Professional Documents

Culture Documents

Mohanta Etal - MPT2009 - Textural Classification Iron Ore

Uploaded by

Ashish ShrivasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mohanta Etal - MPT2009 - Textural Classification Iron Ore

Uploaded by

Ashish ShrivasCopyright:

Available Formats

TEXTURAL FEATURES IN SOME INDIAN IRON ORES

Manoj K. Mohanta1, Rajendra K. Rath1, Shobhana Dey1, Vinod Kumar1, Shibani Mahanta2,4, Hrushi Kesh Dutta3, Madhumita Das2 and Bijay K. Ratha2

Mineral Processing Division, National Metallurgical Laboratory, CSIR, P.O.- Jamshedpur831007. email: mkm_nml@yahoo.co.in, mohanta@nmlindia.org; 2 PG Department of Geology, Utkal University, Vani Vihar, P.O.- Bhubaneswar-751001 3 Qr. No. A/24, LIC Staff Colony, Kadma, P.O.- Jamshedpur-831007 4 presently at Geology Section, Orissa Mining Corporation, OMC House, Bhubaneswar-751001

1

ABSTRACT

The present paper attempts to identify textural features in Indian iron ore, as a part of Process Mineralogy by optical image analysis technique. The emphasis on the goethitisation process and its relation to hematite-martite-goethite texture and micro-porosity is emphasized. The goethitic matrix with relict hematites distinguishable from colloform goethitic matrix is proposed to be treated as different texture. The grain size and shape of the minerals is also variable. The study may throw a new light to the amenability of iron ore to Mineral Processing.

INTRODUCTION

Optimisation of comminution efficiency in iron ore, generation of less fines, and improvement in liberation are of concern in mineral processing. Both the parameters are strongly dependent on the mineralogical texture in the ore. The texture is related to thermodynamic condition the ore has experienced for solid state phase transformation and/or recrystallization in its genetic evolution throughout geological history. As the genetic evolutionary history of iron ore deposits in world over is complex and not very clear, the classification and texture definition is also variable. The correlation of mineralogy and texture to engineering parameters such as strength, comminution efficiency, product size, liberation is attempted in last few decades [1-5]. Banded Iron Formation (BIF) of Archean age was made up of interlayered magnetite, chert/ carbonate and aluminosilicate. The ore forming processes removed carbonates and weathered aluminosilicate minerals to clay and transformed magnetite to (i) micro-platy hematite ore, (ii) Martite goethite ore, (iii) hematite & itabirite/ Banded hematite quartzite (BHQ) ores. Though ore forming process is complex hydrothermal enrichment, hydrothermal leaching, hydration, dehydration, weathering, channel deposition, concretion/cementation, the ultimate product is the association of hematite, martite/magnetite, goethite along with quartz and clay [3-4, 6-7]. Mineralogical association and complex texture in iron ore is attributed by genetic complexity. The present investigation is aimed at developing a basic understanding in correlating mineralogy and texture with the mineral to mineral relationship with its possible genetic link so that some of the texture-parameters can be construed and re-defined. The special focus is on establishing the genetic link between goethite and hematite/martite, and its manifestation in various ores to re-define the texture. The goethite-hematite iron ore sourced from the deposit in Bonai-Keonjhar-Singhbhum area in eastern India, belongs to the Iron ore Group of Singhbhum craton and goethite-martite ore from Chitradurga Schist belt of Archean age. The former deposit is indicated as supergene modified hydrothermal type with friable saprolitic ore derived from a precursor hydrothermally altered iron ore formation, successively enriched by supergene activity and subsequently altered to the present state [7] and the latter is derived

from magnetitic ore. In general, the ore is comprised of dense martite, microplaty hematite, vitreous goethite, colloform goethite, ochreous goethite, recrystallised goethite at various proportions and closely associated gangue minerals such as quartz, kaolinite. Microplaty hematites are suggested to be defining the schistosity planes related to crystal plastic deformation of hematite during geotectonic process [8-9].

MATERIALS AND METHODS

The hematitic iron ore from Singhbhum-north Orissa region and from Chitradurga Schist belt were studied under polarising microscope Orthoplan model and Zoom stereo microscope, both Leica make, interfaced with QWIN image analysis software. The observations under magnification and optical microscopy were correlated.

RESULTS

Goethite occurs in lateritic ore capping, interlaminations within hard laminated hematitic ore, soft laminated hematitic ore, blue dust, fracture filling and cavity fillings, colloform. The proportion of hematite to goethite vary in all these varieties. So, the textural features in goethite-hematite association were studied in the hard laminated ore, soft laminated ore and lateritic ore and the observations are given below. 1- Replacement hematite texture: Most of the supergene enriched hematitic deposits are of microplaty hematite with martite and relict magnetite. Dense martite lacks micro-porosity as do the magnetite but the reflectance is brighter grey as of hematite under optical microscope. It occasionally contains relict magnetite. Micro-platy hematite is a platy mineral arranged in parallel to sub-parallel often dendritic with intergranular pore space. It occurs with a wide range of length to breadth ratio, often spindle shaped,

Fig.-1: Replacement texture : Martite and microplaty hematite altering to goethite

Fig.2: Replacement texture of Goethite with relict hematite

Fig.3: Cementation texture of colloform goethite grown over martite nuclei. 5X

Fig.4: Cementation texture of colloform goethite along fracture. 5X

specularitic and donot contain relict magnetite. As dense martite transforms to microplaty hematite, micro-porosity becomes more predominant. So, there are two types of replacement within a hematitic ore- (i) magnetite by dense martite and (ii) dense martite by micro-platy hematite. 2- Replacement goethite texture: The goethite in hard laminated hematitic ore is the alteration product of hematite and martite, and is representative of replacement goethites (Fig.1 & 2). The replacement goethite preserves the structure of precursor hematite and martites, and can be coined as microplaty goethite and dense goethite respectively. The micro-platy goethite preserve the intergranular porosity whereas dense goethite contain randomly placed micro-pores. The extent of replacement is variable from low to high degree, in which the relict hematite appear to be enclaved within dense goethite. The extent of replacement is greater at the proximity to voids/cavities, fractures, foliation surface (inclusive of shear foliation). 3- Goethite cementation texture: The cementation texture is observed as pore filling, fracture filling and thus a replacement of intergranular porosity, fracture surface or foliation surface (Fig.3 & 4). As the micropores and fractures are filled, the ore gets consolidated. The precipitation of gel derived from dissolved solids in solution/water precipitate to form gel which transforms by neo-mineralisation to colloform goethite and ochreous goethite and vitreous goethite. So, this texture is possible in the ore which has experienced a depth condition with seasonal water table fluctuation. The hematitic and martitic ores very often exhibit this texture to a minor extent whereas lateritic cap ore in the iron ore deposits exhibit as the most predominant texture. The hematite to goethite ratio is high in the former whereas low to negligible in the latter. Goethite very often cements the larger detrital fragments of high grade and any type of co-detrital material such as quartz, clay, rock fragments/ particulates, regolith etc. thereby forming a complex texture. The ore shows extensive interlocking of gangue even upto a very small size.

DISCUSSION

Based on the above observations, the mineralogical textures in the Indian iron ores can be redefined specific to mineral type, form, shape, and grain to grain relationship as mentioned below. 1- Replacement hematite texture: There are two types of replacement within a hematitic ore- (i) magnetite by dense martite and (ii) dense martite by micro-platy hematite. On this basis, three replacement textures are possible as mentioned below. (i) Dense martite texture: This textrure is exclusively of dense martite with relict magnetite and without micro-pores (ii) Dense martite- micro-platy hematite texture: The modal distribution of dense martite to micro-platy hematite is variable and so is the microporosity, microplaty hematites exhibit texture equivalent to ophitic intergrowth. (iii) Micro-platy hematite texture: The ore is exclusively of microplaty hematite with high degree of microporosity. microplaty hematites exhibit texture equivalent to ophitic intergrowth. 2- Replacement goethite texture: Goethite replaces the precursor hematite and martite to varied extent as per the conditions of weathering and alteration. The replacement texture can be redefined as follows. (i) Microplaty hematite-microplaty goethite texture: The ratio of hematite goethite can be variable. Goethites are of microplaty type. Length to breadth ratio of hematite and goethite is high. (ii) Dense Martite-dense goethite association: The ratio of hematite to goethite is variable as per the extent of alteration. Dense goethite is less porous. Length to breath ratio of goethite and hematite is low. (iii) Dense goethite-relict hematite texture: Goethite is predominant. Hematite is included within goethite similar to poikilitic texture in igneous rocks. (iv) Dense goethite-microplaty hematite texture: The ratio of hematite to goethite can be variable.

(v) Dense goethite: Goethite is predominant. Dense goethite is less porous. Length to breadth ratio is low. (vi) Microplaty goethite: Goethite is predominant. Length to breadth ratio is variable often very high. 3- Goethite cementation texture: The cementation texture is observed as pore filling, fracture filling and thus a replacement of intergranular porosity, fracture surface or foliation surface by goethitic gel and often manifested by colloform micro-structure. The cementation texture can be redefined as follows. (i) Microplaty hematite- cementing ochreous Goethite: Hematitic grain cemented by goethite. (ii) Microplaty hematite-vitreous goethite: vitreous goethite occurs as the facture filling material within fracture in micro-platy hematite (iii) Martite-ochreous goethite texture: The fracture and cavity in martitic ore is cemented by colloform ochreous goethite. (iv) Martite-vitreous goethite texture: The fracture and cavity in martitic ore is cemented by colloform ochreous goethite. (v) Vitreous goethite (exclusive) texture: This goethite is not water dispersible and is optically vitreous in reflectance microscopy. (vi) Ochreous goethite (exclusive) texture: It is unconsolidated cohesive cementing goethite It consists of aggregated fine goethite and clay easily dispersible in water In the above classification, the presence of martite is emphasized as it is the mineral of high grade and strength. The term micro-platy hematite is emphasized to give importance to possible high grade feature but high porosity and low strength. The re-definition of goethite in replacement texture and cementation texture is important for the micro-structure and micro-texture manifested by the ore. The ore strength and dispersibility in water can be accounted to the contribution to slime. This classification scheme may find significance in future Mineral Engineering application.

CONCLUSION

The microscopic observation on the various types of ores is emphasized to a comprehensive reclassification keeping the mineralogical and genetic factor under consideration and to a more specific mineralogical index to ore strength and dispersibility so that it may find application in Mineral Engineering applications

ACKNOWLEDGEMENTS

A part of the work was supported by CSIR network project NWP-0031. Part of the samples analysed were from the pre-doctoral exploratory research of SM and HD.

REFERENCES

1. P. Ramdohr: The ore minerals and their intergrowths, Pergamon press, Germany, 1969, 1174p. 2. J. M. F. Clout: App. Earth Sci. (Trans. Inst. Min. Metall. B), 2003, vol.112, pp.B89-95. 3. J. M. F. Clout: App. Earth Sci. (Trans. Inst.Min. Metall. B), 2006, vol.115, pp.115-125. 4. S. L. Gay: Miner. Engg., 2004, vol.17, pp.1209-1216. 5. M. K. Mohanta, R. K. Rath, S. Dey, and K. K. Bhattacharyya in proc. Conf. Int. Sem.Mineral Processing Technology MPT-2007 , Mumbai, (eds. N.K. Khosla and G.N. Jadhav), 2007 pp.493-496. 6. M. Kneeshaw: Proc. AusIMM, 1984, vol.289, pp.157-162. 7. N. J. Beukes, J. Gutzmer, and J. Mukhopadhyay: App. Earth Sci. (Trans. Inst. Min. Metall. B), 2003, V112, B18B25. 8. C. A. Rosiere and F. J. Rios: App. Earth Sci (Trans. Inst. Min. Metall. B), 2006, V-115, pp.134-138. 9. M. K. Mohanta, R. K. Rath, S. Dey, V. Kumar, K. K. Bhattacharyya and P. K. De, in proc. Conf. Int. Sem. Miner. Process.Tech. (MPT-2008), Trivandrum, April 22-24, 2008, Ind. Inst. Miner. Enggrs., Trivandrum, pp.118-121.

You might also like

- Ir H - Pse 377C PDFDocument4 pagesIr H - Pse 377C PDFAshish ShrivasNo ratings yet

- FWD - Request For Quotation - JML - PK - 17 - 189 - Shriram Enterprises RFQDocument3 pagesFWD - Request For Quotation - JML - PK - 17 - 189 - Shriram Enterprises RFQAshish ShrivasNo ratings yet

- FWD - Request For Quotation - JML - PK - 17 - 189 - Shriram Enterprises RFQDocument3 pagesFWD - Request For Quotation - JML - PK - 17 - 189 - Shriram Enterprises RFQAshish ShrivasNo ratings yet

- SCCDocument8 pagesSCCAshish ShrivasNo ratings yet

- NitDocument7 pagesNitAshish ShrivasNo ratings yet

- Employees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationDocument2 pagesEmployees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationAshish ShrivasNo ratings yet

- Anuj GuptaDocument2 pagesAnuj GuptaAshish ShrivasNo ratings yet

- Chemical Earthing SpeceficationsDocument1 pageChemical Earthing SpeceficationsAshish ShrivasNo ratings yet

- EulaDocument6 pagesEulaAshish ShrivasNo ratings yet

- EulaDocument6 pagesEulaAshish ShrivasNo ratings yet

- Chemical Earthing SpeceficationsDocument3 pagesChemical Earthing SpeceficationsAshish ShrivasNo ratings yet

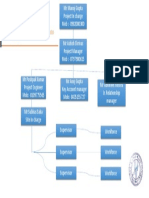

- Organisation Chart @siteDocument1 pageOrganisation Chart @siteAshish ShrivasNo ratings yet

- EulaDocument6 pagesEulaAshish ShrivasNo ratings yet

- (General Knowledge) Chhattisgarh Objective General Knowledge - Iasexamportal - India's Largest Community For Ias, Csat, Upsc, Civil Services Exam Aspirants 2Document9 pages(General Knowledge) Chhattisgarh Objective General Knowledge - Iasexamportal - India's Largest Community For Ias, Csat, Upsc, Civil Services Exam Aspirants 2Ashish ShrivasNo ratings yet

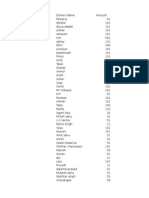

- Ganesh HisabDocument4 pagesGanesh HisabAshish ShrivasNo ratings yet

- 3D AnalyzerDocument1 page3D AnalyzerAshish ShrivasNo ratings yet

- Second Most Populous: State or Union TerritoryDocument4 pagesSecond Most Populous: State or Union TerritoryAshish ShrivasNo ratings yet

- Ashish Shrivas AttendenceDocument1 pageAshish Shrivas AttendenceAshish ShrivasNo ratings yet

- How To Read A Steam Table - TLVDocument5 pagesHow To Read A Steam Table - TLVAshish ShrivasNo ratings yet

- Ashish Shrivas AttendenceDocument1 pageAshish Shrivas AttendenceAshish ShrivasNo ratings yet

- Attendace September 2013 Ashish ShrivasDocument1 pageAttendace September 2013 Ashish ShrivasAshish ShrivasNo ratings yet

- Ashish Shrivas AttendenceDocument1 pageAshish Shrivas AttendenceAshish ShrivasNo ratings yet

- 3D AnalyzerDocument1 page3D AnalyzerAshish ShrivasNo ratings yet

- Ashish Shrivas AttendenceDocument1 pageAshish Shrivas AttendenceAshish ShrivasNo ratings yet

- Ashish Shrivas AttendenceDocument1 pageAshish Shrivas AttendenceAshish ShrivasNo ratings yet

- Attendace November 2013 Ashish ShrivasDocument1 pageAttendace November 2013 Ashish ShrivasAshish ShrivasNo ratings yet

- Diary of A Wimpy Kid 8 - Hard LuckDocument213 pagesDiary of A Wimpy Kid 8 - Hard LuckBaraa Dawod50% (2)

- Sturm - 2010 - Morphology Zircon Granite Boehemiaan - Chemie Der Erde - V70Document12 pagesSturm - 2010 - Morphology Zircon Granite Boehemiaan - Chemie Der Erde - V70Ashish ShrivasNo ratings yet

- C M 1Document1 pageC M 1Antonio Ulloa TorresNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hilfswerk Wien-Salzburg - 11. Meio 2018Document9 pagesHilfswerk Wien-Salzburg - 11. Meio 2018FreieEnergieNo ratings yet

- MHSS ItalyDocument9 pagesMHSS Italyromedic36No ratings yet

- CASBA Directive 2074Document17 pagesCASBA Directive 2074vijaycool85No ratings yet

- Steam TableDocument3 pagesSteam TableMUHAMAD SAUKINo ratings yet

- Rexroth Hd2 ControlairDocument15 pagesRexroth Hd2 ControlairRafaelNo ratings yet

- 3-Storeyed 31-3-2015-Schedule PDFDocument1 page3-Storeyed 31-3-2015-Schedule PDFSi Thu AungNo ratings yet

- MT4400 STRG Flo Amp ValveDocument7 pagesMT4400 STRG Flo Amp ValveBrian Careel0% (1)

- IPE SakibBhaiMagicChothaDocument55 pagesIPE SakibBhaiMagicChothaTousif SadmanNo ratings yet

- Service ManualDocument582 pagesService ManualBogdan Popescu100% (5)

- Cooling and Sealing Air System: Gas Turbine Training ManualDocument2 pagesCooling and Sealing Air System: Gas Turbine Training ManualVignesh SvNo ratings yet

- How The Audiences Feel Closer and Connected To Their Culture With StorytellingDocument7 pagesHow The Audiences Feel Closer and Connected To Their Culture With Storytellingmarcelo quezadaNo ratings yet

- Introduction To Rhetorical Analysis: Week 1Document16 pagesIntroduction To Rhetorical Analysis: Week 1Will KurlinkusNo ratings yet

- Examiners' Report Principal Examiner Feedback January 2018Document7 pagesExaminers' Report Principal Examiner Feedback January 2018WandaNo ratings yet

- 93c3 Document 3Document14 pages93c3 Document 3NONON NICOLASNo ratings yet

- Capital Budgeting and Capital Budgeting and Risk Analysis Risk AnalysisDocument16 pagesCapital Budgeting and Capital Budgeting and Risk Analysis Risk AnalysisHaris FendiarNo ratings yet

- Focus On Teaching - Jim KnightDocument213 pagesFocus On Teaching - Jim KnightFernando TeixeiraNo ratings yet

- Fire Alarm SymbolsDocument6 pagesFire Alarm Symbolscarlos vasquezNo ratings yet

- Final FirstpartDocument11 pagesFinal FirstpartLance Johnpaul SyNo ratings yet

- Labour Law Assignment - Gross NegligenceDocument6 pagesLabour Law Assignment - Gross NegligenceOlaotse MoletsaneNo ratings yet

- ASME Geometric Dimension Ing and Tolerance Professional CertificationDocument20 pagesASME Geometric Dimension Ing and Tolerance Professional CertificationPaul Anthony Red60% (5)

- Application Bright Ideas Education Grant Program For TeachersDocument6 pagesApplication Bright Ideas Education Grant Program For Teachersapi-320983699No ratings yet

- ENGG 3150 Engineering Biomechanics Lab Guide 2006: University of Guelph School of EngineeringDocument13 pagesENGG 3150 Engineering Biomechanics Lab Guide 2006: University of Guelph School of Engineeringالقداري القداريNo ratings yet

- Nokia 2690 RM-635 Service ManualDocument18 pagesNokia 2690 RM-635 Service ManualEdgar Jose Aranguibel MorilloNo ratings yet

- Prof Ed 9-A - Module 6 - Tumacder, DHMLDocument6 pagesProf Ed 9-A - Module 6 - Tumacder, DHMLDanica Hannah Mae TumacderNo ratings yet

- 9A02505 Electrical Machines-IIIDocument4 pages9A02505 Electrical Machines-IIIsivabharathamurthyNo ratings yet

- Digital Signal Processing Lab ManualDocument61 pagesDigital Signal Processing Lab ManualOmer Sheikh100% (6)

- NCR Supplier PPAP Training PresentationDocument166 pagesNCR Supplier PPAP Training PresentationRajeev ChadhaNo ratings yet

- Data Migration Good DocumentDocument16 pagesData Migration Good Documentsambit76No ratings yet

- Of Personality Traits of Only and Sibling School Children in BeijingDocument14 pagesOf Personality Traits of Only and Sibling School Children in BeijingMuhammad Hamza AsgharNo ratings yet

- Module 14-Area ComputationsDocument5 pagesModule 14-Area ComputationsGerovic Parinas50% (2)