Professional Documents

Culture Documents

Underground Mining Loader

Uploaded by

Pedro Pablo Fernández FernándezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Underground Mining Loader

Uploaded by

Pedro Pablo Fernández FernándezCopyright:

Available Formats

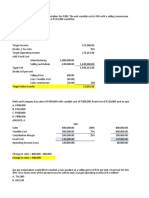

Engine

Engine Model Cat

C11 ACERT

Gross Power SAE J1995 241/263 kW 323/353 hp

Operating Specifications

Nominal Payload Capacity 12 500 kg 27,558 lb

Gross Machine 52 500 kg 115,745 lb

Operating Weight

Bucket Capacities

Bucket Capacity Std. 5.7 m

3

7.5 yd

3

R1700G

Underground Mining

Loader

2

R1700G Underground Mining Loader

Engineered for performance. Designed for comfort. Built to last.

Performance and Agility.

Compact design, high engine power,

higher torque rise, stronger components

and excellent maneuverability ensures

the R1700G is a solid performer.

Unmatched Operator Comfort.

World class operator station fitted with

revolutionary electronics and hydraulic

controls for low effort operation and

increased productivity.

Customer Support

Caterpillar

dealers provide unmatched

product support, anywhere in the world.

With industry-best parts availability

and a wide range of maintenance and

service options, Cat dealers have what

it takes to keep your mining machines

productive. pg. 12

Serviceability

The R1700G is designed for quick and

easy servicing. Simplified service and

maintenance features reduce downtime,

allowing the machine to spend less time

being serviced and more time being

productive. pg. 11

Hydraulics

Powerful Cat hydraulics deliver

excellent digging and lifting forces to

move materials quickly. High volume

pumps and large cylinders provide

quick, powerful response and fast cycle

times. Pilot operated joysticks provide

low effort operation and smooth

control. pg. 6

Power Train Transmission

The Cat four-speed planetary power

shift transmission features heavy duty

components to handle the toughest jobs.

Electronic controls allow smooth

shifting for greater productivity,

durability and longer component life.

pg. 5

Power Train Engine

The Cat

C11 engine with ACERT

Technology delivers the power and

reliability necessary to perform in the

most demanding underground mining

applications. Designed for efficient

operation, excellent fuel efficiency,

lower emissions, reduced engine noise

and lower operating costs. pg. 4

3

Safety

Caterpillar sets the standard when it

comes to safety in the design and

manufacturing of heavy equipment for

the mining industry. Safety is not an

after thought at Caterpillar, but an

integral part of all machine and systems

designs. pg. 13

Buckets

Cat underground loader buckets are

designed for optimal loadability and

structural durability in tough mining

conditions. A ranges of sizes and

configurations are available to match

material conditions and maximize

productivity. pg. 10

Operator Station

The ergonomic cab is designed for

operator comfort and ease of operation

to allow the operator to focus on

production. Controls and gauges are

positioned within easy reach for

optimum efficiency and superior

control all shift long. pg. 8

Structures

Structural components are the backbone

of the R1700G durability. The heavy

duty loader frame is designed and built

to absorb twisting, impact and high

loading forces for maximum durability

and reliability. Z-bar linkage generates

powerful breakout forces and optimum

loading angle. pg. 7

Cat C11 Engine with ACERT

Technology. The Cat C11 engine with

ACERTTechnology is U.S. EPA

Tier 3 and EU Stage III compliant.

It features efficient fuel management

for quick response, high productivity

and exceptional service life. A new,

sculptured cylinder block provides

greater strength and lighter weight.

High Torque Rise. Provides unequalled

lugging force while digging, tramming

and traversing steep grades. Torque rise

effectively matches transmission shift

points for maximum efficiency and fast

cycle times.

Radiator. Modular radiator with swing-

out grill provides easy access for cleaning

or repair. Built in sight gauge allows for

quick, safe coolant level checks.

Pistons. Oil cooled pistons increase

heat dissipation and promote longer

piston life.

ADEM IV System. Controls the fuel

injector solenoids and monitors fuel

injection. This system provides

automatic altitude compensation

and air filter restriction indication.

Turbocharged and Aftercooled. Air-to-air

aftercooling provides improved fuel

economy by packing cooler, denser air

into cylinders for more complete

combustion of fuel and lower emissions.

Electronic Unit Injection (EUI).

Proven high-pressure, direct injection

fuel system electronically monitors

operator demands and sensor inputs

to optimize engine performance.

Design Construction. Caterpillar

designed one-piece cast iron block

provides maximum strength and

durability.

4

Power Train Engine

The Cat

C11 engine with ACERTTechnology delivers the power and reliability

necessary to perform in the most demanding underground mining applications.

Power Shift Transmission.

The Cat four-speed planetary power

shift transmission is matched with the

C11 engine with ACERTTechnology

to deliver constant power over a wide

range of operating speeds.

Hydraulic modulation cushions

transmission shifts and reduces

stress on components.

High contact pump drive and output

transfer gears are used to reduce

sound levels.

Pump drive and output transfer use

high contact gear ratios to reduce

sound levels.

Perimeter mounted, large diameter

clutch packs control inertia for

smooth shifting and increased

component life.

Robust Design. Designed for rugged

underground mining conditions,

the proven planetary power shift

transmission is built for long life

between overhauls.

Electronic Controls. Electronic controls

allow smooth, on-the-go shifting for

greater productivity.

Torque Converter. High capacity torque

converter delivers more power to the

wheels for superior power train

efficiency.

Electronic Autoshift Transmission.

The electronic autoshift transmission

increases operator efficiencies and

optimizes machine performance.

The operator can choose between

manual or auto shift modes.

Transmission Neutralizer. Using the

left brake pedal, the operator can engage

the service brakes and neutralize the

transmission, maintaining high engine

rpm for full hydraulic flow, enhancing

digging and loading functions.

Final Drives. Cat final drives work as a

system with the planetary power shift

transmission to deliver maximum power

to the ground. Built to withstand the

forces of high torque and impact loads,

final drives provide high torque

multiplication to further reduce drive

train stress.

Axles. Heavy duty axles are built

rugged for long-life in the most

demanding environments.

Oscillating Rear Axle. Oscillating rear

axle ensures four-wheel ground contact

for maximum traction and stability at

all times.

Differential. No spin rear differential

reduces tire wear and maximizes

traction in uneven terrain.

Duo-Cone Seals. Duo-Coneseals

between the axle spindle and housings

keep lubrication in and contaminants out.

Brakes. Fully enclosed oil immersed

disc brakes incorporate independent

service and parking brake pistons.

Hydraulic actuated independent circuits

provide improved performance and

reliability.

Cat Electronic Technician. Cat ET

service tool provides service technicians

with easy access to stored diagnostic

data through the Cat Data Link to

simplify problem diagnosis and

increase availability.

5

Power Train Transmission

Designed for durability, the Cat power shift transmission delivers smooth, responsive

performance and reliability in tough conditions.

1

1 Parking/Secondary Piston

2 Service/Retarding Piston

3 Friction Discs

4 Steel Plates

5 Actuating Springs

6 Cooling Oil In

7 Cooling Oil Out

2

7

6

5

4

3

Hydraulic System. Powerful Cat

hydraulics deliver exceptional digging

and lifting forces for fast cycle times.

Lift and Tilt System. High hydraulic

flow rates provide fast hydraulic

cylinder response and powerful lift

forces. Large-bore tilt and lift cylinders

deliver exceptional strength,

performance and durability.

Pilot Controls. Low effort, pilot

operated joystick implement control

with simultaneous lift and tilt functions

optimizes operating efficiency.

Optional Ride Control. The optional ride

control system uses a nitrogen filled oil

accumulator in the hydraulic lift circuit

to act as a shock absorber for the bucket

and lift arms. The lift arm and bucket

response to movement is dampened

over rough ground, reducing fore and

aft pitch, improving cycle times and

load retention. A smoother, more

comfortable ride gives operators the

confidence to travel at speeds above

5 km/h (3 mph) during load and carry

operations.

Cat Hydraulic Hose. Field proven Cat

high pressure XThydraulic hoses are

exceptionally strong and flexible for

maximum system reliability and long

life in the most demanding conditions.

Reusable couplings with O-ring face

seals provide superior, leak free

performance and prolong hose

assembly life.

6

Hydraulics

Cat hydraulics deliver the power and control to keep material moving.

Frame Design. The frame features robust

structural components for outstanding

durability in the toughest loading

conditions. Caterpillar integrates

advanced processes in the design and

manufacture of Cat frames and structures.

Computer modeling and Finite Element

Analysis (FEA) are used extensively

throughout design.

Steel Frame. Strong steel frame structures

are designed to resist twisting forces,

torsional shock and stresses generated

during the loading cycle, while

protecting drive line and hydraulic

system components.

Lift Arms. Solid steel lift arms absorb

high stresses generated during loading

without sacrificing strength or durability.

The linkage design offers excellent

reach and dump clearance for better

productivity. Lift arm support pins

prevent lowering the lift arms during

service and maintenance.

Loader Tower. The four plate loader

tower provides a solid mount for lift

arms, lift cylinders and Z-bar tilt lever.

The loader frame is designed and built

to absorb twisting, impact and high

loading forces.

Cast-Steel Cross Tube. The cast steel

cross tube provides excellent resistance

to torsion and impact loads, keeping pin

bores aligned and extending component

service life.

Z-Bar Loader Linkage. Proven Z-Bar

loader linkage geometry generates

powerful breakout force and an increased

rack back angle for better bucket loading

and material retention.

Sealed Pins. Sealed colleted pins are

fitted to all bucket and lift arm hinge

points for longer pin and bushing life.

This reduces maintenance costs and

extends service intervals. The sealed

joints retain lubrication and prevent

contaminant entry.

Hitch. Spread hitch design widens the

distance between upper and lower hitch

plates to distribute forces and increase

bearing life. Thicker hitch plates reduce

deflection. The wide opening provides

easy service access. Upper and lower

hitch pins pivot on roller bearings to

distribute horizontal and vertical loads

over a greater surface area. Shim adjusted

preload reduces maintenance time.

An on-board steering frame lock pin

is fitted to prevent articulation during

maintenance and service.

7

Structures

Designed for maximum strength and durability in the harshest operating environments.

Ergonomic Layout. The operator station is

ergonomically designed for total machine

control in a comfortable, productive and

safe environment. All controls, levers

switches and gauges are positioned to

maximize productivity and minimize

operator fatigue.

Pilot Controls. Low-effort pilot operated

joystick controls integrate steering,

transmission and implement functions

for smoother, faster cycles with less

operator fatigue.

Electronic Autoshift. Electronic autoshift

allows the operator to choose automatic

or manual shifting. In auto mode, the

operator uses a dash mounted switch

to select the highest gear they wish the

machine to shift to. In this mode, the

transmission shifts at factory preset

shift points so that each shift occurs

at optimum torque and ground speed

for maximum machine performance.

Dual-Pedal Braking. The left pedal

functions as a brake and a transmission

neutralizer so the operator can maintain

high engine rpm for full hydraulic flow

and fast cycle times.

Protective Structure. The operator

station has integrated into its construction

a ROPS Roll-over protective structure

and FOPS Falling object protective

structure. This structure is resiliently

mounted to the frame, reducing

vibration to the operator for a more

comfortable ride.

Suspension Seat. Suspension seat

provides optimal driving position and

enhances operator comfort, all shift long.

8

Setting a new industry standard for comfort and efficiency.

Operator Station

STIC Steering Control. STIC

combines directional selection, gear

selection and steering into a single

lever for maximum responsiveness.

Simple side-to-side motion turns machine

right or left. Transmission shifting

(forward/neutral/reverse) is controlled

using a three position rocker switch.

The thumb operated upshift and downshift

button controls manual shifting.

Optional Enclosed Cab. Optional sound-

suppressed ROPS cab provides a quiet,

secure working environment. Large

window openings offer excellent

visibility in all directions. Enclosed

design provides fresh, pressurized,

temperature-controlled air circulation

with air-conditioned comfort and a more

comfortable working environment.

Optional Ride Control. The system uses

a nitrogen filled oil accumulator in the

hydraulic lift circuit to act as a shock

absorber for the bucket and lift arms.

The lift arm bucket response to movement

is dampened over rough ground, reducing

fore and aft pitch, improving cycle

times and load retention. A smoother,

more comfortable ride gives operators

the confidence to travel at higher speeds

during load and carry applications.

Monitoring System. Caterpillar

Electronic Monitoring System (CEMS)

continuously provides critical machine

data to keep the machine performing at

top production levels. A warning system

alerts the operator of immediate or

impending problems with engine oil

pressure, parking brake engagement,

brake oil pressure, electrical system,

low fuel, hydraulic oil temperature,

coolant level/temperature, transmission

oil temperature and impending brake

application.

Message Center. Three-category

warning system alerts operator of

abnormal machine health conditions.

Gauge Cluster. Maintains a constant

display of vital machine functions,

including: engine coolant temperature,

hydraulic oil temperature, transmission

oil temperature and fuel level.

Speedometer/Tachometer Module.

Monitors three systems: engine speed,

ground speed and gear indicator.

9

Buckets. Aggressive Cat bucket designs

deliver unmatched productivity in the

most demanding applications.

Underground mining buckets are

designed for optimal loadability and

structural reliability to increase

productivity and help lower your

cost-per-ton.

Bucket Selection. Cat underground

loader buckets are available in standard

and high penetration configurations to

meet a range of loading, hauling and

dumping conditions.

Bucket Capacities. Buckets are

available in a range of sizes and

capacities to suit most material types

and densities.

Wear Packages. Weld-on wear plates

in high wear areas are standard.

Additional wear packages are available,

including sacrificial wear strips and

Cat heel shrouds, protect the edges from

damage for longer bucket life and

reduce the need for costly bucket rebuilds.

Cutting Edges. Cat half arrow and cast

half arrow cutting edges extend bucket

life in high wear applications.

10

Buckets

Cat buckets provide the flexibility to match the machine to the material and conditions.

Service Access. Easy access to daily

service points simplifies servicing

and reduces time spent on regular

maintenance procedures.

Ground-Level Access. Allows convenient

servicing to all tanks, air filters, lubrication

points and compartment drains.

Air Filters. Radial seal air filters are

easy to change, reducing time required

for air filter maintenance.

Sight Gauges. Fluid level checks are

made easier with sight gauges.

Diagnostics. Cat Electronic Technician

(Cat ET) Service Tool enables quick

electronic diagnosis of machine

performance and key diagnostic data

for effective maintenance and repairs.

Sealed Electrical Connectors.

Electrical connectors are sealed to lock

out dust and moisture.

Scheduled Oil Sampling. SOS

SM

sampling valves speed sampling and

analysis reliability.

11

Serviceability

Less time spent on maintenance means more time being productive.

Commitment Makes the Difference.

Cat dealers offer a wide range of

solutions, services and products that help

you to lower costs, enhance productivity

and manage your operation more

efficiently. Support goes far beyond

parts and service. From the time you

select a piece of Cat equipment until

the day you rebuild, trade or sell it,

the support you get from your Cat

dealer makes the difference that counts.

Dealer Capability. Cat dealers provide

the level of support you need, on a

global scale. Dealer expert technicians

have the knowledge, experience, training

and tooling necessary to handle your

repair and maintenance needs, when

and where you need them.

Product Support. Cat dealers believe

superior products deserve superior

support. When Cat products reach the

field, they are supported by a worldwide

network of parts distribution facilities,

dealer service centers, and technical

training facilities to keep your equipment

up and running. Cat customers rely on

prompt, dependable parts availability

and expertise through our global dealer

network, ready to meet your needs 24/7.

Service Support. Every piece of

Cat equipment is designed and built

to provide maximum productivity and

operating economy throughout its

working life. Cat dealers offer a wide

range of service plans that will maximize

uptime and return on your investment,

including:

Preventive Maintenance Programs

Diagnostic Programs, such as

Scheduled Oil Sampling and

Technical Analysis

Rebuild and Reman Options

Customer Support Agreements

Technology Products. Cat dealers offer

a range of advanced technology products

designed to improve fleet efficiency,

increase productivity, and lower costs.

www.cat.com. For more information

on Cat products, dealer services, and

industry solutions, visit us on the web

at www.cat.com.

12

Customer Support

Caterpillar

dealers have what it takes to keep mining underground equipment productive.

Product Safety. Caterpillar has been and

continues to be proactive in developing

mining machines that meet or exceed

safety standards. Safety is an integral

part of all machine and systems designs.

Engine Shut Off Switch. A secondary

engine shutoff switch is located at

ground level.

Protective Structure. The operator

station has integrated into its construction

a ROPS Roll-over protective structure

and FOPS Falling object protective

structure. This structure is resiliently

mounted to the frame, reducing

vibration to the operator for a more

comfortable ride.

Brake Systems. Four corner oil-cooled

braking system provides excellent

control. The service brake system is

actuated by modulated hydraulic

pressure, while the parking brake

function is spring applied and hydraulic

released. This system assures braking

in the event of hydraulic failure.

Standard Safety Features.

Interlock

Anti-skid upper deck surfaces

Lower cab light

Ground level compartment sight

glasses

Increased visibility

3-point access to cab and machine

Push out safety glass

Suspension seat

Inertia reel retractable seat belt

Lift arm support pins

Hot and cold side of engine

Steering frame lock

Hinged belly guards

Firewall

Shielded Exhaust

13

Safety

Caterpillar mining machines and systems are designed with safety as their first priority.

14 R1700G Underground Mining Loader specifications

Transmission

Forward 1 4.7 km/h 2.9 mph

Forward 2 8.3 km/h 5.2 mph

Forward 3 14.3 km/h 8.9 mph

Forward 4 24.1 km/h 15 mph

Reverse 1 5.4 km/h 3.3 mph

Reverse 2 9.4 km/h 5.8 mph

Reverse 3 16.4 km/h 10.2 mph

Reverse 4 25.3 km/h 15.7 mph

Hydraulic Cycle Time

Raise 6.8 Seconds

Dump 2.9 Seconds

Lower, empty, float down 2.4 Seconds

Total Cycle Time 12.1 Seconds

Bucket Capacities

Bucket Capacity Std. 5.7 m

3

7.5 yd

3

Bucket Width (Over cutting edge) 2772 mm 109.1 in

Bucket Capacity Optional 4.6 m

3

6 yd

3

Bucket Capacity Optional 5 m

3

6.5 yd

3

Bucket Capacity Optional 6.6 m

3

8.6 yd

3

Bucket Capacity Optional 7.3 m

3

9.5 yd

3

Bucket Capacity Optional 8.8 m

3

11.5 yd

3

Bucket Capacity Optional 5.6 m

3

7.3 yd

3

(Ejector)

Turning Dimensions

Outside Clearance Radius** 6878 mm 270.8 in

Inner Clearance Radius** 3229 mm 127.1 in

Axle Oscillation 8

Articulation Angle 44

**Note: Clearance Dimensions are for reference only.

Engine

Engine Model Cat

C11 ACERT

Rated Power 1,800 rpm

Gross Power SAE J1995 241/263 kW 323/353 hp

Net Power SAE J1349 218/241 kW 293/353 hp

Net Power ISO 9249 218/241 kW 293/353 hp

Net Power 80/1269/EEC 218/241 kW 293/353 hp

Bore 130 mm 5.1 in

Stroke 140 mm 5.5 in

Displacement 11.1 L 680 in

3

Power ratings apply at a rated speed of 1,800 rpm when

tested under the reference conditions for the specified

standard.

Ratings based on SAE J1995 standard air conditions of 25 C

(77 F) and 100 kPa (29.61 Hg) barometer. Power based on

fuel having API gravity of 35 at 16 C (60 F) and an LHV

of 42 780 kJ/kg (18,390 BTU/lb) when engine used at 30 C

(86 F).

Engine derate will commence at an altitude of 3050 m (10,006 ft).

Compliant with U.S. Environmental Protection Agency Tier 3

emissions standards.

Operating Specifications

Nominal Payload Capacity 12 500 kg 27,558 lb

Nominal Payload Capacity 14 000 kg 30,865 lb

Tramming

Gross Machine Operating Weight 52 500 kg 115,745 lb

Nominal Payload Capacity 12 500 kg 27,558 lb

Truck Loading

Static Tipping Load Straight 31 781 kg 70,065 lb

Ahead Lift Arms Horizontal

Static Tipping Load Full Turn 26 306 kg 57,995 lb

Lift Arms Horizontal

Breakout Force (SAE) 20 885 kg 46,051 lb

Weights

Empty 38 500 kg 84,878 lb

Front Axle 16 940 kg 37,346 lb

Rear Axle 21 560 kg 47,532 lb

Loaded 51 000 kg 112,436 lb

Front Axle 37 077 kg 81,741 lb

Rear Axle 13 923 kg 30,695 lb

Loaded Tramming 52 500 kg 115,743 lb

15 R1700G Underground Mining Loader specifications

Standards

Brakes ISO3450, AS2958.1,

CAN-CSA424.30-M90

Cab/FOPS BS EN ISO3449, SAEJ231,

AS2294.3

Cab/ROPS ISO3471, SAEJ1040,

AS2294.2, EN13510

Tires

Tire Size 26.5 25 36 PLY STMS L5S

Service Refill Capacities

Engine Crankcase with Filter 34 L 8.98 gal

Transmission 47 L 12.4 gal

Hydraulic Tank 125 L 33 gal

Cooling System 63 L 16.6 gal

Front Differential and Final Drives 61 L 16.1 gal

Rear Differential and Final Drives 61 L 16.1 gal

Front Differential and Final 90 L 23.8 gal

Drives (With Axle Oil Cooler)

Rear Differential and Final 90 L 23.8 gal

Drives (With Axle Oil Cooler)

Fuel Tank 570 L 150.5 gal

Secondary Fuel Tank 420 L 111 gal

(If Equipped)

252-7194* 281-0445

256-0862 255-9970* (Standard Bucket) 226-5404* 256-0356* 256-0386 Ejector Bucket

Bucket capacity 4.6 m

3

5.0 m

3

5.7 m

3

6.6 m

3

7.3 m

3

8.8 m

3

5.6 m

3

(6.0 yd

3

) (6.5 yd

3

) (7.5 yd

3

) (8.6 yd

3

) (9.5 yd

3

) (11.5 yd

3

) (7.3 yd

3

)

Bucket width over cutting edge 2672 mm 2672 mm 2772 mm 2932 mm 2982 mm 3492 mm 2780 mm

(8'9") (8'9") (9'1") (9'7") (9'9") (11'6") (9'1")

1 Overall height bucket raised 5511 mm 5511 mm 5606 mm 5680 mm 5751 mm 5751 mm 5858 mm

(18'1") (18'1") (18'5") (18'8") (18'10") (18'10") (19'3")

2 Maximum dump height 4899 mm 4899 mm 4899 mm 4899 mm 4899 mm 4899 mm 4913 mm

(16'1") (16'1") (16'1") (16'1") (16'1") (16'1") (16'1")

3 Bucket pin height at maximum lift 4104 mm 4104 mm 4104 mm 4104 mm 4104 mm 4104 mm 4104 mm

(13'6") (13'6") (13'6") (13'6") (13'6") (13'6") (13'6")

4 Dump clearance at maximum lift 2648 mm 2524 mm 2443 mm 2392 mm 2320 mm 2320 mm 2352 mm

(8'8") (8'3") (8'0") (7'10") (7'7") (7'7") (7'9")

5 Digging depth 5 mm (0.2") 15 mm (0.6") 20 mm (1") 26 mm (1") 33 mm (1") 33 mm (1") 76 mm (3")

6 Dump angle at maximum lift 46 46 46 46 46 46 46

7 Reach 1526 mm (5') 1639 mm (5'5") 1741 mm (5'8") 1768 mm (5'10") 1836 mm (6') 1836 mm (6') 1738 mm (5'8")

8 Centerline of front axle 1840 mm 1840 mm 1840 mm 1840 mm 1840 mm 1840 mm 1840 mm

to centerline of hitch (6') (6') (6') (6') (6') (6') (6')

9 Overall length (digging) 10 746 mm 10 915 mm 11 035 mm 11 105 mm 11 207 mm 11 207 mm 11 132 mm

(35'3") (35'10") (36'2") (36'5") (36'9") (36'9") (36'6")

10 Overall length (tramming) 10 447 mm 10 549 mm 10 589 mm 10 663 mm 10 724 mm 10 724 mm 10 706 mm

(34'4") (34'7") (34'9") (35') (35'2") (35'2") (35'1")

11 Ground clearance 429 mm 429 mm 429 mm 429 mm 429 mm 429 mm 429 mm

(1'5") (1'5") (1'5") (1'5") (1'5") (1'5") (1'5")

12 Centerline of back axle 1840 mm 1840 mm 1840 mm 1840 mm 1840 mm 1840 mm 1840 mm

to centerline of hitch (6') (6') (6') (6') (6') (6') (6')

13 Length rear axle to bumper 3439 mm 3439 mm 3439 mm 3439 mm 3439 mm 3439 mm 3439 mm

(11'3") (11'3") (11'3") (11'3") (11'3") (11'3") (11'3")

14 Height to top of hood 1968 mm 1968 mm 1968 mm 1968 mm 1968 mm 1968 mm 1968 mm

(6'6") (6'6") (6'6") (6'6") (6'6") (6'6") (6'6")

15 Height to top of ROPS 2557 mm 2557 mm 2557 mm 2557 mm 2557 mm 2557 mm 2557 mm

(8'5") (8'5") (8'5") (8'5") (8'5") (8'5") (8'5")

16 Tunnel clearance width** 4000 mm 4000 mm 4000 mm 4000 mm 4000 mm 4000 mm 4000 mm

(13'1") (13'1") (13'1") (13'1") (13'1") (13'1") (13'1")

17 Tunnel clearance height** 4000 mm 4000 mm 4000 mm 4000 mm 4000 mm 4000 mm 4000 mm

(13'1") (13'1") (13'1") (13'1") (13'1") (13'1") (13'1")

18 Overall tire width 2650 mm 2650 mm 2650 mm 2650 mm 2650 mm 2650 mm 2650 mm

(8'8") (8'8") (8'8") (8'8") (8'8") (8'8") (8'8")

19 Overall width excluding bucket 2689 mm 2689 mm 2689 mm 2689 mm 2689 mm 2689 mm 2689 mm

(8'10") (8'10") (8'10") (8'10") (8'10") (8'10") (8'10")

20 Overall width including bucket 2790 mm 2790 mm 2894 mm 3050 mm 3104 mm 3610 mm 2902 mm

(9'2") (9'2") (9'6") (10'0") (10'2") (11'10") (9'6")

21 Wheelbase 3680 mm 3680 mm 3680 mm 3680 mm 3680 mm 3680 mm 3680 mm

(12'1") (12'1") (12'1") (12'1") (12'1") (12'1") (12'1")

**Dimensions shown with standard material bucket sizes. High penetration bucket versions also available.

**Clearance dimensions are for reference only.

Dimensions

All dimensions are approximate.

16

17

18

19

20

15

6

7

4

11

8 12 13

10

9

5

14

15

3

2

1

21

46

52

42

7

16

R1700G Underground Mining Loader specifications

17

R1700G Underground Mining Loader specifications

E Empty 38 500 kg (84,878 lb)

L Loaded 51 000 kg (112,436 lb)

Gradeability/Speed/Rimpull

To determine gradeability performance: Read from gross

weight down to the percent of total resistance. Total resistance

equals actual percent grade plus rolling resistance. As a general

guide use 2% for rolling resistance in underground applications

or refer to the Caterpillar Performance Handbook. From the

total resistance point, read horizontally to the curve with

the highest obtainable gear, then down to maximum speed.

Usable rimpull will depend upon traction available and

weight on drive wheels.

Typical Field Empty Weight

Loaded Weight

L

0

10

20

30

40

50

60

70

80

90

100

0 2 4 6 8 10 12 14 16 18 20

R

i

m

p

u

l

l

N

x

1

0

0

0

(

l

b

s

x

1

0

0

0

)

mph

km/h 3.2 6.4 9.6 12.9 16.0 19.3 22.5 25.7 28.9 32.1

lbf N

445

400

356

311

267

222

178

133

89

44

Gross Weight

Speed

T

o

t

a

l

R

e

s

i

s

t

a

n

c

e

(

G

r

a

d

e

p

l

u

s

R

o

l

l

i

n

g

)

1st Gear

2nd Gear

3rd Gear

4th Gear

Direct Drive

26.5x25 Tires

25%

20%

15%

10%

5%

E

Standard Equipment

Standard equipment may vary. Consult your Caterpillar dealer for details.

Power Train

Cat C11 ATAAC Diesel Engine with ACERT

Technology, 6-Cylinder

Long Life Coolant

SAFRFull Hydraulic Enclosed Wet Multiple-Disc Brakes

Planetary Powershift Transmission with Automatic Shift

Control, 4 Speed Forward/4 Speed Reverse

Engine Air Intake Precleaner

Torque Converter

Transmission Neutralizer

Fuel Priming Aid

Crossflow radiator

Other Standard Equipment

Bucket Positioner, Return To Dig

Catalytic Exhaust Purifier/Muffler Group

Engine And Transmission Belly Guards

Fenders, Front, Rear

Firewall

Hardox 450 Bucket Lip

Rear Frame Protection Wear Bars 100 50 mm (4 2 in)

Semi Centralized Lubrication Points

Swing Out Radiator Grill

Tires, 26.5 25 36 PLY STMS L5S

Electrical

Alternator, 95-amp

Battery Disconnect Switch, Ground Level

Corrosive Protection Spray

Diagnostic Connector

Electric Starting, 24-volt

Engine Shutdown Switch

External Lighting System, Front, Rear

Low Maintenance Batteries

Reversing Alarm

Starting And Charging System

Operator Environment

Caterpillar Electronic Monitoring System (CEMS)

Electric Horns

Gauges

Engine Coolant Temperature

Fuel Level

Hydraulic Oil Temperature

Speedometer

Tachometer

Pilot Hydraulic Implement Controls, Single Joystick

ROPS/FOPS Structure

Suspension Seat With Retractable Seat Belt

Wheel Steer

18

R1700G Underground Mining Loader specifications

19 R1700G Underground Mining Loader specifications

Optional Equipment

Optional equipment may vary. Consult your Caterpillar dealer for details.

Heater, Air Conditioning

Oil Sample Adapters

Operators Station

Air Conditioning

Pressurizer

Dome Light

Radio Ready

Payload Control System (PCS)

Remote Activated Fire System

Remote Control Systems

Proportional

Retrieval attachment

Reversible Steering, Wheel Steer

Ride Control System

Seat Covers

Secondary Steering System

Service Tools

STICSteering

Tee Seat

Alternative Tire Arrangements

Automatic Lube System

Auxiliary Start Receptacle

Brake Light

Brake Pressure Gauges

Brake Release Arrangements

Bucket Heel Shrouds

Bucket Sacrificial Wear Strip Package

Centralized Lube System, Manual

Draw Bar Attachment, Bolt-on

Electronic Access Module

Fast Fill System

Coolant

Engine

Fuel

Hydraulic

Transmission

Fire Extinguishers

Fire Suppression System

Front Light Protectors

R

For more complete information on Cat products, dealer services,

and industry solutions, visit us on the web at www.cat.com

2007 Caterpillar

All Rights Reserved

Printed in U.S.A.

Materials and specifications are subject to change without notice.

Featured machines in photos may include additional equipment.

See your Caterpillar dealer for available options.

CAT, CATERPILLAR, their respective logos, Caterpillar Yellow and the

POWER EDGE trade dress, as well as corporate and product identity used herein,

are trademarks of Caterpillar and may not be used without permission. AEHQ5607-01 (9-07)

R1700G Underground Mining Loader

You might also like

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- LS Gen IV Engines 2005 - Present: How to Build Max PerformanceFrom EverandLS Gen IV Engines 2005 - Present: How to Build Max PerformanceRating: 5 out of 5 stars5/5 (2)

- Swap LS Engines into Chevelles & GM A-Bodies: 1964-1972From EverandSwap LS Engines into Chevelles & GM A-Bodies: 1964-1972Rating: 4.5 out of 5 stars4.5/5 (3)

- Nexus Undercarriage Cross Reference GuideDocument185 pagesNexus Undercarriage Cross Reference GuideRomanNo ratings yet

- 814F2Document20 pages814F2Josep Venancio AlbornozNo ratings yet

- Scoop R1600 6yd3Document20 pagesScoop R1600 6yd3Mario Silva Zea0% (1)

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorFrom EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNo ratings yet

- AD30Document20 pagesAD30Percy CheroNo ratings yet

- Wheel Loader 988GDocument24 pagesWheel Loader 988GChristian Kari100% (1)

- 972H Wheel LoaderDocument20 pages972H Wheel Loaderarnold100% (1)

- Storage Reservior and Balancing ReservoirDocument19 pagesStorage Reservior and Balancing ReservoirNeel Kurrey0% (1)

- A Cat.740 ArticDocument20 pagesA Cat.740 ArticSang Sang BaronganNo ratings yet

- CAT Front Shovel 385CDocument16 pagesCAT Front Shovel 385CCraciun AndreiNo ratings yet

- Tren ScoopDocument16 pagesTren ScoopHugoRamosMamaniNo ratings yet

- Cat 950 HDocument20 pagesCat 950 Hstefan_barabas4760100% (1)

- E1 994D SpecalogDocument24 pagesE1 994D SpecalogAngelo Meza Villalva100% (1)

- LHD R1300G Cargador de Bajo Perfil CaterpillarDocument16 pagesLHD R1300G Cargador de Bajo Perfil CaterpillarCesar Chu AcevedoNo ratings yet

- Underground Haulage Selection: Shaft or Ramp For A Small-Scale Underground MineDocument6 pagesUnderground Haulage Selection: Shaft or Ramp For A Small-Scale Underground MineluisparedesNo ratings yet

- Motor Grader: Engine WeightsDocument20 pagesMotor Grader: Engine Weightsagegnehutamirat100% (2)

- 315D CatDocument20 pages315D CatFernando Omar Arena100% (1)

- Track-Type Tractor - d11r (Tractor Oruga)Document24 pagesTrack-Type Tractor - d11r (Tractor Oruga)Christian Kari100% (2)

- CVP Solution (Quiz)Document9 pagesCVP Solution (Quiz)Angela Miles DizonNo ratings yet

- CAT 789C BrochureDocument28 pagesCAT 789C BrochurezaneswingNo ratings yet

- Cat 583TDocument20 pagesCat 583Traulosvaldo_1100% (1)

- R1600HDocument20 pagesR1600HTefi' NeolaNo ratings yet

- Articulated TruckDocument20 pagesArticulated TruckWildan RahdyasNo ratings yet

- Cat R1900G PDFDocument20 pagesCat R1900G PDFMarcelo Gonzalez AcuñaNo ratings yet

- 966HDocument24 pages966Hagegnehutamirat100% (1)

- 775F OhtDocument28 pages775F OhtDavid FortierNo ratings yet

- Camion Articulado Ejector 730Document20 pagesCamion Articulado Ejector 730Edgar Carpio RiveraNo ratings yet

- An Application of Branch and Cut to Open Pit Mine SchedulingDocument24 pagesAn Application of Branch and Cut to Open Pit Mine Schedulingsrivasthu100% (1)

- Cat D8R NewDocument20 pagesCat D8R Newagegnehutamirat100% (5)

- SC invalidates Ordinance allowing oil depots in Pandacan due to population densityDocument2 pagesSC invalidates Ordinance allowing oil depots in Pandacan due to population densityMigs Raymundo100% (1)

- 789C SpecalogDocument28 pages789C SpecalogJesus Almanzar Santos100% (1)

- Underground Mining LoaderDocument20 pagesUnderground Mining LoaderPedro Pablo Fernández FernándezNo ratings yet

- 3 0 Visual Weld InspectorDocument74 pages3 0 Visual Weld InspectorVincent Sofia RaphaelNo ratings yet

- Underground Mining Loader: Engine Operating SpecificationsDocument20 pagesUnderground Mining Loader: Engine Operating SpecificationsJ Phol Caceres CayoNo ratings yet

- R2900GDocument20 pagesR2900Gozeto03No ratings yet

- R3000HDocument20 pagesR3000HRichard DouglasNo ratings yet

- Scoop R1600 6yd3Document20 pagesScoop R1600 6yd3Mario Silva Zea0% (1)

- 980hspecalog PDFDocument20 pages980hspecalog PDFAraceli AndersonNo ratings yet

- C 10296078Document20 pagesC 10296078Jose Lozano PiscoNo ratings yet

- Underground Mining Loader: Engine Operating SpecificationsDocument20 pagesUnderground Mining Loader: Engine Operating SpecificationsJames PaitooNo ratings yet

- Underground Mining LoaderDocument20 pagesUnderground Mining LoaderMisael Josue Castro HuancayoNo ratings yet

- Underground Mining LoaderDocument20 pagesUnderground Mining LoaderMisael Josue Castro HuancayoNo ratings yet

- Especificaciones Tecnicas Cat R1300g-EDocument20 pagesEspecificaciones Tecnicas Cat R1300g-EGianfranco GardellaNo ratings yet

- Wheel LoaderDocument28 pagesWheel LoaderDario BegazoNo ratings yet

- Off-Highway TruckDocument32 pagesOff-Highway TruckTeeyas PutreeNo ratings yet

- CAT Motor Grader 12KDocument20 pagesCAT Motor Grader 12KCraciun Andrei100% (1)

- Cat 785DDocument24 pagesCat 785DDavyda VedaNo ratings yet

- 966H PDFDocument24 pages966H PDFAlberto CovarrubiasNo ratings yet

- Cargador Frontal 994FDocument32 pagesCargador Frontal 994FGian Marco PCNo ratings yet

- Underground Mining Loader: Engine Operating SpecificationsDocument20 pagesUnderground Mining Loader: Engine Operating SpecificationsFabian MorquechoNo ratings yet

- 785d Mining TrucksDocument24 pages785d Mining TrucksWynand Van ZylNo ratings yet

- Track-Type Tractors: Engine WeightsDocument20 pagesTrack-Type Tractors: Engine WeightsagegnehutamiratNo ratings yet

- Retroexcavadora Cat 385CDocument24 pagesRetroexcavadora Cat 385CMax Tapia Castillo100% (1)

- Aehq6166 00Document28 pagesAehq6166 00AlbertoNo ratings yet

- Off-Highway TruckDocument28 pagesOff-Highway TruckrodizianoNo ratings yet

- 320D GC Series 2: Hydraulic ExcavatorDocument28 pages320D GC Series 2: Hydraulic ExcavatorPurwoko100% (1)

- Cat 944FDocument32 pagesCat 944FForomaquinas100% (2)

- TractorDocument20 pagesTractorPepe AlfredNo ratings yet

- Pipelayer: Engine Engine (Continued)Document20 pagesPipelayer: Engine Engine (Continued)Daniel Marx ChillitupaNo ratings yet

- 14H (I) PDFDocument20 pages14H (I) PDFSandoval Luis100% (2)

- Aehq6098 01Document16 pagesAehq6098 01Pedro Pablo Fernández FernándezNo ratings yet

- C19 0Document2 pagesC19 0Pedro Pablo Fernández FernándezNo ratings yet

- Mate Matic AsDocument1 pageMate Matic AsPedro Pablo Fernández FernándezNo ratings yet

- AB InBev Code of Business Conduct PDFDocument10 pagesAB InBev Code of Business Conduct PDFcristian quelmis vilca huarachiNo ratings yet

- TicketDocument2 pagesTicketbikram kumarNo ratings yet

- Part 9. Wireless Communication Towers and Antennas 908.01 Purpose and IntentDocument12 pagesPart 9. Wireless Communication Towers and Antennas 908.01 Purpose and IntentjosethompsonNo ratings yet

- IBM TS3500 Command Line Interface (CLI) ExamplesDocument6 pagesIBM TS3500 Command Line Interface (CLI) ExamplesMustafa BenmaghaNo ratings yet

- Siyaram S AR 18-19 With Notice CompressedDocument128 pagesSiyaram S AR 18-19 With Notice Compressedkhushboo rajputNo ratings yet

- Sample Contract Rates MerchantDocument2 pagesSample Contract Rates MerchantAlan BimantaraNo ratings yet

- fr1177e-MOTOR CUMMINS 195HPDocument2 pagesfr1177e-MOTOR CUMMINS 195HPwilfredo rodriguezNo ratings yet

- Shubh AmDocument2 pagesShubh AmChhotuNo ratings yet

- Company Profi Le: IHC HytopDocument13 pagesCompany Profi Le: IHC HytopHanzil HakeemNo ratings yet

- UPGRADEDocument2 pagesUPGRADEVedansh OswalNo ratings yet

- Data SheetDocument14 pagesData SheetAnonymous R8ZXABkNo ratings yet

- VB 2Document11 pagesVB 2Sudhir IkkeNo ratings yet

- Javascript: What You Should Already KnowDocument6 pagesJavascript: What You Should Already KnowKannan ParthasarathiNo ratings yet

- PaySlip ProjectDocument2 pagesPaySlip Projectharishgogula100% (1)

- Hillingdon Health Visiting ServiceDocument12 pagesHillingdon Health Visiting ServiceAnnikaNo ratings yet

- Converting An XML File With Many Hierarchy Levels To ABAP FormatDocument8 pagesConverting An XML File With Many Hierarchy Levels To ABAP FormatGisele Cristina Betencourt de OliveiraNo ratings yet

- Unit 13 AminesDocument3 pagesUnit 13 AminesArinath DeepaNo ratings yet

- Schedule of Charges General Banking 2022Document18 pagesSchedule of Charges General Banking 2022Shohag MahmudNo ratings yet

- A CASE STUDY OF AU SMALL FINANCE BANK'S SHRIRAMPUR BRANCHDocument9 pagesA CASE STUDY OF AU SMALL FINANCE BANK'S SHRIRAMPUR BRANCHprajakta shindeNo ratings yet

- Pass Issuance Receipt: Now You Can Also Buy This Pass On Paytm AppDocument1 pagePass Issuance Receipt: Now You Can Also Buy This Pass On Paytm AppAnoop SharmaNo ratings yet

- A. Readings/ Discussions Health and Safety Procedures in Wellness MassageDocument5 pagesA. Readings/ Discussions Health and Safety Procedures in Wellness MassageGrace CaluzaNo ratings yet

- Technical Skills:: Surabhi SrivastavaDocument3 pagesTechnical Skills:: Surabhi SrivastavaPrasad JoshiNo ratings yet

- Instruction/Special Maintenance Instruction (IN/SMI)Document2 pagesInstruction/Special Maintenance Instruction (IN/SMI)ANURAJM44No ratings yet

- Building A Computer AssignmentDocument3 pagesBuilding A Computer AssignmentRajaughn GunterNo ratings yet

- For-tea Tea Parlour Marketing Strategy Targets 40+ DemographicDocument7 pagesFor-tea Tea Parlour Marketing Strategy Targets 40+ Demographicprynk_cool2702No ratings yet