Professional Documents

Culture Documents

Chew Shu Niu (Ijmpc) 2002

Chew Shu Niu (Ijmpc) 2002

Uploaded by

Hamid MojiryCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chew Shu Niu (Ijmpc) 2002

Chew Shu Niu (Ijmpc) 2002

Uploaded by

Hamid MojiryCopyright:

Available Formats

International Journal of Modern Physics C, Vol. 13, No.

6 (2002) 719738 c World Scientic Publishing Company

SIMULATION OF UNSTEADY INCOMPRESSIBLE FLOWS BY USING TAYLOR SERIES EXPANSION- AND LEAST SQUARE-BASED LATTICE BOLTZMANN METHOD

Y. T. CHEW, C. SHU, and X. D. NIU Department of Mechanical Engineering, National University of Singapore 10 Kent Ridge Crescent, Singapore 117576 Received 4 December 2001 Revised 31 January 2002 In this work, an explicit Taylor series expansion- and least square-based lattice Boltzmann method (LBM) is used to simulate two-dimensional unsteady incompressible viscous ows. The new method is based on the standard LBM with introduction of the Taylor series expansion and the least squares approach. The nal equation is an explicit form and essentially has no limitation on mesh structure and lattice model. Since the Taylor series expansion is only applied in the spatial direction, the time accuracy of the new method is kept the same as the standard LBM, which seems to benet for unsteady ow simulation. To validate the new method, two test problems, that is, the vortex shedding behind a circular cylinder at low Reynolds numbers and the oscillating ow in a lid driven cavity, were considered in this work. Numerical results obtained by the new method agree very well with available data in the literature. Keywords : Lattice Boltzmann equation; explicit method; Taylor series expansion; least square approach; unsteady ow; incompressible.

1. Introduction The study of unsteady uid systems has been a major interest for uid dynamic researchers over almost the last whole century due to its great relevance to engineering applications in reality. As the need to account for the eect of timedependence presents a considerable diculty of analysis, numerical simulation plays an important role in this eld. Conventional methods for simulating viscous unsteady ow include, macroscopically, numerical integration of the NavierStokes equations, and, microscopically, molecular dynamics simulation. However, the former has particular diculty on the implementation of complex geometries while the latter is extremely intensive in computation. Recently, the lattice Boltzmann method (LBM),1,2 which originated from the lattice gas cellular automata (LGCA), has provided an alternative approach for solving continuum problems on various physical systems. The LBM is based on gas-kinetic representations of uid ow in a strongly reduced particle velocity space, in which ow is described through the evolution of the discrete particle

719

720

Y. T. Chew, C. Shu & X. D. Niu

distribution functions on uniform lattices. Hydrodynamic variables are computed at the lattice nodes as moments of the discrete distribution functions. One of the advantages of the LBM is that it can recover the unsteady incompressible NavierStokes equations with second-order of accuracy in space and time at low Knudsen number and low frequency limit through Taylor series and ChapmanEnskog expansions.3,4 Thus it is expected that the LBM can simulate the unsteady uid problems in well accuracy. In fact, under the low frequency limit, the characteristic time T of the LBM is in the order of (M a)1 t , where M a is the global Mach number, is the Knudsen number and t is the particle streaming time. Therefore, the LBM can be applied to the unsteady uid systems with a range of Strouhal numbers of Str = L/U T = t /T M a O (1) (L and U is the characteristic length and velocity, respectively). Many numerical experiments5 8 have conrmed this conclusion. The major advantage of LBM is its algebraic form and ease for application. However, due to the use of uniform lattice, the broad application of the LBM in engineering has been greatly hampered, especially for the problems with curved boundaries or with high Reynolds numbers, which need to use a nonuniform mesh to obtain high-resolution results in the very thin boundary layer. Theoretically, the feature of lattice-uniformity is not necessary to be kept because the distribution functions are continuous in physical space. Currently, there are two ways to remove the diculty of the standard LBM for application to complex problems with nonuniform meshes. One is the so-called interpolation-supplemented LBM (ISLBM) proposed by He and his colleagues.7 9 They successfully applied this approach to simulate ows past an impulsively started cylinder. The other is based on the solution of a dierential lattice Boltzmann equation (LBE). For complex problems, the dierential LBE can be solved by the nite dierence (FDLBE) method with the help of coordinate transformation10 or by the nite volume method.11,12 These methods have been successfully applied to solve quite a number of complex problems. However, the ISLBE has an extra computational eort for interpolation at every time step, and it also has a strict restriction on the selection of interpolation points. For the FDLBE and FVLBE methods, one need to select ecient approaches such as upwind schemes to do numerical discretization in order to get the stable solution. As a consequence, the computational eciency greatly depends on the selected numerical scheme. In addition, the time accuracy of FDLBE and FVLBE methods is reduced due to truncation error of discretization in time as compared to the standard LBM. In the present work, an explicit Taylor series expansion- and least square-based LBM is proposed. The new method is based on the standard LBM with introduction of Taylor series expansion in the spatial direction and least squares optimization. The nal form of the method is an algebraic formulation, in which the coecients depend only on the coordinates of mesh points and lattice velocity, and are computed in advance. The new method can be easily applied to dierent other lattice models. Since the Taylor series expansion is applied only in the spatial direction, the

Simulation of Unsteady Incompressible Flows

721

time accuracy of the new method is kept the same as the standard LBE. Thus, it is expected that the new method can well simulate the unsteady ow problems. To validate this, two unsteady ows problems are considered in this work. One is the vortex shedding ow behind a circular cylinder. The investigation of vortex shedding in the wake of a circular cylinder at low Reynolds number is very important because it can provide some basic insights into the vortex shedding mechanism. The other case is the oscillating ow in a lid driven cavity. This problem is often chosen to test new numerical schemes for simulation of unsteady ows. There are many publications8,13 22 on these two cases in the literature. So, it is ideal to use them as unsteady benchmarks to verify the present method. 2. Taylor Series Expansion- and Least Squares-Based LBM The method developed in this work is based on the fact that the distribution function is a continuous function in physical space and can be well dened in any mesh system. Let us start with the standard LBM. The two dimensional, standard LBE with BGK approximation can be written as: f (x + ex t, y + ey t, t + t)

eq f (x, y, t) f (x, y, t) , = 0, 1, . . . , M , (1) where is the single relaxation time; f is the density distribution function along eq is its corresponding equilibrium state, which depends on the the direction; f local macroscopic variables such as a density and velocity U(u, v ); t is the time step and e (ex , ey ) is the particle velocity in the direction; M is the number of discrete particle velocities. Obviously, the standard LBE consists of two steps: collision and streaming. The macroscopic density and momentum density U are dened as:

= f (x, y, t) +

=

=0

f ,

U =

=0

f e .

(2)

Suppose that a particle is initially at the grid point (x, y, t). Along the direction, this particle will stream to the position (x + ex t, y + ey t, t + t). For a uniform lattice, x = ex t , y = ey t . So, (x + ex t , y + ey t ) is on the grid point. In other words, Eq. (1) can be used to update the density distribution functions exactly at the grid points. However, for a nonuniform grid, (x+ex t , y +ey t ) is usually not at the grid point (x + x, y + y ). In the numerical simulation, we are interested only in the density distribution function at the mesh point for all the time levels. So, the macroscopic properties such as the density, ow velocity can be evaluated at every mesh point. To get the density distribution function at the mesh point (x + x, y + y ) and the time level t + t , we need to apply the Taylor series expansion or other interpolation techniques such as the one used by He et al.7 9 In this work, the Taylor series expansion is used. Note that the time

722

Y. T. Chew, C. Shu & X. D. Niu

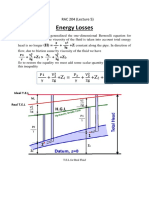

C' C B A' A

Fig. 1.

E' P'

B' E P

D' D

Conguration of particle movement along the direction.

level for the position (x + ex t , y + ey t ) and the grid point (x + x, y + y ) is the same, that is, t + t . So, the expansion in the time direction is not necessary. As shown in Fig. 1, we let point A represent the position (xA , yA ) point A represent the position (xA + ex t , yA + ey t ), and point P represent the position (xP , yP ). Using Eq. (1), we can get the density distribution function at the position A f (A , t + t) = f (A, t) +

eq f (A, t) f (A, t) .

(3)

For the general case, A may not coincide with the mesh point P . In this case, we need to obtain the density distribution function at the mesh point P . This can be done by applying the Taylor series expansion in the spatial direction only. With Taylor series expansion, f (A , t + t) can be approximated by the corresponding function and its derivatives at the mesh point P as: f (A , t + t) = f (P, t + t) + xA + f (P, t + t) f (P, t + t) + yA x y

2 2 f (P, t + t) 1 1 2 f (P, t + t) (xA )2 ( y + ) A 2 x2 2 y 2

+ xA yA

2 f (P, t + t) + O[(xA )3 , (yA )3 ] , xy

(4)

where xA = xA + ex t xp , yA = yA + ey t yp . Note that the above approximation has a truncation error of the third order. Substituting Eq. (4) into Eq. (3) gives f (P, t + t) + xA + f (P, t + t) f (P, t + t) + yA x y

2 2 f (P, t + t) 1 1 2 f (P, t + t) (xA )2 ( y + ) A 2 x2 2 y 2

+ xA yA

f eq (A, t) f (A, t) 2 f (P, t + t) = f (A, t) + . xy

(5)

Simulation of Unsteady Incompressible Flows

723

It is indicated that Eq. (5) is a dierential equation, which involves only two mesh points A and P . Solving Eq. (5) can provide the density distribution functions at all the mesh points. Equation (5) can be considered as a new version of dierential LBE, which can give very accurate numerical results. In this work, we go further to develop a new solution procedure. In fact, our new development is inspired from the RungeKutta method. As we know, the RungeKutta method is developed to improve the Taylor series method in the solution of ordinary dierential equations (ODEs). Like Eq. (5), Taylor series method involves evaluation of dierent orders of derivatives to update the functional value at the next time level. For a complicated expression of given ODEs, this application is very dicult. To improve the Taylor series method, the RungeKutta method evaluates the functional values at some intermediate points and then combines them (through the Taylor series expansion) to form a scheme with the same order of accuracy. With this idea in mind, we look at Eq. (5). We know that at the time level t + t, the density distribution function and its derivatives at mesh point P are all unknowns. So, Eq. (5) has six unknowns in total. To solve for the six unknowns, we need six equations. However, Eq. (5) just provides one equation. We need additional ve equations to close the system. As shown in Fig. 1, we can see that along the direction, the particles at ve mesh points P , B , C , D, E at the time level t will stream to the new positions P , B , C , D , E at the time level t + t. The density distribution functions at these new positions can be computed through Eq. (1), which are given below f (P , t + t) = f (P, t) + f (B , t + t) = f (B, t) + f (C , t + t) = f (C, t) + f (D , t + t) = f (D, t) + f (E , t + t) = f (E, t) +

eq f (P, t) f (P, t) , eq f (B, t) f (B, t) , eq f (C, t) f (C, t) , eq f (D, t) f (D, t) ,

(6) (7) (8) (9)

eq f (E, t) f (E, t) . (10) Using Taylor series expansion, f (P , t + t), f (B , t + t), f (C , t + t), f (D , t + t), f (E , t + t) in above equations can be approximated by the function and its derivatives at the mesh point P . As a result, Eqs. (6)(10) can be reduced to: f (P, t + t) f (P, t + t) + yP f (P, t + t) + xP x y

2 2 f (P, t + t) 1 1 2 f (P, t + t) (xP )2 ( y + ) P 2 x2 2 y 2

+ xP yP

f eq (P, t) f (P, t) 2 f (P, t + t) = f (P, t) + , xy

(11)

724

Y. T. Chew, C. Shu & X. D. Niu

f (P, t + t) + xB +

f (P, t + t) f (P, t + t) + yB x y

2 2 f (P, t + t) 1 1 2 f (P, t + t) (xB )2 ( y + ) B 2 x2 2 y 2

+ xB yB

f eq (B, t) f (B, t) 2 f (P, t + t) = f (B, t) + , xy f (P, t + t) f (P, t + t) + yC x y

(12)

f (P, t + t) + xC +

2 f (P, t + t) 1 2 f (P, t + t) 1 (xC )2 + (yC )2 2 2 x 2 y 2 f eq (C, t) f (C, t) 2 f (P, t + t) = f (C, t) + , xy f (P, t + t) f (P, t + t) + yD x y (13)

+ xC yC

f (P, t + t) + xD +

2 2 f (P, t + t) 1 1 2 f (P, t + t) (xD )2 ( y + ) D 2 x2 2 y 2

+ xD yD

f eq (D, t) f (D, t) 2 f (P, t + t) = f (D, t) + , xy f (P, t + t) f (P, t + t) + yE x y

(14)

f (P, t + t) + xE +

2 f (P, t + t) 1 2 f (P, t + t) 1 (xE )2 + (yE )2 2 2 x 2 y 2 f eq (E, t) f (E, t) 2 f (P, t + t) = f (E, t) + , xy yP = ey t , yB = yB + ey t yP , yC = yC + ey t yP , yD = yD + ey t yP , yE = yE + ey t yP . (15)

+ xE yE where

xP = ex t , xB = xB + ex t xP , xC = xC + ex t xP , xD = xD + ex t xP , xE = xE + ex t xP ,

Equations (5), (11)(15) form a system to solve for six unknowns. Now, we dene f eq (xi , yi , t) f (xi , yi , t) , (16) gi = f (xi , yi , t) +

Simulation of Unsteady Incompressible Flows

725

{ s} T = {V } =

1, xi , yi ,

(xi )2 (yi )2 , , xi yi , 2 2

T

(17)

f ,

f f 2 f 2 f 2 f , , , , x y x2 2 y xy

(18)

where gi is the post-collision state of the distribution function at the ith point and the time level t, {si }T is a vector with six elements formed by the coordinates of mesh points, {V } is the vector of unknowns at the mesh point P , which also has six elements. Our target is to nd its rst element V1 = f (P, t + t). With above denitions, Eqs. (5), (11)(15) can be written as:

6

g i = { si } T { V } =

j =1

si,j Vj ,

i = P, A, B, C, D, E ,

(19)

where si,j is the j th element of the vector {si }T and Vj is the j th element of the vector {V }. Equation system (19) can be put into the following matrix form [s]{V } = {g } , where { g } = { gP , gA , gB , gC , gD , gE } T , (yP )2 (xP )2 yP 1 xP 2 2 2 (yA )2 (xA ) 1 xA yA { sP } T 2 2 { sA } T 2 (yB )2 (xB ) 1 xB yB T { sB } 2 2 = [S ] = [si,j ] = T 2 (yC )2 (xC ) { sC } 1 xC yC { sD } T 2 2 2 2 T ( y ( x ) D D) 1 x { sE } yD D 2 2 2 (yE )2 (xE ) 1 xE yE 2 2 xP yP xA yA xB yB . xC yC xD yD xE yE (20)

Note that when lattice velocity is specied, the matrix [S ] depends only on the coordinates of mesh points, which can be computed once and stored for the application of Eq. (20) at all time levels. In practical applications, it was found that matrix [S ] might be singular or ill conditioned. To overcome this diculty and make the method be more general, we propose the following least squares-based LBM. Equation (19) has six unknowns (elements of the vector {V }). If Eq. (19) is applied at more than six mesh points, then the system is over-determined. For this

726

Y. T. Chew, C. Shu & X. D. Niu

case, the unknown vector can be decided from the least square method. For simplicity, let the mesh point P be represented by the index i = 0, and its adjacent points be represented by index i = 1, 2, . . . , N , where N is the number of neighboring points around P and it should be larger than 5. At each point, we can dene an error in terms of Eq. (19), that is,

6

erri = gi

j =1

si,j Vj ,

i = 0, 1, 2, . . . , N .

(21)

The square sum of all the errors is dened as:

N N

E=

i=0

2 erri = i=0

gi

2 si,j Vj . (22)

j =1

To minimize the error E , we need to set E/Vk = 0, k = 1, 2, . . . , 6, which leads to: [S ]T [S ]{V } = [S ]T {g } , where [S ] is a (N 1 1 [S ] = 1 + 1) 6 dimensional matrix, which is given as: x0 x1 xN y0 y1 yN (x0 )2 2 (x1 )2 2 (xN )2 2 (y0 )2 2 (y1 )2 2 (yN )2 2 (23)

x0 y0 x1 y1 xN yN

(N +1)6

and {g } = {g0 , g1 , . . . , gN }T . The x and y values in the matrix [S ] are given as: x0 = ex t, y0 = ey t , xi = xi + ex t x0 , yi = yi + ey t y0 , for i = 1, 2, . . . , N . (24a) (24b)

Clearly, when the coordinates of mesh points are given, and the particle velocity and time step size are specied, the matrix [S ] is determined. Then from Eq. (23), we obtain {V } = ([S ]T [S ])1 [S ]T {g } = [A]{g } . (25)

Note that [A] is a 6 (N + 1) dimensional matrix. From Eq. (25), we can have

N +1

f (x0 , y0 , t + t) = V1

k=1

a1,k gk1 ,

(26)

Simulation of Unsteady Incompressible Flows

727

5

Fig. 2.

Schematic plot of D2Q7 model on a solid boundary (thick black line).

where a1,k are the elements of the rst row of the matrix [A], which are precomputed before the LBM is applied. Therefore, little computational eort is introduced as compared with the standard LBE. Note that the function g is evaluated at time level t. So, Eq. (26) is actually an explicit form to update the distribution function at time level t + t for any mesh point. In the above process, there is no requirement for the selection of neighboring points. In other words, Eq. (26) is nothing to do with the mesh structure. It needs only to know the coordinates of the mesh points. Thus, we can say that Eq. (26) is basically a meshless form. It can be seen that Eq. (26) is applied along the direction. Here can be any direction. This implies that Eq. (26) can be uniformly applied to the dierent lattice models. In this work, we use the D2Q7 model. The conguration of this model is shown in Fig. 2. The discrete velocity of this model is dened as: = 0, (0, 0) , (27) e = cos ( 1) , sin ( 1) c , = 1, 2, . . . , 6 . 3 3 The parameter c is the particle streaming speed. The uid kinetic viscosity is given by: 2 1 2 c t , 8 eq is chosen to be and the equilibrium density distribution f =

eq = f

(28)

1 1 + 2 6

e U +4 c2

e U c2

U2 c2

(29)

The speed of sound of this model is cs = c/2, and the equation of state is P = c2 s for an ideal gas. Although the proposed method has meshless feature, it is recommended to use a structured grid. This is because in our method, only the coordinates of mesh points are involved. When a structured grid is used, it is easy for us to dene the coordinates of mesh points. In our application, we use a

728

Y. T. Chew, C. Shu & X. D. Niu

i 1, j + 1 i , j + 1 i 1, j i 1, j 1

Fig. 3.

i + 1, j + 1 i + 1, j i + 1, j 1

i, j

i, j 1

Schematic plot of neighboring point distribution around the point (i, j ).

structured grid, and take N as 8 for convenience. As shown in Fig. 3, for an internal mesh point (i, j ) [noted as 0 in Eq. (26)], the eight neighboring points are taken as (i 1, j 1); (i 1, j ); (i 1, j + 1); (i, j 1); (i, j + 1); (i + 1, j 1); (i + 1, j ); (i + 1, j + 1). Therefore, at each mesh point, we need only to store nine coecients a1,k , k = 1, 2, . . . , 9 before Eq. (26) is applied. Note that the conguration of nine mesh points as shown in Fig. 3 is applied in all lattice directions ( = 1, 2, . . . , 6). Implementation of boundary conditions is an essiential issue in LBM. In this work, we found that a complete half-way wall bounceback condition6 is the most simple and ecient method in implementing the boundary condition on the soild wall, where the nonslip condition holds. The complete half-way wall bounceback condition, which originated from LGCA, assigns each f the value of the f in its opposite direction with no relaxation on the bounceback points. The treament is independent of the direction, which gives us more conveniences in treating complicated boundary problems. The complete half-way wall bounceback condition has second order of accuaracy because macroscopic quantities such as stress force is evaluated on the half-way wall between the bounceback row and the rst ow row. As shown in Fig. 2, the ow eld is below the solid boundary represented by the black thick line. For the D2Q7 model, at a boundary point, f4 , f5 and f6 point to the ow eld from the wall, which will be determined from the boundary condition. f1 , f2 , f3 are computed by streaming from points inside the ow eld. Note that when f1 , f2 , f3 are computed by Eq. (26), all the neighboring points involved must be inside the ow eld. In other words, the conguration as shown in Fig. 3 cannot be used for this case. We need to select the neighboring points from one side (bottom part of the wall as shown in Fig. 2). Using the half-way wall bounceback condition, f4 , f5 and f6 are evaluated as: f4 = f1 , 3. Results and Discussion 3.1. Vortex shedding behind a circular cylinder As we know, a periodic vortex shedding will occur for ow behind a circular cylinder when Reynolds number is above the critical value of 49, and the ow f5 = f2 , f6 = f3 . (30)

Simulation of Unsteady Incompressible Flows

729

eld is two-dimensional when Reynolds number is below the second critical value around 149. Above this value, three-dimensional structure of the ow eld becomes essential.13,18 In this part, our study focuses only on two-dimensional vortex shedding behind a circular cylinder. For this reason, the Reynolds numbers (Re = U D/ ), based on the upstream velocity U and the diameter of the cylinder D, are chosen to be 50, 100 and 150. In the ow domain, the following coordinate stretching is used in the radial direction 1 (31) r = r0 + (r r0 ) 1 tan1 [(1 ) tan()] , where r0 = 1 is the cylinder radius, r is the outer boundary, is the parameter to control the coordinate stretching and = (j 1)/(jmax 1) with j representing the index of a mesh point in the radial direction. Uniform grid in the direction is adopted. Three boundary conditions are required in our simulation for this problem. One is at the cylinder surface, where a complete half-way wall bounce back condition described in the previous section is used. Another is on the cut line in the wake, where the periodic boundary condition is imposed. The third is at the far eld boundary r where the free stream ow is taken and the density distribution function is always set to its equilibrium state. A sketch of the problem is shown in Fig. 4. Initially, an asymmetrical ow eld r0 x r0 y (32) u = U 2 , v = U 2 , r r is imposed to serve as an articial initiator for the vortex shedding process. The far eld velocity U and pressure are set to 0.15 and 1.0, respectively. The mesh size of 241 241 is used for all of the above three Reynolds numbers (typical mesh is shown in Fig. 5). The far eld boundary is set at 25.5 diameters away from the center of the cylinder and the time step, in units of D/(2U ), is equal to 0.00375, which corresponds to = 0.72. Our experience showed that this is sucient to capture all the details of the ow at these three Reynolds numbers.

y

Periodic BC x

Fig. 4.

A sketch of the ow past a circular cylinder.

730

Y. T. Chew, C. Shu & X. D. Niu

Fig. 5.

Computational mesh for ow around a circular cylinder.

The most attractive feature of the vortex shedding behind a circular cylinder is the periodic variation of the ow eld. This periodicity can be illustrated by the time evolution of two characteristic parameters, the drag coecient CD and the lift coecient CL . They are dened as: CD = Fx , (1/2)U 2 D CL = Fy , (1/2)U 2 D (33)

where F = [pI + (U + U)] ndl. n is the normal vector of the cylinder surface. The vortex shedding frequency f , which is expressed by the Strouhal number of St = f D/U , can be obtained by measuring the nal period of the lift coecient.

3 2.75 2.5 2.25

1.5

1.45

Drag Coefficient

Drag Coefficient

0 50 100 150 200

2 1.75 1.5 1.25 1 0.75 0.5 0.25 0

1.4

1.35

1.3

1.25 150

160

170

180

190

200

Time

Time

(a) Whole history

(b) Close-up Re = 50;

Fig. 6. Time evolution of drag coecients for dierent Reynolds numbers ( Re = 100; Re = 150).

Simulation of Unsteady Incompressible Flows

1 0.75 0.5

1 0.75 0.5

731

Lift Coefficient

Lift Coefficient

50 100 150 200

0.25

0.25 0 -0.25 -0.5 -0.75 -1 150

-0.25 -0.5 -0.75 -1 0

160

170

180

190

200

Time

Time

(a) Whole history

(b) Close-up Re = 50;

Fig. 7. Time evolution of lift coecients for dierent Reynolds numbers ( Re = 100; Re = 150).

Figures 6 and 7 show the time evolution of the drag and lift coecients for dierent Reynolds numbers. The initially irregular variations of these coecients can be attributed to the initial disturbance. After a certain time, they gradually evolve to periodic oscillations, which become stronger with increase of the Reynolds number. The lift coecient has a stronger oscillation than the drag coecient. From the close-up of these two gures, one can observe that the variation of the drag coecient is two times faster than that of lift coecient. The reason may be due to the fact that the drag coecient is mainly aected by the vortex shedding processes from both sides of the cylinder. This observation has been justied by the study of Braza et al.19

Table 1. Comparisons of average and oscillatory drag and lift coecients and Strouhal numbers with previous studies. Reynolds number Williamson14 St He et al.8 Present Tritton20 He et al.8 Present Braza et al.19 He et al.8 Present Braza et al.19 He et al.8 Present 50 0.123 0.121 0.123 1.450 1.394 1.461 0.002 0.002 0.11 0.18 100 0.164 0.161 0.164 1.350 1.250 1.3668 0.03 0.018 0.0242 0.60 0.64 0.75 150 0.183 0.179 0.176 1.330 1.261 1.314 0.048 0.5 0.98 1.08

CD

CD

CL

732

Y. T. Chew, C. Shu & X. D. Niu

Table 1 lists the detailed comparison of the average values and oscillations (peak to peak) of the drag and lift coecients, and the calculated Strouhal number St with those of the previous studies.8,14,19,20 In Table 1, CD is the mean value of the drag coecient, while CD and CL are oscillations of drag and lift coecients from peak to peak. The results of He and Doolen8 were obtained by the LBM with interpolation technique. The results of Tritton20 were experimental data. Other data shown in Table 1 were the results of NavierStokes equations. Obviously, the present results agree very well with those published previously. As compared to the experimental data of Tritton,20 it seems that the present results have a better accuracy than those of He and Doolen.8 Since the ow patterns are similar for all the simulated Reynolds numbers, only the ow patterns at Re = 100 are presented in the paper. Figure 8 shows the sequence of vortex shedding over a complete cycle using a sequence of instantaneous streamlines and vorticity contours separated by intervals of T /8, where T is the period of the shedding cycle. From the evolution of the streamlines (left of Fig. 8), one can observe that a large vortex sheds from the top while a small vortex appears at the bottom of the cylinder initially. In the meantime, uid below the cylinder is drawn down into the large recirculation region [Fig. 8(a)]. The small vortex forming at the bottom of the cylinder grows and the large vortex travels to downstream

(a) t = T /8

(b) t = T /4

(c) t = 3T /8 Fig. 8. Streamlines (left) and vorticity contours (right) near the wake separated by an interval of T /8.

Simulation of Unsteady Incompressible Flows

733

(d) t = T /2

(e) t = 5T /8

(f) t = 3T /4

(g) t = 7T /8

(h) t = T Fig. 8. (Continued )

while its strength is reduced gradually [Figs. 8(b)8(d)]. When the strength of the small vortex grows to its maximum, it breaks o. After that, another shedding process from the bottom of the cylinder is repeated [Figs. 8(e)8(h)]. The mechanism of the vortex shedding is reected also on the instantaneous vorticity contours. As shown in Fig. 8 (right), the alternative change of the strength of a pair of asymmetric secondary vortices is just the initiator of the vortex shedding from the cylinder. The ow patterns in Fig. 8 match well with the numerical simulations by Eaton21

734

Y. T. Chew, C. Shu & X. D. Niu

and experimental observation by Perry et al.22 The centers (points surrounded by closed streamlines), saddles (points where a streamline crosses itself), separatrices (streamlines containing a saddle point) and instant alleyways between two separatrices described by them are observed also in our simulation. However, we did not observe the coexistence of centers and saddles of two shed vortices suggested by Perry et al.22 Our simulation result is consistent with the simulation results of He and Doolen8 and Eaton.21 3.2. Oscillating ow in a lid driven cavity at Re = 400 Another test case is the oscillating ow in a square cavity. A periodic velocity waveform is imposed on the cavity lid and the time evolution observed in the ow is compared with the numerical results of Soh and Goodrich.16 The periodic lid velocity is given by a sinusoidal waveform: u(t) = U cos(t) , (34)

where U is the maximum lid velocity during the cycle, is the frequency of the oscillation and t is the time. The period of oscillation, T , is related to the frequency by T = 2/ . Our simulation is performed with Re = 400 (Re = U L/ , where L is the characteristic length set as the value of top wall), frequency of = 1 and U = 0.15. Initially, a periodic velocity given by Eq. (34) is imposed. A nonuniform grid of 97 97 with more densely distribution near the boundaries is used, and as a consequence, the time step is set as, in the unit of L/U , 4.5 104 . The oscillatory ow reaches the stable periodic state when the velocity components u and v of each point in the domain at two consequent ow cycles are with a small tolerance of = 105 .

(a) Initial evolution Fig. 9.

(b) Later stage of evolution

Time evolution of drag on the cavity lid.

Simulation of Unsteady Incompressible Flows

735

It was found that the ow reaches the stable periodic state after seven cycles. Figure 9 shows the time evolution of the viscous drag on the lid, which is estimated using the same formula as used by Soh and Goodrich.16 It can be observed that the drag settles down to be periodic very quickly, much quicker than the entire ow eld. The value of maximum drag obtained by the present method agrees very well with that predicted by Soh and Goodrich.16 The instantaneous streamlines obtained by the present method match very well with those of Soh and Goodrich,16 which are shown in Figs. 10 and 11 at t = (5 + )T where = 0.2, 0.3, 0.35, 0.4, 0.45, 0.5, 0.7, 0.8, 0.85, 0.9, 0.95 and 1.0, respectively. Figure 10 shows the streamlines in the rst half of the cycle while Fig. 11 displays the streamlines in the second half of the cycle. As time advances, the direction of the lid movement and the center of the vortex change. The lid velocity passes through zero at t = T /4, after which it reverses its direction. As a result, at t = 0.3T , a counter rotating vorticity is formed in the ow eld at the left corner of the cavity. As the magnitude of the velocity increases in the negative x direction, the size of the second vortex created in the upper left corner of the cavity also increases. At the same time, the primary vortex continuously shrinks until t = T /2. At this point, the velocity reaches its maximum in the negative x direction and the second vortex, which has formed in the left corner of the cavity,

(a) t = 0.2T

(b) t = 0.3T

(c) t = 0.35T

(d) t = 0.4T Fig. 10.

(e) t = 0.45T

(f) t = 0.5T

Instantaneous streamlines in the rst half of a cycle obtained by the present method.

736

Y. T. Chew, C. Shu & X. D. Niu

(a) t = 0.7T

(b) t = 0.8T

(c) t = 0.85T

(d) t = 0.9T Fig. 11.

(e) t = 0.95T

(f) t = T

Instantaneous streamlines in the second half of a cycle obtained by the present method.

attains its maximum size and occupies the entire domain. After this point, the streamlines at each time step are the mirror images of the streamlines at the time t T /2. This nding can be obviously observed by comparing the results of Fig. 10 with those of Fig. 11. The same nding has been shown in the results of Soh and Goodrich.16 3.3. Eect of grid size To show that the present results are accurate, we performed numerical simulations for the vortex shedding ow at Re = 100 and the oscillating ow in a lid driven cavity by using two dierent mesh sizes. For the vortex shedding case, two mesh sizes of 201 201 and 241 241 are used and the time steps are correspondingly set to be, in units of D/(2U ), 0.0045 and 0.00375. For the oscillating ow in the lid driven cavity, the mesh sizes of 81 81 and 97 97 with the same time step are used. The computed Strouhal number St, average value of drag coecient, oscillations (peak to peek) of drag and lift coecients for the vortex shedding case, and the oscillation of drag and phase shift for the oscillating ow case are listed in Table 2. It was found from Table 2 that all discrepancies caused by dierent mesh sizes are less than 5%. This implies that the mesh sizes of 241 241 for the vortex shedding ow and 97 97 for the oscillating ow used in this work are ne enough to provide accurate numerical results.

Simulation of Unsteady Incompressible Flows Table 2. Eect of grid size.

737

Vortex shedding behind the cylinder at Re = 100 Grid 201 201 241 241 St 0.156 0.164 CD 1.3363 1.3668 CD 0.024 0.0242 CL 0.71 0.75

Oscillating ow in the lid driven cavity at Re = 400 Grid 81 81 97 97 Oscillation of drag 58.968 59.713 Phase shift 16.08 15.96

4. Conclusions An explicit Taylor series expansion- and least square-based lattice Boltzmann method is presented, and applied to simulate the two-dimensional unsteady vortex shedding ow behind a circular cylinder and the oscillating ow in the lid driven cavity. The dynamic parameters and ow patterns obtained by the present method are in good agreement with those of previous numerical and experimental studies. The success of this study shows that the present method can be used as a versatile CFD tool to simulate real unsteady ows. The major advantage of the present scheme is that it still keeps the local and explicit features of the standard lattice Boltzmann method. Since the method has a meshless feature and no coordinate transformation is involved, it is very convenient for the present method to be applied to the ow problems with complex geometry. References

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. G. R. McNamara and G. Zanetti, Phys. Rev. Lett. 61, 2332 (1988). F. J. Higuera, S. Succi, and R. Benzi, Europhys. Lett. 9, 345 (1989). H. Chen, S. Chen, and W. H. Matthaeus, Phys. Rev. A 45, R5339 (1991). Y. H. Qian, D. dHumieres, and P. Lallemand, Europhys. Lett. 17, 479 (1992). S. Chen and G. D. Doolen, Ann. Rev. Fluid Mech. 30, 329 (1998). Q. Zou and X. He, Phys. Fluids 9, 1591 (1997). X. He and G. D. Doolen, J. Comp. Phys. 134, 306 (1997). X. He and G. D. Doolen, Phys. Rev. E 56, 434 (1997). X. He, L.-S. Luo, and M. Dembo, J. Comp. Phys. 129, 357 (1996). R. Mei and W. Shyy, J. Comp. Phys. 143, 426 (1998). H. Chen, Phys. Rev. E 58, 3955 (1998). G. Peng, H. Xi, C. Duncan, and S. H. Chou, Phys. Rev. E 59, 4675 (1999). E. Berger and R. Wille, Ann. Rev. Fluid Mech. 4, 313 (1972). C. H. K. Williamson, Phys. Fluids 31, 2742 (1988). M. Hammache and M. Gharib, Phys. Fluids A 1, 1611 (1989). W. Y. Soh and J. W. Goodrich, J. Comp. Phys. 79, 113 (1988). A. L. Gaitinde, Int. J. Numer. Meth. Eng. 41, 1153 (1998). C. H. K. Williamson, Ann. Rev. Fluid Mech. 23, 477 (1996). M. Braza, P. Chassaing, and M. H. Ha, J. Fluid Mech. 165, 79 (1986).

738

Y. T. Chew, C. Shu & X. D. Niu

20. D. J. Tritton, J. Fluid Mech. 6, 547 (1959). 21. B. E. Eaton, J. Fluid Mech. 6, 547 (1959). 22. A. E. Perry, M. S. Chong, and T. T. Lim, J. Fluid Mech. 116, 77 (1982).

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Wave Forces On Vertical CylinderDocument22 pagesWave Forces On Vertical CylinderInayatul LailiyahNo ratings yet

- Hyd - 7Document2 pagesHyd - 7SamNo ratings yet

- Kinematics FundamentalsDocument615 pagesKinematics FundamentalsSalma Abdelfadil100% (1)

- PhysicsDocument39 pagesPhysicsRosdy DyingdemonNo ratings yet

- SCIENCE Q3 Assessment and PerformanceDocument4 pagesSCIENCE Q3 Assessment and PerformanceCastolo Bayucot Jvjc0% (1)

- Analytical Probability Density Functions For Lms Adaptive Filters Using The Fokker-Planck EquationDocument4 pagesAnalytical Probability Density Functions For Lms Adaptive Filters Using The Fokker-Planck EquationHamid MojiryNo ratings yet

- v2 PDFDocument20 pagesv2 PDFHamid MojiryNo ratings yet

- Symbolic Solutions For A Class of Partial Differential EquationsDocument10 pagesSymbolic Solutions For A Class of Partial Differential EquationsHamid MojiryNo ratings yet

- 337 345 PDFDocument9 pages337 345 PDFHamid MojiryNo ratings yet

- Pure Soliton Solutions of Some Nonlinear Partial Differential EquationsDocument8 pagesPure Soliton Solutions of Some Nonlinear Partial Differential EquationsHamid MojiryNo ratings yet

- A Subclass of Quasi Self Adjoint Lubrication Equations: Conservations LawsDocument8 pagesA Subclass of Quasi Self Adjoint Lubrication Equations: Conservations LawsHamid MojiryNo ratings yet

- Solution of Nonlinear Oscillators Using Global Error Minimization MethodDocument8 pagesSolution of Nonlinear Oscillators Using Global Error Minimization MethodHamid MojiryNo ratings yet

- MSP 3407D, MSP 3417D Multistandard Sound Processors: MicronasDocument60 pagesMSP 3407D, MSP 3417D Multistandard Sound Processors: MicronasHamid MojiryNo ratings yet

- Prod CoursesofstudyDocument26 pagesProd CoursesofstudyHamid MojiryNo ratings yet

- The Solution of Second-Order Partial Differential EquationsDocument121 pagesThe Solution of Second-Order Partial Differential EquationsHamid MojiryNo ratings yet

- A Numerical Scheme For Unsteady Flow of A Viscous Fluid Between Elliptic PlatesDocument5 pagesA Numerical Scheme For Unsteady Flow of A Viscous Fluid Between Elliptic PlatesHamid MojiryNo ratings yet

- High Order Discontinuous Galerkin Method For Elastohydrodynamic Lubrication Line Contact ProblemsDocument7 pagesHigh Order Discontinuous Galerkin Method For Elastohydrodynamic Lubrication Line Contact ProblemsHamid MojiryNo ratings yet

- IntroDocument28 pagesIntroHamid MojiryNo ratings yet

- A Generalized Differential Quadrature Solution For Laminated Composite Shells of RevolutionDocument2 pagesA Generalized Differential Quadrature Solution For Laminated Composite Shells of RevolutionHamid MojiryNo ratings yet

- M. Tech. Computer Aided DesignDocument42 pagesM. Tech. Computer Aided DesignHamid MojiryNo ratings yet

- A Cartesian Grid Method For Solving The Two-Dimensional Streamfunction-Vorticity Equations in Irregular RegionsDocument45 pagesA Cartesian Grid Method For Solving The Two-Dimensional Streamfunction-Vorticity Equations in Irregular RegionsHamid MojiryNo ratings yet

- Determination of Moisture Content (AOAC, 1999)Document0 pagesDetermination of Moisture Content (AOAC, 1999)Hamid MojiryNo ratings yet

- Methods Based On The Differential Quadrature in Vibration Analysis of PlatesDocument17 pagesMethods Based On The Differential Quadrature in Vibration Analysis of PlatesHamid MojiryNo ratings yet

- Efficient Numerical Method For Computation of Thermohydrodynamics of Laminar Lubricating FilmsDocument25 pagesEfficient Numerical Method For Computation of Thermohydrodynamics of Laminar Lubricating FilmsHamid MojiryNo ratings yet

- Journal of Computational Physics: J. Wu, C. ShuDocument21 pagesJournal of Computational Physics: J. Wu, C. ShuHamid MojiryNo ratings yet

- The Backward-Tracking Lagrangian Particle Method For Transient Viscoelastic FlowsDocument34 pagesThe Backward-Tracking Lagrangian Particle Method For Transient Viscoelastic FlowsHamid MojiryNo ratings yet

- Ding Shu Tang (IJNME) 2005Document17 pagesDing Shu Tang (IJNME) 2005Hamid MojiryNo ratings yet

- Chen - Shu Et Al (Computers & Structures) 2000Document12 pagesChen - Shu Et Al (Computers & Structures) 2000Hamid MojiryNo ratings yet

- Ding-Shu (JCP 2005)Document24 pagesDing-Shu (JCP 2005)Hamid MojiryNo ratings yet

- CH 09 Part SolutionDocument10 pagesCH 09 Part SolutionHamid MojiryNo ratings yet

- Intso Stso Physics Class Vii Motion and Time Worksheet-6Document3 pagesIntso Stso Physics Class Vii Motion and Time Worksheet-6murali.trichyNo ratings yet

- Journal of Sound and Vibration: Rapid CommunicationsDocument9 pagesJournal of Sound and Vibration: Rapid CommunicationspaulkohanNo ratings yet

- Lift Augmentation Devices!Document25 pagesLift Augmentation Devices!Haider Ali BabaNo ratings yet

- Tutorial Flow Measurement (GROUP D)Document8 pagesTutorial Flow Measurement (GROUP D)Nur Fatiha Aziera Ain Binti Mohd KhimeNo ratings yet

- Uniformly Accelerated MotionDocument2 pagesUniformly Accelerated MotionLeanna Marie F. Olis0% (2)

- Lect 1 MergedDocument173 pagesLect 1 MergedMarian PopescuNo ratings yet

- Phys ReviseDocument1 pagePhys ReviseJohan O'LearyNo ratings yet

- Css Applied Mathematics 1 2009Document2 pagesCss Applied Mathematics 1 2009Bakhita MaryamNo ratings yet

- Lecture 11 12Document5 pagesLecture 11 12Muhammad Attiq Ur RehmanNo ratings yet

- Workenergyandpowerppt 131208202046 Phpapp02Document26 pagesWorkenergyandpowerppt 131208202046 Phpapp02joyNo ratings yet

- A Glance at Bumper Cars From A Physics PerspectiveDocument5 pagesA Glance at Bumper Cars From A Physics PerspectivesNo ratings yet

- Merged 11 Physics ExemplarDocument100 pagesMerged 11 Physics ExemplarGaurav GoyalNo ratings yet

- Cve 305-1,2,3Document56 pagesCve 305-1,2,3Abdurrahman AdigunNo ratings yet

- Assignment01Document3 pagesAssignment01karthikNo ratings yet

- C1 - Introduction To Fluid Mechanics - Rev01Document43 pagesC1 - Introduction To Fluid Mechanics - Rev01kishoreNo ratings yet

- Dynamics and VibrationsDocument19 pagesDynamics and Vibrationsadhi2796No ratings yet

- Midterm Assignment 2 - Motion Along A Straight Line: Page 1 of 3Document3 pagesMidterm Assignment 2 - Motion Along A Straight Line: Page 1 of 3John Michael General0% (1)

- Modal Analysis SprocketDocument23 pagesModal Analysis Sprocketciano654No ratings yet

- G12 Constrained Motion of Connected ParticlesDocument14 pagesG12 Constrained Motion of Connected Particlesrahulnag10febNo ratings yet

- Artificial Transmission Line Dec 16Document33 pagesArtificial Transmission Line Dec 16Arindam SenNo ratings yet

- PHY 111final 104816Document5 pagesPHY 111final 104816loladeolufayoNo ratings yet

- BSLTPCH 2 P 2 B7Document7 pagesBSLTPCH 2 P 2 B7AnjaliNo ratings yet

- Cambridge International ExaminationsDocument12 pagesCambridge International Examinationsrogchen666No ratings yet

- Lecture 5 2Document15 pagesLecture 5 2IbrahimDewaliNo ratings yet