Professional Documents

Culture Documents

Nicola Tesla (US Pat. 447921)

Uploaded by

GaleriaTechniki.PL0 ratings0% found this document useful (0 votes)

23 views5 pagesNIKOLA 'l'ESLA, a subject of the emperor of Austria, has invented certain new and useful Improvements in Alterna.ting-Current liachines. In present use the generators give ordinarily from one to three hundred alternations of current per second. It is of great advantage, on many accounts, to employ in such systems generators capable of producing a much greater number of alternations.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentNIKOLA 'l'ESLA, a subject of the emperor of Austria, has invented certain new and useful Improvements in Alterna.ting-Current liachines. In present use the generators give ordinarily from one to three hundred alternations of current per second. It is of great advantage, on many accounts, to employ in such systems generators capable of producing a much greater number of alternations.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views5 pagesNicola Tesla (US Pat. 447921)

Uploaded by

GaleriaTechniki.PLNIKOLA 'l'ESLA, a subject of the emperor of Austria, has invented certain new and useful Improvements in Alterna.ting-Current liachines. In present use the generators give ordinarily from one to three hundred alternations of current per second. It is of great advantage, on many accounts, to employ in such systems generators capable of producing a much greater number of alternations.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

UNITED STATES PATENT OFFICE.

NIKOLA TESLA, OF NEW YORK, N. Y.

ALTERNATING-ELECTRIC-CURRENT GENERATOR.

SPECIFICATION forming part of Letters Patent No. 447,921, dated March 10, 1891.

A.pplication filed liovembe: 16, 1890. Seriallio. 871,5.54. (lio model.)

To aU whom it may concern:

Be it known that I, NIKOLA 'l'ESLA, a subject of the Emperor of Austria, from Smiljan, Lika, border country of Austria-Hungary, re-

S siding at New York, in the county and State of New York, have invented certain new and useful Improvements in Alterna.ting-Current lIiachines, of which the following is a. speeification, reference being had to the aecompa-

10 nying drawings.

In the systems of distribution of electrical energy from alternating-current generators in present use the generators give ordinarily from one to three hundred alternations of cur-

IS rent per second. I have reeognlzed anddemonstrated in practice that it is of great advantage, on many accounts, to employ in such systems generators capable of producing a very much greater number of alternations

20 per second-say fifteen thousand per second 01' many more. '1'0 produce such a high rate of alternation, it is necessary to construct a machine with a great number of poles or polar projections; but such construction, on this

25 account, in order to be efficient, is rendered difficult. If an armature without polar projections be used, it is not easy to obtain the necessary strength of field, mainly in consequence of the comparatively great leakage of

30 tbe lines of force from pole to pole. If, on the contrary, an armature-core formed or provided with polar projections be employed, it is evident that a limit is soon reached at which the iron is uot economically utilized,

35 being incapable of following without considerable loss the rapid reversals of polarity. To obviate these and other difficulties, Lhave devised a fonn of machine embodying the following general features of construction.

40 I provide a field-magnet core made up of two independent parts formed with grooves for the reception of one or more energizingcoils. The energizing coil, or coils, is completely surrounded by the iron core, except

4S on one side, where OCCUl'S the opening between the polar faces of the core, which opening is made as narrow as the conditions of the machine will permit. The polar faces of the core of the field are not smooth, but formed

50 with a great many projections or serrations, the points of which in one side or polar face are preferably exactly opposite those in the

,-----

-~

other. Between the faces so formed I mount

or support the armature coil or coils and provide either for rotating the field-magnet 01' 55 the armature, or both, and I arrange the said armature-coil or conductor so that it will be symmetrically disposed with respect to the field-that is to say, so that when one portion

of the conductor is passing through the 60 strongest portion of the field the other POl'tion, which .forms the return for the former,

is passing through the weakest points or parts of the field. The strongest points of the field, it will be understood, are those be- 65 tween the projections or points on the polar faces, while the weakest. points lie midway between them.

A fleld-maguet, when constructed as above described, produces, when the energizing-coil 70 . is traversed by a continuous current, a field

of great strength, and one which may be made

to vary greatly in intensity at points not farther distant from one another than the eighth

of an inch. In a machine thus constructed 75 there is comparatively little of that effect which is known as "magnetic leakage," and there is also but a slight armature reaction. Either the armature-eondnctor 01' the fieldmagnet may be stationary while the other 1'0- 30 tates, and as it is often desirable to maintain the conductors stationary and to rotate the field-magnet I have made a special modification of the construction of the machine for this purpose, and with a view in such case of 8S still further simplifying the machine and rendering it more easy to maintain in operation

I arrange the armature-conductors and the frame or supports therefor so as to support also a fixed coil or coils for energizing the 1'0- 90 tating field-magnet, thus obviating the employment of all sliding contacts.

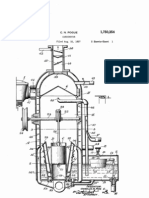

In the accompanying drawings I have illns-. trated the two typical forms of my machine

above referred to. 95

Figure 1 is 11. vertical central section of the machine, taken on lines x x of Fig. 2; and Pig. 2 is a horizontal section 011 line y y of Fig. 1. The machine in these two figures is

one ill which the anuntnre-conductor and the roo field-coil are stationary while the field-mag-

net core revolves. Fig. 3 is a vertical central section of a machine embodying thesame plan

of constrnction, bnt having a stationary field-

Utaguet and rotating armatn re,; Flg. 4: is t1 diagram 1l1listi'aiing the peculiar configlll;ation of tHe ptilai' faces and the relation df the armatura conductor or conductors thereto,

S 1n Figs. 1 and 2, A A designate two cylindrical castings provided with bracket-arms B B, in which latter are bushings C·fol' the rotating shaft. The conductor in which the currents are induced may be constructed or

10 arranged in various ways; but I prefer to form it in the following manner: I take an annular plate of copper D and by means of a 'saw or other cutting-tool cut in it radial slots from one edge nearly through to the other,

[5' beginning alternately from opposite edges.

In this way a continuous zigzag conductor is .formed. '1'0 the inner edge of this plate are secured two rings of non-magnetic metal E, which are insulated from the copper con-

ro duetor, but held firmly thereto, as by means of bolts F. Within the rings E is then placed an annular coil G, which is the energizingcoil for the field-magnet. The conductor D and the parts attached thereto are supported

25 by means of the cylindrical shell or casting AA, the two parts of which are brought together and clamped by bolts F' to the outer edge of the conductor D. The conductor D is also insulated from the shell A ..

30 The core for the field-magnet is built up of two circular parts H H, formed with annular grooves I, which, when the two pints are brought together, form a space for the reception of the energizing-coil G. The central

35 parts or hubs of the cores H II are trued off, so as to fit closely against one another, while the' outer.portlons or flanges which form the polar faces J J are reduced somewhat in thickness to make room for the conductor D, and

40 are serrated on thei r faces or provided in any other convenient way with polar projections. The two parts' of the core H H are mounted on and fixed to the shaft K, and are bound' together by bolts L.'l'be number of serra-

lS tlons in the polar faces isarbltrnry; but there must exist between them and the radial portions of the condnctor D a certain relation, which will be understood bvreferenee to Fig. 4, in which N N represent the projections or

;0 points on one face of the core of the field, and S S the points of the other face. 'I'he condnctor D is shown in this figure in section, a a' designating the. radial portions of

. the conductor, and b the insulating-divisions 55 between the same. The relative width of the parts a a' and the space between any two adjacent points N Nor S S is such that whenthe radial portions a of the conductor are passing between the opposite points N S,

60 where the field is strongest, the intermediate radial portions a' are passing through the widest spaces midway between such points and where the field is weakest. Since the core on one side is of opposite polarity to the

65 part facing it,-all the points or projections of one polar face will be of opposite polarity to those of the other face. Hence, although the

space between any two adjacent points on the sattlefa~Itiay Va ¢xHetnelY small, therewul

be no leakage of tHe magnetic lines behv~~i1 1(J any two points of the same name; but the lines of force will pass across from one set of points to the other, The oonstruction followed obviates to a great degree the distortion of the magnetic lines by the action of the 75 current in the conductor D, in which it will be' observed the .eurrent is flowh;lg at any given time from the center toward the periphery in one set of radial parts a and in the opposite direction in the.adjacent.parts a'. 80

In order to connect the enet·gizing·coil G with a source of continuous current, I have found it convenient to utilize two adjacentradial portions of the conductor D for connect- . ingthe terminals. of the coil Gwith two bind- 85 ing-posts M. For this purpose the plate D is cut entirely through, as shown, and the break thus made is bridged over by a short conductor c.

. At any convenient point the plate D is cut 90 through to form two terminals d, which are connected to binding-posts N.

'I'he core HH, when rotated by the driving'pulley P, generates in the conductors D an alternating current, whleh is taken off from 95 the binding - posts N. It will be observed that from the nature of the construction described this machine is capable of producing

an alternating current of II:n enormously high

rate of alternations. _ 100

When it is desired to rotate the conductor between the faces of a stationary field-magnet, I adopt the construction shown in Fig. B. The conduetor D in this case is 01' may be 'made in substantially the same manner as roS above described by slotting an annular conducting-plate and supporting it between two heads 0, held together by bolts 0 and fixed

to the driving-shaftK. The inner edge of

the plate or cond nctor D is preferably flanged I 10 to secure a firmer union between it and the heads 0. It is insulated from said head. The field-magnet in this case consists of two annular parts H H, provided with annular grooves I for the reception of the coils. The IIS flanges or faces surrounding the annular groove are brought together, while the inner flanges are serrated, as in the previous case,

and form the polar faces. 'rhe two parts H Hare formed with a base R, upon which the 120 machine rests.

S S are non-magnetic bushings secured. or

set in the central opening of the cores. .

The conductor D is cut entirely through at

one point to form terminals, from which in- 115 sulated conductors T are led through the

shaft to colleoting-rings V. . .

What I claim is-

1. The combination, in an annular field of force formed by opposing polar faces with 130 radial grooves' or serrations and with said poles, of a connected series of radialcondoct-

01'8 so disposed with relation to the serrations that while one portion of the radial conduct-

Drs is passing between the strongest parts of polar faces being placed with their grooves the field, 01' the points where the two poles opposite to each other, and a conductor or coil most nearly approach, the adjacent or inter- mounted between said faces with the capamediate conductors will pass through the bility of movement across the lines of force

5 weakest parts of the field, or the points where in a direction at right angles to that of the 45

the two poles are most remote, as set forth. grooves or serrations, as set forth.

2. The combination, with a connected se- 6. In a magneto-electric machine, the com-

ries of radial conductors forming an annular binatlon of a sectional frame, a field-magnet coil, of a stationary two-partsupporting-frame core composed of two connected parts, a rotat-

IO clamped to and insulated from the outer ing shaft on which said core is mounted, a 50 ends of said conductors, a ring formed in two conductor in which currents are to be inparts clamped to the inner ends of the same, duced, the convolutions of which are radially' an energizing-coil contained in said ring, and I disposed. between the polar faces of the field-

a field-core made in two parts and inclosing core and secured to and supported by the

IS said energizing-coil and presenting annular frame, and an energizing-coil for the field- 55 polar faces to the series of radial conductors, core supported by the induced-current coil

as described. and contained in an annular recess formed

3. The combination, with the annular con- by grooves in the faces of the two sections of ducting-plate slotted to form n connected se- the field-core.

20 ries of radial conductors, a sectional support- 7. The combination, with opposing field- 60

lug-frame secured to and insulated from the magnet poles formed with projections or serouter edge of the slotted plate, n sectional rations in their faces, the highest parts 01' ring secured to and insulated from the inner prominences of one face being opposite to edge of said plate: a hollow energizing-coil those of the other, of a conductor the convo-

25 contained in said ring, and a field-core com- Iutions of which are adapted to pass at right 65 posed of two parts bolted together and recessed angles through the magnetic lines between

to inclose the euergialng-eoll, said cores being the opposing prominences, as set forth,

mounted in a rotating shaft, as set forth. 8. The combination, with a rotating field-

4. The combination, with two annular po- magnet core having two opposing and aunu-

30 Iar faces of opposite magnetic polarity and lar polar faces with radial grooves 01' serra- 70 fonned with opposite points, projections, or tions therein systematically disposed, so that serrations, of n conductor turned back upon the highest parts or prominences of one face itself in substantially radial convolutions and lie opposite to those of the other, of a stationmounted in the annular field, whereby a rota- ary conductor with radial convolutions and

35 tion of the field or said conductor will develop mounted between the polar races, as setforth. 75

th~l'ei~ an a1te~'nat!llg cnp'ent, as set forth. NIKOLA TESLt\.

D. '1 he combination, wlth a polar face of ~ ~ .

given polarity formed with grooves 01' serra- Witnesses:

tions, of a polar face of opposite polarity with ROBT. F. GAYLORD,

40 corresponding grooves or serrations, the two PARKER N. PAGE.

(No Model.)

2 Sheets-Sheet 1.

N. TESL.A..

ALTERNATING .ELEOTRIO OURRENT GENERATOR.

No. 447,921. Patented Mar . .10,.1891.

Pin 9

.......-;y.,..

(No Model.)

2 Sheets-Sheet 2.

N. TESLA.

ALTERNATING ELECTRIC CURRENT GENERATOR.

No. 447,921. Patented Mar. 10, 1891.

You might also like

- Teaching On Evolution in European SchoolsDocument32 pagesTeaching On Evolution in European SchoolsGaleriaTechniki.PL100% (1)

- Franklin B. Mead Jr. (US Pat. 5590031)Document15 pagesFranklin B. Mead Jr. (US Pat. 5590031)GaleriaTechniki.PLNo ratings yet

- Thomas Galen Hieronymous (US Pat. 2482773)Document6 pagesThomas Galen Hieronymous (US Pat. 2482773)GaleriaTechniki.PL100% (1)

- US Pat. 3693731Document10 pagesUS Pat. 3693731GaleriaTechniki.PLNo ratings yet

- US Pat. 3881777Document6 pagesUS Pat. 3881777GaleriaTechniki.PLNo ratings yet

- Charles Nelson Pouge (US Pat. 1997497)Document6 pagesCharles Nelson Pouge (US Pat. 1997497)GaleriaTechniki.PLNo ratings yet

- Charles Nelson Pouge (US Pat. 2026798)Document6 pagesCharles Nelson Pouge (US Pat. 2026798)GaleriaTechniki.PL100% (1)

- Canada Patent - 142.352Document18 pagesCanada Patent - 142.352GustavBlitzNo ratings yet

- Canada Patent - 29.537Document24 pagesCanada Patent - 29.537GustavBlitzNo ratings yet

- Nicola Tesla (C 33317)Document16 pagesNicola Tesla (C 33317)GaleriaTechniki.PLNo ratings yet

- Canada Patent - 24.033Document12 pagesCanada Patent - 24.033GustavBlitzNo ratings yet

- Canada Patent - 30.142Document10 pagesCanada Patent - 30.142GustavBlitzNo ratings yet

- Charles Nelson Pouge (US Pat. 1750354)Document5 pagesCharles Nelson Pouge (US Pat. 1750354)GaleriaTechniki.PLNo ratings yet

- Hedy Kesler Markley (US Pat. 2292387)Document7 pagesHedy Kesler Markley (US Pat. 2292387)GaleriaTechniki.PLNo ratings yet

- Nicola Tesla (B 14579)Document9 pagesNicola Tesla (B 14579)GaleriaTechniki.PLNo ratings yet

- Nicola Tesla (B 19426)Document5 pagesNicola Tesla (B 19426)GaleriaTechniki.PLNo ratings yet

- Canada Patent - 135.174Document12 pagesCanada Patent - 135.174GustavBlitzNo ratings yet

- Nicola Tesla (B 16709)Document6 pagesNicola Tesla (B 16709)GaleriaTechniki.PLNo ratings yet

- Nicola Tesla (B 13563)Document5 pagesNicola Tesla (B 13563)GaleriaTechniki.PLNo ratings yet

- Nicola Tesla (B 19420)Document5 pagesNicola Tesla (B 19420)GaleriaTechniki.PLNo ratings yet

- Nicola Tesla (B 14550)Document7 pagesNicola Tesla (B 14550)GaleriaTechniki.PLNo ratings yet

- United Kingdom Patent - 8575Document6 pagesUnited Kingdom Patent - 8575GustavBlitzNo ratings yet

- Nicola Tesla (B 8200)Document8 pagesNicola Tesla (B 8200)GaleriaTechniki.PLNo ratings yet

- United Kingdom Patent - 6502Document5 pagesUnited Kingdom Patent - 6502GustavBlitzNo ratings yet

- United Kingdom Patent - 6481Document9 pagesUnited Kingdom Patent - 6481GustavBlitzNo ratings yet

- Nicola Tesla (B 6527)Document5 pagesNicola Tesla (B 6527)GaleriaTechniki.PLNo ratings yet

- Nicola Tesla (B 11293)Document10 pagesNicola Tesla (B 11293)GaleriaTechniki.PLNo ratings yet

- United Kingdom Patent - 2975Document9 pagesUnited Kingdom Patent - 2975GustavBlitzNo ratings yet

- United Kingdom Patent - 2801Document5 pagesUnited Kingdom Patent - 2801GustavBlitzNo ratings yet

- United Kingdom Patent - 2812Document7 pagesUnited Kingdom Patent - 2812GustavBlitzNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)