Professional Documents

Culture Documents

Exp3 Org Lab

Uploaded by

RA MemijeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Exp3 Org Lab

Uploaded by

RA MemijeCopyright:

Available Formats

INTRODUCTION Organic compounds differ in volatility because of the intermolecular forces present and involved in each compound.

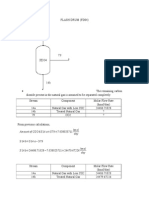

Volatility is based on the equilibrium vapor pressure exerted by the compound at a particular temperature. Compounds having strong intermolecular forces will definitely be more difficult to separate. Thus, compounds having strong intermolecular forces will be less volatile. It is therefore possible to separate compounds from each other in a mixture based on their volatility differences. More volatile compounds will be converted into vapor faster than those that have low volatilities. Thus, the process of separating compounds based on their volatility differences is called distillation. There are several types of distillation. Two of them are the simple and steam distillation, which are used for this experiment. Simple distillation, a volatile compound is separated from a nonvolatile compound by applying heat to the mixture. The vapor is immediately channeled into a condenser. Consequently, the distillate is not pure but rather its composition is identical to the composition of the vapors at the given temperature and pressure. That concentration follows Raoult's law. As a result, simple distillation is effective only when the liquid boiling points differ greatly or when separating liquids from non-volatile solids or oils. For these cases, the vapor pressures of the components are usually sufficiently different that the distillate may be sufficiently pure for its intended purpose. Steam distillation is a method for distilling compounds which are heat-sensitive. The temperature of the steam is easier to control than the surface of a heating element, and allows a high rate of heat transfer without heating at a very high temperature. This process involves bubbling steam through a heated mixture of the raw material. By Raoult's law, some of the target compound will vaporize (in accordance with its partial pressure). The vapor mixture is cooled and condensed, usually yielding a layer of oil and a layer of water. This is used to recover organic compound that exerts very little vapor pressure even at high temperatures. Water is added to increase vapor pressure so that it can have atmospheric pressure at a lower temperature. Thus, in this experiment, the purpose is to (1) assemble a simple and a steam distillation setup, (2) identify and recognize the significance of all parts of the setup and (3) purify a sample using simple and steam distillation. MATERIALS AND METHODS The following are the apparatus used during the experiment: quick fit, pipette, hot plate and Erlenmeyer flask. Meanwhile, the following are the reagents used during the experiment: impure toluene, p-dichlorobenzene, distilled water and ice. The experiment was divided into two parts, basically, the simple and steam distillation parts. For the simple distillation, the setup as shown in Figure 3.1 was assembled first. Impure toluene measuring 15 ml was transferred into the pear-shaped flask. Then it was heated with the aid of the hot plate. The distillate was collected at different temperatures at the rate of 1 drop per second. Definitely, every time a drop of the distillate was collected, the volume was measured. (This was continued until the temperature dramatically increased)

The data recovered from this part was plotted in a graph, and from this the boiling point of the toluene was determined. For the steam distillation, p-dichlorobenzene was used as the reagent. The setup shown in Figure 3.2 was assembled for this part of the experiment. Water in an Erlenmeyer flask measuring 100 ml was boiled to serve as the steam generator for this part. While the water was boiled, pdichlorobenzene was put into the pear-shaped with arm flask, dissolved slightly in 5 ml of water. The set-up now was connected and continued with the distillation. After the distillation process the recovered mixture was cooled and vacuum filtered. Finally, percentage recovery as well as the melting point of the recovered substance was determined. FOR THE RESULTS, Boiling Point of the Sample (C) Total volume collected (ml) Percentage Recovery(%) 110-113 13.4 89.33

Observations The sample is orange in color. It smelled like a substance present in rugby. The sample took some time to boil. However, once it boiled, raise in temperature is fast.

Melting point of the crude sample (C) Melting point of the purified sample (C) Weight of crude sample (g) Weight of the purified sample (g) Percentage recovery (%)

46 -50 50-54 2.0 1.36 68

Observations The mixture is reddish-orange in color. It looked like slightly soluble because of the undissolved particles in the pear-shaped distilland. The mixture took some time to boil. The crystals are yellowish-white. The odor of the crystals is the odor of the toilet deodorizer.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- BS 1881 201 1986 Testing ConcreteDocument28 pagesBS 1881 201 1986 Testing ConcreteShvan Najeeb100% (1)

- Base Oil Production IIDocument15 pagesBase Oil Production IIrvsinghNo ratings yet

- Thesis Research Revision Summary FormDocument1 pageThesis Research Revision Summary FormRA Memije0% (1)

- FM RS 08 15 Final Billing Form v.1Document1 pageFM RS 08 15 Final Billing Form v.1RA MemijeNo ratings yet

- 01 Equipment Design Report FormatDocument15 pages01 Equipment Design Report FormatRA MemijeNo ratings yet

- Petron Corporation Company ProfileDocument2 pagesPetron Corporation Company ProfileRA MemijeNo ratings yet

- Removed Flash Drum Mat BalDocument2 pagesRemoved Flash Drum Mat BalRA MemijeNo ratings yet

- Using Gain (Fixed KC) : DiagramDocument19 pagesUsing Gain (Fixed KC) : DiagramRA MemijeNo ratings yet

- ValvesDocument31 pagesValvesRA MemijeNo ratings yet

- Lecture 6 - CrystallizationDocument29 pagesLecture 6 - CrystallizationRA Memije33% (3)

- On LNG and FLNGDocument46 pagesOn LNG and FLNGRA MemijeNo ratings yet

- Biochemical Engineering Journal: Shangde Sun, Xiaowei ChenDocument7 pagesBiochemical Engineering Journal: Shangde Sun, Xiaowei ChenRA MemijeNo ratings yet

- Ms. Nancy Caringal Memije: 1480 Governor'S Drive Brgy - Bancal Carmona, Cavite 4116Document2 pagesMs. Nancy Caringal Memije: 1480 Governor'S Drive Brgy - Bancal Carmona, Cavite 4116RA MemijeNo ratings yet

- Separations Based On The Motion of Particles ThroughDocument16 pagesSeparations Based On The Motion of Particles ThroughRA Memije0% (1)

- Size ReductionDocument16 pagesSize ReductionRA Memije100% (1)

- Drying: CHE133 Heat and Mass Transfer ApplicationsDocument22 pagesDrying: CHE133 Heat and Mass Transfer ApplicationsRA MemijeNo ratings yet

- Fractional DistillationDocument84 pagesFractional DistillationRA MemijeNo ratings yet

- Characterization of Solid ParticlesDocument10 pagesCharacterization of Solid ParticlesRA MemijeNo ratings yet

- Learning Task 2 - CHE122-1Document17 pagesLearning Task 2 - CHE122-1RA MemijeNo ratings yet

- 01D Basic ConceptsDocument64 pages01D Basic ConceptsRA MemijeNo ratings yet

- Spent Bleaching Earth Sbe The Hidden Treasure From Waste of The Palm Oil Refinery PlantDocument6 pagesSpent Bleaching Earth Sbe The Hidden Treasure From Waste of The Palm Oil Refinery PlantAgustina TriyaniNo ratings yet

- PT Buana Laksa Abadi: 1. Design CriteriaDocument3 pagesPT Buana Laksa Abadi: 1. Design CriteriaKris SiregarNo ratings yet

- 496 GDJGGJGFDocument2 pages496 GDJGGJGFRaluca FarcasNo ratings yet

- Pressure TestsDocument3 pagesPressure TestsfedermNo ratings yet

- Practical Organic ChemistryDocument368 pagesPractical Organic Chemistrycoincoin1No ratings yet

- 21 - Suitability of Shredded Tires For Use in Landfill Leachate Collection SystemsDocument13 pages21 - Suitability of Shredded Tires For Use in Landfill Leachate Collection SystemsbelavelosoNo ratings yet

- ETHYLENEAMINE E-100 (E-100) : Technical BulletinDocument2 pagesETHYLENEAMINE E-100 (E-100) : Technical BulletinRAFAEL MIERESNo ratings yet

- Page 1 To 12Document41 pagesPage 1 To 12bahmanNo ratings yet

- Assignment 5, 6Document4 pagesAssignment 5, 6Tim ChongNo ratings yet

- A307 PDFDocument5 pagesA307 PDFxaviereduardoNo ratings yet

- Worksheet Ch1Document36 pagesWorksheet Ch1Shazia FarheenNo ratings yet

- Study On The Second Stage of Chalcocite Leaching in Column With RedoxDocument12 pagesStudy On The Second Stage of Chalcocite Leaching in Column With RedoxFrancisco CampbellNo ratings yet

- Troubleshooting Precast Cracking in Double Tees - tcm77-1306891 PDFDocument5 pagesTroubleshooting Precast Cracking in Double Tees - tcm77-1306891 PDFsdagnihotriNo ratings yet

- International Earth Science Olympiad (IESO) : RocksDocument14 pagesInternational Earth Science Olympiad (IESO) : RocksansariNo ratings yet

- Safety Data Sheet: ProductDocument4 pagesSafety Data Sheet: ProductAchraf Ben DhifallahNo ratings yet

- Festschrift Hoehler PDFDocument14 pagesFestschrift Hoehler PDFAndrec Crs CrsNo ratings yet

- Vessel Nozzle PDFDocument30 pagesVessel Nozzle PDFEugenia LorenzaNo ratings yet

- ASME B31.5-Refrigeration-PipingDocument11 pagesASME B31.5-Refrigeration-PipingJai100% (2)

- DSM-0329.1 WokaDur NiE ElectrodeDocument4 pagesDSM-0329.1 WokaDur NiE ElectrodeAlireza KhodabandehNo ratings yet

- Scraper Wiper LimpiadorDocument100 pagesScraper Wiper LimpiadorRPINILLA (EICO S.A.)No ratings yet

- Experimental Investigation of Machining Parameters For EDM Using Rectangular Shaped Electrode of en 31 SteelDocument3 pagesExperimental Investigation of Machining Parameters For EDM Using Rectangular Shaped Electrode of en 31 SteelMostafa Adil0% (1)

- Novolastic Subsea Thermal InsulationDocument3 pagesNovolastic Subsea Thermal InsulationCarloBardoliNo ratings yet

- AED Design Requirements:: Breaker and Conductor SizingDocument4 pagesAED Design Requirements:: Breaker and Conductor SizingRicky Respondo TindocNo ratings yet

- Basic of Soil-Soil Formation (DR - Khalid Farooq)Document26 pagesBasic of Soil-Soil Formation (DR - Khalid Farooq)Haseeb Rehman100% (1)

- Box 1.5m 1.5mDocument22 pagesBox 1.5m 1.5mveevimalNo ratings yet

- Design For RC Flat SlabsDocument70 pagesDesign For RC Flat SlabsAil AafaaqNo ratings yet

- Schematic Diagram of Qualitative Tests For Elements in Organic CompoundsDocument5 pagesSchematic Diagram of Qualitative Tests For Elements in Organic CompoundsChristine DomingoNo ratings yet

- Hardness Conversion ChartDocument10 pagesHardness Conversion ChartAshutosh SinghNo ratings yet