Professional Documents

Culture Documents

C 712 - 93 R97 Qzcxmi05m1i5nw

Uploaded by

Rufo Casco0 ratings0% found this document useful (0 votes)

8 views2 pagesThis test method covers determination of degree of bubble formation or surface blistering in one-part, elastomeric Solvent-Release Type Sealants. The type and amount of solvent used in these sealants can sometimes give rise to surface bubbling and blistering problems. This test method is useful in differentiating between a sealant that develops an acceptably smooth surface and one that may have blistering tendencies.

Original Description:

Original Title

C 712 – 93 R97 ;QZCXMI05M1I5NW__

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis test method covers determination of degree of bubble formation or surface blistering in one-part, elastomeric Solvent-Release Type Sealants. The type and amount of solvent used in these sealants can sometimes give rise to surface bubbling and blistering problems. This test method is useful in differentiating between a sealant that develops an acceptably smooth surface and one that may have blistering tendencies.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views2 pagesC 712 - 93 R97 Qzcxmi05m1i5nw

Uploaded by

Rufo CascoThis test method covers determination of degree of bubble formation or surface blistering in one-part, elastomeric Solvent-Release Type Sealants. The type and amount of solvent used in these sealants can sometimes give rise to surface bubbling and blistering problems. This test method is useful in differentiating between a sealant that develops an acceptably smooth surface and one that may have blistering tendencies.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Designation: C 712 93 (Reapproved 1997)

Standard Test Method for

Bubbling of One-Part, Elastomeric, Solvent-Release Type

Sealants

1

This standard is issued under the xed designation C 712; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers determination of the degree of

bubble formation or surface blistering in one-part, elastomeric

solvent-release type sealants when exposed to elevated tem-

peratures.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C 717 Terminology of Building Seals and Sealants

2

D 1191 Test Methods for Concrete Joint Sealers

3

3. Terminology

3.1 DenitionsRefer to Terminology C 717 for denitions

of the following terms used in this test method: compound,

elastomer, elastomeric, sealant, solvent-release sealant, sub-

strate.

4. Signicance and Use

4.1 The type and amount of solvent used in these sealants

can sometimes give rise to surface bubbling and blistering

problems. The substrate used, whether porous or nonporous,

will also have an effect. Although blistering is often caused by

misapplication, this test method is useful in differentiating

between a sealant that develops an acceptably smooth surface

and one that may have blistering tendencies.

5. Apparatus

5.1 Plates, thin aluminum, approximately 3 in. (76 mm)

wide by 5 in. (127 mm) long by 0.012 in. (0.30 mm) thick.

5.2 Blocks, cement mortar, approximately 2 in. (51 mm)

wide by 4 in. (102 mm) long by 1 in. (25 mm) thick prepared

as described in Test Methods D 1191.

NOTE 1Other substrates such as brick, cast stone, marble, stainless

steel, etc., may be specied either in place of the standard materials

specied in 5.1 and 5.2 or in addition to them.

5.3 Frame, at, rectangular, of

1

8-in. (3.2-mm) steel or

brass, with an opening of 1 by 3

3

4 in. (25 by 95 mm) and

outside dimensions of approximately 2 by 4

3

4 in. (51 by 121

mm).

5.4 Spatula, steel, with knife edge.

5.5 Oven, forced-draft type, having a temperature controlled

at 122 6 3.6F (50 6 2C).

6. Test Specimen

6.1 Take the test specimen from a previously unopened

container as received from the sealant manufacturer.

7. Procedure

7.1 Prepare three test specimens on each substrate as fol-

lows: Center the frame on the test substrate and carefully ll it

with compound, avoiding air pockets. Strike off the surface of

the compound ush with the frame, to a uniform thickness of

1

8 in. (3.2 mm). With the spatula, cut all around the outside

edge of the compound and lift the frame straight up and off.

7.2 Condition the specimens for 48 h at 73.4 6 3.6F (23 6

2C) and 50 6 5 % relative humidity.

7.3 Place the specimens in the oven at 122 6 3.6F (50 6

2C) for 72 h.

7.4 After heat exposure, allow the specimens to cool at 73.4

6 3.6F (23 6 2C) for 1 h.

7.5 Examine each specimen for surface gas bubbles and

blisters.

8. Report

8.1 For each substrate, report the total surface area covered

by the bubbles or blisters, estimated to the nearest 0.1 in.

2

(65

mm

2

). The area of bubble formation may be estimated by

1

This test method is under the jurisdiction of ASTM Committee C24 on Building

Seals and Sealants and is the direct responsibility of Subcommittee C24.20 on

General Sealant Standards.

Current edition approved July 15, 1993. Published September 1993. Originally

published as C 712 72. Last previous edition C 712 88.

2

Annual Book of ASTM Standards, Vol 04.07.

3

Annual Book of ASTM Standards, Vol 04.03.

1

Copyright ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

superimposing on the specimen a glass or clear plate ruled into

1

2-in. (13-mm) squares.

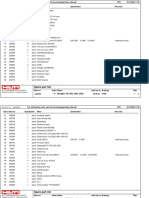

9. Precision and Bias

4

9.1 The precision and bias calculations for this test method

are based on the results of four laboratories testing three

materials using ve specimens per test. The results are given in

Table 1.

9.1.1 At 95 % condence level a variation of as much as

0.59 in.

2

can be expected within a laboratory and 0.60 in.

2

between laboratories. This is based on three materials being

tested by four laboratories.

10. Keywords

10.1 bubbling; elastomeric; solvent-release sealant

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every ve years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

4

Supporting data are available from ASTM Headquarters. Request RR: C24-

1021.

TABLE 1 Precision and Bias Data

Material Average

Estimated Stan-

dard Deviation

Within

Laboratory

Estimated Stan-

dard Deviation

Between Lab-

oratories

Repeat-

ability

Interval

Repro-

ducibility

G1 0.000 0.000 0.000 0.000 0.000

G2 0.064 0.209 0.212 0.590 0.600

G3 0.011 0.028 0.020 0.079 0.078

C 712 93 (1997)

2

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

You might also like

- C 712 - 03 - QZCXMGDocument2 pagesC 712 - 03 - QZCXMGmercab15No ratings yet

- C 772 - 97 Qzc3mi1sruqDocument3 pagesC 772 - 97 Qzc3mi1sruqRufo CascoNo ratings yet

- C 765 - 97 R01 QZC2NQDocument2 pagesC 765 - 97 R01 QZC2NQRufo CascoNo ratings yet

- Astm D2203Document2 pagesAstm D2203JesusNo ratings yet

- Volatility of Oil-And Resin-Based, Knife-Grade, Channel Glazing CompoundsDocument3 pagesVolatility of Oil-And Resin-Based, Knife-Grade, Channel Glazing CompoundsRufo CascoNo ratings yet

- Drying and Firing Shrinkages of Ceramic Whiteware Clays: Standard Test Method ForDocument2 pagesDrying and Firing Shrinkages of Ceramic Whiteware Clays: Standard Test Method ForEliKax!No ratings yet

- C 907 - 98 Qzkwny05oaDocument3 pagesC 907 - 98 Qzkwny05oaRufo CascoNo ratings yet

- C 771 - 03 - QZC3MQDocument2 pagesC 771 - 03 - QZC3MQmercab15No ratings yet

- D 2511Document2 pagesD 2511Asep TheaNo ratings yet

- ASTM D2377-00 Tack-Free Time of Caulking Compounds and SealantsDocument2 pagesASTM D2377-00 Tack-Free Time of Caulking Compounds and SealantsĐỗ Thanh TùngNo ratings yet

- Astm C142Document2 pagesAstm C142Aprizal PanjaitanNo ratings yet

- ASTMD937-97 PetrolatumDocument2 pagesASTMD937-97 Petrolatuminfinity1200100% (1)

- D2919 PDFDocument4 pagesD2919 PDFengahmed22281No ratings yet

- C 1305 - 00 - QzezmduDocument3 pagesC 1305 - 00 - Qzezmdumercab15No ratings yet

- ASTM C 324 (2007) Standard Test Method For Free Moisture in Ceramic Whiteware ClaysDocument1 pageASTM C 324 (2007) Standard Test Method For Free Moisture in Ceramic Whiteware ClaysJerry Delgado TrujilloNo ratings yet

- Astm C1250 - 1 (En)Document2 pagesAstm C1250 - 1 (En)svvasin2013No ratings yet

- Extension-Recovery and Adhesion of Latex Sealants: Standard Test Method ForDocument3 pagesExtension-Recovery and Adhesion of Latex Sealants: Standard Test Method Formercab15No ratings yet

- C 1216 - 92 r97 QzeymtytukveDocument6 pagesC 1216 - 92 r97 QzeymtytukveRufo CascoNo ratings yet

- Astm d5641Document4 pagesAstm d5641Walther LaricoNo ratings yet

- D 2091 - 96 - RdiwotetotyDocument3 pagesD 2091 - 96 - RdiwotetotymorchedtounsiNo ratings yet

- ASTM D 2752 - 88 (Reapproved 2002) Air Permeability of Asbestos FibersDocument9 pagesASTM D 2752 - 88 (Reapproved 2002) Air Permeability of Asbestos Fibersalin2005No ratings yet

- Thermal Integrity of Flexible Water Vapor Retarders: Standard Test Method ForDocument2 pagesThermal Integrity of Flexible Water Vapor Retarders: Standard Test Method Fordinhtung2210No ratings yet

- D 4073 Â " 94 R03 RDQWNZMDocument3 pagesD 4073 Â " 94 R03 RDQWNZMdorbarelNo ratings yet

- Astm C 142Document2 pagesAstm C 142e110807No ratings yet

- D 2444 - 99 Rdi0ndqDocument8 pagesD 2444 - 99 Rdi0ndqHumberto GutierrezNo ratings yet

- Hardness of Mineral Aggregate Used On Built-Up Roofs: Standard Test Method ForDocument2 pagesHardness of Mineral Aggregate Used On Built-Up Roofs: Standard Test Method FordaovandongpktNo ratings yet

- Conducting Exfoliation Corrosion Tests in Aluminum Alloys: Standard Guide ForDocument7 pagesConducting Exfoliation Corrosion Tests in Aluminum Alloys: Standard Guide Forgrats_singcoNo ratings yet

- C 587 - 97 Qzu4ny05nwDocument2 pagesC 587 - 97 Qzu4ny05nwHumberto GutierrezNo ratings yet

- C1162Document2 pagesC1162reefreefNo ratings yet

- Astm B 137 - 95 R00Document2 pagesAstm B 137 - 95 R00gchachlakisNo ratings yet

- Ash in A Graphite Sample: Standard Test Method ForDocument2 pagesAsh in A Graphite Sample: Standard Test Method Forguadalupegomezperez100% (2)

- Sieve Analysis of Mineral Filler For Bituminous Paving MixturesDocument2 pagesSieve Analysis of Mineral Filler For Bituminous Paving MixturesArnold RojasNo ratings yet

- Oil Migration or Plasticizer Bleed-Out of Preformed Tape SealantsDocument2 pagesOil Migration or Plasticizer Bleed-Out of Preformed Tape Sealantssebastian novoaNo ratings yet

- D6909 10 (2016)Document2 pagesD6909 10 (2016)tuyjvbnvNo ratings yet

- Lap Shear Strength of Hot-Applied Sealants: Standard Test Method ForDocument4 pagesLap Shear Strength of Hot-Applied Sealants: Standard Test Method ForRufo CascoNo ratings yet

- Sampling and Testing Ferroalloys For Determination of Size: Standard Test Methods ForDocument2 pagesSampling and Testing Ferroalloys For Determination of Size: Standard Test Methods ForGustavo SuarezNo ratings yet

- ASTM C307 TraçãoConcretoDocument4 pagesASTM C307 TraçãoConcretoLeandro Chiusoli100% (1)

- D3806Document5 pagesD3806Mohamed FaragNo ratings yet

- C 681 - 03 - Qzy4mqDocument2 pagesC 681 - 03 - Qzy4mqmercab15No ratings yet

- C 864 - 99 Qzg2naDocument3 pagesC 864 - 99 Qzg2naRufo CascoNo ratings yet

- C 932 - 03 QZKZMGDocument5 pagesC 932 - 03 QZKZMGHumberto GutierrezNo ratings yet

- ASTM D1171 - 15 - Rubber Deterioration-Surface Ozone Cracking Outdoors or Chamber (Triangular Specimens)Document3 pagesASTM D1171 - 15 - Rubber Deterioration-Surface Ozone Cracking Outdoors or Chamber (Triangular Specimens)Thảo Nhân NguyễnNo ratings yet

- D 7003 - 03Document2 pagesD 7003 - 03luis-12No ratings yet

- C 481 - 99 - QZQ4MQDocument2 pagesC 481 - 99 - QZQ4MQangeljosechuquiureNo ratings yet

- D2095Document3 pagesD2095Rashid SaleemNo ratings yet

- ASTMDocument6 pagesASTMcarmin79100% (2)

- Astm D-113 PDFDocument3 pagesAstm D-113 PDFjulianovmNo ratings yet

- Apparent Density of Activated Carbon: Standard Test Method ForDocument3 pagesApparent Density of Activated Carbon: Standard Test Method ForAlexIvanovichNo ratings yet

- Flexural Strength and Modulus of Elasticity of Chemical-Resistant Mortars, Grouts, Monolithic Surfacings, and Polymer ConcretesDocument6 pagesFlexural Strength and Modulus of Elasticity of Chemical-Resistant Mortars, Grouts, Monolithic Surfacings, and Polymer ConcretesAlejandro ValdesNo ratings yet

- D 2527 - 83 R01 - Rdi1mjcDocument2 pagesD 2527 - 83 R01 - Rdi1mjcjamaljamal20No ratings yet

- Hardness of Mineral Aggregate Used On Built-Up Roofs: Standard Test Method ForDocument2 pagesHardness of Mineral Aggregate Used On Built-Up Roofs: Standard Test Method FordaovandongpktNo ratings yet

- D7105-06 (2013) Standard Test Method For Determining The Adhesive and Cohesive Strength Between Materials in Roofing or Waterproofing Membranes and SystemsDocument3 pagesD7105-06 (2013) Standard Test Method For Determining The Adhesive and Cohesive Strength Between Materials in Roofing or Waterproofing Membranes and SystemsSatya kaliprasad vangaraNo ratings yet

- C 1135 - 00 QzexmzuDocument4 pagesC 1135 - 00 QzexmzuRufo CascoNo ratings yet

- D897 617621-1Document3 pagesD897 617621-1Fernando Cardeño LopezNo ratings yet

- D 3772 - 97 - Rdm3nzitotcDocument2 pagesD 3772 - 97 - Rdm3nzitotcMorched TounsiNo ratings yet

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites XIFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites XIJonathan SalemNo ratings yet

- C466Document2 pagesC466Rufo CascoNo ratings yet

- D 1758 - 02 Rde3ntgDocument8 pagesD 1758 - 02 Rde3ntgJosé Ramón GutierrezNo ratings yet

- D 2719 - 89 R01 Rdi3mtktodlsmde - PDFDocument9 pagesD 2719 - 89 R01 Rdi3mtktodlsmde - PDFRufo CascoNo ratings yet

- D 3345 - 74 R99 Rdmzndu - PDFDocument3 pagesD 3345 - 74 R99 Rdmzndu - PDFRufo CascoNo ratings yet

- D 3224 - 95 Rdmymjqtotu - PDFDocument2 pagesD 3224 - 95 Rdmymjqtotu - PDFRufo CascoNo ratings yet

- D 1758 - 96 Rde3ntgtukveDocument9 pagesD 1758 - 96 Rde3ntgtukveRufo CascoNo ratings yet

- Toughness of Wood-Based Structural Panels: Standard Test Method ForDocument3 pagesToughness of Wood-Based Structural Panels: Standard Test Method ForRufo CascoNo ratings yet

- D 2718 - 00 Rdi3mtgtmda - PDFDocument6 pagesD 2718 - 00 Rdi3mtgtmda - PDFRufo CascoNo ratings yet

- D 3737 - 02 Rdm3mzctukveDocument32 pagesD 3737 - 02 Rdm3mzctukveJosé Ramón GutierrezNo ratings yet

- D 1990 - 00 Rde5otatmdbfmq - PDFDocument26 pagesD 1990 - 00 Rde5otatmdbfmq - PDFRufo CascoNo ratings yet

- D 5516 - 01 Rdu1mtytmde - PDFDocument7 pagesD 5516 - 01 Rdu1mtytmde - PDFRufo CascoNo ratings yet

- D 1990 - 00 R02 Rde5ota - PDFDocument26 pagesD 1990 - 00 R02 Rde5ota - PDFRufo CascoNo ratings yet

- D 2719 - 89 R01 Rdi3mtkDocument10 pagesD 2719 - 89 R01 Rdi3mtkJosé Ramón GutierrezNo ratings yet

- D 5055 - 02 Rduwntutmdi - PDFDocument23 pagesD 5055 - 02 Rduwntutmdi - PDFRufo CascoNo ratings yet

- D 6007 - 96 Rdywmdctoty - PDFDocument8 pagesD 6007 - 96 Rdywmdctoty - PDFRufo CascoNo ratings yet

- D 5764 - 97a R02 RDU3NJQ - PDFDocument5 pagesD 5764 - 97a R02 RDU3NJQ - PDFRufo CascoNo ratings yet

- D 3200 - 74 R94 Rdmymdatnzrsotrfmq - PDFDocument2 pagesD 3200 - 74 R94 Rdmymdatnzrsotrfmq - PDFRufo CascoNo ratings yet

- D 4278 - 02 Rdqynzg - PDFDocument3 pagesD 4278 - 02 Rdqynzg - PDFRufo CascoNo ratings yet

- D 1554 - 00 - Rde1ntqtmdaDocument3 pagesD 1554 - 00 - Rde1ntqtmdagrats_singcoNo ratings yet

- D 5516 - 01 Rdu1mtytmde - PDFDocument7 pagesD 5516 - 01 Rdu1mtytmde - PDFRufo CascoNo ratings yet

- D 6815 - 02 Rdy4mtu - PDFDocument11 pagesD 6815 - 02 Rdy4mtu - PDFRufo CascoNo ratings yet

- D 2606 - 94 R00 Rdi2mdy - PDFDocument2 pagesD 2606 - 94 R00 Rdi2mdy - PDFRufo CascoNo ratings yet

- D 1624 - 71 R00 Rde2mjq - PDFDocument1 pageD 1624 - 71 R00 Rde2mjq - PDFRufo CascoNo ratings yet

- D 1166 - 84 R95 Rdexnjytodrsotvfmq - PDFDocument4 pagesD 1166 - 84 R95 Rdexnjytodrsotvfmq - PDFRufo CascoNo ratings yet

- E 1124 - 97 Rtexmjqtotc - PDFDocument7 pagesE 1124 - 97 Rtexmjqtotc - PDFRufo CascoNo ratings yet

- ASTM D 1108 - 96 (Reapproved 2001) Dichloromethane Solubles in WoodDocument2 pagesASTM D 1108 - 96 (Reapproved 2001) Dichloromethane Solubles in Woodalin2005No ratings yet

- D 1758 - 96 Rde3ntgtoty - PDFDocument7 pagesD 1758 - 96 Rde3ntgtoty - PDFRufo CascoNo ratings yet

- C 271 - 99 Qzi3mqDocument2 pagesC 271 - 99 Qzi3mqAndre AlvesNo ratings yet

- C 711 - 93 R97 Qzcxms05m1i5nw - PDFDocument3 pagesC 711 - 93 R97 Qzcxms05m1i5nw - PDFRufo CascoNo ratings yet

- D 1110 - 84 R95 Rdexmtatodrsotvfmq - PDFDocument2 pagesD 1110 - 84 R95 Rdexmtatodrsotvfmq - PDFRufo CascoNo ratings yet

- Court Rules Arrest of Vessel a Covered RiskDocument3 pagesCourt Rules Arrest of Vessel a Covered Riskretep69phNo ratings yet

- MCB Bank Internship ReportDocument9 pagesMCB Bank Internship ReportZahid ButtNo ratings yet

- G.pushkala - SC - Sexual HarassmentDocument11 pagesG.pushkala - SC - Sexual HarassmentSCOIBlogNo ratings yet

- 1971 1999 PDFDocument74 pages1971 1999 PDFSheraz UmarNo ratings yet

- Theory of Law and Economics Law and EconomicsDocument5 pagesTheory of Law and Economics Law and EconomicsMuhammad ZikriaNo ratings yet

- Pro-choice or pro-life? The case for women's rights and rape victimsDocument2 pagesPro-choice or pro-life? The case for women's rights and rape victimsTreseaNo ratings yet

- Week 7-Virtue Ethics of AristotleDocument27 pagesWeek 7-Virtue Ethics of AristotleNikki MallariNo ratings yet

- 10 Demerits of Caste System in IndiaDocument7 pages10 Demerits of Caste System in Indiarabiya altafNo ratings yet

- Tony Cliff State Capitalism in Russia (1955-1974)Document160 pagesTony Cliff State Capitalism in Russia (1955-1974)sergevictorNo ratings yet

- ILOVEYOU worm: One of the most destructive computer viruses everDocument4 pagesILOVEYOU worm: One of the most destructive computer viruses everDayday, Irine Irish N.No ratings yet

- Frank Spence ValuationDocument2 pagesFrank Spence ValuationShivam AryaNo ratings yet

- SHS LESSON 6 Ownership and OrganizationDocument9 pagesSHS LESSON 6 Ownership and OrganizationPaul AnteNo ratings yet

- Election Laws and Comelec: Notes by BB GhurlDocument28 pagesElection Laws and Comelec: Notes by BB GhurlRonnie Garcia Del RosarioNo ratings yet

- InvoiceDocument1 pageInvoicejkjeetkr8t80% (1)

- Simpsons - String PDFDocument6 pagesSimpsons - String PDFPaola RussoNo ratings yet

- Lecture Notes On Ethics and Nigerian Legal SystemDocument39 pagesLecture Notes On Ethics and Nigerian Legal Systemolaoluwalawal19No ratings yet

- THE FILIPINO IS WORTH DYINGDocument2 pagesTHE FILIPINO IS WORTH DYINGDanitza1459100% (2)

- Modules 13, 14 and 15Document11 pagesModules 13, 14 and 15George EvangelistaNo ratings yet

- Medical Malpractice and Negligence StandardsDocument2 pagesMedical Malpractice and Negligence StandardsRuthy SegoviaNo ratings yet

- Subanon Tribe Question Set.Document1 pageSubanon Tribe Question Set.MARK BRIAN FLORESNo ratings yet

- Marques v. Far East BankDocument3 pagesMarques v. Far East Bankmiles1280100% (1)

- Telkom 4 at 108.0°E - LyngSatDocument5 pagesTelkom 4 at 108.0°E - LyngSatEchoz NhackalsNo ratings yet

- Bank Audit MPDocument8 pagesBank Audit MPAbhai AgarwalNo ratings yet

- Spare Part List: Breaker TE 705 120V USADocument7 pagesSpare Part List: Breaker TE 705 120V USAJoseLuisCarrilloMenaNo ratings yet

- MN003401A01-AA HP Switch and Router General Configuration GuideDocument28 pagesMN003401A01-AA HP Switch and Router General Configuration Guidehardian affandy100% (1)

- 03 Arabay Vs CFIDocument3 pages03 Arabay Vs CFIJustin Andre Siguan100% (1)

- Instructions For Discharging Public Debt With Private ChecksDocument4 pagesInstructions For Discharging Public Debt With Private Checkssspikes93% (166)

- In Re: Grand Prix Fixed Lessee LLC, Case No. 10-13825, (Jointly Administered Uder Case No. 10-13800)Document3 pagesIn Re: Grand Prix Fixed Lessee LLC, Case No. 10-13825, (Jointly Administered Uder Case No. 10-13800)Chapter 11 DocketsNo ratings yet

- ACT IR224UN Lplus Manual v1.1.6 080115Document23 pagesACT IR224UN Lplus Manual v1.1.6 080115Danilo Gomes de AndradeNo ratings yet

- Gable Shed Plan: Free Streamlined VersionDocument9 pagesGable Shed Plan: Free Streamlined VersionjesusdoliNo ratings yet