Professional Documents

Culture Documents

Maharshi Dayanand University Rohtak: Syllabus and Courses of Reading For M.Tech (Mechanical Engineering)

Uploaded by

Ramesh PandaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Maharshi Dayanand University Rohtak: Syllabus and Courses of Reading For M.Tech (Mechanical Engineering)

Uploaded by

Ramesh PandaCopyright:

Available Formats

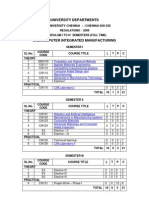

SYLLABUS M.Tech. ( Mechanical Engg.

MAHARSHI DAYANAND UNIVERSITY, ROHTAK

Maharshi Dayanand University Rohtak

Syllabus and Courses of Reading for M.Tech (Mechanical Engineering)

(Manufacturing and Automation)

Examination

Session 2011-2012

Available from : Incharge (Publication) Maharshi Dayanand University Rohtak-124 001 (Haryana)

Price : At the Counter : Rs. 50/-

By Regd. Parcel : Rs. 90/By Ordinary Post : Rs. 70/-

SYLLABUS M.Tech. ( Mechanical Engg.)

2 Third Semester

Subject Code 951 953 -955 957 959

MAHARSHI DAYANAND UNIVERSITY, ROHTAK

M.TECH (MANUFACTURING AND AUTOMATION) SYLLABUS 20011-12 The Credit requirements of the course : 65 Core courses : 10 Programme Elective Courses : 02 General Elective : 01 CORE COURSES First Semester

Subject Code 831 832 833 834 Subject Credit (L-T-P) Marks Weightage Theory Sessional 3 3 3 3 3-0-0 3-0-0 3-0-0 3-0-0 100 100 100 100 50 50 50 50

Subject

Credit (L-T-P) Marks Weightage Theory Sessional 4 3 3 1 1 5 17 3-2-0 3-0-0 3-0-0 0-0-2 0-0-2 0-0-10 9-2-14 100 100 100 Ext. 25 25 100 425 50 50 50 Int. 25 25 100 325

Mechanical Design II Simulation and Analysis General Elective CIM Lab Seminar Minor Project Total

Metal Forming Analysis Welding and allied processes Mechatronics & product design Design, Planning and control of production systems Foundry Technology Computational Lab Welding Lab Mechatronics Lab Crash Course Total

Note :The student will have to select one subject from list of Program Elective-I and one subject from list of Program Elective-II and one subject from list of General Elective as under : LIST OF PROGRAM ELECTIVE - I

835 836 837 838 917

3 1 1 1 0 18

3-0-0 0-0-2 0-0-2 0-0-2 3-0-0 18-0-6

100 Ext. 25 25 25 * 575

50 Int. 25 25 25

921 923 925 927 970

ROBOTIC ENGINEERING INDUSTRIAL INSPECTION QUALITY CONTROL TECHNIQUES DESIGN AND METALLURGY OF WELDED JOINTS LIST OF PROGRAM ELECTIVE - II AUTOMOBILE ENGINEERING FINITE ELELMENT METHOD MACHINE TOOL DYNAMICS ARTIFICIAL INTELLIGENCE IN MANUFACTURING LIST OF GENERAL ELECTIVE - II VALUE ENGINEERING ADVANCED THEORY OF VIBRATIONS ENERGY, ECOLOGY AND ENVIRONMENT TOTAL QUALITY MANAGEMENT COMPUTER INTERGRATED MFG.

325

972 974 976

* Student has to pass the examination No. credit is given for this subject SECOND SEMESTER Subject Code 904 906 -Subject Project Management Mechanical Design I Prog. Elective I Prog. Elective- II Automation in Mfg. Automation Lab CAD/CAM Lab Cultural awareness & Communication Total 18 18-2-4 550 300 * Student has to pass the examination No. credit is given for this subject Credit (L-T-P) Marks Weightage Theory Sessional 3 4 3 3 3 1 1 1 3-0-0 3-2-0 3-0-0 3-0-0 3-0-0 0-0-2 0-0-2 3-0-0 100 100 100 100 100 Ext. 912 914 916 25 25 * 50 50 50 50 50 Int. 25 25

980 982 984 986 988

-908

FOURTH SEMESTER Subject Code 952 Subject Credit (L-T-P) Marks Weightage External Sessional 12 12 0-0-24 0-0-24 400 400 100 100

Major Project Total

SYLLABUS M.Tech. ( Mechanical Engg.)

MAHARSHI DAYANAND UNIVERSITY, ROHTAK

M.D. University, Rohtak (Haryana) Scheme of Studies & Examination for Master of Technology in Mechanical Engineering (Specialization : Manufacturing & Automation) The performance of the student of M.Tech Electrical Device & Power System Course shall be graded on the basis of percentage of marks and corresponding grades as mentioned below : A) Marks 85 75 65 50 40 00

A+ A B C D E < < < < < <

L 3

T 0

P 0

831 : METAL FORMING ANALYSIS Sessional : 50 Marks Theory : 100 Marks Total : 150 Marks Duration of Exam : 3 Hrs.

Grade

A+ A B C D E Performance Excellent Very Good Good Fair Pass Repeat < < < < < <

Marks

100 85 75 65 50 40 Division First First First Second Third Fail

Stress- Strain relations in Elastic and plastic Deformations, Yield Criteria for Ductile Metals, Work hardening and Anisotropy in Yielding, Flow Curves. Formulations of plastic deformation problems, application of theory of plasticity for solving metal forming problems using Slab method, Upper and lower Bound methods, Slip line field theory. Effects of temperature and strain rate in metal working, friction and lubrication in Hot and Cold working. Technology and analysis of important metal forming processesForging, Roiling, Extrusion. Wire drawing, Sheet Metal forming processes like Deep drawing, Stretch forming, Bending Application of Finite Element Methods to Metal Forming Processes- special Discretization, Shape function, Stiffness matrices and their assembly, Implicit and explicit formulations, Elasto-plastic approximations, Lagrangian Vs Eularian schemes, Material integration schemes, auxiliary equations for contact, friction and incompressibility, Thermo-mechanical problem formulation, steady state solutions for Drawing, Forging, rolling and extrusion problems Case Studies- analysis and validation of metal forming processes problems by standard softwares. Forming defects in products and their critical effects, remedies. An introduction to use of International standards in Metal Forming Problem solutions and system Design.

Letter Grades

Note : The candidate who have passed all the semesters examination in the first attempt obtaining at least 75% marks in aggregate shall be declared to have passed in the first division with Distinction mentioned in the degree. B) Actual percentage of Marks Obtained and Corresponding grades should be mentioned on detailed marks certificate of student. To obtain D grade a student must have secure at least 40% mar ks in eac s ubject of the semester Examination. Student who earned and E grade or less than 40% marks in any subject shall have reappear in that subject.

C)

SYLLABUS M.Tech. ( Mechanical Engg.)

MAHARSHI DAYANAND UNIVERSITY, ROHTAK

REFERENCE BOOKS: 1. Metal Forming Analysis- R. H. Wagoner, Cambridge University Press. 2. Theory of Elasticity- Dally and Riley 3. Mechanical Metallurgy- Dieter, McGraw Hill Inc. Metal Forming Handbook by H Frontzek, M Kasparbauer , Springer Verleg Note : In the Semester Examination, the exmainer will set eight questions in all, covering the entire syllabus and the students will be required to attempt only five questions.

Arc welding processes : Electric arc welding principle, MIG: welding equipment and processes, shielding gas, types of metal transfer. Tungsten inert gas arc welding (GTAW): - welding equipment, electrodes, inert gases and torches. Submerged arc welding (SAW):- principle of processes, applications, fluxes and welding electrodes used. CO2 welding: - difference from MIG welding, Principle of operation, equipment, welding parameters and applications. Solid state welding: Introduction, main features and applications of Ultrasonic welding, Friction welding and Explosive welding. Welding of plastics: Difficulties in welding of Plastics, Processes for welding of Plastics. Weldability of specific materials: Stainless Steel, Aluminum and Cast Iron, Surfacing and metal spraying: Surfacing methods such as SMAW, MIG, TIG, SAW.Thermal spraying: Introduction, Procedures, Applications, Advantages and Disadvantages. Thermal cutting of metals: introduction, types, principle and operation of flame and plasma cutting. Under water Welding: Introduction, methods and applications. Automation in Welding: Introduction, Semiautomatic welding, Automatic welding, Welding mechanization, Flexible Automated Welding, Robotic welding, Types of Welding Robots, Robot Selection Mechanics, Joint tracking system. REFERENCE BOOKS: 1. Modern welding technology:- carry H. B. (PH). 2. Weldin" technology :- A. C. Devis 3. Welding and welding Technology :- Little (TMH) 4. Welding technology :- R. S. Parmar

832 : WELDING AND ALLIED PROCESSES L 3 T 0 P 0 Sessional : 50 Marks

Theory : 100 Marks Total : 150 Marks Duration of Exam : 3 Hrs. Review of welding processes like gas, arc and resistance welding. Welding Power Sources: Types of power sources, External VI characteristics for constant current and constant voltage power sources, Rectifiers, Solid-state Rectifiers, Inverter systems, Duty cycle. Arc welding consumables : Types of electrodes, AWS and Indian system of classification and coding of covered electrode for mild steel, Shielding gases and associated mixtures.

Metal transfer : Short circuit/ dip transfer. Free flight. Globular type. Spray type, Forces affecting metal transfer. Weld bead geometry and shape factors, Weld dilution.

SYLLABUS M.Tech. ( Mechanical Engg.)

MAHARSHI DAYANAND UNIVERSITY, ROHTAK

5. AWS- welding handbook (IV - VI) Edition Note : In the Semester Examination, the exmainer will set eight questions in all, covering the entire syllabus and the students will be required to attempt only five questions.

System models - Engg. Systems, rotational, translation, elected mechanical, Hydraulic mechanical system., System Transfer functions. First-second order system in series. Design and selection of Mechatronics systems namely sensors line encoders and revolvers, stepper and servomotors Ball screws, solenoids, line actuators and controllers with application to CNC system, robots, consumer electronics products etc, Design of a Mechatronic Product using available software CAD packages MATLAB and SIMULINK. REFERENCE BOOKS: 1. Mechatronics by W.Bolton, published by Addison Worley Longman Pvt. Ltd., India Brander, Delhi. 2. Automation Production System System and CIMS by Mikel P Grooer, Phentice Hall of India Pvt. Ltd, New Delhi. Note : In the Semester Examination, the exmainer will set eight questions in all, covering the entire syllabus and the students will be required to attempt only fivwe questions.

833 : MECHATRONICS PRODUCT DESIGN L 3 T 0 P 0 Sessional : 50 Marks

Theory : 100 Marks Total : 150 Marks Duration of Exam : 3 Hrs. Introduction to Mechatronics systems and components, Principles of basic electronics - Digital logic, number system logic gates, Sequence logic flip flop system, JK flip flop, D-flip flop. Microprocessors and their applications - Microcomputer computer structure/rnicrocontrolles, Integrated circuits - signal conditioning processes, various types of amplifiers, low pass and high pass filters. Sensors -sensors and transducers. Displacement, position proximity sensors, velocity, force sensors. Fluid pressure temperature, liquid level and light sensors. Selection of sensors., Actuators, Pneumatic and hydraulic systems, Mechanical actuation system. Electrical actuation system. Other Electrical/ Electronic hardware in Mechatronic system. Principles of Electronic system communication, Interfacing, A.D. and D.A.converters. Software and hardware principles and tools to build mechatronic systems., Basic system models mathematical models, mechanical and other system Building blocks.

835 : FOUNDRY TECHNOLOGY L 3 T 0 P 0 Sessional : 50 Marks

Theory : 100 Marks Total : 150 Marks Duration of Exam : 3 Hrs. 1. Items ( Domestic and Engg.) made by foundry technology. Advantage and limitations of foundry technology and other manufacturing process. 2. Castability and factors favoring castability. Ferrous and Non ferrous casting metals and alloys and items made of them.

SYLLABUS M.Tech. ( Mechanical Engg.)

10

MAHARSHI DAYANAND UNIVERSITY, ROHTAK

3. Melting furnaces for cast iron , cast steels, aluminium alloys, brass and bronzes. 4. Solidification of castings. 5. Mold design considerations: Conceptual, functional and production phase. Pattern and core design considerations, traffic rules applications. Examples, case studies. 6. Gating system elements: objectives,practical rules,optimal time filling, types of pouring basin, types of gates, types of risers. 7. Special casting methods: Gravity die casting, cold chamber die casting, hot chamber die casting, investment casting, centrifugal casting,shell mold casting.continuous casting. 8. Rough cleaning ( Fettling ) and surface cleaning of castings. 9. Casting inspection. 10. Repair and salvage of castings. 11 .Heat treatment of castings. 12. Quality control of castings. 13. Pollution control in foundry. 14. Modernisation of foundry. REFERENCE BOOKS: 1. Principal of metal casting by Richard W.Heine , Carl R Hoper. Philip C. RosenthaT, Tata Me Graw Hill. 2. Principal of foundary technology by P. L. Jain , Tata Me Graw Hill 3. Foundary practice by W.H. Salmon 4. Principles of manufacturing materials and processes by J. S. Campbell, Tata Me Graw Hill.

5. Materials and processes in manufacturing by E. P. degnamo, McMillan publishing 6. Production technology by P. C. Sharma, S. Chand and Co. 7. American Standard of metals ( ASM ) ( Vol. 1-14 ) Note : In the Semester Examination, the exmainer will set eight questions in all, covering the entire syllabus and the students will be required to attempt only five questions.

836 : COMPUTATIONAL LAB L T P 2 Sessional : 25 Marks Theory : 25 Marks Total : 50 Marks Duration of Exam : 3 Hrs. Experiment No. 1 & 2 Modelling in 2- D & Image scanning using Pro- E. Experiment No. 3 & 4 Modelling in 3- D of machine tool parrs like gear details, machine tool beds, tai'stocks, and assembly drawings of machine tools like lathe machine components, power drives, jigs & fixtures, power presses etc. using Pro- E. Experiment No. 5 & 6 Use of various types of surfaces in 3- D modelling, animation features and other editing entities in machine tool assemblies in Pro- E. Experiments No. 7 & 8 Kinematic and dynamic simulation of various mechanisms in machines, process simulation like Pro- Cast, Pro- Mould and other machining features.

SYLLABUS M.Tech. ( Mechanical Engg.)

11

12

MAHARSHI DAYANAND UNIVERSITY, ROHTAK

Experiment No. 9 & 10 Tool path generation, Part programming- G& M Codes development for machining operations using Pro- E, Physical interpretation of machining features and tool geometries. Note : Students will have to perform at least 8 experiments out of the above list. L T P 2

838 : MECHATRONICS LAB Sessional : 25 Marks Theory : 25 Marks Total : 50 Marks Duration of Exam : 3 Hrs. LIST OF EXPERIMENTS: 1. To verify truth table of various gates such as AND,OR,NOR.NOT,etc. 2 3 4 5 6 7 8 9 To realize a logic equation Y=AB+CD. Selection of sensor for a particular application from Catalogue/ Internet. Design a mechatronics product/system and incorporate application of mechatroiiics for enhancing product values. To study the hardwares and softwares of mechatronics kit. To move a table in X-direction within the range of proximity sensors using Control-X software. To rotate a table using DAC system. To move a table in Y-direction within the range of proximity sensors using Control-X software. To run a motor with PLC.

837 : WELDING LAB L T P 2 Sessional : 25 Marks Theory : 25 Marks Total : 50 Marks Duration of Exam : 3 Hrs. List of Experiments in Welding 1. To study Heat flow in Welding (Equipment for use-Gas Welding equipment) 2. To study Bead Geometry, Hardness of Bead, Micro structure of welding Bead in case of: i) MIG Welding ii) SAW Welding

iii) FCAW Welding (By changing electrode diameter & carriage speed) 3. To conduct under water welding ( to study bead shape & microstructure) Note : Students will have to perform at least 8 experiments out of the above list.

10 To run a conveyor with computer. 11 To study the movement of actuating cylinders and sensors. 12 To study mechatronics and their interfacing in a CNC machine. 13 Life prediction from computer programme based on mathematical model. Note : Students will have to perform at least 8 experiments out of the above list.

SYLLABUS M.Tech. ( Mechanical Engg.)

13

14

MAHARSHI DAYANAND UNIVERSITY, ROHTAK

904 : PROJECT MANAGEMENT L 3 T 0 P 0 Sessional : 50 Marks Theory : 100 Marks Total : 150 Marks Duration of Exam : 3 Hrs. 1. Theory & Background : Definitions, hard & soft projects, multiproject management, program management , project phases, project control project groups. Go/no go decisions. 2 Idea Phase : Idea selction, development of project contract, determination of project organization, development of project order. 3 Defintion Phase : Phase steps : Project description, project results, work breakdown structure, Input management, Project leader ship. 4 Planning Phase : Development of responsibility matrix, detail project planning, risk & change analysis, arranging input. 5 Implementation Phase : Project monitoring & control, project adjustment, dealing with people. 6 Implementation & After Care : Evaluation and closure of a project. REFERENCE BOOKS: 1. Project Management handbook, Cleland , D.I. and W.R. King, USA. 2. Project Management Body of Knoweldge (PMBOK), Project. 3. Handbook for project oriented organization, Rath S. Hoogland, R. and Turner, J.R. Note : In the Semester Examination, the exmainer will set eight questions in all, covering the entire syllabus and the students will be required to attempt only five questions. L 3 T 2 P -

906 : MECHANICAL DESIGN-I Sessional : 50 Marks Theory : 100 Marks Total : 150 Marks Duration of Exam : 4 Hrs. 1. Concept Desgin : Brainstorming methods and sketching 2 Quality Function Development. 3 Material Characteristics : Mechanical, thermal and electrical properties. 4 Design : Design for assembly. Design for manufacturing. 5 Production technologies : Metal forming, casting , maching, surface treatment, welding, bonding, fastening, clinching. REFERENCE BOOKS: 1. Quality Function development ,L. Cohen. 2. Manfacturing Engg. : Principles for Organization, D.T. Koenig. 3. Materials Science and Engineering : An Introduction , W.D. Callister Jr. 4. Handbook of Aluminum : Alloy Production and Materials Manfacturing Vol. 2, G.E. Totten. 5. CAD Software Catia, Dassault system. Note : In the Semester Examination, the exmainer will set eight questions in all, covering the entire syllabus and the students will be required to attempt only five questions.

SYLLABUS M.Tech. ( Mechanical Engg.)

15

16

MAHARSHI DAYANAND UNIVERSITY, ROHTAK

908 : AUTOMATION IN MANUFACTURING L 3 T 0 P 0 Sessional : 50 Marks

Theory : 100 Marks Total : 150 Marks Duration of Exam : 3 Hrs. 1. Introduction: Automation in Production System, Principles and Strategies of Automation, Basic Elements of an Automated System, Advanced Automation Functions, Levels of Automations, introduction to automation productivity.

destruction devices, logic devices, schimit triggering devices, developing pneumatic circuits for automatic die casting machine. 7. Modeling and Simulation for manufacturing Plant Automation: Introduction/ need for system Modeling, Building Mathematical Model of a manufacturing Plant, Modern ToolsArtificial neural networks in manufacturing automation, AI in manufacturing, Fuzzy decision and control, robots and application of robots for automation. REFERENCE BOOKS: 1. Handbook of design, manufacturing and Automation : R.C. Dorf, John Wiley and Sons. 2. Automation, Production Systems and Computer Integrated Manufacturing, M.P.Groover, Pearson Education. 3. Industrial Automation : W.P. David, John Wiley and Sons. 4. Computer Based Industrial Control, Krishna Kant, EEE-PHI 5. An Introduction to Automated Process Planning Systems, Tiess Chiu Chang & Richard A. Wysk 6. Manufacturing assembly Handbook:- BrunoLotter 7. Anatomy of Automation, Amber G.H & P. S. Amber, Prentice Hall. 8. Performance Modeling of Automated Manufacturing Systems, Viswanandham, PHI. 9. Automatic process control system and Hardware - R.P. Hunter, Prentice Hall. Note : In the Semester Examination, the exmainer will set eight questions in all, covering the entire syllabus and the students will be required to attempt only five questions.

2. Material handling systems: Overview of Material Handling Systems-Rotary feeders, oscillating force feeder, vibratory feeder, elevator type and Centrifugal type feeders, Principles and Design Consideration, Material Transport Systems, Storage Systems. 3. Automated Manufacturing Systems: Components, Classification and Overview of Manufacturing Systems, Manufacturing Cells, GT and Cellular Manufacturing, FMS, FMS and its Planning and Implementation, Flow lines & Transfer Mechanisms, Fundamentals and Analysis of Transfer Lines, product design for automatic assembly. 4. Control Technologies in Automation: Industrial Control Systems, Process Industries Verses Discrete-Manufacturing Industries, Continuous Verses Discrete Control, Computer Process and its Forms. Sensors, Actuators and other Control System Components. 5. Evaluation of automatic production: product manufacturabiiity, orientation devices- active and passive devices, parts orientation and escapement. 6. Pneumatic and hydraulic components and circuits: Boolean algebra, pneumatic sensors and amplifiers, jet

SYLLABUS M.Tech. ( Mechanical Engg.)

17

18

MAHARSHI DAYANAND UNIVERSITY, ROHTAK

912 : AUTOMATION LAB L T P 2 Sessional : 25 Marks Theory : 25 Marks Total : 50 Marks Duration of Exam : 3 Hrs. List of experiments : 1. To study the hardware of a retrofit and CNC machine tools. 2. Selection of various equipments required with the specifications from Internet/Catalogue: To convert a manual machine tool/system into an automatic machine tool/system. 3. To write programme with G code and M code for a component. 4. To simulate machining of component using PRO- E. 5. Study and applications of Hydaulic software. 6. Study and applications of Pneumatic software. 7. Study and applications of Robotic software. 8. Study and applications of PLC software. 9. To design an automated part feeder. 10. Developing pneumatic circuits for machines and systems. Note : Students will have to perform at least 8 experiments out of the above list. 914 : CAD/CAM LAB L T P 2 Sessional : 25 Marks Theory : 25 Marks Total : 50 Marks Duration of Exam : 3 Hrs. List of Practicals SECTION -I 1. Develop a general purpose code to cany out the Rotation of

an object about an axis passing through two points. 2. Develop a general purpose code to carry out i) an Orthographic projection

ii) Dimetric projection , given foreshortening factor Fz. iii) An Isometric projection iv) A Perspective Projection given Zc, 3. Develop general purpose code, given two arbitrary projections and the respective transformation matrices and the reconstructed coordinates of the vertices of the Object. 4. Develop a general purpose code to carry out the Reflection of an Object about an arbitrary plane passing through Three points. SECTION -II 1. Develop a general purpose code for integrated i) Cubic Spline with Different Boundary conditions

ii) Bezier curve iii) B- spline - its Various types and Best Fit B- spline. Given: a) Coordinates of the Control Points b) Boundary conditions , if any. c) Order of the curve, if required, and Match the output to projected image of any CAD/CAM package. SECTION - III 1. Develop an optimized Tool Path for Economic Machining and generate the same in GUI ( IDEAS/PRO-E/any CAD software) for interpretation.

SYLLABUS M.Tech. ( Mechanical Engg.)

19

20

MAHARSHI DAYANAND UNIVERSITY, ROHTAK

2. Study of Graphics Formats and Conversion from one format to another. 3. Generate the Meshing of the CONICAL Cylindrical Surface (a part of stepped cylindrical surface) using any simulation Package. 4. study of OpenGL programming for the customization of any CAD package. 5. Development of following surface patches : i) Bilinear Coons Patch

4. Prototying : Rapid prototyping, hammer forming. 5. Design of Experiments, test methods. 6. Risk Analysis : Failure modes and effect analysis, root cause analysis. REFERENCE BOOKS: 1. Rapid prototying ; Principles and applications, R.I.Noorani. 2. GD & T for Mechanical Design, G.R. Cogono. Note : In the Semester Examination, the exmainer will set eight questions in all, covering the entire syllabus and the students will be required to attempt only five questions.

ii) Tensor Product Bezier Surface. SECTION - IV 1. Solid Modelling Exercises using any CAD/CAM package. (from a given list of 10 Tutorials) 2. Generative machining interpretation for various tool paths for machining of Curved surfaces. Note : Students will have to do at least half of practicals in each sectoin.

953 : SIMULATION AND ANALYSIS L 3 T 0 P 0 Sessional : 50 Marks Theory : 100 Marks Total : 150 Marks Duration of Exam : 3 Hrs. 1. Finite Element Analysis 2 Computational Fluid Dynamics

951 : MECHANICAL DESIGN-II L 3 T 2 P Sessional : 50 Marks Theory : 100 Marks Total : 150 Marks Duration of Exam : 4 Hrs. 1. Cost Engineering : Integrated cost price calculation, Activity based costing, Toolibng Amortizing based costing, Tooling amortizing, Budgeting,cost estimating, cost down emgineerign. 2 Tolerance Design ; Geometry Dimensioning & Tolerancing 3. Dimensioning and Packaging

REFERENCE BOOKS: 1. Finit Element Analysis with Error Estimators : An Introduction to the FEM and Adaptive Error Analysis for Engineering Students, J.E. Akin. 2. Computational Methods for Fluid Dynamics, J.H. ferziger. 3. Accident Injury , A.M. Nahum. 4. The Multibody System Approach to Vehicle Dynamics, M. Blundell.

SYLLABUS M.Tech. ( Mechanical Engg.)

21

22

MAHARSHI DAYANAND UNIVERSITY, ROHTAK

5. Introduction to Physical Modelling with Modelling, m. Tiller. 6. Vehicle Refinement : controlling Noise and Vibration in Road, M. Harrison. Note : In the Semester Examination, the exmainer will set eight questions in all, covering the entire syllabus and the students will be required to attempt only five questions.

Programmes Electives - I 921 : ROBOTIC ENGINEERING L 3 T 0 P 0 Sessional : 50 Marks Theory : 100 Marks Total : 150 Marks Duration of Exam : 3 Hrs. 1. Introduction : Automation and Robotics, Historical Development, Definitions, Basic Structure of Robots, Robot Anatomy, complete classification of robots, Fundamentals about Robot technology, Factors related to use Robot performance, Basic robot configurations and their relative merits and demerits, Types of drive systems and their relative merits, the wrist and Gripper subassemblies. Concepts and Model about basic control system, transformation and block diagram of spring mass system, control loops of robotics systems, PTP and CP Trajectory planning, Different Types of controllers, control approaches of robots. 2. Kinematics of Robot Manipulator : Introduction, General description of robot manipulator, Mathematical Preliminaries on vectors and Matrices, Homogenous representation of objects, Robotic manipulator joint Co-ordinate system, Euler Angle and Euler Transformations, Roll-Pitch-Yaw (RPY), Transformation, Relative Transformation, Direct and inverse Kinematics; solution, D H Representation and displacement Matrices for standard configurations, Geometrical approach to Inverse Kinematics. Homogeneous Robotic differential transformation : Introduction, Jacobian transformation in Robotic Manipulation. 3. Robotic Workspace and Motion Trajectory : Introduction, General structures of robotic workspaces, Manipulations with in revolute joints, Robotic workspace performance index, Extreme reraches of Robotic hands, Robotic Task

955 : CIM LAB

L T P 2 Sessional : 25 Marks Theory : 25 Marks Total : 50 Marks Duration of Exam : 3 Hrs. LIST OF EXPERIMENTS : 1. To study general features of Machining Center. 2. To prepare the CNC part program for machining a prismatic component on CNC machining centre. 3. To study the general features of a CNC Turning center. 4. To prepare the CNC part program for machining of a Cylindrical Component. 5. Study and Applications of Robotic system in Automated storage and Retrieval system. 6. Application and Control of robotic system in Flexible manufacturing System. 7. To study the general features of Automated Guided Vehicle. 8. To study the general configuration of CMM and its Application in CIM environment. 9. Machine Vision and Quality Control in CIM environment. 10. Study and Applications of Conveyer System in CIM system. 11. Study and application of CIM software. Note : Students will have to perform at least 8 experiments out of the above list.

SYLLABUS M.Tech. ( Mechanical Engg.)

23

24

MAHARSHI DAYANAND UNIVERSITY, ROHTAK

Description. Robotic Motion Trajectory Design : Introduction, Trajectory Interpolators, Basic structure of Trajectory Interpolators, Cubic Joint Trajectories. General Design consideration on Trajectories : 4-3-4 & 3-5-3 Trajectories, Admissible Motion Trajactories. 4. Dynamics of Robotic Manipulators : Introduction, Bond Graph Modeling of robotic manipulators, examples of bond Graph dynamic modeling of robotic manipulator. Brief Discussionon Lagrange - Euler (LE) Dynamic modeling of robotic manipulators : Preliminary definitions, Generalized robotic coordinates, Dynamic constraints, velocity and Acceleration of moving frames, Robotic Mass distribution and Inertia Tensors, Newton's equation, Euler Equations, The Lagrangian and Lagrange's Equations. Application of Lagrange - Euler (LE) Dynamic Modeling of Robotic Manipulators : Velocity of Joints, Kinetic Energy T of Arm, Potential Energy V of Robotic Arm, The Lagrange L, Two Link Robotic Dynamics with distributed Mass, Dynamic Equations of Motion for A General Six Axis Manipulator. 5. Robot Teaching : Introduction, Various Teaching Methods, Task Programming, Survey of Robot Level Programming Languages, A Robot Program as a Path in Space, Motion Interpolation., WAIT, SIGNAL & DELAY Commands, Branching, Robot Language Structure, various Textual Robot Languages Such as VAL II, RAIL, AML and their Features, Typical Programming Examples such as Palletizing, Loading a Machine Etc, 6. Robot Sensing & Vision: Various Sensors and their Classification, Use of Sensors and Sensor Based System in Robotics, Machine Vision System, Description, Sensing, Digitizing, Image Processing and Analysis and Application of Machine Vision System, Robotic Assembly Sensors and Intelligent Sensors. 7. Industrial Applications: Objectives, Automation in

Manufacturing, Robot Application in Industry, Task Programming, Goals of AI Research, AI Techniques, Robot Intelligence and Task Planning, Modern Robots, Future Application and Challenges and Case Studies. 8. Languages Such as VAL II, RAIL, AML and their Features, Typical Programming Examples such as Palletizing, Loading a Machine Etc, 9. Robot Sensing & Vision: Various Sensors and their Classification, Use of Sensors and Sensor Based System in Robotics, Machine Vision System, Description, Sensing, Digitizing, Image Processing and Analysis and Application of Machine Vision System, Robotic Assembly Sensors and Intelligent Sensors. 10. Industrial Applications: Objectives, Automation in Manufacturing, Robot Application in Industry, Task Programming, Goals of AI Research, AI Techniques, Robot Intelligence and Task Planning, Modern Robots, Future Application and Challenges and Case Studies. REFERENCE BOOKS: 1. A Robot Engineering Textbook - Mohsen Shahinpoor - Harper & Row publishers, New York. 2. Robotics, control vision and intelligence, Fu, Lee and Gonzalez. McGraw Hill International. 3. Introduction to Robotics, John 1 Craig, Addison Wesley Publishing. 4. Robotics for Engineers , Yoram Koren, McGraw Hill International. 5. Industrial Robotics, Groover, Weiss, Nagel, McGraw Hill International. 6. Robot Technology Fundaments, Keramas, Thomson Vikas Publication House Company. 7. Fundamentals of Robotics Analysis and Control, Schilling, PHI. 8. Introduction to Robotics, Niku, Pearson Education, Asia. 9. Foundation of Robotics, Yoshikawa, PHI (EEE).

SYLLABUS M.Tech. ( Mechanical Engg.)

25

26

MAHARSHI DAYANAND UNIVERSITY, ROHTAK

10. Robotic Engineering - An Integrated approach, Klafter, Chmielewski and Negin, PHI. 11. Robot Vision and Sensor Controls, Rooks B, Vol-3 North Holland. 12. Robot Engineering Textbook - Mohsen Shahinpoor - Harper &. Row publishers, New York. 13. Robotics, control vision and intelligence, Fu, Lee and Gonzalez. McGraw Hill International. 14. Introduction to Robotics, John 1 Craig, Addison Wesley Publishing. Note : In the Semester Examination, the exmainer will set eight questions in all, covering the entire syllabus and the students will be required to attempt only five questions. 923 : INDUSTRIAL INSPECTION L 3 Sessional : 50 Marks Theory : 100 Marks Total : 150 Marks Duration of Exam : 3 Hrs. Design consideration for Gauges and measuring instruments: material selection for gauges, hardness and surface finish, tolerance for linear and dimensional chains, limits, fits and tolerance as per Indian and international standards, design of plug gauge, snap gauge, center distance gauge. Inspection of threads and gears : thread gauge design, thread size measurement by two wire and three wire methods, vernier gear tooth gauge design. Surface textures: components of machined surface texture, specification of surface texture, surface roughness measuring device and techniques, design of pneumatic gauges in process gauging methods. Geometrical and positional tolerances T 0 P 0

Geometrical and physical limitations in measuring devices. REFERENCES: 1. Metrology:-1 .C. Gupta (Dhanpat Rai Pub.) 2. Engg. Metrology :- R. K. Rajput (S. K. Kataria and sons) 3. Metrology :- R. K. Jain. 4. PSG design data book for Gauge design. Note : In the Semester Examination, the exmainer will set eight questions in all, covering the entire syllabus and the students will be required to attempt only five questions. 925 : QUALITY CONTROL TECHNIQUES L 3 Sessional : 50 Marks Theory : 100 Marks Total : 150 Marks Duration of Exam : 3 Hrs. Statistical concepts in Qua lity Control, Graphical Representation of Grouped Data, Continuous and Discrete Probability Distributions, control limit Theorem, Introduction to Quality Control, process Control and Product Control, Chance and Assignable causes of Quality variation, Advantages of shewhart control charts, Process Control charts for variables, X, R and P charts, fixation of control limits. Type I and Type II Errors, Theory of runs, Interpretation of Out of Control points, Probability limits, Initiation of control charts, Trial control limits, Determination of aimed at value of Process Setting, Rational method of sub grouping, control chart parameters, control limits and specification limits, Natural tolerance limits, Relationship of a process in Control to upper and lower specification limits, process capability studies. Special control charts for variables, group control chart, arithmetic moving X and R charts. Geometric moving chart, control chart with reject limits, steady trend in Process average T 0 P 0

SYLLABUS M.Tech. ( Mechanical Engg.)

27

28

MAHARSHI DAYANAND UNIVERSITY, ROHTAK

with constant dispersion, trend chart with sloping limits, variable subgroup size. Variables inspection and Attributes inspection, Relative merits and demerits, Control charts for Attributes, p chart and np chart, varying control limits, high defectives and low defectives, special severe test limits, C chart, U chart, Dodge demerit chart. Quality rating, CUSUM or Cumulative sum control chart, Average run length (ARL) Relative efficiency or sensitivity of control chart. Probability theory, binomial and Poisson distribution, Acceptance Inspection, 100% Inspection, No Inspection and sampling Inspection, operating characteristic curve (O.C. curve). Effect of sample size and Acceptance number, type A and type B O.C. curves, Single, Double and Multiple sampling Plans, SS Plan. Acceptance/Rejection and Acceptance/Rectification Plans, Producers Risk and Consumer's Risk, Indifference Quality level, Average Outgoing quality (AOQ) curve, AOQL, quality protection offered by a sampling Plan, Average sample Number (ASN) curve, Average Total Inspection (ATI) curve. REFERENCE BOOKS 1. Statistical Quality control by E.L. Grant 2. Quality control and Industrial Statistics, by A.J. Duncan 3. Quality control by Dale H. Bestefield 4. Total Quality Control by A.Y. Feigenboum 5. Elementary S.O.L. by I.W.Burr, M. Dekkar Note : In the Semester Examination, the exmainer will set eight questions in all, covering the entire syllabus and the students will be required to attempt only five questions.

927 : DESIGN AND METALLURGY OF WELDED JOINTS L 3 Sessional : 50 Marks Theory : 100 Marks Total : 150 Marks Duration of Exam : 3 Hrs. Weld defects: common weld defects like weld cracks, LOP, LOF, porosity, blow holes etc., remedies and control, welding symbols. Cost analysis of welded joints: costing factors of welding jobsfabrication cost, material cost, preparation cost, finishing cost, overhead cost etc., economy in preparation and welding a job, labour accomplishment factor, cost calculation of welded jobs. Prediction and control of distortion: calculation of longitudinal contraction, transverse contraction, angular contraction due to single weld pass, control of welded distortion, and calculation of shrinkage. Residual stresses: introduction, types, effect of thermal stresses, control of residual welding stresses. Destructive and non destructive testing of welds: destructive tests, equipment required and test piece geometry for tensile test, bend test, impact test, hardness test, brittle and fatigue failure tests, non destructive tests for welds:-dye penetrate inspection, magnetic particle inspection etc. Weldability tests: definition and concept of weldability, purpose and types of weldability tests such as hot cracking test, root cracking tests, hydrogen induced cracking test, cruciform test. Weld ability of metals: welding techniques, preparation of joints and electrode types for gray cast iron welding, aluminium welding, austenitic steels , titanium and its alloys. Welding metallurgy: thermal effect of welding on parent metal, structure of fusion welds, effect of cooling rate, weld metal solidification and heat affected zone. Automation in welding: introduction and concept, classification T 0 P 0

SYLLABUS M.Tech. ( Mechanical Engg.)

29

30

MAHARSHI DAYANAND UNIVERSITY, ROHTAK

of welding automation, economics of welding automation. REFERENCE BOOKS: 1. Modern welding technology:- carry H. B. (PH). 2. Welding technology: - A. C. Devis. 3. Welding and welding Technology : Little (TMH) 4. Welding technology : R. S. Parmar. 5. AWS - welding handbook (IV- VI) Edition. 6. Elements of machine design : Pandya and shah. Note : In the Semester Examination, the exmainer will set eight questions in all, covering the entire syllabus and the students will be required to attempt only five questions. Programme Electives -II 970 : AUTOMOBILE ENGINEERING L 3 T 0 P 0 Sessional : 50 Marks Theory : 100 Marks Total : 150 Marks Duration of Exam : 3 Hrs. Chassis, Steering and suspension system : Chassis, steering column, steering rack, wheel alignment, tires, sprung and unsprung mass, springs, shock absorbers, wishbones, uprights. Power train system : Engines, transmission, clutch, shafts, differentials, fuel system,, ignition system, cooling system, exhaust system (incl. after treatment). Brake passive and active safety system : Energy absorption pedestrain protection, two circuit brake system, brake calipers, discs, master brake cylinder, brake booster, ABS, ASR, ESP, airbag systems, safety belts system. Body systems and configurations : Roadster, convertible, sallon, coupe, hatchback, 2+2, SUV panels, glazing system, mirror system.

5. Interior System (INCL.HVAC, Climate Control). 6. Electric & Electronics System and Vehicle Architecture : Wiring, data bus systems, power supply system, diagnositic and OBD systems, sensors and actuators, ECU's EMC. Performance, economy and emissions Power train efficiency, acceleration, deceleration, lunch, shiftability. Steering, ride, handling, braking, comfort Power NVH, wind NVH, road NVH Chassis, body, power train, other systems. Occupant accommodation, controls and displays, night and whether acclimatization EU law, US law, world specification.

ATTRIBUTES :

Vehicle dynamics Noise and Vibration harshness (NVH) Vehicle durability Driving environment

1.

Vehicle certification

REFERENCE BOOKS: 1. The Automotive Chassis, Reimpell, UK 2. Advanced Engine technology, H. Heisler, GE 3. Voertuigtechiniek I,II and, Wide. 4. Fahrwerktechnik : Grundlagen , Reimpell, Stoll, Betzek, Germany. 5. Fahrzeuggetriebe, Grundlagen, Auswahl, Aualegung and Konstruktion, Lecher, Naunheimer, Germany. 6. Intelligent Vehicle technology and Trend, Richard Bishop, UK. Note : In the Semester Examination, the exmainer will set eight questions in all, covering the entire syllabus and the students will be required to attempt only five questions.

2.

3.

4.

SYLLABUS M.Tech. ( Mechanical Engg.)

31

32

MAHARSHI DAYANAND UNIVERSITY, ROHTAK

972 : FINITE ELEMENT METHODS L 3 T 0 P 0 Sessional : 50 Marks Theory : 100 Marks Total : 150 Marks Duration of Exam : 3 Hrs.

b. Time integration methods: explicit, implicit, explicit-implicit methods. c. Stability, convergence and consistency d. Hyperbolic systems: structural dynamics and wave propagation e. Parabolic system: transient heat transfer f. Modal solution for natural frequencies and mode shapes g. Modal Superposition method for structural dynamics 5. Nonlinear analysis a. Nonlinear solution procedures b. Newton-Raphson, modified Newton-Raphson, and secant methods c. Line search algorithm d. Automatic time step control 6. Material nonlinearity a. Rate independent elastoplasticity with return-mapping algorithm b. Isotropic and kinematic hardening with Baushinger effect c. Consistent tangent operator d. Objective rate and finite rotation elastoplasticity e. Multiplicative decomposition and finite deformation elastoplasticity 7. Geometric nonlinearity a. Generalized strain and stress b. Total and Updated Lagrangian formulation c. Kirchhoff stress and Cauchy stress 8. Boundary nonlinearity a. Frictionless contact problems b. Penalty, Lagrange multiplier, augmented Lagrange multiplier, and perturbed Lagrange multiplier methods c. Frictional contact problems including frictional return-

1. Review of basic FEM concepts FEM Discretization and the Direct Stiffness Method: Basic concepts of structural modeling, Review of the stiffness method of structural analysis, Modeling stiffness, loads and displacement boundary conditions Formulation of Finite Elements: Mathematical interpretation of finite elements, variational formulation, Development of continuum elements, shape functions, consistent loads, Isoparametric elements for plane stress, Numerical integration, Convergence requirements. Computer Implementation of the Finite Element Method : Pre processing: model definition, Element level calculations, Equation assembly, Equation solver, Post processing: strain and stress recovery. 2. Advanced topics in linear problems : Static condensation and sub-structuring, Patch test and incompatible element, pformulation 3. Advanced Beam, Plate and Shell elements : a. Timoshenko beam theory (shear locking) b. Plate and shell theory i. ii. Thin plate and Mindlin plate (shear and membrane locking) Mixed formulation for plate and shell iii. Degenerated shell formulation

4. Dynamic analysis using FEM a. Consistent mass and lumped mass, mass lumping technique

SYLLABUS M.Tech. ( Mechanical Engg.)

33

34

MAHARSHI DAYANAND UNIVERSITY, ROHTAK

mapping algorithm d. Rigid-flexible contact and flexible-flexible contact e. Multiplicative decomposition and finite deformation elastoplasticity 9. Geometric nonlinearity a. Generalized strain and stress b. Total and Updated Lagrangian formulation c. Kirchhoff stress and Cauchy stress 10. Boundary nonlinearity a. Frictionless contact problems b. Penalty, Lagrange multiplier, augmented Lagrange multiplier, and perturbed Lagrange multiplier methods c. Frictional contact problems including frictional returnmapping algorithm d. Rigid-flexible contact and flexible-flexible contact Assignments and Tutorials are essential part of this course. Various programming and formulation problems will be assigned through the course of study. In addition, students are required to complete one project is related to computer implementation of FEM concepts, application to plasticity, solving nonlinear structural problems using commercial programs. Note : In the Semester Examination, the exmainer will set eight questions in all, covering the entire syllabus and the students will be required to attempt only five questions. L 3 T 0 P 0

974 : MACHINE TOOL DYNAMICS Sessional : 50 Marks Theory : 100 Marks Total : 150 Marks Duration of Exam : 3 Hrs. Chatter in machine Tools : sources of chatter, primary chatter, regenerative chatter, chatter frequency, forced vibration for machine tools, forced vibration due to perturbance of the cutting process, forced vibration due to perturbance of equivalent elastic system, theories of machine tool chatter: Tlusty's, Kudinovs, Tobias theories. Machine tool stability: dynamic characteristic of the cutting process, general procedure for assessing the dynamic characteristic of machine tool in single degree and many degree of freedom system, methods of reducing the instability in machine tool, dynamic acceptance tests Damping in machine tools: requirements of damping system,. Viscous dampers, active dampers. Static and dynamic analysis of machine tools: lumped parameter method, finite element method. Chatter in grinding machine. REFERENCE BOOKS : 1. Principles of machine Tools:- G.C.Sen and Amitabh Bhattacharya( New central book agency Calcutta) 2. Machine Tool Design: - S.K. Mehta (TMH) Note : In the Semester Examination, the exmainer will set eight questions in all, covering the entire syllabus and the students will be required to attempt only five questions.

SYLLABUS M.Tech. ( Mechanical Engg.)

35

36

MAHARSHI DAYANAND UNIVERSITY, ROHTAK

976 : ARTIFICIAL INTELLIGENCE IN MANUFACTURING L 3 Sessional : 50 Marks Theory : 100 Marks Total : 150 Marks Duration of Exam : 3 Hrs. Definition, basic concepts of artificial Intelligence, scope, role and potential of artificial intelligence in manufacturing, Expert systems, Popular AI application. Overview of Expert systems, architecture, comparison with procedural programming, developing Expert system for typical manufacturing domains, implementation and maintenance, stateof- art Expert system application, case study. Al theory problems, problem spaces and search, Heuristic search technique, Knowledge acquisition and knowledge representation, predicate logic, procedurals, Declarative knowledge, forward V/ s backward reasoning AI architecture, overview of advanced features, planning, learning, natural language processing, neural nets, fuzzy logic, object oriented programs. Case studies, examples of AI, theoretical concepts to manufacturing problems, CAD, CAPP, scheduling GT, CIM system. Domains welding, casting, forming, metal cutting, maintenance. Note : In the Semester Examination, the exmainer will set eight questions in all, covering the entire syllabus and the students will be required to attempt only five questions. 980 : VALUE ENGINEERING L 3 Sessional : 50 Marks Theory : 100 Marks Total : 150 Marks Duration of Exam : 3 Hrs. Introduction, Life cycle of a Product, Definition, objectives and T 0 P 0 T 0 P 0

methodology of value Engineering, Comparison with other cost reduction techniques, unnecessary cost. Quantitative definition of values, alternatives to increase value, Type of value, estimation of product quality/performance, Functions: definition, types and relationship between different functions in design of a Product, functional cost, functional worth, test for poor value, aim of value engineering. Systematic approach, Phases of value engineering Job plan: General phase, information phase, function phase creation/speculation phase, evaluation phase, investigation phase, recommendation and implementation phase. Decision /evaluation Matrix: Quantitative comparison of alternatives, estimation of weight factors and efficiency. FAST diagramming: Critical path of function, How, why and when logic, supporting and all time functions. Ground rule for FAST diagram. CASE STUDIES 1. Value Engineering - A systematic Approach - A.E. Mudge 2 3 Techniques of value analysis and value engineering - L. D. Miles Value engineering for cost reduction and product improvement HSMittal : In the Semester Examination, the exmainer will set eight questions in all, covering the entire syllabus and the students will be required to attempt only five questions. 982 : ADVANCED THEORY OF VIBRATIONS L 3 Sessional : 50 Marks Theory : 100 Marks Total : 150 Marks Duration of Exam : 3 Hrs. Single degree of freedom systems, two degree of freedom systems: spring coupled, mass coupled, vibration absorbers, and vibration isolation. T 0 P 0

Note

SYLLABUS M.Tech. ( Mechanical Engg.)

37

38

MAHARSHI DAYANAND UNIVERSITY, ROHTAK

Multi degree of freedom systems: Lagrange's equation, close couples and far coupled systems, Dunkerley's approximation method, Rayleigh method, matrix method, matrix iteration, orthogonality principle, orthogonality, expansion theorem and modal analysis, Stodola method, Holzer method, Galerkin method, Rayleigh- ritz method, .Myklested -prohl method for far coupled systems, transfer matrix method Experimental methods in vibration analysis: vibration instruments, vibration exciters, transducers and measurement devices, analyzers, vibration tests:- free and forced vibration tests. Vibration of continuous systems: Transverse, flexural, torsional vibration of beams, Timoshenko beam, Hamilton principle, vibration of plates, collocation method, Myklested prohl method. Transient vibrations: Duhame's integral, method of step input, phase plane -method, method of laplace transformation, drop test spectra by laplace transformations. Non linear vibrations: non linear vibrations and superposition principle, examples of non linear vibrations, method of dealing with non linear vibrations, phase plane trajectories, method of direct integration, perturbation method, iteration method, Fourier series.

REFERENCE BOOKS:

6. An introduction to mechanical vibrations :- Steidel (John Wiley) 7. Elements of vibration analysis :- Meirovitch (TMH) Note : In the Semester Examination, the exmainer will set eight questions in all, covering the entire syllabus and the students will be required to attempt only five questions.

984 : ENERGY, ECOLOGY AND ENVIRONMENT

L 3 Sessional : 50 Marks Theory : 100 Marks Total : 150 Marks Duration of Exam : 3 Hrs. Origin of the earth, Earth's temperature and atmosphere. Sun as a source of energy, nature of its radiation, Biological processes, photo-synthesis, Food chains, Marine ecosystem. Ecosystem theories, Autoecology. sources of energy, classification of energy sources, quality and concentration of an energy source, characteristics temperature. Fossil Fuels: coal, oil, gas, geothermal, tidal and nuclear energy. Solar, wind, hydropower, biomass. Reasources of energy and energy use pattern in different regions of the world. Environmental degradation, primary and secondary pollutants. Thermal and radioactive pollution, air and water pollution. Micro climatic effects of pollution, Pollution from stationary and mobile sources. Biological effects of radiation, heat and radioactivity disposal. Pollution abatement methods. Note : In the Semester Examination, the exmainer will set eight questions in all, covering the entire syllabus and the students will be required to attempt only five questions. T 0 P 0

1. Theory of vibration with applications:- W. T. Thomson (PHI) 2. Theory and practice of mechanical vibrations:- J. S. Rao & K. Gupta (Wiley eastern) 3. Mechanical vibration :- S. S. Rao (Addison Wesley) 4. Vibration and noise for Engineers :- Kewal Pujara (Dhanpat Rai and Co.). 5. Mechanical vibrations :- G. K. Grover and Nigam (Nem chand and sons )

SYLLABUS M.Tech. ( Mechanical Engg.)

39

40

MAHARSHI DAYANAND UNIVERSITY, ROHTAK

986 : TOTAL QUALITY MANAGEMENT L 3 T 0 P 0 Sessional : 50 Marks Theory : 100 Marks Total : 150 Marks Duration of Exam : 3 Hrs.

REFERENCE BOOKS:

1. "Total Quality Management" by Oakland (Butterworth Heinamann Ltd.) 2. "Managing for total quality from Deming to Taguchi and SPC" by Logothetis N. (PHI) 3. "Total Quality Control" by Feigenbaum A.V. (MGH) 4. "Total Quality Management" by Besterfield Dale H (Pearson Education) 5. "A slice by slice guide to TQM" by John Gilbert (Affiliated East West Press). 6. "The TQM toolkit - a guide to practical techniques for TQM" by Waller Jenny, Allen Derek and Burna Andrew (Kogan Page). Note : In the Semester Examination, the exmainer will set eight questions in all, covering the entire syllabus and the students will be required to attempt only five questions.

Introduc tion : Quality - Basic concepts, dimensions, economics of quality, quality Gurus. TQM: Definition, evolution, journey from inspection to TQM, comparison at different stages, dimensions of TQM, TQM viewpoints, reasons for adopting TQM. Introspection to TQM environment : Sphere of TQM. components of TQM. TQM - Managing Total Quality, Factors affecting TQM environment, Classification and interaction among factors. Researchers' viewpoint, TQM as a system, steps in TQM implementation, Road blocks in TQM implementation, Reasons for TQM failure. Role of soft options in TQM : Hard vs. Soft factors, Role and expectation of employer, employee, customer and supplier from organization and vice versa. Human factors in TQM, Role of top management commitment, work culture, motivation, coordination, attitude, innovation. Quality initiatives in organizations : Role of tools and techniques in TQM, Classification of tools and techniques Problem identification, Data analysis, Graphical, Creativity, Company wide. Brief description of Quality awards - MBNQA, Deming award, European quality award, Australian quality award. TQM Effectiveness : Impact of TQM, Need and difficulty in measuring TQM effect, Parameters governing effect of TQM and the attributes thereof.

SYLLABUS M.Tech. ( Mechanical Engg.)

41

42

MAHARSHI DAYANAND UNIVERSITY, ROHTAK

988 : COMPUTER INTEGRATED MANUFACTURING L 3 T 0 P 0 Sessional : 50 Marks Theory : 100 Marks Total : 150 Marks Duration of Exam : 3 Hrs. Introduction: CAD/ CAM defined, computer technology: introduction, central processing unit, types of memory, input/ output, the binary number system, computer programming languages. Automation: CIM, reasons of automation, automation strategy. Conventional Numerical Control: basic components of NC system, NC motion control system, applications of NC, advantages and disadvantages of NC, problems with conventional NC, NC controller technology, computer Numerical control, advantages of CNC, functions of CNC, Direct Numerical Control, components of a DNC system, functions of DNC, advantages of DNC. NC part programming: introduction, punched tapes in NC, tape coding and format, NC words, manual part programming, computer assisted part programming, The part programmer's job, the computer's job, NC part programming languages, APT language, geometry statements, motion statements, post processor statements, auxiliary statements. Robotics technology: joints and links, common robot configuration, work volume, drive systems, types of robot control, accuracy and repeatability, end effectors, sensors in robotics, applications of robots. Automated material Handling and FMS.: material handling function, types of material handling equipments, conveyor systems, types of conveyors, automated guided vehicle system, applications, FMS, components of a FMS, types of systems,

where to apply FMS technology, FMS workstation, planning the FMS. Computer aided quality control: Introduction, terminology in quality control, the computer in QC, contact and non contact Inspection methods- optical and non optical , computer aided testing. Computer Integrated Manufacturing systems: Introduction, types of manufacturing systems, machine tools and related equipments, material handling system, computer control system, functions of a computer in CIMS. benefits of CIMS. REFERENCE BOOKS: 1. Automation, Production systems and Computer Integrated Manufacturing :- Groover M. P. (PHI) 2. CAD/CAM : - Zimmers and Groover (PHI) 3. Approach to computer integrated design and manufacturing :- Nanua Singh (John Wiley and sons) Note : In the Semester Examination, the exmainer will set eight questions in all, covering the entire syllabus and the students will be required to attempt only five questions.

You might also like

- Multiscale Modeling of Additively Manufactured Metals: Application to Laser Powder Bed Fusion ProcessFrom EverandMultiscale Modeling of Additively Manufactured Metals: Application to Laser Powder Bed Fusion ProcessNo ratings yet

- M.tech 2013-2015Document32 pagesM.tech 2013-2015vysnktNo ratings yet

- Electrochemical Micromachining for Nanofabrication, MEMS and NanotechnologyFrom EverandElectrochemical Micromachining for Nanofabrication, MEMS and NanotechnologyRating: 4 out of 5 stars4/5 (1)

- M. Tech. Mechanical Engineering Scheme and Syllabi for Computer Integrated ManufacturingDocument51 pagesM. Tech. Mechanical Engineering Scheme and Syllabi for Computer Integrated ManufacturingAnonymous VDnLHNG7QQNo ratings yet

- Me Manufacturing Curriculum-2Document11 pagesMe Manufacturing Curriculum-2Arun KumarNo ratings yet

- M.tech. (Mechanical Engineering) Part-Time (Semester System)Document37 pagesM.tech. (Mechanical Engineering) Part-Time (Semester System)Sarabjeet SinghNo ratings yet

- Production and Industrial EngimeeringDocument47 pagesProduction and Industrial Engimeeringrathish14uNo ratings yet

- Embedded Mechatronic Systems, Volume 1: Analysis of Failures, Predictive ReliabilityFrom EverandEmbedded Mechatronic Systems, Volume 1: Analysis of Failures, Predictive ReliabilityNo ratings yet

- M.tech Mechanical Engg. (I &P)Document44 pagesM.tech Mechanical Engg. (I &P)Upender DhullNo ratings yet

- Engineering Applications: A Project Resource BookFrom EverandEngineering Applications: A Project Resource BookRating: 2.5 out of 5 stars2.5/5 (1)

- MTECH Manufacturing EnggDocument10 pagesMTECH Manufacturing EnggSudhir KumarNo ratings yet

- SAURASHTRA UNIVERSITY ME MECH CoursesDocument19 pagesSAURASHTRA UNIVERSITY ME MECH CoursesRaj K PatelNo ratings yet

- MECH Syllabus 2010-11Document55 pagesMECH Syllabus 2010-11Srinivasa Reddy NallimilliNo ratings yet

- DR. APJ ABDUL KALAM TECHNICAL UNIVERSITY STUDY SCHEME FOR B.TECH MANUFACTURING TECHNOLOGYDocument28 pagesDR. APJ ABDUL KALAM TECHNICAL UNIVERSITY STUDY SCHEME FOR B.TECH MANUFACTURING TECHNOLOGYSuraj OjhaNo ratings yet

- Tool DesignDocument29 pagesTool DesignPavan TejaNo ratings yet

- Syllabus Vjti Structural EnggDocument276 pagesSyllabus Vjti Structural EnggPravin AwalkondeNo ratings yet

- Un Conventional Machining Processes SyllabusDocument2 pagesUn Conventional Machining Processes SyllabusKalai ArasanNo ratings yet

- University of Kerala: Syllabus For Vii SemesterDocument43 pagesUniversity of Kerala: Syllabus For Vii SemesterSreekanthKottavilayilNo ratings yet

- Mechatronics SyllabusDocument41 pagesMechatronics SyllabusElstonD'cruzNo ratings yet

- Advanced ManufacturingDocument13 pagesAdvanced ManufacturingnagNo ratings yet

- UploadedFile 129816616088888750Document35 pagesUploadedFile 129816616088888750Jeyaram KumarNo ratings yet

- Ab-094 Welding Examiner SyllabusDocument8 pagesAb-094 Welding Examiner SyllabusRavindra LeleNo ratings yet

- AMIE Syllabus - Mechanical EngineeringDocument14 pagesAMIE Syllabus - Mechanical EngineeringAbhishek SharmaNo ratings yet

- Final BTech MechanicalDocument31 pagesFinal BTech MechanicalAniket GaikwadNo ratings yet

- Maulana Abul Kalam Azad University of Technology, West BengalDocument45 pagesMaulana Abul Kalam Azad University of Technology, West BengalDebarshi GhoshNo ratings yet

- Shivaji University, Kolhapur Syllabus Structure of Second Year (S.E. Auto.) Automobile Engineering Course SchemeDocument45 pagesShivaji University, Kolhapur Syllabus Structure of Second Year (S.E. Auto.) Automobile Engineering Course SchemeAmol KharatNo ratings yet

- MTech Machine Design PDFDocument41 pagesMTech Machine Design PDFswapnilNo ratings yet

- MACHINEDESIGNDocument35 pagesMACHINEDESIGNBrandon AllenNo ratings yet

- B Tech Mechanical Engineering 6thDocument17 pagesB Tech Mechanical Engineering 6thprakashkumarsenNo ratings yet

- Mechanical EngineeringDocument15 pagesMechanical EngineeringASHISH ANAND100% (1)

- AMIE Section B Syllabus MechanicalDocument23 pagesAMIE Section B Syllabus MechanicalparameshwaranpraveenNo ratings yet

- R16 B.Tech Mechanical EnggDocument34 pagesR16 B.Tech Mechanical EnggmechhodNo ratings yet

- Csvtu 8th Sem Syllabus For Mechanical EngineeringDocument34 pagesCsvtu 8th Sem Syllabus For Mechanical Engineeringveer_s0% (1)

- Me366 Advanced Metal Joining TechnologyDocument3 pagesMe366 Advanced Metal Joining TechnologyDrKim J SeelanNo ratings yet

- Production EngineeringDocument39 pagesProduction EngineeringkeepingbusyNo ratings yet

- Master of Science (Mechanical Engineering) : Graduate Modules Applied MechanicsDocument3 pagesMaster of Science (Mechanical Engineering) : Graduate Modules Applied MechanicsWajid AliNo ratings yet

- Jain Un Syllabus 4th SemDocument13 pagesJain Un Syllabus 4th SemAnshul LallNo ratings yet

- B.Tech II Year Mechanical Engineering Study Scheme for Sem IVDocument6 pagesB.Tech II Year Mechanical Engineering Study Scheme for Sem IVRoshan Virat PandeyNo ratings yet

- Machine Design TEList Spring 2016Document3 pagesMachine Design TEList Spring 2016Reynald De VeraNo ratings yet

- 31 M.E Ed R2010Document61 pages31 M.E Ed R2010Jason JohnsonNo ratings yet

- Mechanical Engineering Course on Unconventional Machining ProcessesDocument2 pagesMechanical Engineering Course on Unconventional Machining ProcessesN Dhanunjaya Rao BorraNo ratings yet

- Third Year Second Semester: Department of Mechanical Engineering - Course CatalogueDocument8 pagesThird Year Second Semester: Department of Mechanical Engineering - Course CatalogueSudeep GamerNo ratings yet

- Credits Total Marks: Sathyabama Institute of Science and TechnologyDocument1 pageCredits Total Marks: Sathyabama Institute of Science and TechnologyGiridharan RuNo ratings yet

- Course Curriculum: Uttar PradeshDocument3 pagesCourse Curriculum: Uttar PradeshHtat Myat AungNo ratings yet

- Puter Integrated Manufacturing SyllabusDocument41 pagesPuter Integrated Manufacturing SyllabusJoswa CaxtonNo ratings yet

- Me Manufacturing CurriculumDocument37 pagesMe Manufacturing CurriculumJeyaram kumarNo ratings yet

- Mechanical EngineeringDocument23 pagesMechanical EngineeringAntony AshleyNo ratings yet

- MCE 417 Course CompactDocument7 pagesMCE 417 Course CompactKEHINDE BABALOLANo ratings yet

- Computer Integrated Manufacturing 05 63xxDocument97 pagesComputer Integrated Manufacturing 05 63xxAnonymous mcFvPwzXNo ratings yet

- Machining Science: Jigs & FixturesDocument77 pagesMachining Science: Jigs & FixturesChidu KNo ratings yet

- APEGBC Eng Syllabus MechanicalDocument22 pagesAPEGBC Eng Syllabus MechanicalbaljinderNo ratings yet

- Renewable Energy TechnologiesDocument8 pagesRenewable Energy Technologiesd.sarukNo ratings yet

- Syllabus - SEM VI-DE 1 (ME-AE) - Advanced Manufacturing ProcessesDocument3 pagesSyllabus - SEM VI-DE 1 (ME-AE) - Advanced Manufacturing ProcessesAnonymous gvikC9AsDNo ratings yet

- B.Tech 6th Sem ME Final 1Document14 pagesB.Tech 6th Sem ME Final 1World TodayNo ratings yet

- M.E. MANUFACTURING ENGINEERING AU SyllabusDocument35 pagesM.E. MANUFACTURING ENGINEERING AU SyllabusJoswa CaxtonNo ratings yet

- VIIIth Semester Scheme and SyllabusDocument21 pagesVIIIth Semester Scheme and SyllabusJitesh DewanganNo ratings yet

- Ntegrated Mechanical Design: Unit 1-Fundamentals and Design of Shafts: Two MarksDocument2 pagesNtegrated Mechanical Design: Unit 1-Fundamentals and Design of Shafts: Two MarksRamesh PandaNo ratings yet

- Applied Mathematical Modelling: Sameh S. HabibDocument11 pagesApplied Mathematical Modelling: Sameh S. HabibRamesh PandaNo ratings yet

- Job Description of OPTRADocument1 pageJob Description of OPTRARamesh PandaNo ratings yet

- Frictions Stir WeldingDocument2 pagesFrictions Stir WeldingRamesh PandaNo ratings yet

- Drilling MachineDocument87 pagesDrilling MachineRamesh Panda50% (4)

- ED 9223 Mechanism Design and Simulation PDFDocument4 pagesED 9223 Mechanism Design and Simulation PDFSelva KumarNo ratings yet

- Grinding MachineDocument1 pageGrinding Machinevenkateshyadav2116No ratings yet

- Gears Cutting and GrindingDocument8 pagesGears Cutting and GrindingАлександар ВујаковићNo ratings yet

- Workshop ManualDocument77 pagesWorkshop ManualRajesh Kumar RNo ratings yet

- V Sem With ConsolidatedDocument30 pagesV Sem With ConsolidatedRamesh PandaNo ratings yet

- IENG 475 Lecture 05Document27 pagesIENG 475 Lecture 05Ramesh PandaNo ratings yet

- Unit82 Surface Grinding OperationsDocument49 pagesUnit82 Surface Grinding OperationsRamesh PandaNo ratings yet

- Turning Operations: LatheDocument74 pagesTurning Operations: LatheDinesh MuralitharanNo ratings yet

- Center Lathe 01Document32 pagesCenter Lathe 01arun_premnathNo ratings yet

- 22Document36 pages22Thangaraj ManimaranNo ratings yet

- IIIrd Sem - Mtech SyllabusDocument9 pagesIIIrd Sem - Mtech SyllabusRamesh PandaNo ratings yet

- Code No 4Document1 pageCode No 4Ramesh PandaNo ratings yet

- Ramesh 5yr Experience...Document5 pagesRamesh 5yr Experience...Ramesh PandaNo ratings yet

- Project On Acc Cement PDFDocument130 pagesProject On Acc Cement PDFAnkit TiwariNo ratings yet

- 10 1 1 718 8383 PDFDocument10 pages10 1 1 718 8383 PDFIbrahim KhanNo ratings yet

- E ABB Azipod CZ Brochure 2010-LowresDocument4 pagesE ABB Azipod CZ Brochure 2010-LowresSamuel Alves de SouzaNo ratings yet

- EscalatorDocument10 pagesEscalatorsagrikakhandkaNo ratings yet

- Mansi Gode's Family Background and EducationDocument1 pageMansi Gode's Family Background and Educationmuralidhar paraskar 1306No ratings yet

- Astm C117Document3 pagesAstm C117Balletvaki100% (1)

- Epicor10 Techrefscheduling 102300Document203 pagesEpicor10 Techrefscheduling 102300dgerritswvm100% (1)

- Microsoft Project TutorialDocument15 pagesMicrosoft Project TutorialMalaak_wNo ratings yet

- Flasking Wax EliminationDocument9 pagesFlasking Wax Eliminationh20pologtNo ratings yet

- D3 Volume-II PDFDocument259 pagesD3 Volume-II PDFKrishna ManandharNo ratings yet

- Uninyvin Cables Specifications:: Miracle Cables (India) Pvt. LTDDocument1 pageUninyvin Cables Specifications:: Miracle Cables (India) Pvt. LTDRathnam RaviNo ratings yet

- Surface Mount Technology PresentationDocument23 pagesSurface Mount Technology Presentation11090480No ratings yet

- Price Elasticity of Demand HandoutDocument2 pagesPrice Elasticity of Demand HandoutvuduyducNo ratings yet

- CTC 235 NacelleDocument201 pagesCTC 235 NacelleGoutam Saha60% (5)

- Visual and Ultrasonic Inspection of CraneDocument7 pagesVisual and Ultrasonic Inspection of CranePDDELUCA100% (2)

- Lumpsum ContractDocument3 pagesLumpsum ContractjopuNo ratings yet

- Chatbot - The Future of Customer ServiceDocument28 pagesChatbot - The Future of Customer ServiceTruong LeNo ratings yet

- 57e4d64a5ae56 1317890 SampleDocument32 pages57e4d64a5ae56 1317890 Samplemanaswini sharma B.G.100% (2)

- HAAS 3D Model Tutorial PDFDocument1 pageHAAS 3D Model Tutorial PDFRicardoPagésMarínNo ratings yet

- BC182, BC182A, BC182B Amplifier Transistors: NPN SiliconDocument5 pagesBC182, BC182A, BC182B Amplifier Transistors: NPN SiliconGrigoras Laura IoanaNo ratings yet

- Frederick Winslow TaylorDocument6 pagesFrederick Winslow TaylorAngela AllenNo ratings yet

- GE Lighting Systems Price Book - Outdoor Designers Guide 10-78 - 3-79Document88 pagesGE Lighting Systems Price Book - Outdoor Designers Guide 10-78 - 3-79Alan Masters100% (1)

- Leslie Paula Ruliog Resume PDFDocument2 pagesLeslie Paula Ruliog Resume PDFLeslieNo ratings yet

- 5SDocument30 pages5SPrema Nanda HottaNo ratings yet

- Reynaers Product Overview CURTAIN WALLDocument80 pagesReynaers Product Overview CURTAIN WALLyantoNo ratings yet

- Internal Audit Checklist - MaintenanceDocument2 pagesInternal Audit Checklist - MaintenanceSachin Ramdurg92% (12)

- DRM - OfSAA Interface User GuideDocument17 pagesDRM - OfSAA Interface User GuidePrasad BillahalliNo ratings yet

- Process Failure Modes and Effects Analysis Process Failure Modes and Effects AnalysisDocument2 pagesProcess Failure Modes and Effects Analysis Process Failure Modes and Effects AnalysisEnzo AscañoNo ratings yet

- A.C. Project - Five BrandsDocument40 pagesA.C. Project - Five BrandsNitinAgnihotriNo ratings yet

- SVKM's NMIMS University Mukesh Patel School of Technology Management & EngineeringDocument3 pagesSVKM's NMIMS University Mukesh Patel School of Technology Management & EngineeringmgordhandasNo ratings yet

- The Game: Penetrating the Secret Society of Pickup ArtistsFrom EverandThe Game: Penetrating the Secret Society of Pickup ArtistsRating: 4 out of 5 stars4/5 (131)

- Secrets of the Millionaire Mind: Mastering the Inner Game of WealthFrom EverandSecrets of the Millionaire Mind: Mastering the Inner Game of WealthRating: 4.5 out of 5 stars4.5/5 (197)

- Coastal Alaska & the Inside Passage Adventure Travel GuideFrom EverandCoastal Alaska & the Inside Passage Adventure Travel GuideNo ratings yet

- Proof of Heaven: A Neurosurgeon's Journey into the AfterlifeFrom EverandProof of Heaven: A Neurosurgeon's Journey into the AfterlifeRating: 3.5 out of 5 stars3.5/5 (165)

- Geneva, Lausanne, Fribourg & Western Switzerland Travel AdventuresFrom EverandGeneva, Lausanne, Fribourg & Western Switzerland Travel AdventuresNo ratings yet

- Vietnam, Laos & Cambodia Adventure GuideFrom EverandVietnam, Laos & Cambodia Adventure GuideRating: 4 out of 5 stars4/5 (7)

- Jamaica: A Guide to the Food & RestaurantsFrom EverandJamaica: A Guide to the Food & RestaurantsRating: 4 out of 5 stars4/5 (1)

- Hollywood & the Best of Los Angeles Travel GuideFrom EverandHollywood & the Best of Los Angeles Travel GuideRating: 4.5 out of 5 stars4.5/5 (2)

- Nassau & the Best of the Bahamas Travel GuideFrom EverandNassau & the Best of the Bahamas Travel GuideRating: 5 out of 5 stars5/5 (1)