Professional Documents

Culture Documents

SPE 153072 Production Data Analysis in Eagle Ford Shale Gas Reservoir

Uploaded by

Fernando Montes de OcaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SPE 153072 Production Data Analysis in Eagle Ford Shale Gas Reservoir

Uploaded by

Fernando Montes de OcaCopyright:

Available Formats

SPE 153072

Production Data Analysis in Eagle Ford Shale Gas Reservoir

Bingxiang Xu, SPE, China University of Petroleum-Beijing, University of Adelaide; Manouchehr Haghighi, and

Dennis Cooke, SPE, University of Adelaide; Xiangfang Li, SPE, China University of Petroleum-Beijing

Copyright 2012, Society of Petroleum Engineers

This paper was prepared for presentation at the SPE/EAGE European Unconventional Resources Conference and Exhibition held in Vienna, Austria, 20-22 March 2012.

This paper was selected for presentation by an SPE program committee following review of information contained in an abstract submitted by the author(s). Contents of the paper have not been

reviewed by the Society of Petroleum Engineers and are subject to correction by the author(s). The material does not necessarily reflect any position of the Society of Petroleum Engineers, its

officers, or members. Electronic reproduction, distribution, or storage of any part of this paper without the written consent of the Society of Petroleum Engineers is prohibited. Permission to

reproduce in print is restricted to an abstract of not more than 300 words; illustrations may not be copied. The abstract must contain conspicuous acknowledgment of SPE copyright.

Abstract

Eagle Ford shale in South Texas is one of the recent shale play in US which the development began in late 2008. So far many

horizontal wells have been drilled and put into production using hydraulic fracturing. Production behaviour in shale gas

reservoirs unlike conventional reservoirs is different in various plays and there are no published reports for production data

analysis in Eagle Ford shale.

We have used the linear dual porosity type curve analysis technology to analyse the production behaviour and to estimate the

essential parameters for this reservoir. This type curve was constructed based on transient production rate with constant well

pressure in a closed boundary of stimulated reservoir volume (SRV) with double porosity approach. In order to analyse the

early production data we used Bellos and Nobakhts approach to account for apparent skin.

In this study, three flow regimes were identified consisting of 1- bilinear flow; 2- matrix linear flow; and 3- boundary

dominated flow. For the analysis of early flow regime, two possibilities of transition flow and apparent skin have been

considered. First, the fracture permeability was estimated to be around 820 nano Darcy based on transition flow analysis.

Second, the matrix permeability was estimated to be either 181 or 255 nano Darcy based on two different approaches in matrix

linear flow regime. Furthermore, original gas in place (OGIP) and SRV were estimated from the boundary dominated flow

regime. To validate the estimated matrix permeability, a single porosity numerical model with high permeability transverse

fractures was built to match the production history. The permeability from simulation was in a good agreement with type curve

analysis.

Production forecasting has also been carried out using different adsorption isotherms. The results showed that the effect of

desorption depends on the reservoir pressure and the shape of adsorption isotherm curve. In early time of production,

desorption is usually not effective, however, for long-term production forecasting, it is necessary to account for this

phenomenon by providing an accurate isotherm.

Introduction

Decline curve analysis (DCA) has been used as an effective method for the production forecasting and reserves estimation in

shale gas reservoirs. Since production of shale gas reservoirs is usually from a stimulated reservoir volume (SRV) generated

by hydraulic fracturing in a horizontal well and also because the shale gas reservoirs have very different petrophysical

properties from conventional gas reservoirs, the production data analysis is different from conventional DCA methods

developed first by Arps (1945), and modified by other authors such as Fetkovich (1987), Palacio and Blasingame (1993),

Agarwal et al. (1999). The petrophysical difference makes naturally fractured shale gas reservoirs generate more complex

fracture network than traditional bi-wing fracture (Cipolla et al., 2009). This fracture network leads to a SRV region. The

initial active region of a shale gas reservoir only exists in the SRV, which is usually monitored by micro-seismic technique

(Inamdar et al., 2010; Bello and Wattenbarger, 2010). Due to ultra-low matrix permeability and high fracture conductivity, the

flow does not follow the radial behaviour similar to the conventional gas reservoirs; however, it follows a linear flow instead

(Bello and Wattenbarger, 2010; Al-Ahmadi et al., 2010). Also shale gas reservoirs contain both free gas in macro pores and

adsorbed gas on matrix surface area.

2 SPE 153072

To use production analysis technique for shale gas, Lee and Gatens III. (1985), Hazlet et al. (1986), constructed a set of type

curves for the Devonian shales using a solution for constant pressure in a bounded dual-porosity reservoir based on the

Warren-Root model. Lewis and Hughes (2008) proposed production data analysis for shale gas using a modified material

balance time to account for desorption. However, these methods were based on radial flow. Matter et al. (2008) showed that

using conventional type curve technique to analyse the shale gas well performance may result in false radial flow when the

fracture conductivity is finite. It was found that the best-fit match with the Arps hyperbolic decline gives constant values (b)

greater than 1 (Baihly et al., 2010). This can cause to have physically unreasonable properties (Lee and Sidle, 2010). As a

result, Valk and Lee (2010) developed a stretched exponential production decline model. Duong (2010) also introduced a

derived decline model that is based on long-term linear flow in a large number of wells in tight and shale-gas reservoirs.

Wattenbarger et al. (1998) presented a linear flow approach to analyse production of fractured tight gas wells. The model was

based on homogeneous and linear reservoirs with infinite conductivity hydraulic fracture. El-Banbi (1998) developed a

transient dual porosity model for linear reservoirs. Recently many authors developed and applied type curves based on the

transient dual porosity model and analysed shale gas production data, such as Bello and Wattenbarger (2008; 2009; 2010),

Moghadam et al.(2010), Nobakht et al.(2010), Al-Ahmadi et al.(2010), and Anderson et al.(2010). However, desorption was

ignored in these literatures, and also production was assumed to be from SRV only. Ozkan et al. (2009), Brown et al. (2009)

and Brohi et al. (2011) recently presented tri-linear flow solutions for tight gas and shale gas reservoirs. It was concluded that

outer unstimulated reservoir is subject to supply gas in later times, which depends on the permeability of the outer region.

In current study, we have used the same dual porosity linear flow type curves presented by Bello and Wattenbarger (2010) to

analyse the Eagle Ford Shale gas production data. Different flow regimes have been identified and the reservoir properties

such as matrix permeability and completion efficiency or SRV have been evaluated. Also we have predicted the estimated

ultimate recovery (EUR) and the future gas rate based on different assumptions.

Basic Theory and Methodology

Most shale gas production data show a long-term transient linear flow regime. This linear flow can be detected by a one-half

slope on log-log plot of rate versus time. Dual porosity transient linear flow type curves for multi-stage hydraulic fractured

horizontal well for shale gas were developed by Bello and Wattenbarger (2010). Four flow regimes exist in these type curves

as follows:

Regime1: Early linear flow in fracture system

Regime2: Bilinear flow caused by both fracture and matrix system

Regime3: Linear flow in matrix system

Regime4: Boundary dominated flow

The combination of area with permeability can be calculated based on the following equations:

Early linear flow:

( )

1

1 1262

m

C

T

k A

m f t

f cw

! =

+

" #

(1)

Bilinear flow:

( ) [ ]

2

25 . 0

1 4070

m

C k

T

k A

m f t m

f cw

! =

+

" #

(2)

Matrix linear flow:

( )

3

1 1262

m

C

T

k A

m f t

m cm

! =

+

"

(3)

Where m

1

, m

3

are straight line slopes on the [ ]

g wf i

q p m p m / ) ( ) ( ! vs t plot, and m

2

is the straight line slope from the

[ ]

g wf i

q p m p m / ) ( ) ( ! vs

25 . 0

t plot.

Following two approaches are available to include the apparent skin effects. Apparent skin is the result of flow convergence

around a horizontal well (Bello and Wattenbarger, 2009); and an extra pressure drop caused by bottom-hole pressure

calculation (Nobakht et al., 2010); or pressure drop within finite conductivity fractures (Anderson et al., 2010) in early linear

flow or bilinear flow.

1. Bellos approach

Bello (2009) demonstrated that the effect of skin on the linear reservoir response diminishes gradually with time. When the

effect of skin is considered, the straight line through origin becomes a curve with a nonzero intercept on the specified plot

[ ]

g wf i

q p m p m / ) ( ) ( ! vs. t . The following empirical equation (Bello and Wattenbarger, 2009) was derived.

SPE 153072 3

b

t m

b

t m

q

p m p m

g

wf i

3

3

45 . 0

1

) ( ) (

+

+ =

!

(4)

2. Nobakhts approach

Nobakht et al. (2010) stated that the effect of skin yields a straight line with intercept as it is shown in equation (5).

b t m

q

p m p m

g

wf i

+ =

!

3

) ( ) (

(5)

Eagle Ford Reservoir and Well Description

Eagle Ford shale is a calcareous shale play located in South Texas, US, which lies beneath the Austin chalk and extends

laterally all the way across Texas from the southwest to the northeast part of the state (Inamdar, 2010; Stegent et al., 2010;

Mullen et al., 2010). Its depth ranges from 2,500 to 14,000 ft; the thickness ranges from 50 to more than 300 ft, the pressure

gradients are between 0.4 and 0.8 psi/ft, and TOC ranges from 2 to 9% (Stegent et al., 2010). Core data analysis shows that the

gas saturation is between 83% and 85%, permeability varies between 1 to 800 nd (Inamdar, 2010). Fig. 1 displays the general

areas where the reservoir produces oil (top), high liquids or condensate (middle), and predominately dry gas (bottom). In late

2008 the first few exploration wells in the Eagle Ford were drilled in LaSalle County in the gas window of the play (Stegent et

al., 2010).

Fig. 1: Lateral extent of Eagle Ford shale in south Texas (Mullen, 2010)

Well A is a horizontal dry gas producer which was completed with a ten stages proppant fracture stimulation treatment in a

4,000 ft lateral. Each 400 ft stage was perforated with four, two-foot clusters spaced 75 ft apart. According to the results of

production log and radioactive log, only 20 transverse fractures are effective on production. Stimulated reservoir volume

(SRV) of 169 MMft

3

was estimated by fracturing modelling. The pay zone height is 283 ft. Summary of reservoir and fluid

properties data in Table 1 is from Bazan et al. (2010).

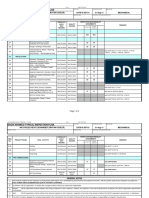

Table 1: Properties Data for Well A (Bazan et al., 2010)

Well radius (ft) 0.333

Lateral length (ft) 4000

Pay zone height (ft) 283

Depth, TVD (ft) 10875

HC* porosity (%) *(!hc = !eff (1-Sw)) 5.76

Reservoir pressure (psi) 8,350

Temperature (

o

R) 745

Gas compressibility(10

-5

psi

-1

) 6

Viscosity(cp) 0.03334

Effective fracture number 20

SRV (MMft

3

) 169

The daily gas rate in Fig. 2 and original bottom-hole flowing pressure (BHFP) in Fig. 3 for 250 days are also from Bazan et al.

(2010). In order to minimize the effect of data fluctuation, BHFP was smoothed using an exponential smoothing algorithm

(Lewis and Hughes, 2008). The equation used in the smoothing is

( ) ( ) ( ) ( ) 1 1 ! " ! + " = t x t x t x

smth smth

# # (6)

4 SPE 153072

The dampening factor (!) is 0.25. From the smoothed plot (Fig. 3), the BHFP can be assumed constant after 50 days.

Therefore, the type curve with constant BHFP can be used to analyse the data.

Fig. 2: Gas rate and cumulative production (Bazan et al., 2010) Fig. 3: Original and smoothed bottom-hole flowing pressure

Flow Regimes Identification

Based on Fig. 4 and Fig. 5, three following flow regimes were identified: 1-bilinear flow or apparent skin effect, 2- matrix

linear flow, and 3- boundary dominated flow. Fig. 4 is a log-log plot of normalized rate [ ] ) ( ) ( /

wf i

p m p m q ! versus time. In

the very early times the data exhibits a negative " slope indicating either a bilinear flow or apparent skin effect, while in the

later times the data exhibits negative one-half slope indicating matrix linear flow.

Fig. 4: Normalized rate vs time Fig. 5: Normalized pseudo-pressure vs square root of time

Fig. 5 is the normalized pseudo-pressure [ ] q p m p m

wf i

/ ) ( ) ( ! versus t . In this figure, we observed a deviation of early time

data from straight line and having an intercept on the axis of normalized pseudo-pressure. This behaviour indicates to have a

non-linear flow such as skin effect, while in later times; the data indicate a straight line, which is a typical characteristic of

linear flow. In very late times, the data begin to derivate from the straight line at about 225 days indicating the boundary

effect. Since this time period is relatively short, the boundary effect cannot be identified from the log-log plot.

Linear Flow Parameters Analysis

The half-width of the drainage area (rectangular geometry) can be calculated from in following simple calculation (Fig. 6). We

have assumed bi-wing hydraulic fracture geometry and slab matrix bulk. The half-width is equivalent to SRV divided by 2x

e

h.

ft 75

283 4000 2

10 169

2

6

!

" "

"

= =

h x

SRV

y

e

e

It is noted that y

e

can also be estimated from OGIP if SRV is not known. Average fracture spacing L was calculated from well

length 4,000 ft divided by the number of effective fractures which is 20.

ft 200

20

4000

= = L

Well-face cross-sectional area to flow is:

2 6

ft 10 264 . 2 283 4000 2 2 ! = ! ! = " " = h x A

e cw

Total matrix-fracture surface area in a double porosity slab model was calculated from the below equation:

2 6

ft 10 698 . 1 20 2 2 ! = ! ! ! = h y A

e cm

SPE 153072 5

Fig. 6: Reservoir geometry for dual porosity slab model

Based on the flow regimes identification two possibilities were analysed below.

Bilinear Flow Followed by Matrix Linear Flow

We have plotted

[ ] q p m p m

wf i

/ ) ( ) ( ! vs

25 . 0

t

and [ ] q p m p m

wf i

/ ) ( ) ( ! vs t in Figs. 7a and 7b respectively to obtain m

2

=

283333 and m

3

= 111250.

(a) [ ] q p m p m

wf i

/ ) ( ) ( ! vs t (b) [ ] q p m p m

wf i

/ ) ( ) ( ! vs

25 . 0

t

Fig.7: Specialized plot analysis

Then

m cm

k A was determined based on the following calculation:

( )

0.5 2 4

3

md ft 10 49 . 2

111250

1

03334 . 0 0.00006 0576 . 0

745 1262 1 1262

! " = !

" "

"

= ! =

+

m

C

T

k A

m f t

m cm

#

Since the fracture porosity can be negligible compared to the matrix porosity, ( )

m t

C ! was assumed to be equal to ( )

m f t

C

+

! .

Due to high reservoir average pressure in early production, the gas desorption is negligible. And also the rock compressibility

is ignored. Therefore, the total compressibility C

t

was assumed to be equal to C

g

.

Matrix permeability was evaluated from the following calculation:

md 10 15 . 2

10 ! 1.698

10 ! 2.49

4

2

6

4

2

!

" =

#

#

$

%

&

&

'

(

=

)

)

*

+

,

,

-

.

=

cm

m cm

m

A

k A

k

Fracture permeability K

f

was estimated from the following:

( ) [ ]

[ ]

0.5 2 4

25 . 0

4 4

2

25 . 0

md ft 10 48 . 6

283333

1

03334 . 0 0.00006 0576 . 0 10 15 . 2 10 0 . 3

745 4070

1 4070

! " =

"

" " " " " "

"

=

! =

# #

+

m

C k

T

k A

m f t m

f cw

$ %

6 SPE 153072

Where matrix block shape factor, for slab model is

2 4

2

ft 10 0 . 3

12

! !

" = =

L

#

md 10 2 . 8

10 ! 2.264

10 ! 6.48

4

2

6

4

2

!

" =

#

#

$

%

&

&

'

(

=

)

)

*

+

,

,

-

.

=

cw

f cw

f

A

k A

k

This fracture permeability is low because the well-face cross-sectional area has been used.

Matrix Linear Flow with Apparent Skin

Bellos Approach

In this approach, two parameters of m

3

=111250 and intercept b=2.1#10

5

were obtained from Fig.7a, and then substituted into

the equation (4). The initial relation of production rate versus time accounting for apparent skin is given:

5

5

10 1 . 2

111250 45 . 0

1

10 1 . 2

111250

) ( ) (

!

!

+

!

+ =

"

t

t

q

p m p m

wf i

(7)

We used above equation to match the production data and fortunately obtained acceptable results by initial guess (Figs. 8a and

8b). In case of not good matching, we need to assume m

3

and b as matching parameters to reach reasonable results. Based on

m

3

= 111250, we estimated the matrix permeability as 2.15#10

-4

md.

(a) Log-Log plot (b) Square root of time plot

Fig. 8: Fitting the results with Equation 7.

Nobakhts Approach

From the plot of [ ]

g wf i

q p m p m / ) ( ) ( ! vs t , (Fig. 9), a straight line has been drawn through the data points and the intercept

5

10 5 . 1 ! = b was obtained.

Fig. 9: Specialized plot to obtain intercept b for Nobakhts approach

SPE 153072 7

Then calculating modified normalized pressure as follow:

b

q

p m p m

q

p m p m

wf i

m

wf i

!

!

=

"

#

$

%

&

' ! ) ( ) ( ) ( ) (

(8)

Plotting [ ] { }

m

wf i

q p m p m ) ( ) ( ! versus time on log-log plot, as shown in Fig. 10, indicated a one-half slope even in the early

time. Plotting [ ] { }

m

wf i

q p m p m ) ( ) ( ! vs t , as shown in Fig.11, the slope is m

3

=93750.

( )

4

10 95 . 2

93750

1

03334 . 0 0.00006 0576 . 0

745 1262 1 1262

! = "

! !

!

# " =

+

m

C

T

k A

m f t

m cm

$

So the estimated matrix permeability was calculated below.

md 10 02 . 3

10 ! 1.698

10 ! 2.95

4

2

6

4

2

!

" =

#

#

$

%

&

&

'

(

=

)

)

*

+

,

,

-

.

=

cm

m cm

m

A

k A

k

In Fig. 11, we also found out the time at the end of straight line has been changed, which is at 132 days.

Fig. 10: Modified normalized rate vs time on log-log plot Fig. 11: Modified [ ] q p m p m

wf i

/ ) ( ) ( ! vs t

Estimation of OGIP

The approach for estimating OGIP has been previously presented by Wattenbarger et al (1998). This method is based on the

assumption that boundary dominated flow begins when the pressure at the centre of the matrix block starts to decline. The

formula is given in Equation (9).

( )

3

6 . 200

OGIP

m

t

B C

TS

esl

i

g t

gi

! =

(9)

In our case we have

3

0032 . 0 00006 . 0 03334 . 0

745 6 . 200

OGIP

m

t

esl

!

" "

"

=

For Bellos approach:

m

3

=111250, t

esl

=225 days, then OGIP= 3.15 Bscf

For Nobakhts approach:

m

3

=93750, t

esl

=132 days, then OGIP= 2.87 Bscf

When OGIP is known, the SRV can be obtained using the following equation:

gi

gi

S

B

!

"

=

OGIP

SRV (10)

Then Bellos approach: SRV=175 MMft

3

; Nobakhts approach: SRV=159 MMft

3

. Comparing the estimated SRV with

previous given value of 169 MMft

3

, Bellos approach overestimates 6 MMft

3

in SRV, while Nobakhts approach

underestimates 10 MMft

3

. However, both methods give a reasonable value.

8 SPE 153072

Numerical Simulation and Discussion

A numerical simulation has been designed to validate the results from type curve matching. We have developed a single

porosity single phase model. In this model, 20 transverse fractures have been defined as very high permeable path along the

horizontal wellbore evenly (Fig. 12). The well is placed in the centre of the reservoir. The reservoir area is assumed to be equal

to the area of SRV. Other parameters for simulation are shown in Table 1.

Fig. 12: Simulation model for well A, 20 transverse fractures

Fig. 13: History matching of well A

Fig. 13 shows the good matching of simulated data with actual production history except some points in the initial data which

is affected by the fracture system. The matching matrix permeability was 1.25 #10

-4

md. Comparing this matching

permeability from simulation with the above results from type curve analysis indicates the permeability from type curve is

higher especially 172% of Bellos and 242% of Nobakhts (Table 2). Ibrahim & Wattenbarger (2006) stated that the effect of

drawdown on transient linear flow could lead to overestimation of

m cm

k A and OGIP, and developed the following empirical

equation to estimate the correction factor.

2

0857 . 0 0852 . 0 1

D D cp

D D f ! ! = (11)

Where D

D

is the drawdown parameter defined by the following equation:

) (

) ( ) (

i

wf i

D

p m

p m p m

D

!

= (12)

We used an average bottom-hole pressure of 1500 psi and obtained D

D

=0.941, then the correction factor of 0.884 is

determined as following:

844 . 0 941 . 0 941 . 0 0857 . 0 941 . 0 0852 . 0 1 = ! ! " ! " =

cp

f

The correction factor was applied to modify matrix permeability, OGIP and SRV. The results are shown in Table 2. The

modified matrix permeability is still higher than the permeability from simulation. We believe this difference is related to the

assumption of dual-porosity flow behaviour in type curve analysis while we have used a single porosity model in reservoir

simulation. The reason a single porosity model was used is that we could not get good results by using matrix shape factor "

of 3.0#10

-4

ft

-2

in double porosity simulation. Also in Bellos approach, only the effect of convergence skin was considered,

and the pressure drop in horizontal wellbore was not included. In overall, the permeability from simulation was in the range of

acceptable agreement with type curve analysis. Since the effect of skin exhibits a curve deviated from the straight line with

having an intercept (Fig. 9), Bellos approach is closer to the numerical simulation result (Table 2).

SPE 153072 9

Table 2: Parameters estimation and modification

Approach

OGIP, Bscf SRV, MMft

3

Matrix permeability, 10

-4

md

Original Modified Original Modified Original Modified

Numerical

simulation

Bellos 3.15 2.66 175 148 2.15 1.81

1.25

Nobakhts 2.87 2.42 159 134 3.02 2.55

It is needed to mention that the modified SRV are lower than the SRV reported from hydraulic fracture modelling, especially

86% for Bellos case and 79% for Nobakhts case (Table 2). However, these results are also in the acceptable range of

estimation. The modified OGIP is either 2.66 or 2.42 Bscf, which represents the total free gas in SRV region because the

adsorbed gas has not been included in the calculation.

Production Forecasting

Dual porosity linear flow model can be used to predict the shale gas production. However, many parameters are required and

this would lead to uncertainties of the results. For boundary dominated flow in this case, material balance and pseudo-steady

flow equation were combined and used for production forecasting. The material balance for volumetric gas reservoirs

accounting for desorption (King, 1990) is given:

!

!

"

#

$

$

%

&

' =

G

G

z

p

z

p p

i

i

1

* *

(13)

p

zRTC

z

z

E

!

+

=

1

*

(14)

Where, C

E

is equilibrium isotherm. The rock and water compressibility is assumed to be negligible. Pseudo-steady flow

equation for gas reservoir is given below.

[ ] ) ( ) (

wf cp g

p m p m J q ! = (15)

Where, J

cp

is the production index for the constant bottom-hole pressure. For well A, the latest production data were used to

calculate an average J

cp

. This value depends on average pressure or OGIP. Then two results can be obtained for two different

OGIP values of Bellos and Nobakhts cases.

Fig.14 is the production forecasting of 15 years for well A at constant bottom-hole pressure 1500 psi. Due to the larger OGIP

value in Bellos approach, we have obtained a little higher production rate than Nobakhts case. The gas rate decline with time

and the decline rate gradually close to a constant value after 15 years. It is noted that the production forecasting in our

calculation is underestimated because the contribution of un-stimulated zone to production was not considered.

Fig. 14: 15 years production forecasting, no desorption Fig. 15: Adsorption isotherms Barnett Shale (Bartenhagen,

2009); Woodford Shale (Jack Breig, 2010)

In order to investigate the effect of desorption, two adsorption isotherms (Fig. 15) were used for production forecasting

(adsorption isotherm for Eagle Ford was not available), Isotherm 1 has a low Langmuir pressure which is around 300 psi,

while isotherm 2 has the value of 1500 psi. Fig. 16 is the production forecasting of 15 years for different adsorption isotherms

at constant bottom-hole pressure of 500 psi. It is illustrated that the higher Langmuir pressure releases more adsorbed gas and

results in higher gas production. However, the effect of desorption using isotherm 1 is not significant due to the relative high

average reservoir pressure not allowing gas desorption in this case. However, for long-term production forecasting, it is always

needed to account for desorption. As seen in Table 3, gas desorption can make the EUR to be up to 27% higher.

10 SPE 153072

Fig.16: Production forecasting for different adsorption isotherms

Table 3: EUR comparison

EUR at 30 years, Bscf

Bello Nobakht

No desorption 2.38 2.22

Isotherm 1 2.58 2.42

Isotherm 2 3.00 2.82

Conclusions

Three flow regimes of bilinear flow; matrix linear flow; and boundary dominated flow are found in Eagle Ford shale

production data.

Fracture permeability was calculated to be around 820 nd based on bilinear flow analysis and the assumption of slab

model.

The effect of apparent skin has been considered based on two different approaches of Bello and Nobakht methods.

OGIP was estimated by boundary dominated flow to be 2.42 or 2.66, and SRV was estimated to be 134 or 148 MMft

3

which is close to the reported value of SRV in hydraulic fracture modelling.

Matrix permeability was estimated to be 181 or 255 nd by matrix linear flow analysis. The results are validated by

numerical simulation. The permeability from simulation was in the range of acceptable agreement with type curve

analysis.

Production forecasting has been carried out with different adsorption isotherms. The results showed that the effect of

desorption depends on both reservoir pressure and adsorption isotherm. In early times when the reservoir pressure is high

the gas desorption is usually not important; however, for long-term production forecasting, it is needed to account for

desorption based on a laboratory measured isotherm.

Nomenclature

A

cw

= well face cross-sectional area to flow, ft

2

A

cm

= total matrix surface area draining into fracture system, ft

2

B

g

= formation volume factor at initial reservoir pressure, rcf/scf

b = intercept of field data on the [m(p

i

) m(p

wf

)]/q

g

vs. t

0.5

plot, psi

2

/cp/Mscf/day

C

f

= hydraulic fracture conductivity, md-ft

C

t

= total compressibility at initial reservoir pressure, psi

-1

C

E

=equilibrium isotherm, 1b-moles/ft

3

D

D

=drawdown parameter, fraction

f

CP

= drawdown correction factor, dimensionless

G = gas in place, scf

G

p

= cumulative gas production, scf

h = reservoir thickness, ft

J

cp

= production index for the constant bottomhole pressure, Mscf/day/psi

2

/cp

k

f

= fracture permeability, md

k

m

= matrix permeability, md

L = fracture spacing for slab model, ft

m

1

= slope of the line matching the early linear flow data and passing through the origin on the square root of time plot

m

2

= slope of the line matching the bilinear flow data and passing through the origin on the quarter root of time plot

SPE 153072 11

m

3

= slope of the line matching the matrix linear flow data and passing through the origin on the square root of time plot

m(p) = pseudopressure (gas), psi

2

/cp

p

i

= initial reservoir pressure, psi

p

wf

= wellbore flowing pressure, psi

p = average reservoir pressure, psi

q

g

= gas rate, Mscf/day

R = gas constant, J K

$1

mol

$1

S

gi

= initial gas saturation, fraction

T = absolute temperature,

o

R

t = time, days

t

esl

= time to end of straight line on the square root of time plot, days

x

e

= drainage area length (rectangular geometry), ft

y

e

= drainage area half-width (rectangular geometry), equivalent to fracture half-length, ft

z = compressibility factor, fraction

z

*

=modified compressibility factor account for gas desorption, fraction

Greek symbols

! = dampening factor, dimensionless

% = dimensionless interporosity parameter

= viscosity, cp

& = dimensionless storativity ratio

" = porosity

'=shape factor, ft

-2

Subscript

i = initial

f = fracture

m = matrix

f+m = total system (fracture + matrix)

References

Agarwal, R.G., Gardner, D.C., Kleinsteiber, S.W., et al. 1999. Analyzing Well Production Data Using Combined-Type-Curve and Decline-

Curve Analysis Concepts. SPE Reservoir Res Eval. & Eng 2 !5"# 478-486. SPE-57916-PA. http://dx.doi.org/10.2118/57916-PA.

Al-Ahmadi, H.A., Almarzooq, A.M. and Wattenbarger, R.A. 2010. Application of Linear Flow Analysis to Shale Gas Wells-Field Cases.

Paper SPE 130370 presented at the SPE Unconventional Gas Conference held in Pittsburgh, Pennsylvania, USA, 2325 February.

http://dx.doi.org/10.2118/130370-MS.

Anderson, D.M., Nobakht.M., Moghadam, S., et al. 2010. Analysis of Production Data from Fractured Shale Gas Wells. Paper SPE 131787

presented at the SPE Unconventional Gas Conference held in Pittsburgh, Pennsylvania, USA, 23-25 February.

http://dx.doi.org/10.2118/131787-MS.

Arps, J.J. 1945. Analysis of Decline Curves. Trans., AIME, 160: 228-247.

Baihly, J., Altman, R., Malpani, R., et al. 2010. Shale Gas Production Decline Trend Comparison over Time and Basins. Paper SPE 135555

was presented at the SPE Annual Technical Conference and Exhibition held in Florence, Italy, 19-22 September.

http://dx.doi.org/10.2118/135555-MS.

Bartenhagen, K. 2009. Evaluation of Shale Gas Reservoirs Focus on Haynesville, http://etgpa.org/wp-content/uploads/2010/07/20090310-

%E2%80%93-Evalutation-of-Shale-Gas-Reservoirs-with-Focus-on-the-Haynesville-Shale-%E2%80%93-Schlumberger.pdf

(downloaded 12 December 2010).

Bazan, L.W., Larkin, S.D., Lattibeaudiere, M.G., et al. 2010. Improving Production in the Eagle Ford Shale with Fracture Modeling,

Increased Conductivity and Optimized Stage and Cluster Spacing Along the Horizontal Wellbore. Paper SPE138425 presented at the

SPE Tight Gas Completions Conference held in San Antonio, Texas, USA, 23 November. http://dx.doi.org/10.2118/138425-MS

Bello, R.O. and Wattenbarger, R.A. 2008. Rate Transient Analysis in Naturally Fractured Shale Gas Reservoirs. Paper SPE 114591

presented at the CIPC/SPE Gas Technology Symposium 2008 Joint Conference, Calgary, Alberta, Canada, 16 -19 June.

http://dx.doi.org/10.2118/114591-MS

Bello, R.O. and Wattenbarger, R.A. 2009. Modeling and Analysis of Shale Gas Production with a Skin Effect. Paper CIPC 2009-082

presented at the Canadian International Petroleum Conference, Calgary, Alberta, Canada, 16 -18 June. http://dx.doi.org/10.2118/2009-

082.

Bello, R.O. 2009. Rate Transient Analysis in Shale Gas Reservoirs with Transient Linear Behaviour. PhD Dissertation, Texas A &M U.,

College Station, Texas (May 2009).

Bello, R.O. and Wattenbarger, R.A. 2010. Multi-stage Hydraulically Fractured Shale Gas Rate Transient Analysis. Paper SPE 126754

presented at the SPE North Africa Technical Conference and Exhibition held in Cairo, Egypt, 14 - 17 February.

http://dx.doi.org/10.2118/126754-MS.

Breig, J. 2010. Gas Shale: Adsorbed Component Assessment, http://www.ogs.ou.edu/MEETINGS/Presentations/Shales2010/Breig.pdf

(downloaded 12 December 2010).

12 SPE 153072

Brohi, I., Pooladi-Darvish, M., and Aguilera R. 2011. Modeling Fractured Horizontal Wells As Dual Porosity Composite Reservoirs-

Application to Tight Gas, Shale Gas and Tight Oil Cases. Paper SPE 144057 was presented at the SPE Western North American

Regional Meeting held in Anchorage, Alaska, USA, 7-11 May. http://dx.doi.org/10.2118/144057-MS.

Brown, M. Ozkan, E., Raghavan, R., and Kazemi, H. 2009. Practical Solutions for Pressure Transient Responses of Fractured Horizontal

Wells in Unconventional Reservoirs. Paper SPE125043 presented at the 2009 SPE Annual Technical Conference and Exhibition held in

New Orleans, Louisiana, USA, 4-7 October. http://dx.doi.org/10.2118/125043-MS.

Cipolla, C.L., Lolon, E.P., Erdle J.C., et al. 2009. Reservoir Modeling in Shale-Gas Reservoirs. Paper SPE125530 presented at the 2009 SPE

Eastern Regional Meeting held in Charleston, West Virginia, USA, 23-25 September. http://dx.doi.org/10.2118/125530-MS.

Duong, A.N. 2010. An Unconventional Rate Decline Approach for Tight and Fracture-Dominated Gas Wells. Paper CSUG/SPE137748 was

presented at the Canadian Unconventional Resources & International Petroleum Conference held in Calgary, Alberta, Canada, 19-21

October. http://dx.doi.org/10.2118/137748-MS.

El-Banbi, A.H. 1998. Analysis of Tight Gas Wells. PhD Dissertation, Texas A &M U., College Station, Texas (May 1998).

Fetkovich, M.J. 1980. Decline Curve Analysis Using Type Curves. J.Pet Tech June:1065-1077. SPE-4629-PA.

http://dx.doi.org/10.2118/4629-PA.

Hazlett, W.G., Lee, W.J. and Narahara, G.M. 1986. Production Data Analysis Type Curves for the Devonian Shales. Paper SPE 15934

presented at the SPE Eastern Regional Meeting held in Columbus, Ohio, November 12-14. http://dx.doi.org/10.2118/15934-MS

Ibrahim, M. and Wattenbarger, R.A. 2006. Rate Dependence of Transient Linear Flow in Tight Gas Wells. J. Cdn. Pet. Tech 45(10):18-20,

October. SPE-06-10-TN2. http://dx.doi.org/10.2118/06-10-TN2.

Inamdar, A., Malpani, R., Atwood, K., et al. 2010. Evaluation of Stimulation Techniques Using Microseismic Mapping in the Eagle Ford

Shale. Paper SPE 136873 presented at the SPE Tight Gas Completions Conference held in San Antonio, Texas, USA, 23 November.

http://dx.doi.org/10.2118/136873-MS.

King, G.R. 1990. Material Balance Techniques for Coal Seam and Devonian Shale Gas Reservoirs. Paper SPE 20730 presented at the 65th

Annual Technical Conference and Exhibition of the Society of Petroleum Engineers held in New Orleans, LA, 23-26 September.

http://dx.doi.org/10.2118/20730-MS.

Lee, W.J. and Gatens Ill, J.M. 1985. Analysis of Eastern Devonian Gas Shales Production Data. Paper SPE 14506 presented at the SPE 1985

Eastern Regional Meeting Held in Morgsntown, West Virginia, 6-8 November. http://dx.doi.org/10.2118/14506-MS.

Lee W.J. and Sidel, R.E. 2010. Gas Reserves Estimation in Resource Plays.Paper SPE 130102 was presented at the SPE Uncoventional Gas

Conference held in Pittsburgh, Pennsylvania, USA, 23-25 February. http://dx.doi.org/10.2118/130102-MS.

Lewis, A.M. and Hughes, R.G. 2008. Production Data Analysis of Shale Gas Reservoirs. Paper SPE 116688 presented at the SPE Annual

Technical Conference and Exhibition, Denver, Colorado, 21 - 24 September. http://dx.doi.org/10.2118/116688-MS.

Mattar, L., Gault, B., Morad, K., et al. 2008. Production Analysis and Forecasting of Shale Gas Reservoirs: Case History-Based Approach.

Paper SPE 119897 presented at the 2008 SPE Shale Gas Production Conference, Fort Worth, Texas, 16-18 November.

http://dx.doi.org/10.2118/119897-MS.

Moghadam S., Matter, L. and Pooladi-Darvish, M. 2010. Dual Porosity Typecurves for Shale Gas Reservoirs. Paper CSUG/SPE 137535

presented at the Canadian Unconventional Resources & International Petroleum Conference held in Calgary, Alberta, Canada, 19-21

October. http://dx.doi.org/10.2118/137535-MS.

Mullen, J. 2010. Petrophysical Characterization of the Eagle Ford Shale in South Texas. Paper CSUG/SPE 138145 presented at the Canadian

Unconventional Resources & International Petroleum Conference held in Calgary, Alberta, Canada, 19-21 October.

http://dx.doi.org/10.2118/138145-MS.

Nobakht, M. and Mattar, L. 2010. Analyzing Production Data from Unconventional Gas Reservoirs with Linear Flow and Apparent Skin.

Paper CSUG/SPE 137454 presented at the Canadian Unconventional Resources & International Petroleum Conference held in Calgary,

Alberta, Canada, 19-21 October. http://dx.doi.org/10.2118/137454-MS.

Ozkan, E., Brown, M., Raghavan, R., and Kazemi, H. 2009. Comparison of Fractured Horizontal-Well Performance in Conventional and

Unconventional Reservoirs. Paper SPE 121290 was presented at the 2009 SPE Western Regional Meeting held in San Jose, California,

USA, 24-26 March. http://dx.doi.org/10.2118/121290-MS.

Palacio, J.C. and Blasingame, T.A.1993. Decline-Curve Analysis Using Type CurvesAnalysis of Gas Well Production Data. Paper SPE

25909 presented at the 1993 SPE Joint Rocky Mountain Regional and Low Permeability Reservoirs Symposium, Denver, CO, 26-28

April. http://dx.doi.org/10.2118/25909-MS.

Stegent, N.A., Wagner, A.L., Mullen, J., et al. 2010. Engineering a Successful Fracture-Stimulation Treatment in the Eagle Ford Shale.

Paper SPE 136183 presented at the SPE Tight Gas Completions Conference held in San Antonio, Texas, USA, 23 November.

http://dx.doi.org/10.2118/136183-MS.

Valk, P.P. and Lee, W. J. 2010. A Better Way to Forecast Production from Unconventional Gas Wells. Paper SPE 134231 was presented at

the SPE Annual Technical Conference and Exhibition held in Florence, Italy, 19-22 September. http://dx.doi.org/10.2118/134231-MS.

Wattenbarger, R.A., El-Banbi A.H., Villegas M.E., et al. 1998. Production Analysis of Linear Flow into Fractured Tight Gas Wells. Paper

SPE 39931 presented at the 1998 SPE Rocky Mountain Regional/ Low-Permeability Reservoirs Symposium and Exhibition held in

Denver, Colorado, 5-8 April. http://dx.doi.org/10.2118/39931-MS.

You might also like

- Chemical Process Retrofitting and Revamping: Techniques and ApplicationsFrom EverandChemical Process Retrofitting and Revamping: Techniques and ApplicationsGade Pandu RangaiahNo ratings yet

- Pgi Unconventional ResourcesDocument40 pagesPgi Unconventional ResourcesGhassen LaouiniNo ratings yet

- Package2 SRU Addendum DocumentsDocument19 pagesPackage2 SRU Addendum DocumentsSIVANo ratings yet

- EU Shale Gas Myths and TruthDocument7 pagesEU Shale Gas Myths and TruthdownbuliaoNo ratings yet

- Saes T 101Document6 pagesSaes T 101nadeem shaikhNo ratings yet

- SATR-J - 6801 - Rev 0 PDFDocument6 pagesSATR-J - 6801 - Rev 0 PDFAdel KlkNo ratings yet

- Certifiedlist Petroleum EngineeriingDocument8 pagesCertifiedlist Petroleum EngineeriingashaikhNo ratings yet

- Engineering ProcedureDocument50 pagesEngineering Procedure MohammedNo ratings yet

- 31-SAMSS-010 - 25 Oct 2018Document9 pages31-SAMSS-010 - 25 Oct 2018Fayez Al-ahmadiNo ratings yet

- OTC 22997 Overcoming Field Development Challenges in Depleting Ultra HPHT West Franklin FieldDocument10 pagesOTC 22997 Overcoming Field Development Challenges in Depleting Ultra HPHT West Franklin FieldRasheed YusufNo ratings yet

- RFP Clause Q010 - LOCAL DELIVERY PO (NON-CONCURRENT)Document40 pagesRFP Clause Q010 - LOCAL DELIVERY PO (NON-CONCURRENT)SamiNo ratings yet

- Company ProfileDocument6 pagesCompany Profilevivek mahobiyaNo ratings yet

- The Corrosion of Superduplex SS in Different Types of SeawaterDocument9 pagesThe Corrosion of Superduplex SS in Different Types of SeawaterdevangmajithiaNo ratings yet

- MP-HSEQ-JD - Batch 2 Topside HSE Supervisor - OffshoreDocument3 pagesMP-HSEQ-JD - Batch 2 Topside HSE Supervisor - Offshoredwi ari wNo ratings yet

- GE in Saudi Arabia, Manufacturing Technology CenterDocument11 pagesGE in Saudi Arabia, Manufacturing Technology CenterAsif SajwaniNo ratings yet

- EPA-600-2-85-106 Evaluation of The Efficiency of Industrial Flares: Flare Head Design and Gas CompositionDocument140 pagesEPA-600-2-85-106 Evaluation of The Efficiency of Industrial Flares: Flare Head Design and Gas CompositionkrcomeyNo ratings yet

- GRP Pipe Case History - Revised Shoiaba Eng Large DiaDocument4 pagesGRP Pipe Case History - Revised Shoiaba Eng Large DiaA.Subin DasNo ratings yet

- The Khuff Formation - Play Elemetns and Development HistoryDocument17 pagesThe Khuff Formation - Play Elemetns and Development Historymohan kumarNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument3 pagesSaudi Aramco Typical Inspection PlanOmer aliNo ratings yet

- Saso PDFDocument1 pageSaso PDFKhyle Laurenz DuroNo ratings yet

- SAES-L-460 PDF Download - Pipeline Crossings Under Roads - PDFYARDocument7 pagesSAES-L-460 PDF Download - Pipeline Crossings Under Roads - PDFYARZahidRafiqueNo ratings yet

- 18-SAMSS-493 - Two Part Polyurethane Duct SealantDocument5 pages18-SAMSS-493 - Two Part Polyurethane Duct Sealantmedication abbasNo ratings yet

- Group-5 HF AssignmentDocument42 pagesGroup-5 HF AssignmentHitakshi KubavatNo ratings yet

- Saep 12Document39 pagesSaep 1269badbutchNo ratings yet

- FOR BID: Refining & NGL Projects Department North RT Refinery & Ju'Aymah NGL Projects DivisionDocument2 pagesFOR BID: Refining & NGL Projects Department North RT Refinery & Ju'Aymah NGL Projects DivisionBilel MahjoubNo ratings yet

- Major Water Pipeline Project Supplies Oil Fields in IraqDocument3 pagesMajor Water Pipeline Project Supplies Oil Fields in IraqJoseph NNo ratings yet

- Sabp A 001Document22 pagesSabp A 001kuse2456No ratings yet

- 01-SAMSS-023 PDF - Intrusive Online Corrosion MonitoringDocument4 pages01-SAMSS-023 PDF - Intrusive Online Corrosion MonitoringZahidRafiqueNo ratings yet

- Satip e 007 01Document2 pagesSatip e 007 01Anonymous 4e7GNjzGWNo ratings yet

- 71372-Successful Well Control in The Cantarell Field ApplyinDocument12 pages71372-Successful Well Control in The Cantarell Field ApplyinIván VelázquezNo ratings yet

- ME430 Air Conditioning Quiz and Exam QuestionsDocument9 pagesME430 Air Conditioning Quiz and Exam Questionskakajssh yhsusuaiwNo ratings yet

- Qatar North Field GTL Project: ConfidentialDocument23 pagesQatar North Field GTL Project: ConfidentialMostafa KorttamNo ratings yet

- Reference ListDocument4 pagesReference ListAliZenatiNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument1 pageInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinNo ratings yet

- Sabp J 902Document9 pagesSabp J 902kartik_harwani4387No ratings yet

- 20IPTC Call For Papers Brochure Extended DeadlineDocument8 pages20IPTC Call For Papers Brochure Extended DeadlineAnkit SharmaNo ratings yet

- Saes Q 004Document24 pagesSaes Q 004AasimNo ratings yet

- Chloride SCC of 316 SST PDFDocument5 pagesChloride SCC of 316 SST PDFSH1961No ratings yet

- SAUDI ARAMCO BOILER INSPECTION PLANDocument4 pagesSAUDI ARAMCO BOILER INSPECTION PLANAnonymous 4e7GNjzGWNo ratings yet

- Oil & Gas Industry in Arabic World 1Document42 pagesOil & Gas Industry in Arabic World 1Suleiman BaruniNo ratings yet

- MOC FinalDocument40 pagesMOC FinalAvinash MuralaNo ratings yet

- 2 FF For SIF Patrick FlandersDocument12 pages2 FF For SIF Patrick FlandersSaahil KhanNo ratings yet

- Pipeline Technology Conference 2020: GRP Piping FailuresDocument14 pagesPipeline Technology Conference 2020: GRP Piping FailuresEnrico Manfrinato100% (1)

- RCP Method Prevents Corrosion in Stainless Steel PipingDocument9 pagesRCP Method Prevents Corrosion in Stainless Steel PipinghamidNo ratings yet

- D 6646 - 01 Rdy2ndytukveDocument10 pagesD 6646 - 01 Rdy2ndytukveClaudio JavierNo ratings yet

- Oil and Natural Gas Wells: Types, Uses, and ImportanceDocument23 pagesOil and Natural Gas Wells: Types, Uses, and ImportanceASOMA .YNo ratings yet

- Saep 327Document13 pagesSaep 327Abdullah BakhurjiNo ratings yet

- Pressure Relief SAES A 004Document1 pagePressure Relief SAES A 004viswamanojNo ratings yet

- Syaukani Muhammad AliDocument6 pagesSyaukani Muhammad AlidotcomNo ratings yet

- File-Chemical InjectDocument58 pagesFile-Chemical InjectEnvNo ratings yet

- SAEP-321 Performance Qualification Testing and Certification of Saudi Aramco WeldersDocument28 pagesSAEP-321 Performance Qualification Testing and Certification of Saudi Aramco WeldersSergey KichenkoNo ratings yet

- 34 Samss 718Document14 pages34 Samss 718Eagle SpiritNo ratings yet

- SATIP-W-011-01 Rev 8Document10 pagesSATIP-W-011-01 Rev 8saravananmenmathiNo ratings yet

- 4.2 - Ali - MoosaviDocument23 pages4.2 - Ali - MoosaviRavie OuditNo ratings yet

- Surge Analysis Report for Water Transmission SchemeDocument201 pagesSurge Analysis Report for Water Transmission SchemeALINo ratings yet

- Quantitative Risk Analysis SafDocument5 pagesQuantitative Risk Analysis Safkibweant100% (2)

- 13 Very Important Type Tests of A Low Voltage Switchgear Carried Out by The ManufacturerDocument10 pages13 Very Important Type Tests of A Low Voltage Switchgear Carried Out by The ManufacturerAhmed BoussoffaraNo ratings yet

- Mont Belvieu, Texas Ethane Storage Hub: Warnings For AppalachiaDocument7 pagesMont Belvieu, Texas Ethane Storage Hub: Warnings For AppalachiaJames BruggersNo ratings yet

- ConocoPhillips 10K 20120221Document200 pagesConocoPhillips 10K 20120221Gianluca FerrariNo ratings yet

- OTC-25330-MS Deepwater Methane Hydrate Gravel Packing Completion Results and ChallengesDocument14 pagesOTC-25330-MS Deepwater Methane Hydrate Gravel Packing Completion Results and ChallengesFernando Montes de OcaNo ratings yet

- SPE 81545 Water Flood Conformance in A Highly Faulted Carbonate ReservoirDocument6 pagesSPE 81545 Water Flood Conformance in A Highly Faulted Carbonate ReservoirFernando Montes de OcaNo ratings yet

- Goldenrulesreport PDFDocument150 pagesGoldenrulesreport PDFRizkaNo ratings yet

- Leader SummariesDocument7 pagesLeader SummariesRicardo André MonterrubioNo ratings yet

- Persuasive Technical Presentations PDFDocument3 pagesPersuasive Technical Presentations PDFFernando Montes de OcaNo ratings yet

- Some Practical Aspects of Reservoir ManagementDocument11 pagesSome Practical Aspects of Reservoir ManagementFernando Montes de OcaNo ratings yet

- BP Statistical Review of World Energy 2017 Full ReportDocument52 pagesBP Statistical Review of World Energy 2017 Full ReportFredyNo ratings yet

- Goldenrulesreport PDFDocument150 pagesGoldenrulesreport PDFRizkaNo ratings yet

- Annex of Regulation and Best PracticeDocument2 pagesAnnex of Regulation and Best PracticeFernando Montes de OcaNo ratings yet

- World Energy Balances 2017 OverviewDocument21 pagesWorld Energy Balances 2017 OverviewJessica TangNo ratings yet

- The Facts About Hydraulic Fracturing and Seismic ActivityDocument2 pagesThe Facts About Hydraulic Fracturing and Seismic ActivityFernando Montes de OcaNo ratings yet

- BP Statistical Review of World Energy 2017 Full ReportDocument52 pagesBP Statistical Review of World Energy 2017 Full ReportFredyNo ratings yet

- Study of The Potential Impacts of Hydraulic Fracturing On Drinking Water Resources: Progress Report by The U.S. Environmental Protection Agency, December 2012Document278 pagesStudy of The Potential Impacts of Hydraulic Fracturing On Drinking Water Resources: Progress Report by The U.S. Environmental Protection Agency, December 2012Randall WestNo ratings yet

- Spe 17620 MSDocument16 pagesSpe 17620 MSFernando Montes de OcaNo ratings yet

- SPE-171089-MS Yacimientos de Aceite PesadoDocument27 pagesSPE-171089-MS Yacimientos de Aceite PesadoFernando Montes de OcaNo ratings yet

- EOR: Promesa Incumplida o Un Gran Futuro?: Fernando Cabrera Eduardo ManriqueDocument25 pagesEOR: Promesa Incumplida o Un Gran Futuro?: Fernando Cabrera Eduardo ManriqueFernando Montes de OcaNo ratings yet

- Spe 24605 PaDocument4 pagesSpe 24605 PaFernando Montes de OcaNo ratings yet

- Spe 173465 Stu PDFDocument10 pagesSpe 173465 Stu PDFFernando Montes de OcaNo ratings yet

- Craff and Howkins ApreDocument226 pagesCraff and Howkins ApreFernando Montes de OcaNo ratings yet

- BK - Scrum and CMMIDocument132 pagesBK - Scrum and CMMIcoolgoroNo ratings yet

- Leadership Learnings From Chhatrapati SHDocument5 pagesLeadership Learnings From Chhatrapati SHSagar RautNo ratings yet

- Nested Group PowerShellDocument3 pagesNested Group PowerShellNeha SinghNo ratings yet

- Process Management: Operating SystemsDocument48 pagesProcess Management: Operating SystemsvidishsaNo ratings yet

- Multipoint Socket Profile VW 010 43: KonzernnormDocument4 pagesMultipoint Socket Profile VW 010 43: KonzernnormRicardo Vitoriano100% (1)

- AIR Intelligence Manual 33 308100 004 RemoteDocument88 pagesAIR Intelligence Manual 33 308100 004 RemoteLeChancheNo ratings yet

- Em 2 SupplyDocument4 pagesEm 2 Supplykrishn murariNo ratings yet

- WB4303EDocument1 pageWB4303EcwiksjNo ratings yet

- SchoolofLifeSciencesAdmissionOpen2021-2022Document4 pagesSchoolofLifeSciencesAdmissionOpen2021-2022Amiruddin RafiudeenNo ratings yet

- Understanding Operating Systems Fifth Edition: Memory Management: Virtual MemoryDocument21 pagesUnderstanding Operating Systems Fifth Edition: Memory Management: Virtual MemoryRidzuan DolahNo ratings yet

- Ticketreissue PDFDocument61 pagesTicketreissue PDFnicoNicoletaNo ratings yet

- PLAXIS Tutorial ManualDocument124 pagesPLAXIS Tutorial ManualPeteris Skels100% (2)

- Akeeba Backup Guide PDFDocument185 pagesAkeeba Backup Guide PDFJhon ArteagaNo ratings yet

- SAP-Press - Abap Development For Sap HanaDocument30 pagesSAP-Press - Abap Development For Sap HananicocastanioNo ratings yet

- FREE UX Books @UXlinksDocument4 pagesFREE UX Books @UXlinksSyaifudin MashuriNo ratings yet

- F940wgot TWD Installation MDocument8 pagesF940wgot TWD Installation Mchaubinhkhang110686No ratings yet

- Sustainable Energy and Resource ManagementDocument318 pagesSustainable Energy and Resource ManagementRajdeepSenNo ratings yet

- Mapping UCLA Network DrivesDocument2 pagesMapping UCLA Network DriveswebscaleNo ratings yet

- MDN 1508DSDocument108 pagesMDN 1508DSdocazanNo ratings yet

- VTT R 01177 17Document27 pagesVTT R 01177 17Joseph BookerNo ratings yet

- Smart Bell Notification System Using IoTDocument3 pagesSmart Bell Notification System Using IoTTony StankNo ratings yet

- John Deere 125 HP PDFDocument2 pagesJohn Deere 125 HP PDFJulio TovarNo ratings yet

- Djdusty VideolistDocument302 pagesDjdusty VideolistgonduNo ratings yet

- BUK9Y53-100B DatasheetDocument12 pagesBUK9Y53-100B Datasheetisomeso21No ratings yet

- Installation Guide: For Packetfence Version 8.3.0Document270 pagesInstallation Guide: For Packetfence Version 8.3.0Ferjani TarekNo ratings yet

- Computer LanguagesDocument3 pagesComputer LanguagesGurvinder Singh100% (1)

- VisQ Queue Manager System Guide Version 10.3Document27 pagesVisQ Queue Manager System Guide Version 10.3MSC Nastran Beginner100% (1)

- Slabs Are Plate Elements Forming Floors andDocument5 pagesSlabs Are Plate Elements Forming Floors andyasas89No ratings yet

- Unit 8 #10 Doppler - Effect - PPTDocument13 pagesUnit 8 #10 Doppler - Effect - PPTPrasanta NaskarNo ratings yet

- Communication in AfricaDocument5 pagesCommunication in AfricaJaque TornneNo ratings yet