Professional Documents

Culture Documents

Bracing Connection

Bracing Connection

Uploaded by

rajedmaglinteOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bracing Connection

Bracing Connection

Uploaded by

rajedmaglinteCopyright:

Available Formats

Design Calculation for Bracing Connection - Joint SWF-SF8

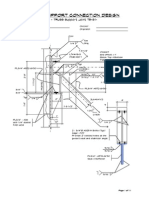

1.) LAYOUT

HSS8X8X1/4

HSS8X4X1/8

2 1

8.0

3/16" 3/16" 3/16" 3/16"

8" 8"

Typ

PL 0.375 - A36

4.0

Typ

3/16" 3/16"

4" 4"

9"

10"

5"

4

HSS8X8X1/2

11 1/2" 10 11/16"

5"

3

9" 8" 8" 10"

Typ

3/16" 3/16"

HSS8X8X1/4 8.0 10"

PL 0.375 - A36

2.)

REQUIRED STRENGTHS: Member 1: Axial Load, Ta Axial Load, Ca Member 2: Axial Load, Ta Axial Load, Ca Member 3: Axial Load, Ta Axial Load, Ca

= =

10.0 10.0

kips (Tension) kips (Compression)

= =

20.0 20.0

kips (Tension) kips (Compression)

= =

15.0 15.0

kips (Tension) kips (Compression)

3.)

MATERIAL & GEOMETRIC PROPERTIES: Member 1: Size: Fy Fu

HSS8X4X1/8 = 46 = 58

ASTM A500 Gr. B ksi ksi

Page 1 of 12

Design Calculation for Bracing Connection - Joint SWF-SF8

B HT A t Member 2: Size: Fy Fu B HT A t Member 3: Size: Fy Fu B HT A t Member 4: Size: Fy Fu B HT A t = = = = 4.00 8.00 2.70 0.116 in in in in

HSS8X8X1/4 = 46 = 58 8.00 = 8.00 = 7.10 = 0.233 =

ASTM A500 Gr. B ksi ksi in in in in

HSS8X8X1/4 = 46 = 58 8.00 = 8.00 = 7.10 = 0.233 =

ASTM A500 Gr. B ksi ksi in in in in

HSS8X8X1/2 = 46 = 58 8.00 = 8.00 = 13.50 = 0.465 =

ASTM A500 Gr. B ksi ksi in in in in ASTM 36 ksi ksi in

Gusset Plate: Fy = Fu = tgusset =

36 58 3/8

4.)

BRACE CONNECTION MEMBER 1: Brace to Gusset Plate Weld: Electrode Class Fu Fv = = = = = = = = = E700XX

Nominal Tensile Strength of Weld 70.00 Ksi Allowable Weld Shear Strength 0.6 Fu / 2 21.00 Ksi Size of Weld 0.1875 in. (Use 0.1250 in. for calculation)

w Pw

Shear Capacity of 1/8" weld per Linear Inch

Page 2 of 12

Design Calculation for Bracing Connection - Joint SWF-SF8

= = = L1 Vw = = = = = 0.707 * Fv * w (0.707 * 21 * 0.125) 1.856 Kips/in Length of Weld 4.00 in. Weld Shear Capacity Pw * 4 L2 29.694 Kips

Vw

>

10.00

Kips

(OK)

Tension Yielding of the Brace: Rn/ = = = Capacity from 'Limit State of Tension Yielding of Brace' Fyb * Ag1 1.67 74.37 kips 10.00 kips (OK) >

Tension Rupture of the Brace: Rn/ Capacity from 'Limit State of Tension Rupture of Brace' Fub * Ae = 2.00 where: 4.00 in = (Length of Weld in HSS) L B H x U An Ae = = = = = = = = = = 8.00 4.00 in in (Width of HSS Section) (Height of HSS Section) =

(B2 + 2 * B * H) / (4 * (B + H)) 2.667 in 1 - (x / L) 0.333 Ag1 - 2 * (tp + 0.0625) * t1 2.599 in U * An 0.866 25.12 kips in > 10.00 kips (OK)

Rn/

Whtimore Section L= L= 2 lw tan 30 + B 8.619 in 0.000 0.000 in in = 1.67 B= 4.00 in

Whitmore width in Vertical Member = Whitmore width in Horizontal Member =

Check tension yielding on the Whitmore section

Page 3 of 12

Design Calculation for Bracing Connection - Joint SWF-SF8

Rn = Fy Aw Rn = 36 x [ ( 8.619 - 0 - 0 ) x 0.375 ] Rn = Rn/ 116.35 = kips 69.67 kips > 10.00 kips (OK)

Check block shear rupture of the gusset Rn = = Nominal Block Shear Strength of Gusset ( =2)

2 x Min[ (0.6 x Fu x Anv + Ubs x Fu x Ant); (0.6 x Fy x Agv + Ubs x Fu x Ant) ] Where: Ubs = 1.0 Ant = Net Area with Tension Resistance = Bbrace x tgusset = 1.50 in

2

Agv = Gross Area with Shear Resistance = 2 x lw x tgusset = 3.00 in

2

Anv = Net Area with Shear Resistance = Rn/ = 3.00 75.90 in

2

kips

>

10.00

kips

(OK)

Plate Buckling of Connection Plate Ap = = = = = = = = = = = Effective Plate Cross-sectional Area L*t 3.232 in Plate Unbraced Length of Whitmore Section 5.66 in. Effective Length Factor 1.200 Radius of Gyration t / 3.464 0.108 in. 62.740 > 25

Lcr

K Lcr/r

From Specification E3 Fe = = ()*E/(KL/r) ksi 72.71

>

0.44*Fy = 15.84 ksi

Page 4 of 12

Design Calculation for Bracing Connection - Joint SWF-SF8

Fcr = [0.658^(Fy/Fe)]*Fy 29.26 ksi Allowable Strength in Compression Ap * Fcr 1.67 56.63 kips > 10.00 kips (OK)

Rn/

= =

MEMBER 2: Brace to Gusset Plate Weld: Electrode Class Fu = = = = = = = = = = = = = = = = = E700XX

Nominal Tensile Strength of Weld 70.00 Ksi Allowable Weld Shear Strength 0.6 Fu / 2 21.00 Ksi Size of Weld 0.1875 in.

Fv

(Use

0.1250 in. for calculation)

Pw

Shear Capacity of 1/8" weld per Linear Inch 0.707 * Fv * w (0.707 * 21 * 0.125) 1.856 Kips/in Length of Weld 8.00 in. Weld Shear Capacity Pw * 4 L2 59.388 Kips

L1 Vw

Vw

>

20.00

Kips

(OK)

Tension Yielding of the Brace: Rn/ = = = Capacity from 'Limit State of Tension Yielding of Brace' Fyb * Ag3 1.67 195.57 kips > 20.00 kips (OK)

Tension Rupture of the Brace: Rn/ Capacity from 'Limit State of Tension Rupture of Brace' Fub * Ae = 2.00 where: =

Page 5 of 12

Design Calculation for Bracing Connection - Joint SWF-SF8

L B H x = = = = = = = = = = = 8.00 8.00 8.00 in in in (Length of Weld in HSS) (Width of HSS Section) (Height of HSS Section)

2 (B + 2 * B * H) / (4 * (B + H)) 3.000 in

1 - (x / L) 0.625 Ag3 - 2 * (tp + 0.0625) * t3 6.896 in U * An 4.310 124.99 kips

An

Ae

in > 20.00 kips (OK)

Rn/

Whtimore Section L= L= 2 lw tan 30 + B 17.238 in 0.000 4.200 in in = 1.67 B= 8.00 in

Whitmore width in Vertical Member = Whitmore width in Horizontal Member =

Check tension yielding on the Whitmore section Rn = Fy Aw Rn = 36 x [ ( 17.238 - 0 - 4.2 ) x 0.375 ] Rn = Rn/ 176.01 = kips kips > 20.00

105.39

kips

(OK)

Check block shear rupture of the gusset Rn = = Nominal Block Shear Strength of Gusset ( =2)

2 x Min[ (0.6 x Fu x Anv + Ubs x Fu x Ant); (0.6 x Fy x Agv + Ubs x Fu x Ant) ] Where: Ubs = 1.0 Ant = Net Area with Tension Resistance = Bbrace x tgusset = 3.00 in

2

Agv = Gross Area with Shear Resistance = 2 x lw x tgusset

Page 6 of 12

Design Calculation for Bracing Connection - Joint SWF-SF8

= 6.00 in

2

Anv = Net Area with Shear Resistance = Rn/ = 6.00 151.80 in

2

kips

>

20.00

kips

(OK)

Plate Buckling of Gusset Plate Ap = = = = = = = = = = = Effective Plate Cross-sectional Area L*t 6.464 in Plate Unbraced Length of Whitmore Section 1.00 in. Effective Length Factor 1.200 Radius of Gyration t / 3.464 0.108 in. 11.085 < 36 25 ksi

Lcr

K Lcr/r

Thus Fcr = Fy = Rn/ = =

Allowable Strength in Compression Ap * Fcr 1.67 139.35 kips > 20.00 kips (OK)

Gusset Plate to Colum:

C1 e1

T2

A C1H

C1v

T2

L1

L2

Page 7 of 12

Design Calculation for Bracing Connection - Joint SWF-SF8

Solving for component forces: C1H = = C1V = = T2 e1 L1 L2 L L = 10 (1) [ (1.32) + (1) ] 6.0 kips

5 (1.32) [ (1.32) + (1) ] 8.0 20.0 kips kips

= = = = = L1

3.04 11.5 5.0 + L2 16.5

in in in

in

The normal stress is, ft = P/L + 3M/L

The in-plane stress is, fv = V/L

Consider section A-A P = = = = T2 - C1V 12.0

kips

C1V x e1 24.2 kip-in

then, ft and, V

0.996

kip/in

= = =

C1H 6.0 0.366

kips kip/in

fv

The resultant is, f = = [ (0.996) + (0.366) ] 1.061 kip/in

Check weld size

Page 8 of 12

Design Calculation for Bracing Connection - Joint SWF-SF8

Fv = = = = = = w = = = = = = = Allowable Weld Shear Strength 0.6 Fexx / 2 [ Fexx = 70ksi] 21.00 Ksi tan 0.366 0.996 deg 20.1746 rad 0.352

Size of Weld 0.1875 in.

(Use

0.1250 in.

for calculation)

Pw

Shear Capacity of 1/8" weld per Linear Inch 0.707 * Fv * w * (1.0 + 0.50 sin1.5) (0.707 * 21 * 0.125) * (1.101) 2.044 Kips/in 4.088 Kips/in > 1.06 Kips/in (OK)

2 Pw

Check plate stress fa = fa = fv = fv = ft tgusset 2.656 fv tgusset 0.976 = ksi = ksi < 1.00 0.375 < 0.37 0.38

0.6Fy/ = Fy/ =

( = 1.67) 22 ksi ( = 1.5) 14 ksi (OK) (OK)

Check HSS wall Force component perpendicular to HSS wall Ft = ft x L = 16.43 kips

HSS wall capacity Rn/ = [ Fy t2 / (1- tp/B)] [ (2N/B + 4(1 -tp/B)0.5 ) Qf] Fy t tp B N Qf Rn/ MEMBER 3: Brace to Gusset Plate Weld:

Page 9 of 12

( = 1.5)

where: = = = = = = 46 0.465 3/8 8.00 16.5 1 kips > 16.43 kips (OK)

55.8657

Design Calculation for Bracing Connection - Joint SWF-SF8

Electrode Class Fu = = = = = = = = = = = = = = = = = E700XX

Nominal Tensile Strength of Weld 70.00 Ksi Allowable Weld Shear Strength 0.6 Fu / 2 21.00 Ksi Size of Weld 0.1875 in.

Fv

(Use

0.125 in.

for calculation)

Pw

Shear Capacity of 1/8" weld per Linear Inch 0.707 * Fv * w (0.707 * 21 * 0.125) 1.856 Kips/in Length of Weld 8.00 in. Weld Shear Capacity Pw * 4 L2 59.388 Kips

L1 Vw

Vw

>

15.00

Kips

(OK)

Tension Yielding of the Brace: Rn/ = = = Capacity from 'Limit State of Tension Yielding of Brace' Fyb * Ag4 1.67 195.57 kips > 15.00 kips (OK)

Tension Rupture of the Brace: Rn/ Capacity from 'Limit State of Tension Rupture of Brace' Fub * Ae = 2.00 where: 8.00 in L = (Length of Weld in HSS) B H x = = = = = = = =

2

8.00 8.00

in in

(Width of HSS Section) (Height of HSS Section)

(B + 2 * B * H) / (4 * (B + H)) 3.000 in 1 - (x / L) 0.625 Ag4 - 2 * (tp + 0.0625) * t4 6.896 in

An

Page 10 of 12

Design Calculation for Bracing Connection - Joint SWF-SF8

Ae = = U * An 4.310 124.99 kips in > 15.00 kips (OK)

Rn/

Whtimore Section L= L= Width of Whitmore Section Minimum[ (2 x 8.00 tan 30 + 8) , 10 ] 10.000 in = 1.67

Check tension yielding on the Whitmore section Rn = Fy Aw Rn = 36 x [10 x 0.375 ] Rn = Rn/ 135.00 = kips kips > 15.00

80.84

kips

(OK)

Check block shear rupture of the gusset Rn = = Nominal Block Shear Strength of Gusset ( =2)

2 x Min[ (0.6 x Fu x Anv + Ubs x Fu x Ant); (0.6 x Fy x Agv + Ubs x Fu x Ant) ] Where: Ubs = 1.0 Ant = Net Area with Tension Resistance = Bbrace x tgusset = 3.00 in

2

Agv = Gross Area with Shear Resistance = 2 x lw x tgusset = 6.00 in

2

Anv = Net Area with Shear Resistance = Rn/ = 6.00 151.80 in

2

kips

>

15.00

kips

(OK)

Plate Buckling of Gusset Plate Ap = = = = = Effective Plate Cross-sectional Area L*t 3.750 in Plate Unbraced Length of Whitmore Section 1.00 in.

Page 11 of 12

Lcr

Design Calculation for Bracing Connection - Joint SWF-SF8

K = = = = = = Effective Length Factor 1.200 Radius of Gyration t / 3.464 0.108 in. 11.085 < 36 25 ksi

K Lcr/r

Thus Fcr = Fy = Rn/ = =

Allowable Strength in Compression Ap * Fcr 1.67 80.84 kips > 15.00 kips (OK)

HSS wall capacity Rn/ = [ Fy t2 / (1- tp/B)] [ (2N/B + 4(1 -tp/B)0.5 ) Qf] Fy t tp B N Qf Rn/ = = = = = = = 46 0.465 3/8 8.00 10.0 1 kips > 15.00 kips (OK) ( = 1.5)

where:

44.5605

Page 12 of 12

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5808)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hilti HIT-200 System Replaces HIT-HY 150Document3 pagesHilti HIT-200 System Replaces HIT-HY 150rajedmaglinte100% (1)

- Ltil LRN Eb Ezee.:, Clean. Postholes, in Concre, Le !Document2 pagesLtil LRN Eb Ezee.:, Clean. Postholes, in Concre, Le !rajedmaglinteNo ratings yet

- Rule of Thumb Concrete DesignDocument54 pagesRule of Thumb Concrete DesignrunkirNo ratings yet

- SP Slab PresentationDocument19 pagesSP Slab PresentationrajedmaglinteNo ratings yet

- A325 and Class 8.8Document3 pagesA325 and Class 8.8rajedmaglinte100% (1)

- Forged Steel Clevis: Caution: Never Exceed The Working Load LimitDocument1 pageForged Steel Clevis: Caution: Never Exceed The Working Load LimitrajedmaglinteNo ratings yet

- Corrosion Protection of Steel BridgesDocument0 pagesCorrosion Protection of Steel Bridgesrajedmaglinte100% (1)

- HLC Vs KWIK CON IIDocument2 pagesHLC Vs KWIK CON IIrajedmaglinteNo ratings yet

- Beam DesignDocument1 pageBeam DesignrajedmaglinteNo ratings yet

- Bracing ConnectionDocument15 pagesBracing ConnectionrajedmaglinteNo ratings yet

- Truss Support Connection Design T5-S1Document11 pagesTruss Support Connection Design T5-S1rajedmaglinteNo ratings yet

- HSS Flange Plate Moment Connection - Temporary SteelDocument9 pagesHSS Flange Plate Moment Connection - Temporary SteelrajedmaglinteNo ratings yet

- Bracing ConnectionDocument10 pagesBracing ConnectionrajedmaglinteNo ratings yet

- 1030 - Embedded Plate Design - 4 - S7.00Document9 pages1030 - Embedded Plate Design - 4 - S7.00rajedmaglinte100% (2)

- Anchored Brick Veneer Over Steel Studs PDFDocument56 pagesAnchored Brick Veneer Over Steel Studs PDFaomareltayeb100% (1)

- AISC - Structral Steel ConnectionsDocument45 pagesAISC - Structral Steel ConnectionsHan Koko100% (10)

- Hss Beam End Reaction (13 Edition) : W, Kip/ftDocument2 pagesHss Beam End Reaction (13 Edition) : W, Kip/ftrajedmaglinteNo ratings yet

- W14x43 To HSS6x6x1 - 2 Moment ConnDocument21 pagesW14x43 To HSS6x6x1 - 2 Moment ConnrajedmaglinteNo ratings yet

- Bolt Shear CapacityDocument12 pagesBolt Shear Capacityrajedmaglinte0% (1)