Professional Documents

Culture Documents

2

Uploaded by

austenita14Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2

Uploaded by

austenita14Copyright:

Available Formats

Synthesis of dense mullite/MoSi

2

composite for high

temperature applications

Z.I. Zaki

a,b,

, Nasser Y. Mostafa

a,c

, Y.M.Z. Ahmed

b

a

Chemistry Department, Faculty of Science, Taif University, P.O. Box: 888, Al-Haweiah, Taif-Saudi Arabia

b

Advanced Materials Division, Central Metallurgical R&D Institute (CMRDI), P.O. Box: 87, Helwan, Cairo, Egypt

c

Chemistry Department, Faculty of Science, Suez Canal University, Ismailia 41522, Egypt

a b s t r a c t a r t i c l e i n f o

Article history:

Received 12 December 2013

Accepted 6 March 2014

Available online 18 March 2014

Keywords:

Synthesis

Mullite

MoSi

2

Oxidation

Electrical characters

This work is aimed at producing a dense mullite/MoSi

2

composite froma reactive blend of MoO

3

, SiO

2

and Al by

under load-combustion synthesis. Thermodynamic analyses proved the development of the entire combustion

product in molten state with an adiabatic temperature of 2340 K. Diluting the reaction mixture with 25 vol.%

of the combustion product was necessary to produce homogeneity between the obtained phases. The sample

porosity was reduced to ~3.0 vol.% by controlling the pressing load, Al particle size and the delay time. The coef-

cient of thermal expansion of the obtained product was 5.968.93 10

6

K

1

. The obtained dense composite

exhibited good oxidation resistance at 1300 C and a low electrical resistivity (1.80 cm).

2014 Elsevier Ltd. All rights reserved.

Introduction

Due to its unique properties (thermal, electrical and chemical) in

addition to its moderate density, MoSi

2

has received the attention of

many research groups. Despite its weak mechanical properties and

pest oxidation problems, MoSi

2

composites are becoming important

elevated temperature structural materials for application in oxidizing

and aggressive environments specially as heating elements in high

temperature furnaces [1]. On the other hand, mullite (3Al

2

O

3

2SiO

2

),

a typical solid solution oxide, combines high melting point, lowthermal

expansion, low electrical conductivity, good mechanical strength and

resilience at elevated temperatures. Therefore, it is considered as a

potential candidate material for structural applications such as kiln

furniture, protection tubes, and heat insulation parts [2].

MoSi

2

is thermodynamically stable with mullite and a variety of

other ceramic reinforcements, including TiC, ZrO

2

, Al

2

O

3

, TiB

2

, SiC and

Si

3

N

4

[311]. MoSi

2

has also been employed as a conducting phase in

Si

3

N

4

MoSi

2

particulate composites [10]. Alumina composites with

20 vol.% and higher MoSi

2

are electroconductive due to the formation

of a three-dimensional percolating network of the conductive MoSi

2

phase [7,12]. Other composites of MoSi

2

with Mo

5

Si

3

[13], WSi

2

[14],

and ZrB

2

[15,16] were also reported. A composite between MoSi

2

and

mullite is rarely mentioned in the literature. In a trial to improve the

mechanical properties of MoSi

2

by the powder metallurgy route, some

authors used mullite and mullite whisker as reinforcement [17]. Mullite

containing 20 vol.% MoSi

2

was synthesized by hot pressing a mixture of

mullite and MoSi

2

powders at 1650 C with 69 MPa for 2 h. The product

was found to have a K

lc

and strength values up to two times that of

monolithic mullite [18].

Various starting materials and preparation methods have been used

to prepare synthetic mullite and MoSi

2

ceramics. These include reaction

sintering of mechanically mixed powders [1924], hydrothermal treat-

ment of mixtures of sols [2527], and chemical vapor deposition

[2831] for synthesis of mullite. On the other hand, mechanical alloying

[4,32], hot pressing [16], reactive sintering [33], plasma-spray processing

[34] and self-propagating high-temperature synthesis (SHS) are used for

synthesis of MoSi

2

[13,35,36].

Self-propagating high-temperature synthesis (SHS) is one of the

rapidly emerging cost-effective technologies used to synthesize

monolithic and composite in situ ceramics [35,37]. The principle of

this technique is that the initial reagents, when ignited, spontaneously

transform into products due to the exothermic heat of the reaction.

The major problem to overcome in the SHS processing of refractory

ceramics is the high-retained porosity of the synthesized products.

However, applying sudden mechanical pressure during the reaction

has resulted inhighly dense materials [38,39]. The densicationbehavior

inthat case is only due to the compactionand is favored by the formation

of liquid phases during the reaction [39]. The very short processing time

of typical SHS reactions limits the diffusion phenomena responsible for

the material shrinkage in other processes [40]. Therefore SHS under the

load process represents a one-step manufacturing route capable of

Int. Journal of Refractory Metals and Hard Materials 45 (2014) 2330

Corresponding author.

http://dx.doi.org/10.1016/j.ijrmhm.2014.03.006

0263-4368/ 2014 Elsevier Ltd. All rights reserved.

Contents lists available at ScienceDirect

Int. Journal of Refractory Metals and Hard Materials

j our nal homepage: www. el sevi er . com/ l ocat e/ I JRMHM

producing highly dense composites with a homogeneous distribution of

the different phases. Another serious drawback of SHS is it's limitation to

a highly exothermic reaction. Recently, successful management of the

heat evolved from the common SHS reactions have enabled carrying

out side endothermic reactions [36,41,42].

In a previous work, we have successfully prepared a MoSi

2

/mullite

composite in a self sustaining manner without applying external

mechanical pressing. The product unfortunately was highly porous,

cracked and was non-homogeneous [42]. The aim of the current work

is to in-situ develop a high density and homogeneous composite of

MoSi

2

and mullite starting from relatively low cost raw materials

(MoO

3

, SiO

2

and Al) by applying sudden external mechanical pressing.

Designing a composite of MoSi

2

and mullite will result in the fabrication

of a new low cost ceramic conductor that can be easily shaped using an

electric discharge machine and can be used as a heating element. Both

MoSi

2

andmullite resist oxidationat hightemperature andare thermody-

namically stable with each other. The mullite phase will be the matrix

while the MoSi

2

phase will be responsible for conducting the electricity

through that matrix. SHS under load methodology is chosen to perform

simultaneous synthesis and densication of MoSi

2

and mullite where

the technical parameters controlling the process are studied. These

parameters include: diluent vol.%, pressing load, Al particle size and

delaying time. To the best of our knowledge this composite did not syn-

thesize before as a dense object by SHS methods especially from these

starting materials.

Experimental

The materials used in this study were molybdenumtrioxide of 99.5%

purity and 15 m average particle size (Atlantic Equipment Engineers,

NJ, USA), aluminummetal powder of 99.5% purity and different average

particle sizes of 52.3, 37, 18.5 and 5.6 m(GFS Chemicals, Inc., USA) and

silica of 11 m average particle size with 99% purity (Riedel-de Haen,

Germany). Particle size distributionof the rawmaterials was investigated

using Microtrac Bluewave particle size analyzer operated with FLEX soft-

ware (Microtrac S3500). The wet samples were inserted as a suspension

with double distilled water. Ultrasonic waves were used for making the

suspension more homogenous. The powders were mixed in the required

molar ratio to form MoSi

2

-7/9 mullite composite and dry blended in a

slow rotating mill with alumina ball for 5 h. The powder mixture was

uniaxially pressed without a binder at 78 MPa into a cylindrical compact

of 15 mm height and 20 mm diameter with an approximately 55% rela-

tive density. The compact was transferred into a combustion reactor

andplacedintoa steel die lledwithsandwhere the mechanical pressure

was applied on the movable punch. The pressure was transferred to the

green compact through a sand medium. Ignition of samples is carried

out in thermal explosive mode using a resistance coil placed around the

compact. All the work was conducted under vacuum. A detailed proce-

dure of carrying out combustion reactions was provided elsewhere [39].

The electricity was supplied from an AC power source (3040 A). Linear

thermal expansion (LTE) and the coefcient (CTE) of its dense product

were measured using dilatometery (Linseis Inc., Germany, Model L76/

1550) in the temperature range of 200 up to 1250 C with a heating

rate of 10 C/min. The electrical resistivity investigation was carried

out in air under one atmospheric pressure from a room temperature

of up to 900 C with a heating rate of 2 C/min. The data (temperature

vs resistivity) were recorded every 2 min. Oxidation resistance of the

combustion product was investigated in open atmosphere at 1300 C

for 3 hinorder to determine the thermodynamic stability (compatibility)

between the obtained phases of MoSi

2

and mullite. Weight changes

during oxidation were measured by means of an automatic weight re-

cording balance.

Different phases of the combustion products were identied by

X-ray diffraction analysis using an X-ray diffractometer (D8 Advanced

Bruker AXS, GMbH, Karlsruhe, Germany). The microstructure of speci-

mens was investigated using a scanning electron microscope (SEM,

Model JSM-5410, JEOL, Tokyo, Japan) equipped with electron dispersive

spectroscopy (EDX). SEM investigation is conducted on polished

surfaces coated with gold to ensure good electrical conductivity of the

entire components of the sample. Sample porosity was measured via

Archimedes' method (submersion in water).

Results and discussions

Adiabatic temperatures and molten factions

The combustion process of this work is based on the following reac-

tions:

MoO

3

2SiO

2

14=3Al MoSi

2

7=3Al

2

O

3

H 1470kJ 1

7=3Al

2

O

3

14=9SiO

2

7=9 3Al

2

O

3

2SiO

2

H 52:6kJ 2

MoO

3

2SiO

2

14=3Al 14=9SiO

2

MoSi

2

7=9 3Al

2

O

3

2SiO

2

H 1417:4kJ :

3

It could be easily noticed that reaction (1) is highly exothermic while

reaction (2) is endothermic in its nature. However, according to the

endothermic nature of the reaction (2) it could not proceed alone in a

self-sustaining manner. Meanwhile, the addition of SiO

2

to the reactant

of reaction (1) in a stoichiometric amount (14/9 mol) equivalent to the

quantity of liberatedalumina (7/3 mol) generates the overall reaction(3).

This reaction (3) was found to be highly exothermic in which the heat re-

leased by the progress in reaction (1) will support reaction (2). On the

other handreaction(3) seems to be a complicatedone whichcanbe com-

posed of many reactions. The possible reactions that can compete to yield

reaction (3) and their thermodynamic properties are organized in a con-

secutive manner according to its expected order and given in Table 1.

Regarding reaction (3), the adiabatic combustion temperature and

the fractions of molten phases of the products can be calculated from

the following equation:

H

r;298

Z

To

298

C

p

MoO

3

2SiO

2

14=3Al 14=9SiO

2

dT

Z

2303

298

C

p

MoSi

2

s

dT 7=9

Z

2123

298

C

p

3Al

2

O

3

2SiO

2

s

dT

H

f;MoSi2

7=9H

f;3Al2O32SiO2

4

where, H

(r,298)

is the enthalpy change of reaction (3), C

p

is the specic

heat capacity, H

(f,MoSi2)

and H

(f,3Al2O32SiO2)

are the enthalpies of

fusion [42], and and are the molten fractions of MoSi

2

and mullite

respectively.

Fig. 1 shows the adiabatic temperatures and the molten fractions of

mullite and MoSi

2

phases calculated from Eq. (4) as a function of initial

temperatures. It is found that the adiabatic temperature at 298 K is

equal to 2340 K. This temperature exceeds the melting points of mullite

(2123 K) and MoSi

2

(2303 K). This means that both phases will be

produced in the molten states. This could be a good point in order

to produce a highly dense mullite/MoSi

2

structure via compaction

during the reaction progress.

Table 1

Expected sequence of the reactions involved in the combustion process.

Reaction H, kJ G, kJ

1 MoO

3

+ 2Al = Mo + Al

2

O

3

927.5 911

2 3SiO

2

+ 4Al = 3Si + 2Al

2

O

3

614.1 589

3 Mo + 2Si = MoSi

2

131.3 115

4 3Al

2

O

3

+ 2SiO

2

= (3Al

2

O

3

2SiO

2

) 67.6 56.0

24 Z.I. Zaki et al. / Int. Journal of Refractory Metals and Hard Materials 45 (2014) 2330

Synthesis of mullite/MoSi

2

composite

The work is started using a sample having aluminum with an

average particle size of 37 m and ignited by a thermal explosion

mode. A compaction pressure of 82 MPa is suddenly applied during

the reaction. The combustion product was characterized by phase

identication using XRD analysis, shown in Fig. 2. The pattern

revealed that MoSi

2

and mullite appear as the main phases while alu-

mina appears as a minor one. On the other hand no peaks character-

istic for the starting materials are detected. This indicates that the

reaction between the starting precursors have been going to comple-

tion according to reaction (3) using thermal explosion mode under

applied pressure. However the microstructure homogeneity of such

a composite is regarded as one of the highly important parameters

that have a direct impact on its physicmechanical properties. Ac-

cordingly the microstructure of the produced composite has been in-

vestigated via SEM analysis. Fig. 3a presents the SEM micrograph of

the produced composite. It could be noticed that there is almost a com-

plete separation between the different phases such that one big MoSi

2

ball is developed at the center of the specimen and other small ones

are found embedded into the mullite matrix. This could be attributed

to the fact that the combustion temperature of reaction (3) is very

high (T

ad

= 2340 K) as shown in Fig. 1. This temperature exceeds the

melting points of MoSi

2

(2303 K) and that of mullite (2123 K) causing

a high agglomeration of the melting MoSi

2

phase especially during

compaction. This inhomogeneous microstructure is responsible for de-

teriorating all the physicalmechanical properties of the produced

composite.

Fig. 1. Adiabatic combustion temperatures and molten fractions of MoSi

2

& mullite as a function of initial temperature and dilutions.

Fig. 2. XRD of combustion product prepared by using samples having 37 m Al particle size pressed during the reaction at 82 MPa.

25 Z.I. Zaki et al. / Int. Journal of Refractory Metals and Hard Materials 45 (2014) 2330

According to the previous investigation, the vigor of the reaction (3)

should be inhibited to some extent for preventing the agglomeration of

the molten MoSi

2

during compaction. One solution is the addition of

diluents which could compensate some of the heat evolved from re-

action (3) and decreasing the probabilities for agglomeration of the

molten MoSi

2

phase. In this regard and in order to keep the sample

Fig. 3. SEMimages of combustion products containing: a) no diluents b) 20 vol.% dilution c) 25 vol.% dilution and BES images of d) 30 vol.% dilution pressed during the reaction at 82 MPa.

Fig. 4. Effect of dilution amount, pressing load and Al average particle size on the combustion product porosity.

26 Z.I. Zaki et al. / Int. Journal of Refractory Metals and Hard Materials 45 (2014) 2330

composition without changes the combustion product of reaction (3) is

crushed, pulverized to pass a 20 m sieve and used as a diluent. In this

case the combustion reactions will be proceeding as follows:

MoO

3

2SiO

2

14=3Al 14=9SiO

2

x MoSi

2

7=9 3Al

2

O

3

2SiO

2

1 x MoSi

2

7=9 3Al

2

O

3

2SiO

2

H 1417:4 kJ

5

where x, is the weight percentage of the diluents.

Regarding reaction (5), the adiabatic combustion temperature and

the fractions of molten phases of the products can be calculated from

the following equation:

H

r;298

Z

To

298

Cp

MoO

3

2SiO

2

14=3Al 14=9SiO

2

x

MoSi

2

7=9 3Al

2

O

3

2SiO

2

dT 1 x

Z

2303

298

Cp MoSi

2

s

dT

Z

Tad

2303

Cp MoSi

2

1

dT 7=9 1 x

Z

2123

298

Cp 3Al

2

O

3

2SiO

2

s

dT

Z

Tad

2123

Cp 3Al

2

O

3

2SiO

2

1

dT

1 x H

f;MoSi2

7=9 1 x H

f;3Al2O32SiO2

6

where, x is the number of moles of the product which is added to the

reaction media as a diluent.

For comparison, the adiabatic temperatures and the molten frac-

tions of mullite and MoSi

2

phases as a function of initial temperatures

and dilution volume percentage are assembled in Fig. 1. It is clear that

increasing the amount of diluents in the reaction medium at any value

of the initial temperature leads to a parallel decrease in adiabatic tem-

perature. This could be highly useful in controlling the microstructure

of the produced product. The XRD of all samples produced with different

dilution amounts varied from 10 to 30 wt.% (not shown) and revealed

that the target composite of mullite/MoSi

2

is the main phase without de-

tection of any peaks for the reactant precursors. The addition of dilution

did not affect the phase composition of the produced sample according

to the fact that it is one of the products during the reaction between the

starting precursors. The microstructure of the sample produced with dif-

ferent dilution percentages (20, 25, and 30 wt.%) are investigated and

compared with that of the sample without dilution, Fig. 3. It reveals a reg-

ular decrease in the particle size of MoSi

2

(from several mm to few m)

with a signicant improvement in the homogeneity among sample

phases with an increasing diluent volume percentage. At 20 vol.% dilu-

ents (Fig. 3b), although a large agglomerate of MoSi

2

phase is still present

in the combustion product, its amount as well as particle size are largely

reduced compared with one without a dilution (Fig. 3a). However, a

complete disappearance of agglomerated phase is achieved at 25 vol.%

diluents (Fig. 3c). This could be attributed to the continuous decrease in

the combustion temperatures and the molten fractions of mullite and

MoSi

2

phases by increasing the amount of diluents. With a further in-

crease in the dilution addition to 30 vol.% (Fig. 3d), although a homoge-

neous microstructure is also produced, a higher degree of porosity

could be clearly noticeable. The behavior of increasing sample porosity

with dilution addition was clearly observed in all samples. The porosities

of these samples were measured and given in Fig. 4. These measured

porosities conrmed the observation from SEM images that the porosity

of the sample increased with an increase in the amount of diluents.

Although the sample having a 25 vol.% diluent has a higher porosity

than the 0, 10 and 20 vol.% diluents' samples, it has the highest degree

of homogeneity among its phases. Accordingly, a trial was made for

enhancing the densication parameter of such sample via varying the

pressing load during the reaction.

The effect of different pressing loads (82292 MPa) on the sample

open porosity is investigated using the sample having a 25 vol.% dilution

and the results are shown in Fig. 4. It is found that the pressing load has a

strong effect on the sample porosity such that a sharp decrease in

the sample porosity is achieved. The sample porosity is reduced to

~3.65 vol.% upon applying a mechanical pressure of 117 MPa and

falls to 2.09 vol.% at 234 MPa. While with further increase in the

pressing load (at 292 MPa) there is not much of an enhancement in

sample porosities noticed. On the other hand SEM investigation of the

microstructure of the sample pressed at 234 shows homogeneous

distribution of the different phases such that no collection of phases is

formed due to pressing (Fig. 5a). This is a conrmation that increasing

the pressing load enhances the densication parameter of such com-

posite without any changes in both phase formation as well as the

microstructure homogeneity.

However, it is well known that the Al particle size usually plays a very

important role during the combustion synthesis process. Accordingly,

the effect of reducing Al particle size (52.3, 37, 18.5 and 5.6 m) on

the porosity and microstructure of the product is investigated under

Fig. 5. BES images of combustion product containing 25 vol.% diluent pressed at 234 MPa,

a) using 37 mparticle size Al, b) 5.6 mparticle size Al, and c) 37 mparticle size Al after

20 s of reaction.

27 Z.I. Zaki et al. / Int. Journal of Refractory Metals and Hard Materials 45 (2014) 2330

the mechanical pressing of 234 MPa with the sample containing

25 vol.% diluent. This trial was made in order to reduce the sample

porosity of the produced sample as much as possible. Fig. 4 illustrates

the effect of Al particle size on the porosity of the samples. This gure

shows that reducing the Al particle size to 5.6 m leads to an increase in

the porosity of the sample. This is because ner Al particle size usually

leads to vigorous reactions. On the other hand, increasing Al particle

size from 37 to 52.3 m does not affect the porosity of the sample. Al-

though the sample produced using Al 5.6 m still has a low porosity

(~4.6 vol.%), it suffers from non-homogeneity between phases such that

agglomerations of MoSi

2

are noticed as it can be seen from the SEM

image (Fig. 5b). These results revealed that although the particle size of

Al could play an important role during the reaction between the starting

precursors, it did not affect the densication parameter of the sample

using the modied SHS technique.

Another trial for enhancing the sample porosity is to control the

delay time at which the pressing load is applied. Delaying the time of

pressing is important in some cases in order to give enough time for

the gases evolved during combustion to release. This may help in reduc-

ing the sample porosity. Therefore the pressing loadis investigatedbefore

the beginning of the reaction, during the reaction, and 5, 10, 15 and 20 s

after the reaction has nished. The effect of delay time on the porosity of

the samples is given in Fig. 6. It is concluded that pressing the sample at

any time after starting the reaction and up to 10 s after the reaction has

nished leads to almost the same sample porosity. Delaying the pressing

time for more than 10 s leads to an increase in the sample porosity due to

a dramatic reduction of the combustion temperature with time. This

behavior is also noticed during SEM investigation (Fig. 5c).

Composite properties

Coefcient of thermal expansion

Althoughoptimizing the controlling parameters lead to a highdensity

composite, it suffers fromthe existence of microcracks. The coefcient of

thermal expansion (CTE) as a function of temperature (2001250 C) is

Fig. 6. Effect of delay time on the sample porosity.

Fig. 7. Coefcient of thermal expansion and electrical resistivity behavior of the dense product at different temperatures.

28 Z.I. Zaki et al. / Int. Journal of Refractory Metals and Hard Materials 45 (2014) 2330

given in Fig. 7. It can be seen that the presence of MoSi

2

(~18.96 vol.%) as

a second phase increases the CTE of the mullite matrix (5.968.9310

6

K

1

) compared with CTE of pure mullite in the same temperature range

(4.46.510

6

K

1

). This means that during cooling, the mullite matrix

will suffer from thermal stress that causes the development of such

cracks. On the other hand, a simple calculation of volume changes

shows that reaction (3) is accompanied by a decrease in volume equal

to 18% due to the conversion of the reactants to the product. The fast

reaction and sudden cooling behavior of combustion synthesis and the

mismatch in the thermal expansion coefcient between MoSi

2

and

mullite may contribute to the formation of cracks.

Electrical resistivity

The electrical resistivity behavior at different temperatures is given in

Fig. 7. The measured electrical resistivity of this composite is 1.8 cmat

room temperature. This reects its good electrical conductivity at room

temperature which will facilitate its machining into complex shapes by

using the economical electrical discharge machining (EDM) technique.

This technique essentially needs the component tobe electrically conduc-

tive (resistivity b 100 cm) [33]. By increasing the temperature, the

electrical resistivity slightly increases as a common behavior for resis-

tance heating elements.

Oxidation resistance investigation

Oxidation resistance of the dense combustion product was carried

out in open atmosphere at 1300 C for 3 h. No weight gains or weight

losses were noticed. This ensures that this composite has good resistance

to oxidation within the investigated temperature range. XRD pattern of

the oxidized specimen at 1300 C, Fig. 8, shows the existence of a SiO

2

cristobalite phase and a weak diffraction pattern of alumina. There is no

evidence for the decomposition of MoSi

2

to the Mo-rich phase (Mo

5

Si

3

)

as commonly reported for samples containing MoSi

2

[31,32]. This could

be attributed to the embedding of MoSi

2

grains in the mullite matrix

which prevents direct contact between MoSi

2

grains and atmospheric

oxygen.

Conclusion

Combustion synthesis under load methodology has been successfully

used to produce a high density mullite/MoSi

2

composite having less than

3.0 vol.% porosity. The sample treated without dilution was totally

inhomogeneous. The addition of a 25 vol.% combustion product as a

diluent was necessary to produce a homogeneous product. The lowest

sample porosity was achievedupon applying 234 MPa mechanical pres-

sure during the combustion reaction. Using Al with an average particle

size less than 37 mwas found to increase sample porosity. The obtain-

ed high density composite has good oxidation resistance at 1300 C and

low electrical resistivity (1.8 cm) at room temperature. The mea-

sured coefcient of the thermal expansion of this product was 5.96

8.93 10

6

K

1

in the temperature range of 2001250 C.

References

[1] Yao Z, Stiglich J, Sudarshan TS. Molybdenum silicide based materials and their prop-

erties. J Mater Eng Perform 1999;8:291304.

[2] Schneider H, Schreuer J, Hildmann B. Structure and properties of mullitea review. J

Eur Ceram Soc 2008;28:32944.

[3] Sun L, Pan J. Fabrication and characterization of TiC-particle-reinforced MoSi

2

com-

posites. J Eur Ceram Soc 2002;22:7916.

[4] Zakeri M, Ramezani M. Synthesis of MoSi

2

TiC nanocomposite powder via mechanical

alloying and subsequent annealing. Ceram Int 2012;38:13537.

[5] Meng J, Lu J, Wang J, Yang S. Preparation and properties of MoSi

2

composites rein-

forced by TiC, TiCN, and TiB

2

. Mater Sci Eng A 2005;396:27784.

[6] Ignat S, Sallamand P, Nichici A, Vannes B, Grevey D, Cical E. MoSi

2

laser claddinga

new experimental procedure: double-sided injection of MoSi

2

and ZrO

2

. Surf Coat

Technol 2003;172:23341.

[7] Kbel S, Plschke J, Vogt U, Graule TJ. MoSi

2

Al

2

O

3

electroconductive ceramic com-

posites. Ceram Int 2004;30:210510.

[8] Raju GB, Basu B, Suri AK. Thermal and electrical properties of TiB

2

MoSi

2

. Int J Refract

Met Hard Mater 2010;28:1749.

[9] Micele L, Palombarini G, Guicciardi S, Silvestroni L. Tribological behaviour and wear re-

sistance of a SiCMoSi

2

composite dry sliding against Al

2

O

3

. Wear 2010;269:36875.

[10] Manukyan KV, Kharatyan SL, Blugan G, Kocher P, Kuebler J. MoSi

2

Si

3

N

4

composites:

inuence of starting materials and fabrication route on electrical and mechanical

properties. J Eur Ceram Soc 2009;29:205360.

[11] Shon I-J, Lee D-M, Doh J-M, Yoon J-K, Ko I-Y. Consolidation and mechanical proper-

ties of nanostructured MoSi

2

SiCSi

3

N

4

from mechanically activated powder by

high frequency induction heated sintering. Mater Sci Eng A 2011;528:12125.

[12] Lin GY, Costil V, Jorand Y, Fantozzi G. Experiments on packing and sintering of com-

posite powder mixtures of MoSi

2

+ Al

2

O

3

platelets. Ceram Int 1999;25:36773.

[13] Yeh CL, Chen WH. Combustion synthesis of MoSi

2

and MoSi

2

Mo

5

Si

3

composites. J

Alloy Compd 2007;438:16570.

[14] Ingemarsson L, Halvarsson M, Hellstrm K, Jonsson T, Sundberg M, Johansson LG,

et al. Oxidation behavior at 3001000 C of a (Mo, W) Si

2

-based composite contain-

ing boride. Intermetallics 2010;18:7786.

[15] Guicciardi S, Swarnakar AK, Van der Biest O, Sciti D. Temperature dependence of the

dynamic Young's modulus of ZrB

2

MoSi

2

ultra-refractory ceramic composites.

Scripta Mater 2010;62:8314.

[16] Liu H-T, Wu W-W, Zou J, Ni D-W, Kan Y-M, Zhang G-J. Insitu synthesis of ZrB

2

MoSi

2

platelet composites: reactive hot pressing process, microstructure and mechanical

properties. Ceram Int 2012;38:475160.

[17] McFayden AA, Thomas G, Petrovic JJ. Mullite whiskermolybdenum disilicide

composites. Ceram Eng Sci Proc 1995;16:14754.

Fig. 8. XRD of the combustion product treated in air at 1300 C for 3 h.

29 Z.I. Zaki et al. / Int. Journal of Refractory Metals and Hard Materials 45 (2014) 2330

[18] Brynsvold R. Processing of a mullite matrix, molybdenum disilicide reinforced com-

posite. University of Washington; 1991.

[19] S-k Zhao, Y Huang, C-a Wang, X-x Huang, J-k Guo. Mullite formation from reaction

sintering of ZrSiO

4

/-Al

2

O

3

mixtures. Mater Lett 2003;57:171622.

[20] Mazzei AC, Rodrigues JA. Aluminamullitezirconia composites obtained by re-

action sintering: Part I. Microstructure and mechanical behaviour. J Mater Sci

2000;35:280714.

[21] Sarydikmen H, Kushkonmaz N. Microstructure and phase analysis of ethyl silicate-

bonded alumina-zircon refractories. Refract Ind Ceram 2005;46:2126.

[22] Chen CY, Lan GS, Tuan WH. Preparation of mullite by the reaction sintering of

kaolinite and alumina. J Eur Ceram Soc 2000;20:251925.

[23] Chen G, Qi H, Xing W, Xu N. Direct preparation of macroporous mullite supports for

membranes by in situ reaction sintering. J Membr Sci 2008;318:3844.

[24] Kong LB, Ma J, Huang H. Mullite whiskers derived from an oxide mixture activated

by a mechanochemical process. Adv Eng Mater 2002;4:4904.

[25] Ribero D, Restrepo R, Paucar C, Garca C. Highly refractory mullite obtained through

the route of hydroxyhydrogels. J Mater Proc Technol 2009;209:98690.

[26] Kaya C, He JY, Gu X, Butler EG. Nanostructured ceramic powders by hydrothermal

synthesis and their applications. Microporous Mesoporous Mater 2002;54:3749.

[27] Somiya S, Yoshimura M, Suzuki M, Yanaguchi T. Mullite powder from hydrothermal

processing. In: Somiya S, Davies RF, Pask JA, editors. Ceramic transactions mullite

and mullite matrix composites. Westerville, OH: American Ceramic Society; 1990.

p. 287317.

[28] Basu SN, Kulkarni T, Wang HZ, Sarin VK. Functionally graded chemical vapor depos-

ited mullite environmental barrier coatings for Si-based ceramics. J Eur Ceram Soc

2008;28:43745.

[29] Botero CA, Jimenez-Piqu E, Kulkarni T, Fargas G, Sarin VK, Llanes L. Cross-sectional

nanoindentation and nanoscratch of compositionally graded mullite lms. Surf Coat

Technol 2011;206:192731.

[30] Hou P, Basu SN, Sarin VK. Structure and high-temperature stability of compositionally

graded CVD mullite coatings. Int J Refract Met Hard Mater 2001;19:46777.

[31] Armas B, Sibieude F, Mazel A, Fourmeaux R, de Icaza Herrera M. Low-pressure chemical

vapour deposition of mullite layers using a cold-wall reactor. Surf Coat Technol

2001;141:8895.

[32] Zamani S, Bakhsheshi-Rad HR, Shokuhfar A, Vaezi MR, Kadir MRA, Shaee MRM.

Synthesis and characterization of MoSi

2

Mo

5

Si

3

nanocomposite by mechanical

alloying and heat treatment. Int J Refract Met Hard Mater 2012;31:23641.

[33] Cabouro G, Le Gallet S, Chevalier S, Gaffet E, Grin Y, Bernard F. Dense Mosi

2

produced

by reactive ash sintering: control of Mo/Si agglomerates prepared by high-energy

ball milling. Powder Technol 2011;208:52631.

[34] Wu H, Li H-j, Lei Q, Fu Q-g, Ma C, Yao D-j, et al. Effect of spraying power on micro-

structure and bonding strength of MoSi

2

-based coatings prepared by supersonic

plasma spraying. Appl Surf Sci 2011;257:556670.

[35] Liu G, Li J, Chen K. Combustion synthesis of refractory and hard materials: a review.

Int J Refract Met Hard Mater 2013;39:90102.

[36] Zaki ZI, Mostafa NY, Rashad MM. High pressure synthesis of magnesium alumi-

nate composites with MoSi

2

and Mo

5

Si

3

in a self-sustaining manner. Ceram Int

2012;38:52317.

[37] Feng P, Qu X, Akhtar F, Islam SH. Self-propagating high temperature synthesis of

MoSi

2

matrix composites. Rare Metals 2006;25:22530.

[38] Mishra SK, Das SK, Sherbacov V. Fabrication of Al

2

O

3

ZrB

2

in situ composite by SHS

dynamic compaction: a novel approach. Compos Sci Technol 2007;67:244753.

[39] Vallauri D, ShcherbakovVA, KhitevAV, Deorsola FA. Studyof structureformationinTiC

TiB

2

MexOy ceramics fabricatedby SHS anddensication. Acta Mater 2008;56:13809.

[40] Khina BB, Formanek B, Solpan I. Limits of applicability of the diffusion-controlled

product growth kinetic approach to modeling SHS. Phys B Condens Matter

2005;355:1431.

[41] Zaki ZI. Combustion synthesis of mullitetitanium boride composite. Ceram Int

2009;35:6738.

[42] Zaki ZI, Hessien MM, Ahmed YMZ. Synthesis of molybdenum silicide/mullite com-

posites for high-temperature applications. Int J Self Propag High Temp Synth

2011;20:7281.

30 Z.I. Zaki et al. / Int. Journal of Refractory Metals and Hard Materials 45 (2014) 2330

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- User Manual: Samsung Medison Diagnostic Ultrasound SystemDocument686 pagesUser Manual: Samsung Medison Diagnostic Ultrasound SystemHuế Trần100% (1)

- Indian Income Tax Return Acknowledgement: Do Not Send This Acknowledgement To CPC, BengaluruDocument1 pageIndian Income Tax Return Acknowledgement: Do Not Send This Acknowledgement To CPC, BengaluruDrsex DrsexNo ratings yet

- Genie PDFDocument264 pagesGenie PDFjohanaNo ratings yet

- Decommissioning HSE PDFDocument105 pagesDecommissioning HSE PDFRafael Rocha100% (1)

- To Be or Not To Be Healthy 4144Document3 pagesTo Be or Not To Be Healthy 4144Vesna Milosavljevic100% (1)

- Nomenclature Practice ProblemsDocument4 pagesNomenclature Practice ProblemsMax DavidsonNo ratings yet

- Antibacterial Effects of Essential OilsDocument5 pagesAntibacterial Effects of Essential Oilsnightshade.lorna100% (1)

- Norsok R 002Document186 pagesNorsok R 002robson2015No ratings yet

- Trombly - Pump Status PDFDocument8 pagesTrombly - Pump Status PDFilhamNo ratings yet

- ACED Murugadoss PPT TAFEDocument91 pagesACED Murugadoss PPT TAFEMarikya GuptaNo ratings yet

- 2nd Year HEROES SUMMARIESDocument4 pages2nd Year HEROES SUMMARIESMustafa NizamiNo ratings yet

- Life Everlasting 2021001Document11 pagesLife Everlasting 2021001realangelinemylee2020721001No ratings yet

- Assignment 1 Front SheetDocument9 pagesAssignment 1 Front SheetBách PhạmNo ratings yet

- 7 Solidification, Casting Defects.Document5 pages7 Solidification, Casting Defects.Ahmad AbdNo ratings yet

- AJINOMOTO 2013 Ideal Amino Acid Profile For PigletsDocument28 pagesAJINOMOTO 2013 Ideal Amino Acid Profile For PigletsFreddy Alexander Horna Morillo100% (1)

- Anti Vawc PrimerDocument6 pagesAnti Vawc PrimerCiddy Montemayor100% (1)

- Clase No. 24 Nouns and Their Modifiers ExercisesDocument2 pagesClase No. 24 Nouns and Their Modifiers ExercisesenriquefisicoNo ratings yet

- Aahaa Puttu Flour ProjectDocument53 pagesAahaa Puttu Flour ProjectApple ComputersNo ratings yet

- Lab Risk AssessmentDocument8 pagesLab Risk Assessmentaqilah haronNo ratings yet

- Aqa Food Technology Coursework Mark SchemeDocument7 pagesAqa Food Technology Coursework Mark Schemeafjwdbaekycbaa100% (2)

- National Federation OF Sugar Workers (NFSW), Petitioner, vs. ETHELWOLDO R. OVEJERA Et. Al., RespondentsDocument32 pagesNational Federation OF Sugar Workers (NFSW), Petitioner, vs. ETHELWOLDO R. OVEJERA Et. Al., RespondentsRon GawatNo ratings yet

- Gene SileningDocument30 pagesGene SileningSajjad AhmadNo ratings yet

- Pressure MeasurementDocument293 pagesPressure MeasurementGlen Lauren PerezNo ratings yet

- Evaluation and Comparison of Highly Soluble Sodium Stearyl Fumarate With Other Lubricants in VitroDocument8 pagesEvaluation and Comparison of Highly Soluble Sodium Stearyl Fumarate With Other Lubricants in VitroSvirskaitė LaurynaNo ratings yet

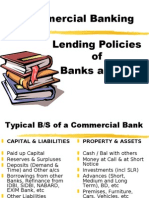

- Lending Policies of Indian BanksDocument47 pagesLending Policies of Indian BanksProf Dr Chowdari Prasad80% (5)

- Disease PreventionDocument14 pagesDisease PreventionJoan InsonNo ratings yet

- 3 Day WorkoutDocument3 pages3 Day Workoutsonu091276No ratings yet

- TMP DEDADocument8 pagesTMP DEDAFrontiersNo ratings yet

- Jepretan Layar 2022-11-30 Pada 11.29.09Document1 pageJepretan Layar 2022-11-30 Pada 11.29.09Muhamad yasinNo ratings yet