Professional Documents

Culture Documents

Bse-Pe-002 1988 12 C-46 S D

Uploaded by

viniciusltOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bse-Pe-002 1988 12 C-46 S D

Uploaded by

viniciusltCopyright:

Available Formats

Objekttyp:

Issue

Zeitschrift:

IABSE structures = Constructions AIPC = IVBH Bauwerke

Band(Jahr): 12(1988) Heft C-46: Repair and rehabilitation of bridges: case studies I

Erstellt am: 10.01.2012

Nutzungsbedingungen Mit dem Zugriff auf den vorliegenden Inhalt gelten die Nutzungsbedingungen als akzeptiert. Die angebotenen Dokumente stehen fr nicht-kommerzielle Zwecke in Lehre, Forschung und fr die private Nutzung frei zur Verfgung. Einzelne Dateien oder Ausdrucke aus diesem Angebot knnen zusammen mit diesen Nutzungsbedingungen und unter deren Einhaltung weitergegeben werden. Die Speicherung von Teilen des elektronischen Angebots auf anderen Servern ist nur mit vorheriger schriftlicher Genehmigung des Konsortiums der Schweizer Hochschulbibliotheken mglich. Die Rechte fr diese und andere Nutzungsarten der Inhalte liegen beim Herausgeber bzw. beim Verlag.

SEALS

Ein Dienst des Konsortiums der Schweizer Hochschulbibliotheken c/o ETH-Bibliothek, Rmistrasse 101, 8092 Zrich, Schweiz

retro@seals.ch http://retro.seals.ch

ISSN

0377-7286

IABSE

PERIODICA 3/1988

PERIODICA AIPC IVBH PERIODICA

M

M

g*

August 1988

W^A

M^L

^k

^ L.

IABSE STRUCTURES C-46/88

CONSTRUCTIONS AIPC

IVBH

BAUWERKE

Repair and Rehabilitation of Bridges Case Studies 1

Reparation et restauration de ponts Exemples concrets I Instandsetzung und Sanierung Fallstudien 1 von Brcken

nternational Association for Bridge and Structural Engineering Association Internationale des Ponts et Charpentes nternationale Vereinigung fr Brckenbau und Hochbau

IABSE AIPC

IVBH

Editor Publisher Advertising Redacteur Editeur Annonces Redaktion Herausgeber Inserate

IABSE

- AIPC - IVBH

(Int+

41

ETH-Hnggerberg

CH-8093 Zrich, Switzerland

Tel.:

1)377 26 47

Telex: Telegr.:

822 186 IABS CH

IABSE, CH-8093 Zrich

Papers published under the sole responsibility of the author(s).

Les

articles sont publies sous

la

seule responsabilite de (des) l'auteur(s).

Die

Artikel werden unter der alleinigen Verantwortung des oder der Autoren verffentlicht.

IABSE

PERIODICA 3/1988

IABSE

STRUCTURES C-46/88

41

Repair and Rehabilitation of Bridges

Reparation et restauration de ponts Exemples concrets Instandsetzung und Sanierung von Brcken Fallstudien

- Case

-

Studies

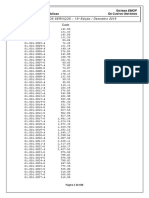

Table of Contents

- Table

des matieres

Inhaltsverzeichnis

Page

1.

The Sioux Narrows Bridge, Ontario (Canada)

42

2.

Instandsetzung und Verbreiterung der Brcke ber die Grosse Erlauf in Purgstall (sterreich)

Steel Strip Reinforced Concrete Bridge (Denmark)

44 46 48

50 52 54

3. 4.

5. 6. 7. 8. 9.

Repairing Work of the Kyrjoki Bridge (Finland)

radioscopie pour l'auscultation des ouvrages d'art (France) Automatisation pour verinage de haute precision (France) Off Ramp of Hanshin Expressway in Osaka (Japan)

La

Elevated Bridge

The Bridge

in

in

Hanshin Expressway

in

in

Osaka (Japan)

56 58 60

62

the Radnicka Street

Beigrade (Yugoslavia)

10. 11.

Rehabilitation of Yamuna Bridge

at Kairana (India)

Rehabilitation of Girna Bridge (India)

IABSE STRUCTURES

Publication

November 1988

- Publication

Programme

in 1988

- 1989

1988

Theme

Repair and Rehabilitation of Bridges

in IABSE

Editorial Deadline Secretariat

1,

August

- Case

February 1989

Studies II Reparation et restauration de ponts Exemples concrets II Instandsetzung und Sanierung von Brcken Fallstudien II

Structures in Portugal Constructions au Portugal Bauwerke in Portugal

Structures Structures Tragwerke

in

November

1,

1988

May 1989

Sanitary Engineering

February

1,

1989

en genie sanitaire im Siedlungswasserbau

August 1989

Recent Structures Constructions recentes Neuzeitliche Bauwerke

May

1,

1989

IABSE members are invited to contribute to this series IABSE STRUCTURES. Guidelines for pre paring contributions are available at the IABSE Secretariat.

membres de l'AIPC sont invites preparer une contribution pour cette sehe CONSTRUCTIONS AIPC. Des directives pour la preparation des contributions peuvent etre obtenues au Secretariat de l'AIPC

Les

Die IVBH-Mitglieder sind eingela den, einen Artikel fr diese Reihe IVBH BAUWERKE zu unterbreiten Richtlinien fr die Vorbereitung der

Beitrge

knnen

beim

Sekretariat

der IVBH bezogen

werden

42

IABSE

STRUCTURES C-46/88

IABSE

PERIODICA

3/1988

1.

The Sioux Narrows Bridge, Ontario (Canada)

Owner:

Design:

Work Duration:

Ministry

Ontario

of

Transportation

of

Structural Office and Research and Development Branch 6 months

1982

Completion:

The Sioux Narrows Bridge is on Highway 71 linking Fort Frances and Kenora in northwest Ontario. The bridge was constructed in 1936 with a wooden Howe truss main span of 64 m, Figure 1. It is believed to be the

longest Single America.

span

wood

highway

bridge

in

North

the time of these studies, the concept of a pre stressed longitudinally laminated wood deck had been developed by the Ministry. This prestressed deck type acted like a homogeneous slab, and exhibited much better load distributed characteristics than the old nailed laminated decks. It was calculated that the longitudinal distribution would be improved enough to reduce the stresses in the floor beams to acceptable levels. The decision was made to replace the old deck with a new wood deck, with 190 mm deep laminated prestressed transversely with 25 mm bars at 1.525 m centres, tensioned by hydraulic jacks.

At

This bridge was one of the first to be listed under the Heritage Bridge Program of the Ontario Government,

being an outstanding example of wood bridge construc tion, built of B. C. Douglas Fir in sizes no longer available Most timber highway bridges have been replaced after about 40 years. Plans were prepared for the replace ment of the Sioux Narrows bridge in 1975 when the deck was showing signs of deterioration, and the vehicle loads greatly exceeded the design loads. A condition survey showed the truss members to be in good condition, however, and studies were started to try to rehabilitate and keep this heritage bridge in service. Analysis indicated adequate load capacity in the main trusses, but a significant overstress in the transverse floor beam king post and tie bars, Figure 2. The floor system consisted of a traverse nailed laminated wood deck on longitudinal wood stringers, which were

The deck was replaced one lane at a time, Figure 3, so the bridge could remain open to traffic. The prestressing bars were coupled together for construction of the second lane. A new asphalt wearing surface was then applied to the wood deck.

Fll scale bridge testing using custom designed load vehicles. Instrumentation and mobile laboratory for the computerized data acquisition System is a regulr feature of the Mmistry's evaluation procedures. Load testing of the deck system was carried out before deck replacement and after, Figure 4. Eight floor beams were instrumented by attaching strain gauges to the steel tie bars. The greatly improved longitudinal distribution characteristics of the prestressed deck was confirmed by a reduction of 35% in the truss bar strains for the same tests as carried out on the old deck. No further strengthening of the floor system is needed. The only other members that may need replacing are the main truss hanger bars, which will be tested shortly.

supported

by

transverse wood beams every 2.3

m.

:;..

/R

T.

l

~-rY

'sasss

/

^-^

* %

TJr

tr

(Bh,

wm

Lyz.

Ml

"%

:m^L-

**C

JMmm

v

>,

1

Fig.

1

General view of bridge

IABSE

PERIODICA 3/1988

IABSE

STRUCTURES C-46/88

43

NEW PRESTRESSED 190 mm

EXISTING 25 mm ASPHALT PLANK

LONGITUDINAL LAMINATED

WOOD DECK

EXISTING 140 mm TRANSVERSE

LAMINATED

WOOD DECK

^MMMMMMM

BIO mm TYP

TO

290 mm

-

lL

NEW CONTINUOUS

ASPHALT SURFACE

Tlj

9

i

345

405

TRANSVERSE

WOOD BEAM

115 mm

X

FLOOR BEAM TRUSSED BV TWO

45 mm

<P

BARS

LONGITUDINAL WOODSTRINGERS

Fig.

2

Cross section of floor System

I

wwwSki

' ; 1

f

N

Fig. 4

k

Load testing the rehabilitated bridge

*

*,

5*1

s

3

\ %

By the application of detailed analysis and testing and the use of an innovative deck rehabilitation scheme, the life of this heritage wood structure has been extended

well beyond 50 years, and under fll highway loads

is

performing satisfactorily

(R.A.

f/y.

Placing prestressed wood deck

Dorton)

44

IABSE

STRUCTURES C-46/88

IABSE

PERIODICA 3/1988

Instandsetzung und Verbreiterung der Brcke ber die Grosse Erlauf in Purgstall (sterreich)

Eigentmer:

Land Niedersterreich

Landesstrassenverwaltung, Brckenbau

Baujahr: Instandsetzung: Entwurf:

1872

1980

K. Koncki, Zivil Ing. ingenieur fr Bauwesen, Wien Ausfhrende Firma: Bau- und Zimmermeister Ing. K. Grillnberger, Purgstall an

Dipl.

der Erlauf

-rz

Bauaufsicht:

Abteilung BI2-D, Brckenbau, beim Amt der N Landesregie

rung 7,5 Monate

1980

Bauzeit:

Bild

Brcke ber der Grossen Erlauf in Purgstall,

1977

Verkehrfreigabe:

Die

Bogenbrucke, genannt Marktbrcke, berbrckt die eine Schlucht eingeschnittene Grosse Erlauf und verbindet so die beidseits des Flusses gelegenen Orts teile. Auf Grund des Ergebnisses einer routinemssigen Brckenkontrolle wurde eine allgemeine Instandsetzung vorgemerkt. Die sehr schmale Fahrbahn, der nur auf einer Seite verfgbare Gehsteig und der sichtbar mangelhafte Zustand der Brstungsmauern veranlasste berdies die Gemeindevertretung von Purgstall bei der Brckenbauabteilung des Amtes der N Landesregie rung einen Umbau des Objektes zu beantragen. Es wurde Zivilingenieur Dipl. Ing. K. Koncki mit der ber prfung des Bestandes und der Ausarbeitung eines Verbreiterungsprojektes be Instandsetzungs- und auftragt.

tief

in

Hinterfllung:

Dicht gelagertes Gemenge aus Rundschotter, Sand.

Kies und

Widerlager:

Direkt an die steilen Felswnde der Schlucht angebaut. Vorhandes Kavernen waren bei der Erbauung mit einem Gemenge aus Mrtel und Steinen ausgefllt worden.

Fundierung:

Fundamente sind unmittelbar auf die felsige Fluss sohle aufgesetzt. rtliche Auswaschungen (Kolke) be deuteten eine gewisse Gefhrdung. Eine eingehende Flussgrundsondierung ergab die Stellen fr SicherungsDie

massnahmen.

berprfung und Naturaufnahme

erbaute Marktbrcke lagen keinerlei Aufzeichnungen vor, weil das Brckenarchiv des Landes Niedersterreich im Laufe des 2. Welt krieges durch einen Brand zerstrt worden ist.

im

Brstung:

Aus Sandstein, an vielen Stellen rissig und

abgewittert,

ber die

Jahre

1872

nicht erhaltungswrdig.

Aufschlussbohrungen lieferten die ntigen Bohrkerne und Kenntnisse ber den Aufbau der Bogenbrucke.

Zusammenfassend kann der Zustand der tragenden Bauteile als zufriedenstellend bezeichnet werden. Auch die sicherlich vorhandenen Tragreserven, ableitbar aus dem 107jhrigen weitgehend schadensfreien Bestand, rechtfertigten eine Instandsetzung und eine Adaptierung auf eine zeitgemsse Bentzbarkeit.

Es konnte davon ausgegangen werden, dass eine Vergrsserung der stndigen Last durch die Verbreiterung und die erhhten Verkehrslasten aus dem nunmehr mglichen Begegnungsverkehr noch gut vom Bauwerk aufgenommen werden knnen.

Ergebnisse/Abmessungen:

Eingespannter kreisfrmiger Bogen

Achssttzweite Bogenstick

Breite des Bogens Dicke des Gewlbes

23,44

5,19 m 6,88 m 1,25 m

Quadermauerwerk:

Porser Kalkstein (Rauhwacke), sehr guter Zustand, stark streuende Druckfestigkeiten von ca. 7 N/mm2 bis ca. 20 N/mm2. Gewlbeoberseite verputzt, darber zur Abdichtung ein 5 cm starker Lehmschlag. Fugenmrtel teilweise ausgewittert, die Festigkeit war nicht feststell in den Bereichen der Auswitterung starker bar;

Statische Begutachtung

Der statischen berprfung des Bestandes und der Projektierung der Verbreiterung wurden die erhobenen Naturmasse und Materialkennwerte sowie die gelten den NORMEN zu Grunde gelegt. Einzelne Masse und die Bogenform wurden an grossformatigen Photos er mittelt. Die Berechnung wurde fr die Lastflle stndige Last und Temperaturnderung, +/- 10C, durchgefhrt.

Pflanzenwuchs.

IABSE

PERIODICA 3/1988

IABSE

STRUCTURES C-46/88

45

Ermittlung der Verkehrslasteinflsse wurden die entsprechenden Einflusslinien fr 3 reprsentative Stellen erstellt und nach Maxima und Minima aus gewertet. Im Scheitel und im Viertelpunkt traten maxi male Druckspannungen von 1,33 N/mm2 und keine Zug spannungen auf. Im Kmpferbereich ergaben sich im Extremfall Randdruckspannungen von 2,38 N/mm2 und Zugspannungen von 0,41 N/mm2. Bei Ausschluss von Zugspannungen eine maximale Randdruckspannung von 2,48 N/mm2. Damit wurde im ungnstigsten Fall eine Sicherheit von mindestens 3 erreicht. Wegen des Abbaues der Spannungsspitzen durch Kriecherscheinun gen ber einen Zeitraum von 107 Jahren drfte die Sicherheit hher liegen. Die Ergebnisse der in sich genauen statischen Nach rechnung sind wegen der doch unprzisen Ausgangsgrssen diskussionswrdig Auch aus diesem Grund wurde die vor der Nachrechnung geschtzte Last beschrnkung fr LKW ber 20 t belassen.

Fr die

"SEI

*

Projektbeschreibung und Baudurchfhrung

Die Vergrsserung der Nutzbreite von ca. 6,3 m auf 9,0 m teilt sich 6,00 m fr die Fahrbahn und die beidseits angeordneten Gehsteige von je 1,50 m.

fh

erforderlichen Abbrucharbeiten wurde die Gewlbehinterfllung unter geringem Druck (2 bar) durch Zementinjektionen weiter verfestigt, ca. 750 lfm 5 cm, in einem Raster von 75 cm; ver Bohrungen, D braucht wurden fr die Injektionen ca. 47 t Zement.

Nach

den

Bild2

Auskragung von unten, 1988

Quer ber die Bogenbrucke wurden auskragende Fertig teilbalken aus Stahlbeton der Gte B 400 verlegt, im Auskragungsbereich wurden Stahlbetonfertigteilplatten aufgelegt, auf die hernach im Verbund ein bewehrter Aufbeton zur Erzielung einer Durchlaufwirkung auf gebracht wurde. Im Fahrbahnbereich wurde ber den Fertigteilbalken eine durchlaufende und lastverteilende Stahlbetonplatte auf elastischer Bettung hergestellt. Die neue Brstung aus Stahlbeton wurde dem Original mit geringen Vereinfachungen nachgebildet. Die Pfeiler der Brstung bestehen aus profilierten Stahlbetonhlsen, die ber vertikal stehende verzinkte und ber Boden platten am Tragwerk befestigte I-Profile gestlpt und ausbetoniert wurden. Eine dachfrmige Abdeckung bildete den Anschluss nach oben. Der ussere Gesimsabschluss besteht aus profilierten Stahlbetonfertig teilen. Alle Sichtflchen wurden zur Anpassung an den Altbestand sandgestrahlt und die Betonteile deshalb mit einer erhhten Betondeckung hergestellt.

Bild

Brcke ber der Grossen Erlauf in Purgstall,

1988

Brckenentwsserung war unzulnglich. Um stren Durchdringungen des Bogens zu vermeiden, wurde die Fahrbahn kuppenfrmig ausgebildet und an den Brckenenden Einlaufschchte vorgesehen, die an die bestehende angeschlossen Strassenentwsserung werden konnten. Auch die Entwsserung der Tragwerksabdichtung erfolgt ber diese Schchte.

de

Die

Fr den Bau der Verbreiterung war eine Einrstung nicht ntig, lediglich fr die Beseitigung des Bewuchses und die Ausbesserung bzw. Herstellung der Verfugung des Quadermauerwerkes waren leichte Gerste erforder lich. Der Fussgnger- und Radfahrverkehr ber die Brcke war immer mglich

Besondere Schwierigkeiten bei der Baudurchfhrung ergaben sich aus dem Bestand von verschiedenen Ein bauten (Leitungen), die planlich nicht erfasst waren und im Zuge der berprfung auch nicht halbwegs exakt erfassbar waren, ohne das Objekt weitgehend ab zutragen.

Dieses Projekt, insbesondere die Wiederherstellung der Brstung, wurde dadurch gewrdigt, dass die Ge meinde Purgstall mit der Goldenen Kelle, einem Preis fr besondere gelungene Ortsbildpflege, ausgezeichnet

wurde.

(P.

Ortner)

46

IABSE

STRUCTURES C-46/88

IABSE

PERIODICA 3/1988

3.

Steel Strip Reinforced Concrete Bridge (Denmark)

Owner:

rate

The Danish Road Directo by County of Fre

Strengthening

reinforcement was necessary in Order to improve the load-bearing capacity of the bridge to meet presentday load Standards. An assessment of the bearing capacity of the intact bridge had shown that the struc ture of the 2 side bays did not comply with these Standards. By adding in these bays some local reinforce ment, a higher load-bearing Classification for the bridge could be obtained.

The

In of the each two end bays 9 steel plates (400 x 5850 x 6 mm, st. 37) were bonded to the con crete. When the bridge is subjected to the stipulated maximum load, the permissible tensile strength for the steel will only be 50% utilized. In addition, the shear force to be transferred by the glue Joint is only 10% of the permissible force. In other words, reinforcement

deriksborg Design and supervision: Cowiconsult, Consulting Engineers and Planners AS, Copenhagen Contractors: Armton AIS, Copenhagen Works Duration: May 10 Juny 22, 1985 Closed for traffic: June 6-July 4, 1985

Main Quantities of Material

Steel plates st. 37 Other Repair Works Water proofing membrane: Wearing course: Expansion joints:

1931 kg (41 m2)

320 m2 320 m2

30 m

with plenty of built-in safety.

The planning of the reinforcement work began in 1984. This involved some study of experience obtained abroad and some contact with experts from other countries, particularly in regard to the choice of bonding agent. This resulted in the choice of an epoxy bonder (Sikadur 31).

had

Introduction

The

canal bridge at Frederiksvaerk was reinforced in 1985 by glueing steel strips onto the underside of the bridge deck. This method is relatively unknown in

have

The

Denmark, where similar cases of bridge strengthening normally been solved by adding external pre stressing cbles and additional reinforced concrete.

reinforced concrete bridge in question is an arch bridge 45 m long, 13.5m wide, built in 1950 and designed by Cowiconsult. Above the 27.5 m span of the arch itself, the bridge deck is divided into sections. At either end of the arch there is a 7 m bay.

Before the actual work on reinforcing commenced, tests to be made of the tensile strength of the bridge concrete and the adhesive properties of the bondmg agent on the concrete surface. Altogether, tests were made with six plates all of which were tested to break ing point.

All

ruptures occured either in the concrete itself or on surface between the concrete and the bondmg agent Based on the results, the compressive strength of the concrete was assessed as minimum 25 N/mm2.

the

To

afford the best possible contact surface, extensive preparation of the concrete surfaces had to be carried

out

s ***

m

m

im

From measurements taken in connection with a load bearing test, it was established that the bondmg agent fully transferred the shear forces between the concrete and the steel plates. In addition, the distribution of stresses in the steel plates as measured was in keeping with the calculated stress-conditions for cracked and uncracked concrete cross-section.

A

Canal Bridge at Frederiksvaerk.

load-bearing test carried out one year later produced little divergence in measurements from the year before. It is intended to repeat the load-bearing tests for some time to come, to check whether the function of the reinforcing might alter in the course of time.

IABSE

PERIODICA 3/1988

IABSE

STRUCTURES C-46/88

47

1

Bolts only

Steel

Cross section of bridge deck.

**

end of plate

at

plates bonded by epoxy

Tensile stress

t

at

rupture

cfT= (N/mm2)

1.94

Other Repair Works

During the same period other repair works took place, such as replacement of water proofing membrane and wearing course The new water proofing membrane

1.67

81

81

1.74

1.74

consists of 2 layers of 3 mm fibre reinforced bitumen sheetings glued on top of the repaired bridge deck. A special 3 mm plastic/bitumen protection membrane then was applied. Then. a porous asphalt layer of

10-15 mm was applied

of

as

drain layer. Finally,

layers

wearing course were applied. New expansion joints at the bridge ends were also carried out (Thorma joint type). Besides. new traffic railings were installed along the carriageway in Order to prevent heavy vehicles from entering the footwalks.

Adhesion of the bonding measured by tests on

slabs.

test

(J0rgen Birger Kragerup, Leif Jonsen)

VL

'

5*J

%a

i*in

Bridge deck reinforced with bonded steel plates. The strain gauges were used bonding. The bolts are removed after completion.

to

verify the efficiency of the

48

IABSE

STRUCTURES C-46/88

IABSE

PERIODICA 3/1988

4.

Repairing Work of the Kyrjoki Bridge (Finland)

Main caracteristics of the bridge:

Owner and contractor:

arched span 26,50 m overall length 54,00 m width of the 7,75 m roadway width of the 3,25 m walkway Roads and Waterways

\

Wm

dministration District of Kymi

Engineering

Ky,

*mm

'

..;

-.

-...

~~~~~..

Designer of the

repairing works:

Consulting Company Jorma Huura Finland

1963 1983

ii

m

Fig.

1

Tampere,

Date of construction: Date of repairing:

The

Kyrjoki bridge before repairing

The

Kyrjoki bridge (Fig. 1) is located in a dell which causes that water is flowing on to the bridge more than otherwise. During wintertime the bridge is exposed to the salt-frost action. The bridge was built in 1963 when concrete was not air entrained. Consequently the con crete in the edge beams was scaling very badly twenty years after construction of the bridge.

The edge of the existing

structure was stenghtened by two-meter-long steel plates which were clued by epoxy

During designing of the repairing work, the widening possibilities of the bridge were also studied. The calcula tions proved that the bridge could be made wider by one meter so that the total width of the walkway became 3,25 m. The cantilever edge was designed to carry 100 kN concentrated load which corresponds to the axle load of the vehicles used for road maintenance.

resin to the surface of the bridge deck (Fig. 2). The thickness of the Joint between the plate and the con crete surface was mm. Epoxy resin was injeeted into the Joint. The shear strength requirement of the epoxy resin was 1.0 MN/m2. The injection was done before removing the moulds and the scaffoldings. The work was based on the research done by Technical Research Centre of Finland. The corresponding method has been used afterwards successfully in various repairing works.

1

was calculated that the distance of the cracks in the slender cantilever would be 1,5 meters. On the other hand, it was supposed that the cracking of the concrete

It

50

l 2000

2%

macadam

2750

35 Y

OO

iir-i

M

'

JL

Ji,

I I I

1_

Existing structure

Steel plates

Fig.

2

0

160

x

750

^^

Original edge beam

c/c 680

The cross

section of the cantilever edge with the clued steel plates

IABSE

PERIODICA 3/1988

IABSE

STRUCTURES C-46/88

49

could be avoided by over-dimensioning the reinforce ment, by proper mix design and by careful planning and execution of the concreting and curing works. These assumptions proved to be right.

reinforcement bars of the old structure were exposed about one meter and the new bars were anchored into the old concrete structure (Fig. 3). The quantity of the cement in concrete was 300 kg/m3 and the water-cement ratio was 0,50. The size of the aggre gate was between 0 and 16 mm. Air entraining agent (aircontent 4,5-5,5%), plasticizer and retarder (retardation 24 h) were used. The concreting work started at noon and the work was finished the following morning at 6 o'clock. The air temperature was between +15 and

The

+ 18C.

5~J

if

ifl

/

Fig. 4

The new

sidewalk after the repairing work

.>

The

N

protecting and surfacing layers of the repaired bridge deck were accomplished as follows (Fig. 2): 1. The waterproofing was made of rubberbitumen membrane, which was covered by ordinary bitumen

sheets. levelling and drainage layer was made of macadam (without binder). The wearing course was layed of asphaltic concrete.

The

$

2.

3.

The

US

of the total works costs repairing were 100000. Under these circumstances, the construc tion costs of a new pedestrian bridge would have been US$200000. This means that the savings were

US$100000

The repairing work was

Fig.

The

reinforcement of the cantilever

made five years ago and the concrete structures are still in good condition. It is amazing that there are no cracks in the slender edge cantilever whatsoever. (Jorma Huura, Kalevi Falck)

50

IABSE

STRUCTURES C-46/88

IABSE

PERIODICA

3/1988

5.

La

radioscopie pour l'auscultation des ouvrages d'art (France)

Coordination:

des Central Laboratoire Ponts et Chaussees, Paris

done

Etudes-utilisation

Conception-fabrication:

Laboratoire regional des ponts et chaussees de Blois Centre d'Etude et de Cons de truction Prototypes, Le Grand Quevilly

Laboratoires des Ponts et Chausses frangais ont decide d'ameliorer ces Performances, et leurs recherches ont abouti la mise au point du Systeme SCORPION pour la radioscopie des ponts en beton arme ou precontraint.

Les

La

radioscopie

Introduction

methodes de gammagraphie sont encore actuelle ment les seules techniques d'auscultation non-destructives des ouvrages d'art fournissant des informations precises sur la geometrie et l'etat de la structure interne des ponts en beton arme ou precontraint. Elles peuvent permettre, par exemple, de mettre en evidence temps des defauts indetectables par les methodes classiques de surveillance et d'examen visuel, et qui risquent cependant de mettre en cause terme la perennite de l'ouvrage.

Les

Cependant, la gammagraphie classique, qui utilise en general une source de Cobalt 60 et des films radiographiques, presente l'inconvenient d'etre lente et sur tout ponctuelle. En effet, les films ne mesurent que 30 sur 40 centimetres et un grand nombre de cliches est done necessaire pour obtenir une information represen tative. En outre, la gammagraphie ne s'applique qu' des parois de beton d'epaisseur maximale de 60 centi metres, ce qui interdit l'examen de nombreuses parties

En radioscopie, l'emetteur de rayonnement est un generateur electrique de rayons X et le detecteur un Systeme special capable de fournir en temps reel une image sur un moniteur TV, cette image pouvant etre enregistree sur bnde magnetique. Si cette technique est courante dans le domaine medi cal, o l'on utilise des rayonnements de faible energie, son application aux ouvrages d'art a necessite la concep tion d'un accelerateur lineaire de haute energie (4 Megaelectrovolts) utilisable sur chantier et la mise au point d'un nouveau convertisseur rayons X-Iumiere visible adapte cette energie (brevet L. P. C).

d'ouvrages.

Le rayonnement X emis par l'accelerateur lineaire (type Neptune IV, fabrique par la societe CGR-MeV) possede done une energie nettement superieure celle des photos gamma du Cobalt 60 et surtout le flux de ce rayonnement est environ 60 fois plus eleve. Ces deux caracteristiques permettent d'examiner des epaisseurs de beton deux fois plus importantes, avec des temps d'exposition considerablement plus courts et une meilleure definition de l'image. En outre, l'utilisation de

cble

game

ff:.

O-P

manque de coulis

o.

'.'

???>":

.-w.

acter

:

-.9.

i:

manque de coulis

freite

trompette

'K-rY,

/

AD-Z.

DQ

.0."

.'.*?.: -.-Q-z

Q ;:<:

':,

0 :.Q\

:>

?'

:i-::z--.o':,:';.:-\

'*

9

f-,

r

>>:'; "

o

fy'-

'\<>if

i-vJvi-j

:.

.L-.:! o

o

f

Oy.

mauvais contact

..

;:*>\w;:

heterogeneite

vMm:

Fig.

1

Deux exemples de resultats de radioscopie et leur interpretation

J%

IABSE

PERIODICA 3/1988

IABSE

STRUCTURES C-46/88

51

:.:

...

%

--

W,

i#***

Zm\

^P*

&%

mmm.

5*

tf&0^^

R!S"?WQWwH.viri

l*\

f/gj.

2

^>,

Systeme SCORPION pour

la

radioscopie d'un pont

caisson

l'accelerateur lineaire rend plus facile la protection radiologique du personnel et du public: il n'est dangereux que lorsqu'il est sous tension, ce qui permet son transport sans contrainte particuliere Pour la radioscopie des ouvrages d'art, l'accelerateur et le detecteur sont deplaces simultanement par telecommande de part et d'autre de la paroi en beton ausculter. II est ainsi possible, par exemple, dans le cas d'un pont en beton precontraint, de suivre les cbles sur partiquement toute leur longueur, verifier leur position, examiner leur etat et celui des gaines (fils detendus ou rompus, manque du coulis d'injection et etendue du observer les defaut, deformation des gaines (figure 1). ancrages, l'homogeneite du beton, ete Les images etant obtenues en temps reel, la sensibilite de la radioscopie est plus faible que celle de la radiographie (qui permet d'utiliser des temps d'exposition de plusieurs minutes). Son application est done limitee des parois de 70 centimetres environ; pour des epaisseurs plus importantes (jusqu' 1,1 metre) il est toujours possible de realiser des cliches radiographiques complementaires.

camion laboratoire situe environ 80 metres de la zone auscultee. De plus, eile doit posseder des qualites de rigidite et de stabilite sffisantes pour obtenir des images de bonne qualite, ce qui interdit l'utilisation des passerelles de visite classiques

Etant donne la diversite des geometries des ouvrages examiner, il n'a pas ete possible de realiser des le depart un appareil universell c'est pourquoi, le developpement du Systeme SCORPION comprend plusieurs etapes.

Dans un premier temps, un appareil a ete construit pour radioscopie des ponts caissons (figure 2). Dans ce cas, le detecteur est place l'interieur de l'ouvrage: il possede son propre Systeme de deplacement, ses

la

mouvements telecommandes depuis le camion labora toire etant synchronises avec ceux de l'accelerateur situe sur la passerelle. Cet appareil est operationnel depuis 1986.

Au vu de la qualite des resultats obtenus, il a ete decide d'etendre les possibilites de SCORPION d'autres types d'ouvrages et d'abord aux ponts poutres. Cette adaptation sera terminee en Juin 1989.

Utilisation sur chantier

L'accelerateur lineaire, dont la partie emettnee forme un cube de 75 centimetres d'arete environ pesant 240 kg, necessite pour etre utilise sur ouvrages d'art, un bras de manipulation concu specialement sous la forme d'une passerelle qui peut etre aussi utilisee pour l'examen

visuel du pont. Pour des raisons de radioprotection, cette passerelle doit etre entierement telecommandee partir d'un

Conclusion

SCORPION est le premier Systeme de radioscopie televisee en haute energie utilise de fagon operationnelle sur ouvrages d'art en beton arme et precontraint. Ses Performances, notablement superieures celles de la gammagraphie classique, devraient lui permettre un developpement rapide pour le contrle de fabrication d'ouvrages neufs et l'auscultation d'ouvrages anciens.

(J. P.

Chevrier,

R.

Guinez,

J.

Marignier)

52

IABSE

STRUCTURES C-46/88

IABSE

PERIODICA 3/1988

6.

Automatisation pour verinage

de haute

precision (France)

Maitre d'Ouvrage: Maitre d'CEuvre:

Etat

- Direction

des Routes

DDE du Val de Marne et DRE de

l'ile de France

Entreprises: Laboratoire:

Sitraba, Savoure, Cipec

LREP (Bourget)

Description de l'ouvrage

la

viaduc de la Bievre, qui permet le franchissement de valiee de la Bievre par l'auroroute A6a Arcueil (94) est constitue de deux tabliers comportant chacun 6 travees independantes de 36 m de portee.

Le

travees situees de part et d'autre d'une meme pile l'aide de palees metalliques speciales. De ce fait, la circulation n'etait interrompue que le temps du verinage c'est--dire, quelques heures de la nuit. Pour le cas particulier des eulees il etait necessaire de redescendre le soir meme afin de ne pas creer de marche d'escalier sur la Chaussee et d'aeeepter la gene due au peu de hauteur disponible pour reconstituer les des d'appui.

Precision du verinage

Le probleme le plus important restait celui de la precision du verinage. En effet, celui-ci consistait en une denivellation de 2 x 5 poutres avec 0,3 m de precision, alors que les verins etaient positionnes sur des palees de 15 m de hauteur qui risquaient elles meme de tasser par adaptation et par deformation elastique inegale.

Chacune de ces travees est formee de 5 poutres sous Chaussee en beton precontraint reliees par 5 entretoises dont 2 sur appui. L'altitude du tablier par rapport au terrain naturel est variable de 10 18 m de hauteur.

L'ouvrage a ete realise il y a une trentaine d'annees et necessite actuellement des actions d'entretien specialise consistant notamment en l'echange des appareils d'appuis et la refection de leurs bossages.

Cet ouvrages, dont la conception est anterieure aux directives de SETRA, n'integrait par les dispositions necessaires un remplacement aise des appareils d'appui, tant geometriquement pour la mise en place de verins que mecaniquement pour la resistance des entre

II

Par ailleurs, la deformation elastique du chevetre de l'ordre de 0,3 0,6 mm en le dechargeant du poids des poutres lors du verinage etait superieur la precision de ia mesure souhaitee.

toises sur appuis. etait done indispensable, pour le verinage de chaque ligne d'appuis, de trouver des solutions innovantes aux problemes poses.

Afin de tenir compte de ces problemes de deformation, est necessaire de disposer d'une reference fixe de mesure. A cet effet, des fils Invar equipes de capteurs de deplacement sont descendus des poutres jusqu'au sol et permettent d'obtenir l'information absolue sur les deplacements. Mais possedant cette information, il

il

Respect des contraintes de circulation

Afin de ne pas gener

temps necessaire abouts de poutre,

il

la

a

circulation tout en laissant le refection des bossages et des ete convenu de veriner les deux

la

n'etait pas imaginable de la traiter manuellement: la precisin souhaitee etant trop grande. L'asservissement des verins au deplacement apparaissait comme la Solution adaptee car, apportant les avan tages suivants: regroupement de toute les informations sur une centrale permettant une visualisation instantanee de la position des poutres (sensibilite de lecture des appareils de contrle 0,1 mm). rapidite et fiabilite des Operations de verinage. possibilite d'interruption immediate en cas d'anomalies et possibilite de fonctionnement manuel. standardisation d'un verinage de haute precision qui allait se repeter de nombreuses fois (28 verinages ou deverinages pour ce viaduc).

Automatisation des verinages

L'asservissement realise est base sur un micro-ordina teur sur lequel sont transferees les valeurs des deplace ments des poutres par l'intermediaire de capteurs et d'un interface approprie.

deplacements

1

1

**.

special permet d'analyser les valeurs des et d'en deduire les actions necessaires au niveau des verins. II a pour but d'empecher que deux poutres quelconques aient plus de 0,3 mm de deniveliees ce qui revient creer une boucle o les verins effectuent leur course en se rattrapant ou se depassant mais toujours avec moins de 0,3 mm d'ecart.

Un

logiciel

Avant de passer

le

au

verinage de l'ouvrage,

de

il

Fig.

Montage des palees

au

droit d'une pile

fonctionnement electnque et informatique.

bon

l'ensemble

fallait tester hydraulique,

Jt

IABSE

PERIODICA 3/1988

IABSE

STRUCTURES C-46/88

53

t t

ECRAN

3

7>

ENTREEI

Y

o o Fig.

EHSELECTfiOVANNE VERIN p

w

centrale de verinage

ERV1SSEMENT

^Xz> \j^

III

IM

Installation

un

de la

||

Q,

ELECTRO-V

VERIN

de coupure de

IMPRIMANTE

^T

verinage de 30 millimetres. Le temps circulation strictement necessaire est done notablement reduit.

minutes pour

la

Fig. 2

Synoptique

de

I'automatisation

du verinage

Apres une etude specifique afin de s'adapter aux con traintes de l'asservissement, il a ete realise un essai prealable sur l'installation specialisee du LREP. II a permis notamment de mettre jour un certain nombre de difficultes qui ont pu ainsi etre resolues sans aueun risque pour l'ouvrage.

a pu ainsi montrer l'ensemble des mtervenants que dispositif repondait bien ce que l'on en attendait au niveau du respect des tolerances, de la fiabilite de fonctionnement et de la souplesse d'utilisation pour les eventuels incidents (reprise de verinage apres arret intempestif en cours de processus, depistage automatique de fruites, colmatage de tuyauteries, etc.

Durant l'execution, lorsqu'une anomalie mtervenait (blocage d'un Joint, mauvaise Information d'un capteur, le Probleme hydraulique. processus etait auto matiquement stoppe. L'affichage digital sur le pupitre localisait instantanement les problemes et l'edition sur

imprimante de toutes les informations permettait de reflechir aux moyens mettre en ceuvre et de decider de la conduite tenir.

faut preciser que l'architecture generale adoptee permettrait une commande du verinage manuel en cas de disfonetionnement inopme du materiel informatique qui peut se deconnecter instantanement du pupitre de commande.

Enfin,

il

On

le

Conclusion

Ainsi pour repondre au probleme de fragilite des entre toises, CIPEC et le LREP ont realise une automatisation de l'operation de verinage de haute precision.

ont

Mise en ceuvre sur chantier

Celle-ci n'a presente aucune difficulte puisque l'essai au laboratoire avait permis de les traiter prealablement avec le materiel du chantier lui meme soumis des efforts de l'ordre du cinquieme des sollicitations reelles.

automatisee, l'operation s'effectue tres simple ment puisqu'il suffit d'indiquer au micro-ordinateur la valeur du deplacement souhaite pour qu'il prenne en Charge l'ensemble de l'operation qui dure ainsi quelques

Ainsi

debut des reparations les vingt-huit Operations effectuees Le Systeme a ainsi prouve sa fiabilite, sa souplesse d'adaptation aux differents cas rencontres, sa rapidite d'execution et sa securite. Issu d'un imperatif de precision, ce Systeme a devoile de nombreuses autres qualites qui le feront sans aueun doute adopter avantageusement sur d'autres chantiers necessitant ou non une grande precision

Depuis

le

ete

(Y.

Picard,

J. L.

DuchSne,

C.

Lacroix)

54

IABSE

STRUCTURES C-46/88

IABSE

PERIODICA 3/1988

7.

Off Ramp of Hanshin Expressway in Osaka (Japan)

Owner:

Hanshin Expressway Public Cor

poration

Consultant: Contractor: Work's duration (Field work): Repair date:

Prof. Dr.

K.

Horikawa

Co. Ltd.

Takara Giken

4

months

(2

weeks)

1985

Before the actual repair, a model plate girder was reshaped from a uniform section to a non-uniform sec tion by gas cutting and welding under loading. The safety of structure during the repair and the deformation after the repair were studied and also the ultimate strength after the repair was measured. Through these experiments the possibility of the repair and the cares to be paid in the actual repair were examined.

From the above results, the procedures for the repair to recommended are as shown in Fig. 2.

1)

be

Reshape of End Part of Plate Girder Bridge

Corrosion is one type of damages in steel bridges in service and is apt to occur near expansion joints, bearing shoes and so on. In these parts, the thickness of members decreases by corrosion. In an extreme case, the fillet welds between web and lower flange are lost, as shown in Fig. 1. The cause of this example was considered to be the leakage of water with free lime beacuse Stalagmite was found on the lower surface of slab and water dropped even on a fine day.

For the repair of the bridge,

2)

3) 4)

5)

Firstly, welding of vertical stiffener Secondly, welding of horizontal stiffeners It is desirable that the stiffeners marked by * in Fig. 2 is welded on the same level as the lower flange fixed in stage 5) and welded to the next vertical stiffener. Then drilling of a hole And gas cutting Finally, welding of lower flange

Assuming an existing girder with the same proportion as the model, the stresses on each stage are considered to

be as shown in Fig. 3.

were discussed

1)

as

following three procedures alternatives.

2)

3)

Cutting off the corroded part, then a new member with T section is connected using H.T. bolts. Cutting off the corroded part, then a new member with T section is connected using welding at site. Cutting off the corroded part, then only a new lower flange is connected using welding at site. As a result, the plate girder Is reshaped from uniform section to

(1)

Welding of

stiffener

vertical

non-uniform section.

These procedures have both merits and dements. How ever, procedure 3) has merit for repair of bearing shoes, because the working space is secured after the reshape work, and the safety of structure is maintained during the repair.

The safety of structure during the repair and the ultimate strength after the repair should be examined in the case

of heating process under loading.

(2)

Welding of horizontal

stiffeners divided into

four parts

(3) (4)

*

Drilling

Gas

hole

cutting

<

*>'.Q:"

(5)

Welding of

lower

flange

Fig.

An example of corrosion

Fig. 2

Recommended procedures

IABSE

PERIODICA

1988

IABSE

STRUCTURES

C-46/88

55

Stage

Stage

II

Stage

Original section Assume the stresses due to the dead load and the live load as shown in the figure Welding of stiffeners The live load is not considered, because there is no traffic The stress due to the dead load does not change Gas cutting The stress. that exists in the section to be cut off. is redistnbuted Also, the force is shared stiffeners The stress after by horizontal redistribution can be calculated from the following three conditions 1) Difference of strains exists between stiffeners and web 2) The integral of moment by the stresses equilibrates with the external moment 3) The integral of the stresses is equal to

zero

Dead

Live

load

40

Total

load

USL

load

100

Stage

i

100

U

f.

JLflO

7_

A

SB"

W

W

Stage

00*

Stage

m

l-

126

A160

y

46

Stage

IV

lower flange Welding The stress due to the dead load does not change The entire section is effective to resist the live load

of

is

126

Stage

IV

The existing bridge after the repair

(K.

shown

in Fig

w

Fig.

3

Ai

.7

89

/

n

1

18

32

Tr

Horikawa,

H.

Suzuki)

Schematic example of stress (MPa)

<m

\

r ft

Fig. 4

iL-

Existing bridge after remedy

56

IABSE

STRUCTURES C-46/88

IABSE

PERIODICA

3/1988

8.

Elevated Bridge

in

Hanshin Expressway

in

Osaka (Japan)

Owner:

Hanshin

Expressway Public Cor

K.

carry

poration

Consultant: Contractor: Work's duration (Field work): Repair date:

Prof. Dr.

Horikawa

Takara Giken Co. Ltd.

6

months

the force that was carried by the part to be removed, during the repair This repairing method is named By-pass Method. Connections of the new part were of both welding and fastening with H.T. bolts, the lower flange was welded and the web was fastened with H.T. bolts.

(2

weeks)

1986

Replacement of Flange without Traffic Interruption

Heavy corrosion appeared at the lower flange plate, the lower end of web plate and one of the vertical stiffeners of a plate girder bridge (Fig. 1). It was caused by leakage of water through the timber plate used for a mold, which had been left in the concrete slab after completion. The location of the corroded area was the main girder near the span center of a 2-span continuous girder bridge for highway. The bridge was an elevated bridge in such a heavy traffic urban area (Fig. 2), that it was impossible to use any intermediate supports for the girder during repair and also impossible to suspend the traffic on the highway. Thus, the corroded area had to be repaired under loading and Vibration.

1)

Before the repair at Site, experiments were conducted in laboratory under similar loading conditions to the corroded part, containing all the repair process that should be done at site such as gas cutting and welding to examme the validity of the by-pass method as well as the workability of the field welding.

the

Following alternatives were discussed. To remove rust from the surface of the corroded area

and paint

it.

remove rust from the surface of the corroded area and weld a reinforcing cover plate. 3) To remove the corroded area and install new members. Thinking of the heavy corrosion, method 3) was adopted in the repair using a by-pass member, which was to

2)

According to the results of experiments, the by-pass member was applicable to the actual repair at site and also the stress caused by the shrinkage due to welding played a role of intentionally induced pre-stress. However, it was found that lack of fusion and cracks in the first layer could not be avoided when welding was conducted under Vibration. Therefore, to prevent those flaws, following procedures were considered as necessary: 1) To reduce the Vibration as much as possible 2) To make the X type groove for welding and to remove the first layer by gougmg 3) To keep the root gap from mm to zero 4) To make a scallop in the part of web plate where the welding line crosses the web plate

1

To

5) 6)

The

welding process. repaired girder is shown in Fig. 3. The Technical Merit of Kansai Branch of JSCE was awarded for this work.

(K.

To set end tabs To adopt the relay

Horikawa,

H.

Suzuki)

iHsJf'Ti

%&*.:.,,&**

-^E<!5H%(4j~~~f-

Fig.

Corrosion in

bridge

IABSE

PERIODICA 3/1988

IABSE

STRUCTURES C-46/88

57

-)

7

~?*L

*,

m.

Fig.

Elevated bridge

Fig.

Girder after remedy at site

58

IABSE

STRUCTURES

C-46/88

IABSE

PERIODICA 3/1988

9.

The Bridge in the Radnicka Street

in

Beigrade (Yugoslavia)

Owner:

Designer:

The City of Beigrade Construction: Directorate for

Bridges, Bei grade

permitted movement of heavy vehicles by the right main girder only, still increased the unequal deflections of the lateral girders ends causing torsion and additional

The

Rehabilitation: University of

Department Beigrade, Civil Engineering

Contractor:

of

inconvenient

slabs.

stressing

of

reinforced

concrete

deck

Construction and rehabilita Bei tion: Mostogradnja, grade

1968 1984

Date of construction:

Date of

rehabilitation:

order to increase capacity of the primary traffic route, one-way road bridge at the Radnicka street in Beigrade was constructed in 1968. The bridge was built across the five-gauge very busy railway line and the existing street, a temporary structure as the removal of the railway line from the location was antieipated. However, due to postponement of the railway network reconstruc tion, it appeared to be necessary to keep the bridge in exploitation for a significantly longer period.

In

Those slabs were connected to the upper chord of the lateral steel girders by tins anchored into the mass of concrete with four skrews on both supporting edges. In the course of time, the connection was weakened and permanent damages of bridge decks above lateral girders took place. The lateral joints in asphaltic bridge deck, placed on each 2 m along the length of the bridge caused, beside uncomfortable drive, constant unforseen dynamic impacts to the structure of the bndge. The repair of the bridge deck was practically impossible.

REINFORCED CONCRETE BRIDGE DECK

THE

I

MAIN

YX

lO

GIRDER A

I I

The

the

9

bridge is skewed, in vertical curvature with of the 6%, biggest slope length being 334 m and the useful width 6 m, (Fig. 1). x 36 +10

I

'&

The

main box girder, lateral Compound beams, hori zontal bracing and box columns are made of steel. The connection between the main and lateral steel girders is

m

rHE

MAIN

GIRDER B

n x

presented

in

Fig. 2.

2.00

Rectangular prefabricated reinforced concrete deck slabs were supported by lateral girders perpendicular to main girders, their mutual distance being 2 m. The width of the slabs corresponded to the width of the bridge. The slabs were 15 cm thick with haunches of 9 cm on both supporting edges.

As the

10.00

MAIN

GIRDER

direction of lateral girders did not the skew position of the columns, unequal

coincide with deflections of

Fig. 2

The

DEFLECTIONS

the lateral girders ends used to take place whenever a vehicle crossed the bridge and those girders were the supports of reinforced concrete deck slabs, Fig. 3.

connection between main and lateral

steel girders

10,00

9x36,00

GANGES

324,00

pR|MARY

TRAFFIC

ROUTE

10

3'

/

Fig.

1

/xxyyy/y.

minivv

A

9X b> /<&

38

V,

10

I

n,co

00 % F=

9x36,00=324,00

Location plan of the bridge

IABSE

PERIODICA 3/1988

IABSE

STRUCTURES C-46/88

59

QOO

300

00x3x335000

Xfi

150

600x3x335

000

V^1-

*!50*8x3350OO:7/'

570x8

tt!70

335000

570x10x335000

8xb7Q

[=^i

+

S-u

5-15

300x12

2)

(4X3

300x20

ii

5-10

o

<>

5-10

^

400

+

I

300x12

700

^J<

*=

7.0x300

6000

900

F/ff. 3

Unequal deflections on lateral girders ends

by which reinforced concrete deck slabs were

Fig.

The cross section of the bridge after rehabili tation

supported

in 1981, rehabilitation of the bridge had to prefabricated reinforced concrete bridge slabs were replaced by the new slabs with the increased reinforcement without haunches. Through cm thick rubber strips and arbolite substratum the slabs were elastically supported by the lateral girders. The interconnection of slabs was also elastic, achieved by four longitudinal bars sealed by epoxy putty. The strains between the slabs were sealed with a soft material. The basic idea was to enable independent deformation of individual slabs when vehicle crossed the bridge.

That was why,

All

be done.

of the bridge so that the medium longitudinal seam was welded on the site. The connection of the orthotropic plate with the upper chord of the lateral girders was achieved by welding to the lower flange of the ortho

tropic plate, (Fig

Beside

a

4).

correct engineering Solution for the specific case, the application of the orthotropic steel plate achieved a decreased dead load of the structure which in the course of time proved very convenient for the increased live load.

During the detailed inspection of the bridge structure, which was carried out before rehabilitation, other failures were noticed which were removed during the rehabilitation. The first lateral girder was most badly damaged as is was completely subjected to the impact of vehicles when they were Coming to the bridge so that it had to be fully reconstructed. The damaged parts of the steel structure were repaired together with the replacement of strains, corrosion protection and other maintenance works.

However, the rehabilitation did not give the expected results so the bridge had to be rehabilitated again.

relatively expensive but from the engineering point of view the most correct alternative Solution was applied. The reinforced concrete bridge deck slabs were replaced by a orthotropic steel plate. However, due to the required minimum traffic brake and due to the existing connection between lateral and main girders, a modified orthotropic steel plate instead of the classical one was applied. Prefabricated, 10 m long assemblies of the orthotropic plate were delivered to the site and, in order to facilitate erection, their width was half the width

A

After such rehabilitation the bridge is in fll Operation for four years already, without any problems.

(G.

Nenadic, A. Pakvor,

Z.

Darijevit)

60

IABSE

STRUCTURES

C-46/88

IABSE

PERIODICA 3/1988

10.

Rehabilitation

of Yamuna Bridge at Kairana (India)

General Details

The bridge is located at the borders of two States Haryana and Uttar Pradesh. It was constructed in the year 1986. The portion of the bridge towards Uttar Pradesh side was affected in the year 1978 during the

monsoon season.

Structural Details

bridge is 478.8 metres long. Sub-strueture com prises of twin hollow reinforced concrete cellular piers which are supported on 6.1 metre diameter, single circular masonry well foundations. Super structure is made of two cell reinforced concrete box girder of balanced cantilever type with main span of 48.8 metres, and 12.2 metre long cantilevers on either side.

The

The

suspended spans of supported on cantilever tips. one end and segmental roller have been provided for the suspended spans.

24.4 metre length are Steel rocker bearings at bearings at the other end main spans as well as

provided for the river was apparently excessive. Water flow was mainly confined in three spans out of total 10 spans. Moreover the water current was not at right angle to the bridge axis. This caused considerable scouring at one corner of the above well. It settled by 86 cms, in 42 in the longitudinal direction. Conse and tilted by quently, the top of Pier No. 3 supported on the affected well moved longitudinally by 86 cms. Single segmental roller bearings provided on Pier P3 toppled and box girder feil on collapsed bearings with an impact. Total settlement of box girder over pier was 1.34 metres, and 1.68 metres (see at the lower most point of cantilever and 2). The suspended spans supported on can Fig. tilever tips at either end of box girder also got tilted, one in downward and other one in upward direction. Rocker bearings provided at the other pier (No. 4) were not damaged or dislocated due to rotation of span. Some cracks developed in th$ webs of box girder as well as pier cap at the location of impact.

1

Remedial Measures

It was deeided to restore the bridge, as similar floods were not antieipated for a long period. Boulders in steel wire crates were dumped in the form of flexible garland around the affected well No. 3 to increase its stability and reduce the chances of further scour of bed. The pier was strengthened by concrete jacketing, so that it could withstand the loading in tilted position of well and pier.

Distress and its causes

One well foundation (well No. 3) settled as well as tilted during the unprecedented floods in the year 1978. Water level rose above the design high flood level. The river had confined its course towards one bank of the bridge, causing excessive scour around well No. 3. Waterway

illllM

m 0&Z

M

UKJH

SpMMPr

^^S^d.

'y-.

-vim

Fig.

Top

view

JK

IABSE

PERIODICA 3/1988

IABSE

STRUCTURES

C-46/88

61

fi&f Lf

W*>&

?:**T~

jj^gyjp''

..

J^figS^^^c^*---

l^5)

1

*^XJT^

"^SxSHBi

V

*J**fli3

F/ff. 2

Position of segmental roller bearings

The well cap was also strengthened. Six numbers steel supports were erected from the well cap for lifting of the box girder. Each box girder was provided with two lifting points. one on either side of the pier. The large diameter Hydraulic Jacks of 200 tonnes capacity with safety nut arrangement were used for lifting the weight of 800 tonnes. In addition to the jacks stand-by support points were provided. Steel packing was provided over these

support points continuously during lifting Operation. Before commencement of lifting Operation, all the cracks were injeeted with epoxy resins. The sloping suspended spans were properly held with the cantilever tips to prevent any undesirable movement during lifting Operation. To achieve uniform reaction at all the lifting points. all the jacks were connected to a common hydraulic cireuit. The soffit of box girder was sloping. Therefore, wedge shaped steel boxes were fixed to the soffit for getting level surface at lifting points. Lifting arrangement is shown in Fig. 3. Packing boxes of diffe rent heights were planned so as to have a minimum number of them in position at any given time. Tapered steel shims were used to cater for change in inclination of span over supports, during lifting Operation. After bringing the span to the level position, the suspended spans were shifted longitudinally to their original position by use of Freyssinet flat jacks at the expansion Joint positions.

The

Fig. 3

Lifting arrangement

ported, the new pier cap was concreted at the new higher level. Twin fll roller bearings were provided for

transfer of load of the span.

Experience gained

Excessive waterway should not be provided while planning the bridges. Proper guidebunds and other river training works shall be arranged to confine the flow of river in the desired direction.

(P. Y.

main

Operation

in

of

completed

12

days.

alignment of structure was While keeping the span sup-

Man jure, M.

R.

Rohra)

62

IABSE

STRUCTURES C-46/88

IABSE

PERIODICA 3/1988

11.

Rehabilitation

of Girna Bridge (India)

General Details

located near Chalisgaon town in Dhulia Bridge District of Maharashtra State on a State Highway. It has been constructed across river Girna by Public Works Department of Government of Maharashtra in the year

is

Girna

As

was observed that the distress was slowly increasing. such, traffic was suspended over the bridge to prevent any untoward happening. The traffic was diverted from the temporary adjoining bridge.

It

1965.

Remedial Measures

Structural Details

The Bridge is founded on twin well foundation. The wells are of 4.27 metre diameter. The masonry piers of about 9 metre height are supported on wells.

The

superstructure of 247 metre length is of Balanced Cantilever type and consists of 3 beam System with reinforced concrete decking on top. The main spans are 27.4 metre length with 6.86 metre long cantilevers on either side. Suspended spans of 13.7 metre length have been provided between cantilever tips.

Replacement of steel plate bearings by Neoprene Bearings and repairs to damaged concrete portion at the articulation were considered essential. For this purpose, it was necessary to lift the suspended spans and reconcrete the cantilever tips. Lifting of suspended spans was required to be done from the deck level since height of the superstructure was about 15 metres from river

bed (see Fig.

2).

The main beams are supported on steel rocker and roller bearings on piers and the suspended beams rest on

plate bearings at articulation points.

Fabricated steel girders were placed in line with rein forced concrete beams over articulation portion. These steel girders were connected to reinforced concrete beams by means of Alloy steel suspenders at two locations. The hydraulic jacks were placed under the projecting portion of steel girders over the cantilever beams. All hydraulic jacks were connected to a common hydraulic circuit.

Lifting of the suspended span could be achieved by pressunzing the hydraulic circuit. It was possible to obtain almost uniform lifting, by Controlling the valves on the circuitry. The span was raised by about 40 cms. fabricated Specially light was platform weight suspended from the deck for providing access to the articulation zone. Damaged concrete was removed by using pneumatic tools. Additional reinforcement was welded to the existing reinforcement (see Fig. 3) and reconcreting was done by using epoxy bond layer at the interface of old and new concrete. At this face, subsequently, epoxy was injeeted through the inlets provided at the time of concreting. In one span, external prestressing rods were provided to prevent Separation of old concrete to new concrete besides other measures.

was

Nature of Distress and causes

mainly was in the superstructure. In the was observed that the concrete in the zone of articulation is substantially damaged (see Fig. 1). The factors contributing to the damages are outlined below: i) Plate bearings could not function due to jamming

year 1980,

it

ii)

The distress

and absence of expansion gap. The main reinforcement in the

cantilever portion

was

not

of

iii)

was found having excessive cover. Concrete in the articulation zone adequate quality.

a particular span (No. 6), distress noticed in suspended span at articulation was of higher magnitude. Large chunks of concrete were found separated in the span from the cantilever tips and the suspended span had therefore settled by about 40 mm. In most of the articulation tips, wide cracks had developed.

In

Neoprene Bearings were placed in position and the span lowered onto these bearings after the new concrete has attained minimum strength for dead load reaction. The prestressing rods were grouted after 3 months or so, to enable monitoring at articulation during this period. These rods were restressed to make up slight loss of prestress and then grouting was carried

out.

All

the suspended spans were repaired in the same manner except that external prestressing rods were not considered necessary in remaining spans.

Experience gained

This type of rehabilitation has focussed the attention of the engineers on the need for proper detailing and meticulous execution at articulation of the bridges. This experience will be useful for planning similar structures.

Fig.

Distress at articulation

(P. Y.

Manjure,

M.

R.

Rohra)

IABSE

PERIODICA 3/1988

IABSE

STRUCTURES

C-46/88

63

llllll

Un

nt.

itiii

ii

.11

'

-.-.

.-

ftp.

Lifting arrangement for suspended span

f/ff.

Cantilever tip is broken and additional rein forcement is provided

SKA-Anlage-Service 4^ plus

"v*~

berblick.

Mit

dem

SKA-Anlage-Service plus

Als

privater

oder

institutioneller Anleger

knnen

Sie

vom

SKA-Anlage-Service plus Mehrleistungen erwarten: mehr persnliche

Beratung, mehr Engagement, mehr internationale Prsenz und MEHR

BERBLICK DANK BESSERER INFORMATION. Dieses Plus an Leistung

zeichnen wir mit der Pyramide aus, dem Symbol fr das Streben nach Hherem, (ur Stabilitt, Sicherheit und Wissen

Mehr berblick verschaffen

weltweiten direkten Verbindungen

den Spezialisten an allen Brsen im

zu

wir

Ihnen

zB

dank unseren

allen wichtigen Finanzplatzen

zu den

- zu

In- und Ausland sowie

renom

mierten Gruppen und Partnergesellschaften der SKA.

Mehr

berblick verschafft Ihnen aber auch unser dynami

sches Management, unsere aufs modernste ausgebaute elektronische

Infrastruktur,

z.B.

mit dem

computergesteuerten Anlage-Informations-

System (AIS), und selbstverstndlich auch Ihr persnlicher SKA-AnlageBerater.

Oie treffen

Ihre Entscheide auf der Basis von fundierten und

Sie den

umfassenden Informationen Damit

berblick behalten

SCHWEIZERISCHE KREDITANSTALT

SKA

iyZZ:..L

IHI

X

fSl

jm

RESTON Load Measuring Bearinss

:-N-q<ASA

;..:.

iYZ-.-:;.:;.

Bilp1*'

YZ.yZzZL-

XX

y--.,-,:

,L!S&>>

WS

Load chpnges orf bridge bearings as a consequence of subsoil ettlement can be measured with RESTON load measurirfg bearings

MHIMhHI

S*r

YmYYYzZ^yZizzZyZY^

Riesbachstrasse 57

Phone 01/47 78 00

PROCEQ SA

Please send more

CH-8034 Zrich

Telex 817118 pre ch

Switzerland Telefax 01/47 9914

information

!>-.

Name

D RESTON Bndse Beannss

D LASTO-BLOCK Bearings

Company:

D LASTO-STRIP

Bearings for Buildings

D TENSA

Z0>-

Address:

Road Expansion Joints

REPAIR AND REHABILITATION

OF BRIDGES

.)*:

XVV

:

T3EE

UM

WSmXM

i.ftfl

is

XfY-X

1*

'

fc

fp

fcfcr' &i

i **

^:;

-QQ-w^;ffe

peyssinet

DE FRANCS FREYSSINET INTERNATIONAL (S.T.U.P.) - S.N.C. AU CAPITAL DE 22 000 000

ZA

DES MARAIS - 28 RUE DES OSIERS

:

78310 COIGNIERES (FRANCE) - TELEPHONE

TELEX

:

(1) 34 61

61

89 89

FREISIA 699762

- TELEFAX

(1)34

80 61

You might also like

- Einstufungstest Logisch Neu A2Document7 pagesEinstufungstest Logisch Neu A2Dina Clima100% (1)

- Linie1 Pflege - Pruefungstipps Zum Intensivtrainer - GoetheDocument7 pagesLinie1 Pflege - Pruefungstipps Zum Intensivtrainer - GoetheLarysa KalashnikovaNo ratings yet

- Custos Dos Serviços - Dezembro 2019 PDFDocument434 pagesCustos Dos Serviços - Dezembro 2019 PDFviniciusltNo ratings yet

- Custos Dos Serviços - Dezembro 2019 PDFDocument434 pagesCustos Dos Serviços - Dezembro 2019 PDFviniciusltNo ratings yet

- Custos Dos Serviços - Fevereiro 2020 PDFDocument434 pagesCustos Dos Serviços - Fevereiro 2020 PDFviniciusltNo ratings yet

- Franz Dischinger - Ingenieur PortraitDocument6 pagesFranz Dischinger - Ingenieur PortraitviniciusltNo ratings yet

- Franz Dischinger - Ingenieur PortraitDocument6 pagesFranz Dischinger - Ingenieur PortraitviniciusltNo ratings yet

- Bse-Re-003 1998 79 A 087 DDocument7 pagesBse-Re-003 1998 79 A 087 DviniciusltNo ratings yet

- Bse-Pe-002 1988 12 C-47 S DDocument29 pagesBse-Pe-002 1988 12 C-47 S DviniciusltNo ratings yet

- 00 deDocument277 pages00 deditare2924No ratings yet

- 810 GA1 Inbetriebnahme-AnweisungenDocument293 pages810 GA1 Inbetriebnahme-AnweisungenkumbrovNo ratings yet

- 1173 - Busch-Jalousiecontrol II Sortimentsbroschuere Inkl. Jalousie-Komfortschalter - 4 - 10Document16 pages1173 - Busch-Jalousiecontrol II Sortimentsbroschuere Inkl. Jalousie-Komfortschalter - 4 - 10Nikola KovačNo ratings yet

- Präsentation 1Document17 pagesPräsentation 1Eva SengerNo ratings yet