Professional Documents

Culture Documents

Abaqus

Uploaded by

Sri SaiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Abaqus

Uploaded by

Sri SaiCopyright:

Available Formats

2009 SIMULIA Customer Conference 1

Abaqus user element for an accurate modeling of

adhesive joints on coarse meshes

S. J oanns

*,**

, J . Renard

**

* CEMCAT, Parc Universitaire et Technologique,

Rue Lonard de Vinci, 53810 Chang, France

** Centre des Matriaux, Mines de Paris, ParisTech, CNRS UMR 7633 BP 87,

91003 Evry Cedex, France

Abstract: This work is concerned with the Abaqus implementation of a suitable CAE methodology

to get the most benefits of structural adhesive bonding. In this study, we are interested in cohesive

debonding where the adhesive thickness and its non-linear behavior are of major importance.

When subjected to loading, significant stress field gradients may develop around outer edges of

the joint. Because such regions are sites for failure initiation, a specific mesh refinement is

needed. Using SIMULIA solutions, an efficient discretization strategy, inspired by the p-FEM, is

suggested and is implemented as an Abaqus user element. Balancing the accuracy and the

calculation time, in full-scale simulations, it is then possible to capture edge effects and damage

initiation. As the approach is suggested to be used in real applications, a validation example has

been chosen to show the suitability of the methodology on coarse meshes.

Keywords: Structural adhesive bonding, p-FEM, UEL subroutine, scripting.

1. Introduction

Designing safer, lighter and cleaner cars: that is the challenge to take up by constructors and parts

manufacturers at the dawn of the 21st century. In addition to the use of new materials, the

development of lightweight structures needs efficient joining methods. In recent years, structural

adhesive bonding has proven to be highly successful and has become a popular joining technique

for the transportation industry (Fays, 2003). Unlike bolted or riveted joints, adhesive bonding offer

a continuum connection and has an extremely broad range of applications. It is nevertheless true

that the development of structural adhesive bonding is hindered by several difficulties. For

example, the determination of the load-carrying capacity of a bonded structure requires the

analysis of the stress state in a very thin layer which exhibits stress fields gradients.

Indeed, in structural design, it is known for a long time that certain geometries like corners, edges

or notches can cause harmful stresses. It's exactly the same for adhesive bonded joints in which

geometrical characteristics change abruptly. Thats why significant stress field gradients may

develop around outer edges of the joint (edge effects). Because such regions are sites for failure

initiation, a specific analysis is needed. For the most elementary geometric assemblies, like a

single lap joint, analytical approaches seem to be well adapted (Adams, 1992), (Bigwood, 1990).

2 2009 SIMULIA Customer Conference

However, in the case of more complex geometrical configurations, it becomes impossible to

describe the stress state analytically; it is then necessary to use numerical methods (Dean, 2001).

Except for simplest geometries, capturing edge effects requires exploiting all the potential of the

finite element method (Zienkiewicz, 2005).

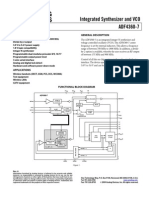

Among SIMULIA solutions, Abaqus offers a library of elements to model behavior of adhesive

joints. For situations where the integrity and strength of interfaces may be of interest, it is possible

to use elements defined with zero thickness. Indeed, Cohesive Zone Modeling (CZM) (Chaboche,

2001), introduced at the end of 1980s in most finite element codes, considers generally that the

failure of an adhesive bond occurs at the interface between the adhesive and the adherends

(adhesive or interfacial failure) rather than within the adhesive material (cohesive failure); see

Figure 1. The CZM approach would treat the adhesive layer as an idealized interfacial surface

material consisting of an upper and lower surface connected by a continuous distribution of

normal and tangential disconnected springs. The assumption here is that if the thickness of the

adhesive layer is small (compared to the length of the joint) the stress distribution through the

thickness of the adhesive layer is negligible. This can be stated mathematically as: as the limit of

the thickness tends to zero, the tractions at the upper and lower interfaces must be equal. This

leads to the simplification that the tractions acting in the springs are uniform across the thickness.

This assumption of zero thickness is not relevant when a crack propagates in the bulk polymer

which constitutes the adhesive. In that case, taking into account the joint thickness and the non-

linear constitutive behavior of the adhesive polymer are of major importance. For the continuation

of this study, we are only interested in this last case with cohesive debonding.

Figure 1. Fracture types of an adhesive joint.

2009 SIMULIA Customer Conference 3

Some specific elements, provided by Abaqus, can be used to model finite-thickness adhesives.

The implementation of the conventional material models for cohesive elements is based on certain

assumptions regarding the state of the deformation in the cohesive layer (Abaqus, 2006). Indeed,

for those elements, it is assumed that the cohesive layer is subjected to only one direct component

of strain, which is the through-thickness strain and to transverse shear strain components. The

above kinematics assumptions are appropriate in situations where a relatively thin and compliant

layer of adhesive bonds two relatively rigid (compared to the adhesive) parts. Moreover, these

assumptions can be accepted inside the cohesive layer but not around its outer edges where

complicated 3D stress could appear with significant gradients. Then, to capture edge-effects, it is

necessary to use a very fine mesh in the regions of such transition zones. Balancing the accuracy

and the calculation time, discretization has to be considered carefully, especially for full-scale

structure simulations. Classical refinement techniques are time consuming and are not well

adapted to industrial applications; Economic advantage requires a reduction of data preparation.

In this context, the aim of the work presented in this paper was the development of an efficient

discretization strategy inspired by the p-FEM, and the extent of the Abaqus adhesive joints library

models for industrial applications with coarse meshes.

2. User elements family based on the p-FEM

Numerical methods presented above require treating the adhesive bonded joints in a singular way

(specific refinement). In the work presented in this paper, we suggest an alternative methodology

which makes it possible to estimate the resistance of the adhesive bonded joint while preserving a

global structural approach and classical numerical tools. Those two points are really key

requirements for industrial applications. For this purpose, we exploit the potential of the p-version

of the finite element method (p-FEM) which is based on hierarchical interpolation

functions (Babuka, 1991).

2.1 A short introduction to the p-FEM and the hierarchical concept

In the finite element method, the error of approximation mainly depends on two parameters: the

finite element mesh and the polynomial degree of elements. The size of the largest element in the

model is generally denoted by h. It is obvious that errors of approximation decreased as h

decreased. When the coarse mesh elements are broken into smaller elements, we speak about h-

refinement. An alternative method, known as p-refinement controls the error of approximation by

increasing the degree p of polynomial interpolation functions. We should note that with p-

refinement, it is convenient to decrease the error of approximation still using the same coarse mesh

elements. High order finite element methods have shown to be efficient in various applications

and are gaining popularity in industry. The p-version of the finite element method is also

associated with the hierarchical concept. Indeed, with the h-refinement method, a serious

drawback exists: when element refinement is made, totally new interpolation functions have to be

generated. In the hierarchic case, all lower order interpolation functions are contained in the higher

order basis.

4 2009 SIMULIA Customer Conference

As the aim of this paper is not to describe exhaustively the p-FEM, we will only focus on the

general concept. More information on the p-FEM and hierarchical approach can be found in

(Peano, 1975), (Babuka, 1991), (Cugnon, 2000) and (Dster, 2001). Lets begin with the classical

Lagrange interpolation and assume that in local (or element) coordinate system, we desire to

define a quantity

e

u by interpolating in space given values

e

U . In a one-dimensional space, the

element interpolation is given by Equation 1 with a set of interpolation functions

e

N .

( ) ( ) | |{ }

e e e

U N u = ( 1 )

Using the well known Lagrange interpolation, it is possible to define a linear interpolation

between two nodes (Equation 2).

( )

( )

( )

| | ( ) ( ) | |

+ =

=

[

=

=

1

2

1

1

2

1

2

1

e

i j

j

j i

j

e

i

N

N

( 2 )

By adding a third (center) node, the same technique can be used to obtain a quadratic

interpolation (Equation 3).

| | ( )( ) ( )( ) | |

2

1 1

2

1

1

2

1

+ =

e

N ( 3 )

Up to this point, with the Lagrange approach, if we desired to increase the interpolation order, we

need to define totally new shape functions. With the hierarchic approach, to get new functions, we

simply add some terms to the old functions. Thus, we add some internal interpolation functions,

i.e. edge functions

e

N

A

, to nodal shape functions

e

N

N

(Equation 4).

| | | |

e

A

e

N

e

N N N = ( 4 )

As the element square matrix will always involve an integral of the product of the derivatives of

the interpolation functions, hierarchical functions are based on orthogonal polynomials. Thats

why p-FEM is generally implemented using Legendre polynomials defined by Equation 5 called

Rodrigues formula.

| |

( ) ( )

(

=

> e e

n

n

n

n

n x

dx

d

n

x L

n / n x

1

! 2

1

, 2 N , 1 ; 1

2 ( 5 )

In the one-dimensional case, to obtain a 2 > p order of interpolation using the hierarchical

approach, we can use Equation 6 and Equation 7.

2009 SIMULIA Customer Conference 5

| | ( ) ( )

{ }

( ) | |

e

p

e

N N

A1

1

2

1

1

2

1

+ = ( 6 )

{ }

( ) ( ) ( ) | | 2

A1

2 4

1

, 2 / N

=

> e

p p

e

p

L L

p

N

p p

( 7 )

In the same way, it is easy to construct hierarchical interpolation functions for 2D and 3D

elements. As we said earlier, for a one-dimensional element, we have nodal and edge interpolation

functions: nodal functions are defined by Lagrange polynomials and edge functions by Legendre

polynomials. For a two-dimensional element, we must add face functions

e

N

F

(Equation 8) and

for a three-dimensional element internal functions

e

N

I

(Equation 9). Face functions and internal

functions are respectively defined by a combination of ( ) q , interpolations and ( ) , q , ,

interpolations.

| | | |

e e e e

N N N N

F A N

= ( 8 )

| | | |

e e e e e

N N N N N

I F A N

= ( 9 )

The Figure 2 gives a graphical representation of a bilinear nodal interpolation associated with a

2nd order hierarchical interpolation for a four nodes 2D element. We can see the representation of

four nodal functions, four edge functions and one face function. For the same element, the Figure

3 gives a graphical representation in the case of a 3rd order of interpolation.

6 2009 SIMULIA Customer Conference

Figure 2. 2D, four nodes element, 2nd order interpolation: graphical representation

of four nodal functions (bilinear), four edge functions and one face function.

Figure 3. 2D, four nodes element, 3rd order interpolation: graphical representation

of a four nodal functions (bilinear), four edge functions of degree two, four edge

functions of degree 3 and four face functions (degree 2x2, 3x2, 2x3, 3x3).

2009 SIMULIA Customer Conference 7

Up to now, we have shown isotropic increase of the element order. With the hierarchical

approach presented above, it is possible to adopt an anisotropic p-refinement of the element

(Dster, 2001). Indeed, we can define independent degrees of interpolation for each space

directions. An example can be seen on Figure 4.

Figure 4. 2D, four nodes element, 5th order interpolation for one edge of the

element.

2.2 A specific formulation for capturing edge effects

Capture the strong variations of the solution in the vicinity of the ends of the joint For this goal

and to introduce more easily the formulation suggested, let us consider a one-dimensional

academic problem: an ideal straight bar composed of a linearly elastic material and subjected

to an axial tension load as depicted in Figure 5. The solution ( ) x u x describes the

displacement of the bar in x direction. The bar is loaded by a force per unit length ( ) x f x in

the bar cross-sectional direction and a punctual load F for = x . The Young modulus is

denoted E , the cross-sectional area A, the density and the bar length . The problem is

modeled by Equation 10 with a clamped end for 0 = x .

8 2009 SIMULIA Customer Conference

Figure 5. The academic bar problem: a simple one dimensional case to introduce

the formulation of the user element family.

( ) ( )

( )

= = =

(

= = =

O e = +

x

A E

F

dx

du

x u

f A

dx

u d

A E

L

, L M for

0 , O M for 0 O

M 0

2

2

( 10 )

Imposing a solution with a very strong variation, we study the efficiency of the hierarchical

formulation according to the selected degree. In Figure 6 the approximation for a degree 8

hierarchical interpolation is plotted together with the exact solution of the problem (Equation 11).

( )

50

x x uex = ( 11 )

At first sight, with a single element of degree 8, we manage with difficulty to approach the exact

solution of degree 50. We can of course continue to increase the order of interpolation or refine

the mesh but that would be to the detriment of the computing time and the aims of this work. It

also should be noted that the oscillations observed do not facilitate the research of the result. If the

integration of the stiffness matrix and the elementary vectors is accessible here analytically, that is

seldom the case for most complex problems. When the element is deformed, the geometrical

transformation is not linear anymore and the J acobian matrix is a sophisticated polynomial

function. Explicit integration becomes impossible and it is then necessary to use numerical

integration techniques.

In this paper, we suggested a way to improve the approximation and capture edge effects without

increase the order of interpolation or refine the mesh (Joanns, 2007).

2009 SIMULIA Customer Conference 9

Figure 6. Approximation of the exact solution by a degree 8 hierarchical

interpolation. Integration points are represented by square symbols.

In order to attenuate oscillations phenomena and better capturing edge effects, we should optimize

the element previously described and distend the solution near the element boundaries. We

choose to supplement the linear geometrical interpolation (Equation 12) by a suitable cubic

interpolation. It is essential that this new function dont modify the values on, but near the

boundaries.

| | ( ) ( )

(

+ = 1

2

1

1

2

1

e

P ( 12 )

The distending parameter is denoted o and we define a new function ( ) o o , , A which

is the cubic additional polynomial (Equation 13).

| | ( ) ( ) ( ) ( )

(

+ = o o , 1

2

1

, 1

2

1

A A P

e

( 13 )

10 2009 SIMULIA Customer Conference

If 1 = o there is no additional transformation but when 0 o the distending becomes

maximal. The new geometrical interpolation functions are no longer identical to the nodal

interpolation of the solution, except if 1 = o . We choose to preserve a pseudo-parametric or sub-

parametric element and the additional transformation intervenes only when 3 > p .

While preserving the degree 8, this additional geometrical transformation enables us to find a

value of o for which the error of approximation becomes minimal (Figure 7).

Figure 7. Approximation of the exact solution by a degree 8 hierarchical

interpolation and applying a geometrical distending of the solution near the

boundaries of the element.

3. A suitable CAE methodology

The family of elements discuss previously is implemented as an Abaqus user element and is

associated with a dedicated pre- and post-processing (Abaqus Python scripts). With this

methodology, it is possible to preserve industrial meshes with a reasonable description of the

adhesive joint behavior while ensuring a total compatibility with Abaqus code. This tool takes the

form of a user subroutine which allows enriching a portion of the mesh, for example the

adhesive layer, with a hierarchical formulation. The subroutine is organized in a modular way and

allows managing the elementary matrix and vectors construction. Since we act only on specific

zones, the global assembly as well as the resolution of the problem is done by Abaqus. In

complement to the UEL subroutine, we have developed pre- and post-processing capabilities. The

purpose of the pre-processing is to transform the input file describing the problem (mesh,

boundary conditions and loads) in order to substitute the standard elements of the adhesive zone

by elements with hierarchical formulation. The program integrates a strategy of classification of

the additional degrees of freedom particularly efficient: the enrichment of hierarchical elements is

entirely controlled by the edges of the elements. Coupled with an error indicator, this choice

makes it possible to consider automatic calculations.

2009 SIMULIA Customer Conference 11

Post-processing provides graphical information for Abaqus visualization module by representing

the results obtained with hierarchical elements. Taken as a whole, the tool implemented represents

about ten thousand lines of Fortran and Python codes with nearly two thirds devoted to the central

subroutine (UEL). The implementation presented above allows considering three dimensional

structural problems. It is based on a hexahedral element formulation, being able to vary the

polynomial degree for the three local directions. The use of anisotropic interpolation leads to very

efficient approximations.

3.1 Patch tests

The successful application of finite element analysis should always include a validation of the

elements to be used and a validation of their implementation in a specific computer program. A

single element test can show the effects of the element geometrical parameters such as convexity,

aspect ratio or skewness. The patch test has been introduced as a complementary check for

continuity intra- and inter-elements. It was developed from physical intuition and later written in

mathematical forms. The concept is fairly simple: to be assured of convergence one must be able

to exactly satisfy the state where the derivatives, in the governing integral statement, take on

constant or zero values. Thus, the patch test provides a simple numerical way to verify that correct

programming was achieved and that the element behaves as it should. We define a patch of

elements to be a mesh where at least one node is completely surrounded by elements. Any node of

this type is referred to as an interior node. The outer nodes are referred to as exterior nodes. The

exterior nodes are utilized to introduce the essential boundary conditions and loads required by the

test. The Figure 8 presents the patch meshes used for 2D and 3D user elements. In order to verify

the transition between standard and user elements, exterior elements are CPE4 or C3D8 elements

and share at least one node with user inner elements. By moving the central node, we have

distorted user elements to see the effect that has on the numerical accuracy of the patch. With

various interpolation configurations, we have applied rigid body modes, constant strain and

constant stress state and controlled the accuracy of the patch response. For example, a rigid body

displacement of the patch should not introduce strain nor stress change.

Figure 8. Patch meshes for 2D and 3D user elements tests.

12 2009 SIMULIA Customer Conference

3.2 2D validation example

Previous tests have validated the behavior of a family of user elements (2D and 3D) based on a

hierarchical interpolation and implemented in Abaqus (Abaqus, 2006). The following paragraph

highlights the relevance of the methodology for high stress gradients. The problem presented here

is directly derived from the 2D patch-test: by the removal of four elements and the readjustment of

the central node, we obtain a L shape. This configuration is particularly interesting from a

numerical point of view since it induces a very strong gradient of stress. The model comprises

twelve 2D elements with four geometrical nodes. The three central elements have elastic

properties ten times higher than those of the peripheral elements. The test consists in imposing a

uniform displacement on the higher border of the L, while immobilizing in a suitable way the base

and the side (Figure 9). On the peripheral edges, the degree of interpolation is fixed (linear

interpolation). For interior edges, the degree is free to evolve anisotropically. A reference mesh,

comprising 2700 elements with linear interpolation (5642 degrees of freedom), makes it possible

to assess the relevance of the hierarchical model which comprises only 378 degrees of freedom on

the Figure 10 (with a maximum degree of four in that case). The Figure 10 confronts the results

obtained for the shear stress field. We can note a very good correlation of the results, even in re-

entrant corner zone while having here very little elements and a relatively weak interpolation

degree (only four).

Figure 9. The L shape helps the numerical validation of the hierarchical

interpolation with very strong gradients of stress. Representation of the boundary

conditions and visualization of the displacement field (magnitude) induced.

2009 SIMULIA Customer Conference 13

Figure 10. Confrontation of the results obtained on a benchmark model (left: 2700

bi-linear elements) and by a hierarchical approach (right: twelve user elements).

The good correlation of these results shows the relevance of the hierarchical

approach for capturing strong variations of the solution.

3.3 3D validation example

In addition to the 2D validation problem, we wished to work on three-dimensional subsystems

representative of adhesive bonded joints. Three configurations were defined: single lap shear

test (Figure 11), peeling test (Figure 12) and compression on tubes. For each one of these tests, we

used the hierarchical approach combined with a non-linear anisotropic behavior dedicated to

adhesive exhibiting high hydrostatic sensitivity (J oanns, 2007).

Starting from a conventional input file, the pre-processing replaces the standard elements of the

targeted zones by user elements with hierarchical formulation. The interpolation compatibility on

transition zones is assured. The initial degree is fixed beforehand but can evolve locally according

to the need. This local adaptation could be obtained automatically by using an error indicator

related to each edge. During this adaptation phase, it is important to use the simplest behavior

model for the adhesive (linear elasticity). Once the desired precision reached, calculation can be

launched with a non-linear and anisotropic behavior. The principal subroutine generates results

files for nodal variables and integration points evaluation. Post-processing performs data

conversions for the visualization module. It is then possible to display results within the adhesive

bonded joint (Figure 12).

14 2009 SIMULIA Customer Conference

Figure 11. Single lap joint. Elements with standard formulation are replaced by

elements with hierarchical formulation around the adhesive joint; the interpolation

compatibility on the transition zone is assured.

Figure 12. Peeling test. Post-processing performs data conversions for the

visualization module. It is then possible to display results obtained by the

hierarchical approach within the adhesive bonded joint.

4. Concluding remarks

The use of finite element methods allow the study of complex configurations. Nevertheless, the

degree of accuracy is in direct correspondence with the number and the type of elements used.

Very often, localized stresses in multi-materials structures impose the use of a great number of

2009 SIMULIA Customer Conference 15

elements. Developments of the numerical analysis led to the emergence of specific tools which

remain more or less applicable to the targeted industrial cases. A new approach, based on a

hierarchical formulation, has been presented in this paper. This tool takes into account the

localized phenomena governing the behavior of adhesive joints while guaranteeing compatibility

with a coarser industrial modeling. This work brings an appropriate response to industrial

constraints. Confrontations between experimental tests and numerical calculations are particularly

encouraging. Finally, the modularity of the implementation allows its extension to other fields of

applications such as detecting delamination on composites materials.

5. References

1. Abaqus/Standard, User's Manual, version 6.6, Hibbitt, Karlsson and Sorensen Inc, 2006.

2. Adams, R. D. and Mallick, V., A method for the stress analysis of lap joints, The J ournal of

Adhesion, vol. 38, no.3-4, pp. 199-217, 1992.

3. Babuka, I. and Szab, B. A., Finite element analysis, J ohn Wiley and Sons, 1991.

4. Besson, J., Cailletaud, G., Chaboche, J . L. and Forest, S., Mcanique non linaire des

matriaux, Herms, 2001.

5. Bigwood, D. A. and Crocombe, A. D., Non-linear adhesive bonded joint design analysis,

International Journal of Adhesion and Adhesives, vol. 10, no. 1, pp. 31-41, 1990.

6. Chaboche, J. L., Feyel, F. and Monerie, Y., Interface Debonding Models: A viscous

regularization with a limited rate dependency, International J ournal of Solids and Structures,

vol. 38, no. 18, pp. 3127-3160, 2001.

7. Cugnon, F. Automatisation des calculs lments finis dans le cadre de la mthode-p, Ph. D.

Thesis, Universit de Lige, Belgium, 2000.

8. Dean, G. D. and Crocker, L., The Use of Finite Element Methods for Design with

Adhesives, Measurement Good Practice Guide, no. 48, National Physical Laboratory, UK,

2001.

9. Dster, A., High order finite elements for three dimensional, thinwalled nonlinear continua,

Ph. D. Thesis, Technische Universitt Mnchen, Germany, 2001.

10. Fays, S., Adhesive Bonding Technology in the Automotive Industry, Adhesion and

Interface, vol. 4, no. 2, pp. 37-48, 2003.

11. J oanns, S., Caractrisation mcanique et outil daide au dimensionnement des collages

structuraux, Ph. D. Thesis, Ecole Nationale Suprieure des Mines de Paris, ParisTech,

France, 2007.

12. Peano, A. G., Hierarchies of conforming finite elements, Ph. D. Thesis, Washington

University, St. Louis, USA, 1975.

13. Zienkiewicz, O. C., Taylor, R. L. and Zhu, J . Z., The Finite Element Method, its basis &

fundamentals, Elsevier Butterworth-Heinemann, Sixth Edition, 2005.

You might also like

- Computational Methods in Nonlinear Structural and Solid Mechanics: Papers Presented at the Symposium on Computational Methods in Nonlinear Structural and Solid MechanicsFrom EverandComputational Methods in Nonlinear Structural and Solid Mechanics: Papers Presented at the Symposium on Computational Methods in Nonlinear Structural and Solid MechanicsAhmed K. NoorNo ratings yet

- Design and Optimization of Composite Parts Using Numerical SimulationsDocument6 pagesDesign and Optimization of Composite Parts Using Numerical SimulationsAndrea CalderaNo ratings yet

- Introduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsFrom EverandIntroduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsNo ratings yet

- ABQUS composites复合材料建模Document18 pagesABQUS composites复合材料建模neuchenxiao100% (1)

- Analysis of Primal and Dual Variables in Structural Shape Control by Piezoelectric Patches Using SolidDocument12 pagesAnalysis of Primal and Dual Variables in Structural Shape Control by Piezoelectric Patches Using SolidFessal KpekyNo ratings yet

- Aluminum HonneycombDocument16 pagesAluminum HonneycombMangesh ThokalNo ratings yet

- ch3Document78 pagesch3David GaoNo ratings yet

- Model Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionFrom EverandModel Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNo ratings yet

- Aluminium Honeycomb Walls Strength AnalysisDocument16 pagesAluminium Honeycomb Walls Strength AnalysisMangesh ThokalNo ratings yet

- Engineering Plasticity: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionFrom EverandEngineering Plasticity: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNo ratings yet

- Composite Modeling White Paper 2014 Rev-0-ReadDocument66 pagesComposite Modeling White Paper 2014 Rev-0-ReadTrexa GyreueNo ratings yet

- Fabrication and Characterization of Gfrp-Polyurethane Composite Sandwich Panels For Earthquake-Resistant BuildingsDocument6 pagesFabrication and Characterization of Gfrp-Polyurethane Composite Sandwich Panels For Earthquake-Resistant BuildingsIJAR JOURNALNo ratings yet

- Abaqus - Mater KirtilDocument15 pagesAbaqus - Mater KirtilBrian MenezesNo ratings yet

- MTech Semester I Exam Questions on Elasticity and PlasticityDocument2 pagesMTech Semester I Exam Questions on Elasticity and PlasticityNaren GujjarNo ratings yet

- On Teaching Finite Element Method in Plasticity With MathematicaDocument10 pagesOn Teaching Finite Element Method in Plasticity With MathematicayesullenNo ratings yet

- Multiaxial Fatigue Life PredictionDocument10 pagesMultiaxial Fatigue Life PredictionGooftilaaAniJiraachuunkooYesusiinNo ratings yet

- Cantilever Beam TutorialDocument7 pagesCantilever Beam TutorialMohammad Ahmad GharaibehNo ratings yet

- Nonlinear Ordinary Differential Equations in Transport ProcessesFrom EverandNonlinear Ordinary Differential Equations in Transport ProcessesNo ratings yet

- Sandwich Panel HistoryDocument7 pagesSandwich Panel HistoryMuhammad AhmedNo ratings yet

- Abaqus Convergence DiscussionDocument21 pagesAbaqus Convergence DiscussionBolarinwaNo ratings yet

- Flexural Analysis of Balsa Core Sandwich Composite - Failure MechaDocument104 pagesFlexural Analysis of Balsa Core Sandwich Composite - Failure MechaManjinderSinghNo ratings yet

- Composite Materials Note Form Nptel in PDFDocument33 pagesComposite Materials Note Form Nptel in PDFM.Thirunavukkarasu100% (1)

- Composite Finite Element Project 1 PDFDocument14 pagesComposite Finite Element Project 1 PDFCharan KumarNo ratings yet

- Manual For Computational Exercises: TMM4160 Fracture MechanicsDocument39 pagesManual For Computational Exercises: TMM4160 Fracture Mechanicsc1315491_513486021No ratings yet

- Abaqus QuestionsDocument12 pagesAbaqus Questionsmadhu77No ratings yet

- Galerkin MethodsDocument7 pagesGalerkin MethodsM sNo ratings yet

- Numerical ExamplesDocument20 pagesNumerical ExampleslitrakhanNo ratings yet

- Finite Element Analysis of Shell StructuresDocument59 pagesFinite Element Analysis of Shell Structuresshayan_saket3899No ratings yet

- Composites Modeler For AbaqusDocument10 pagesComposites Modeler For AbaqusrrjnrNo ratings yet

- Modern Practice in Stress and Vibration Analysis: Proceedings of the Conference Held at the University of Liverpool, 3–5 April 1989From EverandModern Practice in Stress and Vibration Analysis: Proceedings of the Conference Held at the University of Liverpool, 3–5 April 1989J. E. MottersheadNo ratings yet

- Structural Analysis Systems: Software — Hardware Capability — Compatibility — ApplicationsFrom EverandStructural Analysis Systems: Software — Hardware Capability — Compatibility — ApplicationsRating: 5 out of 5 stars5/5 (1)

- Analysis of Composite Materials With AbaqusDocument21 pagesAnalysis of Composite Materials With AbaqusPramod Rakt PatelNo ratings yet

- Serge Abrate-Impact On Composite Structures (1998) PDFDocument301 pagesSerge Abrate-Impact On Composite Structures (1998) PDFShree Biradar0% (1)

- Kurt Miller Tod Dalrymple: Rubber Material Curve Fitting With Abaqus/CaeDocument34 pagesKurt Miller Tod Dalrymple: Rubber Material Curve Fitting With Abaqus/CaePallab Jyoti DasNo ratings yet

- Abaqus Tutorial 1 Basic BracketDocument17 pagesAbaqus Tutorial 1 Basic BracketAbdel DaaNo ratings yet

- ME Structures Theory Elasticity PlasticityDocument3 pagesME Structures Theory Elasticity PlasticityameykatdareNo ratings yet

- Introduction to Finite Element Analysis using ANSYSDocument40 pagesIntroduction to Finite Element Analysis using ANSYSFaruck GNo ratings yet

- Modeling A Dome in AbaqusDocument10 pagesModeling A Dome in AbaqusAndrei Lucaciu100% (1)

- Prevent Negative Volume in Foam ModelsDocument9 pagesPrevent Negative Volume in Foam ModelsGustavo Yippeekayyay GusNo ratings yet

- Abaqus Convergence Issue For Large Deformation of Compression of A CylinderDocument31 pagesAbaqus Convergence Issue For Large Deformation of Compression of A CylinderBolarinwaNo ratings yet

- RBE2Document20 pagesRBE2zakir78No ratings yet

- Timoshenko BeamsDocument3 pagesTimoshenko BeamsCristina VlaicuNo ratings yet

- A Study On Composite Honeycomb Sandwich Panel StructureDocument5 pagesA Study On Composite Honeycomb Sandwich Panel StructureÖmer ŞenNo ratings yet

- Fatigue Life of Rubber Components: Presented By: Abdul Hakim AbdullahDocument20 pagesFatigue Life of Rubber Components: Presented By: Abdul Hakim AbdullahSyah IlhamNo ratings yet

- Composites MaterialsDocument21 pagesComposites MaterialsMayra AmandaNo ratings yet

- Abaqus Composites PDFDocument21 pagesAbaqus Composites PDFranjithkrajNo ratings yet

- Abaqus FaqDocument73 pagesAbaqus FaqTaufiq SaidinNo ratings yet

- Chapter 5 - Plastic ZoneDocument20 pagesChapter 5 - Plastic ZoneHossam SallamNo ratings yet

- Using Abaqus To Model Delamination in Fiber-Reinforced Composite MaterialsDocument18 pagesUsing Abaqus To Model Delamination in Fiber-Reinforced Composite MaterialsdashatanliNo ratings yet

- Fracture Specimen Stree AnalysisDocument15 pagesFracture Specimen Stree AnalysisGaurav PundirNo ratings yet

- Chapter 01Document38 pagesChapter 01Bu sultanNo ratings yet

- Sandwich Composite Analysis SoftwareDocument11 pagesSandwich Composite Analysis SoftwareDouglas RodriguesNo ratings yet

- Damage Evolution LawDocument15 pagesDamage Evolution LawRafael ZanettiNo ratings yet

- 5.deflections Using Energy Methods PDFDocument47 pages5.deflections Using Energy Methods PDFking burgosNo ratings yet

- Sandwich StructuresDocument7 pagesSandwich Structuresrs0004No ratings yet

- Ch#5 CST Element PDFDocument17 pagesCh#5 CST Element PDFAndre Sufadia SimorangkirNo ratings yet

- Computer Generations HistoryDocument1 pageComputer Generations HistorySri SaiNo ratings yet

- Aircraft Perfromance Modelling For ATMDocument12 pagesAircraft Perfromance Modelling For ATMSri SaiNo ratings yet

- PI Datasheet E-821 20150121Document5 pagesPI Datasheet E-821 20150121Sri SaiNo ratings yet

- Our Solar System ExplainedDocument5 pagesOur Solar System ExplainedSri SaiNo ratings yet

- Dinosaur FactsDocument1 pageDinosaur FactsSri SaiNo ratings yet

- Q A For LL ExamDocument12 pagesQ A For LL ExamSri SaiNo ratings yet

- Tutorial 8 - Stability and The S' Plane: © D.J.Dunn 1Document0 pagesTutorial 8 - Stability and The S' Plane: © D.J.Dunn 1Karthi KeyanNo ratings yet

- Intelligent Fault Diagnosis and Prognosis For Engineering Systems PDFDocument454 pagesIntelligent Fault Diagnosis and Prognosis For Engineering Systems PDFSri Sai100% (3)

- DDocument97 pagesDSri SaiNo ratings yet

- Rto - Kar.nic - in Cmv33Document2 pagesRto - Kar.nic - in Cmv33Donald MelansonNo ratings yet

- Data Acquisition in LabVIEW PDFDocument53 pagesData Acquisition in LabVIEW PDFSurajitBaradNo ratings yet

- Human BodyDocument63 pagesHuman BodyNilmani Singh100% (10)

- DAQmx M SeriesDocument424 pagesDAQmx M SeriesCal SargentNo ratings yet

- Piezo Energy Harvester: Piezoelectric Energy Harvesting KitDocument2 pagesPiezo Energy Harvester: Piezoelectric Energy Harvesting KitNadhifa MldNo ratings yet

- Quad With Tilt RotorDocument8 pagesQuad With Tilt RotorSri SaiNo ratings yet

- Reflective Optical Sensors GuideDocument10 pagesReflective Optical Sensors GuideSri SaiNo ratings yet

- ,DanaInfo Onlinelibrary Wiley Com+eae242Document10 pages,DanaInfo Onlinelibrary Wiley Com+eae242Sri SaiNo ratings yet

- Balanced ScorecardDocument34 pagesBalanced ScorecardSri SaiNo ratings yet

- Modern Helicopter AerodynamicsDocument53 pagesModern Helicopter AerodynamicsAulia®100% (1)

- 2GC PMA02 1fDocument10 pages2GC PMA02 1fWahyu WibowoNo ratings yet

- 10 1 1 149Document6 pages10 1 1 149Dominique GruelNo ratings yet

- Quadcopter Full ControlDocument6 pagesQuadcopter Full ControlSandeepsrivatsa100% (1)

- Quad With Tilt RotorDocument8 pagesQuad With Tilt RotorSri SaiNo ratings yet

- Heli TheoryDocument105 pagesHeli TheorySri SaiNo ratings yet

- Rockets and People Volume IstDocument436 pagesRockets and People Volume IstΓιαννης Μπαζιωτης100% (1)

- Quad With Tilt RotorDocument8 pagesQuad With Tilt RotorSri SaiNo ratings yet

- Nokia 1100Document46 pagesNokia 1100kor_m8100% (1)

- Smart Flapping Wing Using Macro-Fiber Composite ActuatorsDocument12 pagesSmart Flapping Wing Using Macro-Fiber Composite ActuatorsSri SaiNo ratings yet

- Lesson - 2: Ports or Devices Communication and Communication - ProtocolsDocument41 pagesLesson - 2: Ports or Devices Communication and Communication - ProtocolsSri SaiNo ratings yet

- WilliamsDocument361 pagesWilliamsSri SaiNo ratings yet

- Textile Technology BookDocument454 pagesTextile Technology BookSivam RaviNo ratings yet

- Adf4360 7Document28 pagesAdf4360 7arulselvambeNo ratings yet

- PTT205 Heat and Mass Transfer: EvaporatorDocument43 pagesPTT205 Heat and Mass Transfer: Evaporatorkkk100% (1)

- Specifications For NTC Thermistor: Dimensions (MM)Document9 pagesSpecifications For NTC Thermistor: Dimensions (MM)aliNo ratings yet

- Rotating Machinery Energy Loss Due To MisalignmentDocument4 pagesRotating Machinery Energy Loss Due To MisalignmentMagoroku D. YudhoNo ratings yet

- Sprint Backlog Specified by Example: Effective AgileDocument40 pagesSprint Backlog Specified by Example: Effective AgileArellano Méndez Yonder StevensNo ratings yet

- Exoskeletons For Human Power Augmentation - BLEEXDocument6 pagesExoskeletons For Human Power Augmentation - BLEEXevoshendorNo ratings yet

- UART Component Examples and Interrupt-Driven Serial CommunicationDocument5 pagesUART Component Examples and Interrupt-Driven Serial CommunicationCarlos Morales CarbajalNo ratings yet

- Workshop IDocument6 pagesWorkshop IValentina GonzálezNo ratings yet

- Duo Binary Modulation For Optical SystemsDocument10 pagesDuo Binary Modulation For Optical SystemsErasmo VizzaccaroNo ratings yet

- Report On Modal Analysis of A Hollow CylinderDocument2 pagesReport On Modal Analysis of A Hollow CylinderkbhattacNo ratings yet

- 2 RCC2 PDFDocument1 page2 RCC2 PDFSaurabh PandeyNo ratings yet

- CWCT Curtain Wall Installation HandbookDocument34 pagesCWCT Curtain Wall Installation HandbookmoudshahineNo ratings yet

- Advantages of Test PlanDocument3 pagesAdvantages of Test PlanGayu ManiNo ratings yet

- Modul Pelatihan Software PlaxisDocument26 pagesModul Pelatihan Software PlaxisTeguh Setyo PurwantoNo ratings yet

- AcademicBulletin2015 16Document140 pagesAcademicBulletin2015 16Sreekumar KsNo ratings yet

- Drive Control (CPC) Unit Component DescriptionDocument2 pagesDrive Control (CPC) Unit Component Descriptionrudi100% (1)

- Fif-12 Om Eng Eaj23x102Document13 pagesFif-12 Om Eng Eaj23x102Schefer FabianNo ratings yet

- A Framework For 21st Century Teaching and LearningDocument6 pagesA Framework For 21st Century Teaching and LearningFiorello Abenes100% (1)

- How Wireless WorksDocument123 pagesHow Wireless WorksAjay GargNo ratings yet

- Workshop (03W 2205)Document152 pagesWorkshop (03W 2205)Евгений Губарев0% (2)

- EIT062 Software TestingDocument190 pagesEIT062 Software TestingMayank SharmaNo ratings yet

- U.G Tank Plan & Details 05-03-18-Foundation & Details PDFDocument1 pageU.G Tank Plan & Details 05-03-18-Foundation & Details PDFbaroraNo ratings yet

- GTM Unix Prog Manual 4.4Document605 pagesGTM Unix Prog Manual 4.4maxedroomNo ratings yet

- D-Link AC750 User ManualDocument101 pagesD-Link AC750 User Manualibcunha100% (1)

- UML notations and symbols summaryDocument6 pagesUML notations and symbols summaryHabibul HaqNo ratings yet

- Vehicle owner's manual essential safety guideDocument232 pagesVehicle owner's manual essential safety guideHamzah Hussain100% (2)

- Management Information System Rensi-VillaDocument3 pagesManagement Information System Rensi-VillaVilla SantikaNo ratings yet

- Cadbury Crisis Management with Integrated Marketing CommunicationsDocument26 pagesCadbury Crisis Management with Integrated Marketing CommunicationsAkash YadavNo ratings yet