Professional Documents

Culture Documents

Chal Copy Rite

Chal Copy Rite

Uploaded by

Daniela BravoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chal Copy Rite

Chal Copy Rite

Uploaded by

Daniela BravoCopyright:

Available Formats

Hydrometallurgy 93 (2008) 8187

Contents lists available at ScienceDirect

Hydrometallurgy

j o u r n a l h o m e p a g e : w w w. e l s ev i e r. c o m / l o c a t e / h yd r o m e t

Leaching of chalcopyrite with ferric ion. Part I: General aspects

E.M. Crdoba a, J.A. Muoz b, M.L. Blzquez b, F. Gonzlez b, A. Ballester b,

a b

Escuela de Ingeniera Metalrgica y Ciencia de los Materiales, Facultad de Ingenieras Fsico-Qumicas, Universidad Industrial de Santander, Bucaramanga, Colombia Departamento de Ciencia de Materiales e Ingeniera Metalrgica, Facultad de Ciencias Qumicas, Universidad Complutense de Madrid, 28040 Madrid, Spain

A R T I C L E

I N F O

A B S T R A C T

This paper presents a review of the literature on chalcopyrite leaching with ferric sulphate in acid medium. The effects of several parameters (ferric salt anion, oxidant concentration, pH and temperature) are examined and possible explanations are offered for the passivation of this sulphide during dissolution. The main theories related with chalcopyrite passivation point to the formation of a diffusion layer surrounding the chalcopyrite during dissolution, consisting of: bimetallic sulphide, copper polysulphide with a decit of iron with respect to chalcopyrite, and elemental sulphur. Recent studies suggest that ferric ion plays two important and opposite roles in this process: as a mineral oxidizing agent and as the agent responsible for chalcopyrite passivation. 2008 Elsevier B.V. All rights reserved.

Available online 2 May 2008 Keywords: Chalcopyrite Leaching Ferric iron Mechanism

1. Introduction Chalcopyrite, (CuFeS2), is the most abundant copper mineral in nature (Dutrizac, 1978) counting for about 70% of copper reserves in the world (Rivadeneira, 2006). In metallurgical applications it is mainly subjected to pyrometallurgical treatment after concentration by a otation process. Hydrometallurgy, as an alternative to pyrometallurgy, presents important advantages such as the possibility of treating lowgrade ores (increasingly more abundant in the case of copper) and easier control of waste, with the attendant benets to the environment. At present, approximately 18% of world copper production is treated by hydrometallurgy (Bravo, 2006). The process involves static leaching in heaps followed by solvent extraction and electrolytic precipitation of copper. Despite that, the only existing industrial processes for the treatment of chalcopyrite concentrates at present are pyrometallurgical. Chalcopyrite is highly refractory under hydrometallurgical conditions, due to surface transformations which render products very stable under oxidizing conditions (Burkin, 1969). Nevertheless, different hydrometallurgical processes have been investigated on both laboratory and pilot scales in attempts to implement these technologies at industrial level. Any proposal for an economically viable hydrometallurgical process for the treatment of chalcopyrite should take into account basic studies that elucidate the chemical and electrochemical aspects governing leaching. This review presents information on the fundamental aspects of chalcopyrite leaching and the problems associated with low copper recoveries from this mineral.

2. Chalcopyrite crystal structure

The chemical formula that best describes chalcopyrite is Cu+Fe3+S2 2 (De Filippo et al., 1988; Boekema et al., 2004; Mikhlin et al., 2004). The crystal structure consists in a relatively simple tetragonal lattice, close to cubic (Betejtin, 1977; Sand et al., 2001), with each sulphur ion surrounded by four metal ions of copper and iron located on tetrahedron angles and in a certain order in each plane (Fig. 1). In the rst and fth planes, corresponding to the lower and upper faces of the tetragonal prism, Fe ions are located at the square angles and Cu ions in the middle. In the third plane, at the prism centre, the order is the reverse. In the second and fourth planes, two Cu ions bond two Fe ions, but there are iron ions underneath copper cations in the second plane, and vice versa in the fourth plane.

Corresponding author. Tel.: +34 91 3944339; fax: +34 91 3944357. E-mail address: ambape@quim.ucm.es (A. Ballester). 0304-386X/$ see front matter 2008 Elsevier B.V. All rights reserved. doi:10.1016/j.hydromet.2008.04.015

Fig. 1. Chalcopyrite crystal lattice (Betejtin, 1977).

82

E.M. Crdoba et al. / Hydrometallurgy 93 (2008) 8187

Although chalcopyrite presents a crystal structure essentially characterized by covalent metalsulphide bonds, its semiconducting properties indicate that not all bonding electrons correspond to simple covalent crystals (Forward and Warren, 1960). The substitution of copper and iron by other metal atoms in the crystal lattice of natural chalcopyrites leads to the formation of n- and p-type semiconductor structures. Fig. 2 shows a simplied energy band diagram for n-type semiconductor chalcopyrite with an energy gap around 0.6 eV (Torma, 1991). While the electronic character of the lower part of the conduction band is given by Fe 3d orbitals, the upper part of the valence band is given by Cu 3d and S 3p orbitals. 3. Chemical leaching of chalcopyrite with ferric ion The leaching of copper from sulphide ore bodies occurs naturally, releasing copper and iron. In ancient times, copper was recovered by cementation with metal iron and iron in the form of ferrous sulphate by evaporation of the solution. The rst reference to the application of ferric acid sulphate solutions to the leaching of copper minerals is dated 1752, at Ro Tinto (Huelva, Spain). At that time, mineral heaps were irrigated with acid solutions and copper recovered by cementation with metal iron. Nevertheless, the development of chalcopyrite leaching processes using ferric solutions has been limited, chiey because the slow kinetics makes for an incomplete mineral attack. More recently, most research on chalcopyrite dissolution has been directed at elucidating reaction mechanisms and improving the leaching rate with ferric sulphate. 3.1. Thermodynamics and stoichiometry of the chalcopyrite dissolution The Pourbaix diagram for the CuFeS2H2O system (Fig. 3) (Garrels and Christ, 1965) shows that the dissolution of chalcopyrite in acid medium takes place through a solid transformation in different intermediate sulphides (Cu5FeS4, CuS, Cu2S), increasingly richer in copper (Biswas and Davenport, 1976). According to this diagram, a pH lower than 4 and an oxidizing redox potential higher than +0.4 V is required to dissolve copper from chalcopyrite. These conditions are achieved using oxidizing agents, the most common being ferric ion as a sulphate or chloride. Chalcopyrite dissolves in the presence of ferric ion according to the following reactions (Dutrizac and MacDonald, 1974): CuFeS2 4Fe3 Cu2 5Fe2 2SCuFeS2 4Fe3 3O2 2H2 OCu2 5Fe2 2H2 SO4 1 2

Fig. 3. Pourbaix diagram for the CuFeS2H2O system at 25 C (Garrels and Christ 1965).

after 5 h of leaching and only 6070% of Fe, probably because it hydrolysed and precipitated during the process. In that study, the recovery of elemental sulphur was as low as 5%, conrming that the reaction is stoichiometric (2). In 1933, Sullivan investigated dissolution of chalcopyrite concentrates in both ferric chloride and ferric sulphate, concluding that around 75% of chalcopyrite dissolves according to reaction (1) and the remaining by reaction (2). The lower rate of sulphate formation was attributed to the presence of dissolved oxygen more than to the action of ferric ion. Ichikuni (1960) established that ferric sulphate dissolved chalcopyrite according to reaction (1); he found only slight deviations of the Cu/Fe molar ratio in solution during the initial stage of leaching with ferric chloride and concluded that there was a preferential dissolution of Fe from the chalcopyrite lattice. Dutrizac et al. (1969) studied the dissolution process of chalcopyrite-sinterized discs in acid ferric sulphate. The stoichiometry of chalcopyrite dissolution was described by reaction (1) and the rate-controlling step was assumed to be the transport of ferric sulphate through a sulphur layer, in constant growth, surrounding the chalcopyrite surface. Then, in 1971, Haver and Wong (1971) proposed a third reaction to describe chalcopyrite dissolution with FeCl3: CuFeS2 3FeCl3 FeCl3 CuCl 4FeCl2 2S3

Several researchers have reported the stoichiometry of chalcopyrite leaching. Chronologically, Traill and McClelland (1926) were the rst to study the dissolution of chalcopyrite with concentrated ferric chloride (70 g/L) at high temperature (95 C); they obtained a copper yield of 90%

These authors found that around 70% of the sulphur was oxidized to elemental sulphur and the remainder to sulphate, and they proposed that copper was dissolved in the monovalent form (Cu+). Dutrizac (1989) established that during chalcopyrite leaching with ferric sulphate at 95 C the sulphide sulphur was practically all oxidized to S (94%). More recently, in 1995, Hackl et al. (1995) found that during leaching of chalcopyrite with ferric sulphate at high temperature and an oxygen pressure of 0.69 MPa, the oxidation of sulphide sulphur to sulphate increased from 28 to 100% when the temperature rose from 110 to 200 C. This was associated with an increase in oxygen consumption. These results indicate that although both reactions (1) and (2) can take place during the leaching of chalcopyrite, the formation of sulphate is limited by the availability of oxygen in the leaching medium. Nevertheless, recent studies have demonstrated that chalcopyrite transforms into intermediate phases and so reactions (1) and (2) must be considered as overall reactions of the chalcopyrite dissolution process. 3.2. Effect of ferric salt anion Sullivan concluded that ferric chloride is a better chalcopyrite leaching agent than ferric sulphate and that the effect was more

Fig. 2. The energy band diagram for chalcopyrite (Torma, 1991).

E.M. Crdoba et al. / Hydrometallurgy 93 (2008) 8187

83

authors estimated that the concentration of Fe3+ and FeHSO2+ 4 ionic species increased when the total iron concentration increased, up to a limiting value of 0.1 M. Above this value, the most important species 3+ was FeSO+ and FeHSO2+ 4. They concluded that the Fe 4 ionic species are responsible for chalcopyrite dissolution in sulphate medium. 3.4. Effect of pH pH also affects chalcopyrite dissolution. According to Dutrizac et al. (1969), the acid prevents hydrolysis and precipitation of ferric salts, since proton attack is negligible. Some researchers (Lu et al., 2000; Antonijevi and Bogdanovi, 2004) have reported poor results for chalcopyrite dissolution at low pH (b 1.0). The rst authors reported that the precipitation of ferric ion as jarosite is possible even at pH 0.9, which shows how readily ferric salts hydrolyse. Antonijevi and Bogdanovi found that at pH lower than 0.5, the chalcopyrite surface lacks iron and this provokes its passivation. Our results (Fig. 4) show that, in a pH range of 0.5 to 2.0, although increased pH favours hydrolysis and precipitation of the oxidant, dissolution of chalcopyrite with ferric sulphate diminishes with decreasing pH. This is understandable if we consider the speciation diagrams for Fe(III) in sulphate medium. These show that the species responsible for oxidation of the chalcopyrite is not Fe3+ proper, but probably Fe(SO4) 2, since that is the only species to show an increase of concentration in the given pH range. 3.5. Effect of temperature Table 1 shows the values of activation energy reported by different researchers during chalcopyrite leaching with ferric ion. It also indicates the kinetic control proposed in each study. The high values of activation energy found by different authors demonstrate the need for high temperatures in order to break down bonds in the chalcopyrite crystal lattice. Our results (Fig. 5) show that the effect of temperature on chalcopyrite chemical leaching is very pronounced in the range between 35 and 68 C. In that range, copper extraction increased from b 3% to N 80% after 13 days of leaching and an activation energy of 130.7 kJ/mol was determined, which is appreciably higher than that reported by other researchers (7188 kJ/mol) in the range of temperature between 50 and 94 C using a sulphate medium (Table 1). Thus, the differences observed are presumably due to the different range of temperature tested. These results agree with the theoretical analysis of Hiskey (1993) who concluded that due to n-type semiconduction of chalcopyrite, the transport of electrons through vacancies is minimum. The rst stage in chalcopyrite oxidation, consumes vacants, which favours the transport of electrons through the crystal lattice. Therefore, the heat consumed in the displacement of ions from the bulk to the surface eliminates vacancies at the surface and promotes the transport of electrons. This means chemical mechanisms control chalcopyrite dissolution; however, as noted earlier, diffusion of the oxidant is also very important in this process. We would note that there are clear differences when using one or other type of medium (sulphate or chloride). The activation energies

Fig. 4. Inuence of pH on chalcopyrite leaching at 68 C and 0.5% PD (100 mL of leaching solution and 0.5 g of mineral).

marked at high temperatures. Dutrizac et al. (1969) found that, in a temperature range between 50 and 100 C, the chalcopyrite leaching rate was linear in chloride medium and parabolic in sulphate medium. Two years later, Dutrizac and MacDonald demonstrated that the addition of chloride ion sped up chalcopyrite dissolution with ferric sulphate at temperatures higher than 50 C (Dutrizac and MacDonald, 1971). At lower temperatures there was no effect. Majima et al. (1985) established that the chalcopyrite leaching rate was approximately one order of magnitude lower with ferric sulphate than with ferric chloride. This agrees with the observation made by these authors that the elemental sulphur formed during leaching was more porous with ferric chloride than with ferric sulphate. These researches support the idea that ferric chloride has greater oxidizing power than ferric sulphate during chalcopyrite leaching. However, several factors restrict the application of ferric chloride on an industrial scale, such as: - The afnity of this ion towards many elements complicates the process of separating copper from the solution. - Chloride solutions are extremely corrosive. - Hydrochloric acid is more expensive than sulphuric acid. The last factor is of prime importance since pyrometallurgical extraction of copper from chalcopyrite, as in other industries, entails the recovery of large amounts of SO2 to achieve sulphuric acid production at very low cost. 3.3. Effect of ferric ion concentration Different researchers have pointed out that the chalcopyrite dissolution rate is strongly affected by ferric ion concentration, but only at low concentrations. At high concentrations, the effect is negligible. Sullivan (1933), Linge (1976), Dutrizac et al. (1969), Muoz et al. (1979) and Kametani and Aoki (1985), among others, found no clear kinetic effect when the ferric ion concentration exceeded 0.01 M. A few authors have observed a relationship of dependence between chalcopyrite dissolution rate and ferric ion concentration. Hirato et al. (1987) found that chalcopyrite dissolution improved when the concentration of ferric sulphate was increased from 0.001 to 0.1 M. These

Table 1 Effect of temperature on the kinetics during the chalcopyrite leaching with ferric ion Medium Ferric sulphate Temperature (C) 5094 6090 5078 3568 6090 5584 50100 Activation energy (kJ/mol) 71 84 88 130.7 60 69 47 Kinetic control Parabolic kinetics Diffusion control Parabolic kinetics Electrochemical control Parabolic-linear kinetics Chemical control Parabolic-linear kinetics Chemical control Linear kinetics Electrochemical control Linear kinetics Electrochemical control Linear kinetics Diffusion control Bibliographic reference Dutrizac et al., 1969 Muoz et al., 1979 Hirato et al., 1987 Crdoba et al., in press Hirato et al., 1986 Majima et al., 1985 Dutrizac, 1978

Ferric chloride

84

E.M. Crdoba et al. / Hydrometallurgy 93 (2008) 8187

Fig. 5. Inuence of temperature on chalcopyrite leaching. Fig. 7. Model of chalcopyrite oxidation by Fe3+ with formation of a low porous layer of elemental sulphur (after Muoz et al., 1979).

are higher in sulphate than in chloride medium, which is consistent with the lower oxidizing power of ferric sulphate (Section 3.2). 4. Passivation of chalcopyrite during leaching with ferric ion After almost a century of research into the mechanisms of chalcopyrite dissolution in ferric medium, there is consensus with respect to the formation of a passivating layer on the surface which slows down the oxidation reaction. But in spite of that, the nature of this lm is still unknown, although it has been postulated that it must have low porosity and/or be a bad electric conductor. Following is an account of the principal theories on this topic. In 1969, Burkin (1969) established that the diffusion lm surrounding the chalcopyrite during leaching with Fe3+ formed by a bimetallic sulphide with chemical and structural properties different from the original raw material, but with the same semiconducting properties. These intermediate products are the result of solid state transformations that favour solubilization of cations from the crystal lattice at different rates. Therefore, the model implies that the reaction takes place preferentially at the interface, within the thickness of a reaction front. Later, Ammou-Chokroum et al. (1977) suggested that the rate of the dissolution process is controlled by the formation and evolution of a compact diffusion layer of a low-solubility copper polysulphide, less reactive than the original chalcopyrite and with less iron. The thickness of this lm is the result of two opposite reactions (Fig. 6): 1) formation of a passive layer, Cp, because solid state diffusion is slower in copper than in iron, which obeys a parabolic law; and 2) linear dissolution of the passive layer, producing an outer lm of porous sulphur with no controlling effect. In 1979, Muoz et al. (1979) postulated that the limiting step in chalcopyrite dissolution with ferric ion is the transport of electrons, necessary to reduce the ferric ion in the solidliquid interface, through an insulating lm of elemental sulphur (Fig. 7). According to this model, the elemental sulphur affects both anodic and cathodic semireactions, limiting the overall redox reaction of chalcopyrite dissolution. This model has been ratied by Dutrizac (1989) and Majima et al. (1985). In 1995, Hackl et al. (1995) proposed a model mixture of chemical and diffusion control to explain the leaching and passivation of chalcopyrite in sulphate medium. This model complements the model of Ammou-Chokroum et al. (1977). Initially, iron dissolves preferentially to copper forming an intermediate disulphide phase, Cu1 xFe1 yS2, where y NN x and x + y 1:

CuFeS2 Cu1x Fe1y S2 xCu2 yFe2 2x ye ; yNNx; x y1 In the second stage:

4 5

Cu1x Fe1y S2 Cu1xz S2 zCu2 1yFe2 2z 1ye

which is slower than the previous stage, the disulphide dissolves to form a copper polysulphide, Cu1 x zS2 or CuSn, where n = 2/(1 x z). This polysulphide is probably responsible for chalcopyrite passivation. Thus, the rate-controlling step consists of a very slow decomposition of copper polysulphide to cupric ions and porous elemental sulphur, with no effect on chalcopyrite passivation: Cu1xz S2 1xzCu2 2S- 21xze 6

This model greatly depends on temperature, since the polysulphide dissolution rate increases with temperature. Chalcopyrite passivation does not occur at 200 C. In a recent work, Hiroyoshi et al. (2001) studied the effect of ferrous ion on chalcopyrite oxidation with ferric ions in sulphuric acid and in the absence of oxygen. They discovered that in the presence of high concentrations of cupric ion, the ferrous ion has a very positive effect on copper extraction and the kinetics were controlled by the ratio of Fe3+/ Fe2+ concentrations or by the redox potential of the solution. However, the ferrous ion adversely affected chalcopyrite oxidation at low cupric ion concentrations. To account for these results, they proposed a reaction model involving incomplete reduction of chalcopyrite, according to the following reaction: CuFeS2 3Cu2 3Fe2 2Cu2 S 4Fe3 7

This reaction is followed by oxidation of Cu2S (more sensitive to leaching than chalcopyrite) by ferric ion: Cu2 S 4Fe3 2Cu2 S- 4Fe2 8

Fig. 6. Model of chalcopyrite oxidation by Fe3+ with formation of an inner layer of polysulphide (Cp) and outer layer of porous sulphur (after Ammou-Chokroum et al., 1977).

The two reactions (7) and (8) give the overall reaction (1), which traditionally describes the leaching of chalcopyrite in ferric medium. According to this model, the rate-controlling step is the initial reduction of chalcopyrite. This only happens when the redox potential of the solution is below a critical value, which in turn is a function of the concentration of ferrous and cupric ions.

E.M. Crdoba et al. / Hydrometallurgy 93 (2008) 8187

85

Nicol and Lazaro (2003) propose a different mechanism to explain the chalcopyrite dissolution at low redox potentials. At potentials lower than 0.4 V, chalcopyrite could be reduced by proton attack: CuFeS2 4H Cu2 Fe2 2H2 S 9

The next step would be the oxidation of hydrogen sulphide by ferric ions: 2H2 S 4Fe3 2S- 4Fe2 4H 10

The overall reaction of this mechanism is again reaction (1). In this model, the rate-controlling step is electrochemical. The rate of reaction (10) decreases when the redox potential of the chalcopyrite surface increases from 0.5 to 0.7 V. Various different studies on chalcopyrite leaching with ferric ion accept the theory that there is a diffusion barrier between the leaching solution and the chalcopyrite that slows down the dissolution rate. However, the nature of this barrier is still in debate since the mechanism of chalcopyrite dissolution by Fe3+ has not yet been elucidated. Crdoba (2005) reports clear evidence that chalcopyrite passivation is related to high redox potentials or high Fe3+/Fe2+ ratios. Ferric/ ferrous sulphate leaching solutions tend quickly to reach a chemical equilibrium where activities of both ions are equal. This is associated with a critical potential of approximately 450 mV vs Ag/AgCl. Then, when the initial redox potential is very high, that tendency to equilibrium favours rapid precipitation of ferric ion as jarosite (Fig. 8) and consequently chalcopyrite passivation. The evidence cited above suggests that passivation of chalcopyrite during leaching is chiey the result of hydrolysis and precipitation of Fe3+ rather than partial transformation of the chalcopyrite surface. 5. Silver-catalyzed chalcopyrite leaching A way to improve the chalcopyrite dissolution rate is by adding Ag+. In 1976, Pawlek (1976) studied the effect of Ag+ on the leaching of chalcopyrite at 110 C and 100 kPa. After 30 min, chalcopyrite dissolution was complete in the presence of silver compared with 40% copper dissolution in the absence of silver. In 1979, Miller and Portillo (1979) proposed a model to interpret the catalytic effect of silver ions in the leaching of chalcopyrite with sulphuric acid/ferric sulphate solutions. The authors suggested that in the absence of silver ions, a dense elemental sulphur layer forms on the mineral surface, acting as a diffusion barrier and delaying the oxidative leaching of chalcopyrite with ferric ions. Conversely, in the presence

Fig. 9. Electrochemical characterization of a massive chalcopyrite electrode at 35 C: a) anodic polarization and b) cyclic voltammetry.

of silver ions the leaching of chalcopyrite takes place according to the following reactions: CuFeS2 4Ag Cu2 Fe2 2Ag2 S Ag2 S 2Fe3 2Ag 2Fe2 S11 12

The rate of copper extraction is faster in the presence of silver ions since the product layer is formed by a mixture of sulphur and Ag2S, which is porous and does not exert a barrier effect on the chalcopyrite dissolution. Price and Warren (1986) reported that the elemental sulphur obtained under silver catalytic conditions, besides being more porous, presented higher electrical conductivity and hence facilitated the transport of electrons through the chalcopyrite surface. The model proposed by Miller and Portillo has since been conrmed by Burkin (1982) and Price and Warren (1986), who detected the formation of silver sulphide on the chalcopyrite surface. At the same time, some authors (Burkin, 1982) have pointed out that silver can substitute copper in the crystal lattice of copper sulphides, given the chemical similarities between copper and silver. With an excess of Ag, the reaction product on the mineral surface could contain silver and silver sulphate. This is undesirable because of the amount of silver that may be consumed and lost before the objective is achieved i.e., to diminish the formation of elemental sulphur on the chalcopyrite surface. An excess of silver can also facilitate the sequestering of silver by jarosite (Carranza et al., 1997; Bolorunduro et al., 2003). The formation of silver jarosite may be represented by reaction:

Ag 3Fe3 2SO2 4 6H2 OAgFe3 SO4 2 OH6 6H

13

6. Electrochemical characterization and passivation of chalcopyrite Fig 9a and b shows the electrochemical behaviour of an electrode of massive chalcopyrite at 35 C. It is accepted that during anodic polarization of chalcopyrite from its rest potential, there are normally two different electrochemical responses (Biegler and Horne, 1985; Warren et al., 1985; Price and Warren, 1986; Gmez et al., 1996). The rst peak, between the rest potential and approximately +740 mV vs. Ag/AgCl, corresponds to the passive zone or prewave, and the second peak, at higher potentials, is known as the transpassive zone. In the passive zone, the chalcopyrite surface transforms into a copper-rich sulphide (CuS) and S because of the preferential dissolution of iron from chalcopyrite. The formation of covellite in this zone has been justied by reaction (14) (Jones and Peters, 1976), reaction (15) (Biegler and Swift, 1979; Biegler and Horne, 1985) or by the transformation of chalcopyrite in an intermediate phase (bornite)

Fig. 8. SEM micrograph of a leaching residue at EInitial = 600 mV.

86

E.M. Crdoba et al. / Hydrometallurgy 93 (2008) 8187

(reaction (16)) followed by oxidation to non-stoichiometric covellite (reaction (17)) (Warren et al., 1985):

CuFeS2 2H2 O1=2CuS 1=2CuSO4 Fe2 S- 4H 6e

14 15 16

conditions must be oxidizing. The presence of ferric ion always plays a central role since it is a by-product of chalcopyrite dissolution irrespective of the leaching conditions tested. The presence of ferric iron in solution affects the process in two ways: It favours leaching of the mineral when the ferric concentration is suitable. It causes passivation of the mineral surface and protects it from attack through the formation of intermediate compounds when the ferric concentration is high. At the same time, the ferrous ion plays an important role in this process by balancing the composition of the leaching solution and delaying the precipitation of ferric ion as jarosite, its nucleation on the mineral surface, and ultimately passivation of the sulphide. References

Ammou-Chokroum, M., Cambazoglu, M., Steinmez, D., 1977. Oxydation menage de la chalcopyrite en solution acide: analyses cintique de ractions. II. Modles diffusionales. Bull. Soc. Fr. Miner. Cristallogr. 100, 161177. Ammou-Chokroum, M., Sen, P.K., Fouques, F., 1981. Electrooxidation of chalcopyrite in acid chloride medium; kinetics, stoichiometry and reaction mechanism. Mineral Processing. Thirteenth International Mineral Processing Congress. In: Laskowski, J. (Ed.), Warsaw. June 49, 1979. Proceedings Part A. Elsevier Scientic Publishing Company, Amsterdam, pp. 759807. Antonijevi, M.M., Bogdanovi, G.D., 2004. Investigation of the leaching of chalcopyrite ore in acidic solutions. Hydrometallurgy 73, 245256. Betejtin, A., 1977. Curso de Mineraloga, 3th Edition. Mir, Mosc, pp. 196446. Biegler, T., Horne, M.D., 1985. The electrochemistry of surface oxidation of chalcopyrite. J. Electrochem. Soc. 132, 13631369. Biegler, T., Swift, D.A.,1979. Anodic electrochemistry of chalcopyrite. J. Appl. Electrochem. 9, 545554. Biswas, A.K., Davenport, W.G.,1976. Extractive Metallurgy of Copper. Pergamon Press, Oxford. Boekema, C., Krupski, A.M., Varaste, M., Parvin, K., Van Til, F., Van Der Woude, F., Sawatzky, G.A., 2004. Cu and Fe valence states in CuFeS2. J. Magn. Magn. Mater. 272276, 559561. Bolorunduro, S.A., Dreisinger, D.B., Van Weert, G., 2003. Fundamental study of silver deportment during the pressure oxidation of sulphide ores and concentrates. Miner. Eng. 16, 695708. Bravo, P. 2006. El panorama de la hidrometalurgia. Revista Minera Chilena, 303. Editec S.A. Publication via on-line (http://www.mch.cl). Santiago, Chile. Burkin, A.R., 1969. Solid-state transformations during leaching. Min. Sci. Engng. 1, 414. Burkin, A.R.,1982. Composition and phase changes during oxidative acid leaching reactions. In: Bautista, R.G. (Ed.), Hydrometallurgical Process Fundamentals. Plenum Press, NY, pp. 113123. Carranza, F., Palencia, I., Romero, R., 1997. Silver catalyzed IBES process: application to a Spanish copperzinc sulphide concentrate. Hydrometallurgy 44, 2942. Crdoba, E.M. 2005. Nuevas evidencias sobre los mecanismos de lixiviacin qumica y biolgica de la calcopirita PhD Thesis. Universidad Complutense de Madrid, 344 pages. Crdoba, E.M., Muoz, J.A., Blzquez, M.L., Gonzlez, F., Ballester, A., in press. Leaching of chalcopyrite with ferric ion. Part II: effect of redox potential. Hydrometallurgy. doi:10.1016/j.hydromet.2008.04.016 De Filippo, D., Rossi, A., Rossi, G., Trois, P., 1988. Surface modications in copper sulphide minerals after bioleaching. In: Norris, P.R., Kelly, D.P. (Eds.), Biohydrometallurgy'87. Proceedings of the International Symposium. Warwick, Inglaterra, pp. 245258. Dutrizac, J.E., 1978. The kinetics of dissolution of chalcopyrite in ferric ion media. Metall. Trans. B 9B, 431439. Dutrizac, J.E., 1989. Elemental sulphur formation during the ferric sulphate leaching of chalcopyrite. Can. Metall. Q. 28, 337344. Dutrizac, J.E., MacDonald, R.J.C., 1971. The effect of sodium chloride on the dissolution of chalcopyrite under simulated dump leaching conditions. Metall. Trans. 2, 23102312. Dutrizac, J.E., MacDonald, R.J.C., 1974. Ferric ion as a leaching medium. Minerals Sci. Engng. 6, 59100. Dutrizac, J.E., MacDonald, R.J.C., Ingraham, T.R., 1969. The kinetics of dissolution of synthetic chalcopyrite in aqueous acidic ferric sulfate solutions. Trans. Metall. Soc. AIME 245, 955959. Forward, F.A., Warren, I.H., 1960. Extraction of metals from sulphide ores by wet methods. Metall. Rev. 5, 137164. Garrels, R.M., Christ, C.L., 1965. Solution, Minerals, and Equilibria. Harper & Row, New York, pp. 213233. Gmez, C., Figueroa, M., Muoz, J.A., Blzquez, M.L., Ballester, A., 1996. Electrochemistry of chalcopyrite. Hydrometallurgy 43, 331344. Hackl, R.P., Dreisinger, D.B., Peters, E., King, J.A., 1995. Passivation of chalcopyrite during oxidative leaching in sulfate media. Hydrometallurgy 39, 2548. Haver, F.P., Wong, M.M., 1971. Recovery of copper, iron and sulphur from chalcopyrite concentrate using a ferric chloride leach. J. Metals 23, 2529. Hirato, T., Kinoshita, M., Awakura, Y., Majima, H., 1986. The leaching of chalcopyrite with ferric chloride. Metall. Trans. B 17B, 1928. Hirato, T., Majima, H., Awakura, Y., 1987. The leaching of chalcopyrite with ferric sulfate. Metall. Trans. B 18B, 489496.

CuFeS2 0:75CuS 0:25Cu2 Fe2 1:25S- 2:5e

CuFeS2 Cu1x Fe1y S2z xCu2 yFe2 zS- 2x ye

Cu1x Fe1y S2z 2zCuSnonstoichiom: 1yCu2 1yFe2 21ye ; where yNx

17

Whether or not the reactions by which CuS is formed are stoichiometric, the different authors agree that this copper sulphide is responsible for chalcopyrite passivation during oxidative dissolution. In the transpassive zone, the passive layer breaks down and massive chalcopyrite dissolution takes place through reactions (18) and (19) (Ammou-Chokroum et al., 1981; Yin et al., 1995, Gmez et al., 1996) or through reaction (20): CuFeS2 Cu2 Fe3 2S- 5e

CuFeS2 8H2 OCu2 Fe3 2SO2 4 16H 17e

18 19 20

CuFeS2 2H2 OCu2 Fe2 3=2S- 1=2H2 SO4 3H 7e

In the anodic polarization curve (Fig. 9a), starting from the rest potential (+230 mV), the two mentioned zones are clearly appreciable. The passivation zone, with two electrochemical responses, A1 and A2, indicates that chalcopyrite dissolves in this low-potential zone through reactions (16) and (17). In the cathodic branch (Fig. 9b), when the scan direction shifts at + 800 mV, current density drops sharply to zero and practically remains there over a wide range of potentials. Finally, from 150 to 500 mV, there is a large cathodic response (peak C). It is in this zone that the reduction of chalcopyrite and covellite takes place, through the following reactions: 2CuFeS2 6H 2e Cu2 S 2Fe2 3H2 S 2CuS 2H 2e Cu2 S H2 S 21 22

When the scan direction shifts to anodic values, the current density again increases, showing two new anodic electrochemical responses at approximately +310 mV (D) and +570 mV (E). According to Biegler and Horne (1985), peak D reects the oxidation of reduction products formed during the cathodic scan, Cu2S or non-stoichiometric sulphides such as Cu8S5, Cu7S4, etc., as follows: Cu2 SCuS Cu2 2e 23

Finally, the anodic peak E may be associated with the prewave reaction (passive zone at low potential, peak A) of chalcopyrite oxidation to CuS and S (reactions (14) to (17)). This peak could further be related to the oxidation reaction of ferrous ion: Fe2 Fe3 e 24

and later precipitation of the ferric ion as proposed by Tshilombo and Dixon (2003). These authors observed the formation of ferric hydroxides during the electrochemical oxidation of chalcopyrite at high potential and temperature and concluded that they are formed by chemical precipitation of ferric ion generated by oxidation of ferrous ion. 7. Conclusions While the refractoriness of chalcopyrite to chemical attack is very much a matter of debate, it is unanimously agreed that the leaching

E.M. Crdoba et al. / Hydrometallurgy 93 (2008) 8187 Hiroyoshi, N., Miki, H., Hirajima, T., Tsunekawa, M., 2001. Enhancement of chalcopyrite leaching by ferrous ions in acidic ferric sulfate solutions. Hydrometallurgy 60,185197. Hiskey, J.B., 1993. Chalcopyrite semiconductor electrochemistry and dissolution. In: Reddy, R.G., Weizenbach, R.N. (Eds.), The Paul E. Queneau International Symposium, Extractive Metallurgy of Copper, Nickel and Cobalt. Volume I: Fundamental Aspects. The Minerals, Metals & Materials Society, pp. 949969. Ichikuni, M., 1960. The dissolution of sulphide minerals in various media. III. Factors intervening in the dissolution of chalcopyrite. Bull. Chem. Soc. Japan 33, 11591162. Jones, D.L., Peters, E., 1976. Electrochemical experiments with chalcopyrite electrodes in aqueous solutions up to 200 C. NACE 4, 443458. Kametani, H., Aoki, A., 1985. Effect of suspension potential on the oxidation rate of copper concentrate in a sulfuric acid solution. Metall. Trans. B 16B, 695705. Linge, H.G., 1976. A study of chalcopyrite dissolution in acid ferric nitrate by potentiometric titration. Hydrometallurgy 2, 5164. Lu, Z.Y., Jeffrey, M.I., Lawson, F., 2000. An electrochemical study of the effect of chloride ions on the dissolution of chalcopyrite in acidic solutions. Hydrometallurgy 56, 145155. Majima, H., Awakura, Y., Hirato, T., Tanaka, T., 1985. The leaching of chalcopyrite in ferric chloride and ferric sulfate solutions. Can. Metall. Q. 24, 283291. Mikhlin, Y.L., Tomashevich, Y.V., Asanov, I.P., Okotrub, A.V., Varnek, V.A., Vyalikh, D.V., 2004. Spectroscopy and electrochemical characterization of the surface layers of chalcopyrite (CuFeS2) reacted in acidic solutions. Applied Surface Science 225, 395409. Miller, J.D., Portillo, H.Q., 1979. Silver catalysis in ferric sulphate leaching of chalcopyrite. In: Lawskosky, A.J. (Ed.), 13th International Mineral Processing Congress. Part A. Elsevier, Amsterdam, pp. 851901. Muoz, P.B., Miller, J.D., Wadsworth, M.E., 1979. Reaction mechanism for the acid ferric sulfate leaching of chalcopyrite. Metall. Trans. B 10B, 149158. Nicol, M.J., Lazaro, I., 2003. The role of non-oxidative processes in the leaching of chalcopyrite. In: Riveros, P.A., Dixon, D., Dreisinger, D.B., Menacho, J. (Eds.), Hydrometallurgy of Copper, Proceedings of Copper 2003, vol. 6. Santiago, Chile, pp. 367381.

87

Pawlek, F.E., 1976. The inuence of grain size and mineralogical composition on the leachability of copper concentrates. Extractive metallurgy of copper, vol. 2. AIME, New York, pp. 690705. Price, D.W., Warren, G.W., 1986. The inuence of silver ion on the electrochemical response of chalcopyrite and other mineral sulde electrodes in sulfuric acid. Hydrometallurgy 15, 303324. Rivadeneira, J., 2006. Introduction. Mining innovation in Latin America Report. Publication via on-line (http://www.mininginnovation.cl/content.htm). Santiago, Chile, pp. 67. Sand, W., Gehrke, T., Jozsa, P., Schippeers, A., 2001. (Bio)chemistry of bacterial leaching direct vs. indirect bioleaching. Hydrometallurgy 59, 159175. Sullivan, J.D., 1933. Chemical and physical features of copper leaching. Trans. Am. Inst. Min. Metall. 106, 515546. Torma, A.E., 1991. Electrochemistry of a semiconductor chalcopyrite concentrate leaching by Thiobacillus ferrooxidans. In: Cooper, W.C., Kemp, D.O., Lagos, G.E., Tan, K.G. (Eds.), Hydrometallurgy and Electrometallurgy of Copper. Pergamon Press, NewYork, pp. 7385. Traill, R.J., McClelland, W.R., 1926. Investigations in Ore Dressing and Metallurgy, vol. 688. Department of Mines, Mines Branch, Rep., Ottawa, pp. 101109. Tshilombo, A.F., Dixon, D.G., 2003. Mechanism and kinetics of chalcopyrite passivation during bacterial leaching. In: Riveros, P.A., Dixon, D., Dreisinger, D.B., Menacho, J. (Eds.), Hydrometallurgy of Copper, Proceedings of Copper 2003, vol. 6. Santiago, Chile, pp. 99116. Warren, G.W., Sohn, H.J., Wadsworth, M.E., Wang, T.G., 1985. The effect of electrolyte composition on the cathodic reduction of CuFeS2. Hydrometallurgy 14, 133149. Yin, Q., Kelsall, G.H., Vaughan, D.J., England, K.E.R., 1995. Atmospheric and electrochemical oxidation of the surface of chalcopyrite (CuFeS2). Geochim. Cosmochim. Acta 59, 10911100.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- RM-11 Metronic Primary Watthour StandardDocument2 pagesRM-11 Metronic Primary Watthour StandardMiko QuijanoNo ratings yet

- Gemplus 3Document6 pagesGemplus 3MickaelNo ratings yet

- Keypad Encoder Approval ReportDocument2 pagesKeypad Encoder Approval ReportMuzammil MetkarNo ratings yet

- TraxxasDocument37 pagesTraxxasRogerio SilvaNo ratings yet

- On PN Junction DiodeDocument12 pagesOn PN Junction DiodeAditya Singh Maurya100% (1)

- 325 Lab 4 ReportDocument8 pages325 Lab 4 Reportapi-241454978No ratings yet

- Digital TutotrialsDocument29 pagesDigital Tutotrialsrktiwary256034No ratings yet

- Laboratory Experiment 1Document14 pagesLaboratory Experiment 1John Bien VelascoNo ratings yet

- Methods For Electronic System Design and Verification Lab Report DAT110Document3 pagesMethods For Electronic System Design and Verification Lab Report DAT110HakimNo ratings yet

- 5 Generation 1 2-1Document12 pages5 Generation 1 2-1Khushi BhayanNo ratings yet

- A Presentation ON: Nano TechnologyDocument23 pagesA Presentation ON: Nano TechnologyBrandon JohnsonNo ratings yet

- ch3 - MichalskiDocument48 pagesch3 - MichalskirquinesNo ratings yet

- My Project ProposalDocument5 pagesMy Project ProposalziaulhaqNo ratings yet

- Magnetic PropertiesDocument21 pagesMagnetic PropertiesHosamHasanNo ratings yet

- Lesson 1452, Optoelectronics: Experiment 6, Photodiode and Phototransistor Current MeasurementsDocument30 pagesLesson 1452, Optoelectronics: Experiment 6, Photodiode and Phototransistor Current MeasurementsMagaNo ratings yet

- Computer MemoryDocument12 pagesComputer MemoryErmin Sehic100% (1)

- Nano TechnologyDocument11 pagesNano TechnologyMay GustiloNo ratings yet

- Daewoo SJ-210H DSJ-6000LHMDocument44 pagesDaewoo SJ-210H DSJ-6000LHMMarco Antonio100% (5)

- Double Patterning LithographyDocument1 pageDouble Patterning Lithographyrashmi sNo ratings yet

- ELEC Checklist 2020 v2Document6 pagesELEC Checklist 2020 v2Refaat Raslan ShaabanNo ratings yet

- Breadboard BasicsDocument11 pagesBreadboard BasicsAbril de Vera0% (1)

- Homemade 3kW Induction Heater - First Prototype Test - YouTubeDocument9 pagesHomemade 3kW Induction Heater - First Prototype Test - YouTubeJoel Antonio Lopez LopezNo ratings yet

- Color Sensor Working Principle and Arduino CodeDocument5 pagesColor Sensor Working Principle and Arduino CodeDhanish VijayanNo ratings yet

- Lab 3Document4 pagesLab 3Pradeep KumarNo ratings yet

- How Integrated Circuit Is Made - Material, Making, Used, Processing, Components, Dimensions, Composition, IndustryDocument6 pagesHow Integrated Circuit Is Made - Material, Making, Used, Processing, Components, Dimensions, Composition, IndustryAbhiNo ratings yet

- Power Electronics (MTE222) : Lecture Week1&2Document29 pagesPower Electronics (MTE222) : Lecture Week1&2Omar Adel MohammedNo ratings yet

- Latha Mathavan Engineering College Latha Madhavan Nagar, Kidaripatti Madurai - 625301Document160 pagesLatha Mathavan Engineering College Latha Madhavan Nagar, Kidaripatti Madurai - 625301priya dharshiniNo ratings yet

- Resistivity of MaterialDocument8 pagesResistivity of MaterialSampath KumarNo ratings yet

- High Voltage Power Supply - Yuliyan Dwi PrabowoDocument2 pagesHigh Voltage Power Supply - Yuliyan Dwi PrabowoyuliandpxxxNo ratings yet

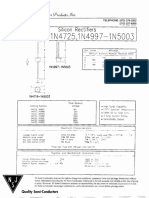

- 1N4719-1N4725.1N4997-1N5005: Silicon RectifiersDocument1 page1N4719-1N4725.1N4997-1N5005: Silicon RectifiersbozajaNo ratings yet