument29 pagesSum11 Pharma PDFMostofa RubalNo ratings yet

- FloatingDocument12 pagesFloatingrobson2015No ratings yet

- Praxis GuideDocument43 pagesPraxis GuideRyan NegadNo ratings yet

- ECE5-014 - A4 - Productsheet REXNORD CHAINDocument2 pagesECE5-014 - A4 - Productsheet REXNORD CHAINTRMNo ratings yet

- Cleaning Bones: General GuidelinesDocument4 pagesCleaning Bones: General GuidelinesSaira SepulvidaNo ratings yet

- Hot TappingDocument21 pagesHot TappingnayakyaNo ratings yet

- SunCoBe ShampooDocument24 pagesSunCoBe ShampooDong YulNo ratings yet

- Atoms and Elements (Chemistry Notes)Document4 pagesAtoms and Elements (Chemistry Notes)wlkernanNo ratings yet

- Vertical Farming: A Revolution To Sustainable Agriculture: Cps41@pitt - Edu Iss33@pitt - EduDocument9 pagesVertical Farming: A Revolution To Sustainable Agriculture: Cps41@pitt - Edu Iss33@pitt - EduShilpa MaratheNo ratings yet

- Nanofabrication For Pattern Transfer Purpose.: Etching Is Done Either in "Dry" or "Wet" MethodsDocument19 pagesNanofabrication For Pattern Transfer Purpose.: Etching Is Done Either in "Dry" or "Wet" MethodsPRAVEEN MNo ratings yet

- Influence of Sequence of Cold Working and Aging Treatment On Mechanical Behaviour of 6061 Aluminum AlloyDocument8 pagesInfluence of Sequence of Cold Working and Aging Treatment On Mechanical Behaviour of 6061 Aluminum AlloywicaksonoNo ratings yet

- Kerosene As HealerDocument17 pagesKerosene As HealerDuncan R Sickler100% (2)

- Lin Jingwei - A Nomadic Furniture For College StudentsDocument129 pagesLin Jingwei - A Nomadic Furniture For College StudentsAarish Netarwala100% (2)

- Description and Solubility - MTZDocument6 pagesDescription and Solubility - MTZPityu PíNo ratings yet

- Experiment No. 2 Classes of Chemical Reactions BackgroundDocument5 pagesExperiment No. 2 Classes of Chemical Reactions BackgroundjonastolentinoNo ratings yet

- Isensee Robert W1943Document17 pagesIsensee Robert W1943DŨNG VŨ NGUYỄN TUẤNNo ratings yet