Professional Documents

Culture Documents

ASME+Inner and Outer Cracks in Internally Pressurized Cylinders

Uploaded by

882636013Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASME+Inner and Outer Cracks in Internally Pressurized Cylinders

Uploaded by

882636013Copyright:

Available Formats

A. S. K O B A Y A SH !

Professor,

M em . A SM E

N . P O L V A N I C H

Graduate Student.

A. F. EMERY

Professor,

M em . A SM E

W. J. LOVE

Professor,

M em . A SM E

University of W ashi ngton,

Departm ent of M echanical Engineering,

Seattle, W ashington

I nner and Outer C rack s in I nternally

Pressuriz ed C ylinders

Stress intensity factors of pressurized surface cracks at the internal surface and un-

pressurized surface cracks at the external surface of an internally pressurized cylinder

are estimated from stress intensity factors of a semi-elliptical crack in a finite-thickness

fiat plate. Curvature effects of the cylinder are determined by comparing two-dimen-

sional finite element solutions of fixed-grip, single edge-notched plates and single edge-

notched cylinders. Stress intensity factors for semi-elliptical cracks with crack aspect

ratios of b/a = 0.2 and 0.98 at crack depths up to 80 percent of the cylindrical wall

thickness are shown for internally pressurized cylinders with outer to inner diameter

ratios, R/Ri, ranging from 10:9 to 5:4 f

or ol

^

er

surface cracks and to 3:2 for inner

surface cracks.

I ntroduction

During the past two years, the authors have used stress in-

tensity factor solutions of a semi-elliptical crack in fiat plate with

a curvature correction to estimate the stress intensity factors of

an unpressurized inner semi-elliptical crack in a pressurized

cylinder [l]

1

and in a thermally shocked cylinder [2] as well as

in a quarter-elliptical crack at the bore of a rotating disk [3].

Some uncertainty in modeling the curvature correction in these

earlier papers led later to revisions in the curvature correction

as well as in the format of presenting the final results [4],

The purpose of this paper is to apply this numerical technique

in estimating the stress intensity factors of a pressurized semi-

elliptical crack at the internal surface (pressurized inner crack)

and an unpressurized semi-elliptical crack at the external sur-

face (outer crack) of an internally pressurized cylinder. Despite

the practical significance of these two problems neither of these

two surface crack configurations has yet been examined in detail.

An approximate three-dimensional solution for a pressurized

inner semi-elliptical crack of a pressurized cylinder was con-

sidered by Underwood [5]. A nother approximate solution for

unpressurized inner and outer-semi-elliptical crack in a pres-

^umber s in brackets designate References at end of paper.

C ontributed by the P ressure V essels and P iping Division and presented

at the P etroleum Mechanical Engineering and P ressure V essels and P iping

C onference, Mexico C ity, Mexico, September 10-24, 1976, of TH E A MERI C A N

SO C I ETY O F MEC H A N I C A L EN G I N EERS. Manuscript received at A SME H ead-

quarters. May 6, 1976. P aper N o. 76-P V P -6.

surized cylinder was obtained by Kobayashi [6]. N either Under-

wood's nor Kobayashi's solutions studied cracks of a depth in

which the effect of back surface had to be considered. The ap-

plication of three-dimensional finite element method to these

problems is still limited at this time due to limitation in computer

capacity and computing costs, despite increasing availability

of three-dimensional finite element codes. The only three-di-

mensional finite element solution to either of the two problems

under consideration is that of Blackburn and H ellen [7] who

computed the stress intensity factor of one pressurized inner

semi-elliptical crack and one unpressurized outer semi-elliptical

crack in a pressurized cylinder with an outer-to-inner diameter

ratio of R/Ri = 1. 461.

O n the other hand, the two-dimensional counterpart of these

two sets of problems has been studied by several investigators.

For example, Bowie and Freese [8] and more recently C lifton,

et al. [9] studied pressurized inner cracks in a pressurized cylinder

and Emery, et al. [10] considered outer cracks in a pressurized

cylinder. The latter problem was also studied by two-dimen-

sional finite element analysis [11].

The above brief review of available two- and three-dimensional

solutions of the two practical problems considered by this paper

indicates the need for more accurate three-dimensional analysis

of surface cracks in a pressurized cylinder.

Method of Approach

The method of approach used in this paper is the previously

described iterative procedure based on the alternating technique

for solving three-dimensional problems in fracture mechanics.

This procedure, with the exception of recent developments by

Journal of Pressure Vessel Technology FEB R UA R Y 1977 / 83

Copyright 1977 by ASME

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 07/11/2014 Terms of Use: http://asme.org/terms

r

^

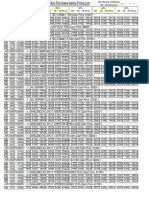

M K M cM K S-|7jj?-./^75(o

Z

8in

2

e b

2

cos

2

e)

l/

M

KS'

K

i/{~hr

,/vs

<

a2s| n29

+

b

*

mZ

* >

l/4

} ///

W-J&

(Ro/rr*l

^ " ' " " o W

b " Pi

2R;'

^R5

Fig. 1 Procedure for estimating stress intensity factor of an outer

semi-elliptical crack in a pressurized cylinder

W&,

"(Ro+Rj)

R0/ Ri =5 / 4

R0/R| * | 0/ 9

CRACK LENGTH , b/(R0-Rj)

Fig. 3 Curvature correction, M o(0), for an outer crack in a pressurized

cylinder /?//?, between 5/4 and 10/9

Smith and his coworkers [12, 13], is limited t o surface cracks in propriate fictitious pressures on the fictitious part of t he ellip-

flat plates. The procedure has been used extensively and is well

documented by t he authors [14, 15] and thus will not be re-

peated here. The actual numerical procedure was improved

substantially by Kobayashi and Enet anya [14] who used ap-

tical crack which protrudes into t he empt y space to force the

numerical convergence of t he iterative procedure. F urt her dis-

cussions on this numerical convergence appear in reference [13].

The stress intensity magnification factors, MKS(0), for a semi-

elliptical crack in flat plates were then converted to those in a

cylinder by using a curvature correction, M

c

(6). The procedure

r

oD~L/ "['"i+'v

a.

1.4

5

1.2

Z

o

I -

a

. 1

(

O

o

UJ

5 i.o

I -

5

O 0. 9

.2 .4 .6 8

CRACK LENGTH, ^/ (Ro-Ri )

1.0

Fig. 2 Curvature correction, Mc(0), for a pressurized inner crack in i

pressurized cylinder of R0/Ri less than 3/2

"%!'> PI

V >

(Ro/Ril*-!

+ 1

Pi INNER PRESSURE

il(V)"Oee<r)

20 40 60 80 100

CIRCULAR ANGLE.fi DEGREES

Fig. 4 Stress intensity magnification factor of an inner semi-elliptical

crack in a pressurized cylinder

84 / FEB R UA R Y 1977 Transactions of the ASME

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 07/11/2014 Terms of Use: http://asme.org/terms

CIRCULAR ANGLE, 8 DEGREES

Fig. 5 Stress intensity magnification factor of an inner semi-elliptical

crack in a pressurized cylinder

used to estimate the curvature correction factor is described in

references [1-4].

The resultant stress intensity magnification factor, MK(6),

for the two problems in this paper are not presented in final

graphical form as in references [1 and 2]. Rather, the users are

asked to multiply the flat plate solutions by the corresponding

curvature correction in order to obtain the resultant stress in-

tensity factor. This format of presenting the anal results allows

for future upgrading of the curvature correction should better

modeling of the curvature correction become available.

Elliptical C rack in a Flat Plate

The pressure profile prescribed on the surface of a semi-ellip-

tical crack in a flat plate is restricted by the availability of these

solutions in the following form

<T(X, y) = -Boo + Boi

0-0

+ Bo

+ B (1)

CIRCULAR ANGLE, 8 DEGREES

Fig. S Stress intensity magnification factor of an inner semi-ellip-

tical crack in a pressurized cylinder

where the cartesian coordinate system and the geometry for

this outer semi-elliptical crack are given in Fig. 1. By's are the

yet-to-be-determined pressure coefficients and b is the semi-

minor diameter of the ellipse. This pressure profile is least

square fitted to the appropriate hoop stress, 0t>&{r), generated

by the prescribed internal pressure, pi, on the uncracked cylinder.

For the pressurized inner semi-elliptical crack, the internal pres-

sure, pi, is added to the hoop stress.

The stress intensity factors for a semi-elliptical crack in a flat

plate and subjected to one of the four components of the pressure

distribution, (r(x, y) = 1, (1 - (/&)), (1 - (y/b)f,

( 1

i.y/b)f, shown in equation (1), are given in references [1 and

2], A simple superposition of these four solutions will then yield

the flat plate solutions with prescribed crack pressures.

Two-Dimensional Analogs

The curvature correction, M{d), previously derived for an

unpressurized inner crack [4] is used for the pressurized inner

semi-elliptical crack problem. The justification for such use is

obvious from the fact that a single curvature correction curve

appears to cover the hoop stress distributions in pressurized

cylinders with external to internal radius ratios, Ro/Ri, varying

from 10/9 to 3/ 2. This insensitivity of the curvature correction

to the Ro/Ri values indicates that it should be applicable to the

inner semi-elliptical crack problem despite the added constant

crack pressure of pu For the unpressurized outer semi-elliptical

crack problem, a new curvature correction, M

e

(6), was deter-

mined following the procedure described .in reference [4].

Results

C urvature Correction M

c

(). I n order to make this paper self-

contained, the curvature correction, M

c

(6), reported in references

[1 and 2] and which is also used here for the pressurized inner

crack problem is reproduced in Fig. 2.

Fig. 3 shows the curvature correction, M

c

(d), for an outer

crack in a pressurized cylinder for Ro/Ri < 5/4. A comparison

of Figs. 2 and 3 shows, as expected from geometric considerations,

that the curvature correction for an outer crack is slightly larger

than that for an inner crack.

The crack depth, b, in Figs. 2 and 3 is the local crack depth

along the periphery of the semi-elliptical crack. The curvature

correction, M

c

(6), thus starts with no correction at the major

axis of the semi-elliptical crack or 6 = 0 deg and reaches its

extreme value at the deepest penetration of the elliptical crack

surface at 6 = 90 deg. N ote that the curvature correction for

the outer crack varies slightly with the cylindrical geometry and

approaches that of the pressurized inner crack for Ro/Ri = 10/ 9.

Pressurized Inner Semi-Elliptical Crack in a Pressurized Cylinder.

For a pressurized inner semi-elliptical crack in a pressurized

cylinder, the crack pressure represented by equation (1) must be

least square fitted to the hoop stress with the superimposed

prescribed inner pressure of

Journal of Pressure Vessel Technology

FEB R UA R Y 1977 / 85

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 07/11/2014 Terms of Use: http://asme.org/terms

20 40 60 80 100

C IRC ULAR A NGL E, 8 DEGREES

Fig. 7 Stress i ntensi ty m agni fi cati on factor of an i nner sem i -ci rcul ar

crack i n a pressuriz ed cyl i nder

ffwfo y) = p<

Ro*/(Ri + yf + l

RMRi* - 1

(2)

where p,- is the prescribed inner pressure. The coordinate system

for the inner surface crack is identical to that shown in Fig. 2.

The least square fitting was accomplished within 0.2 percent of

the hoop stress represented by equation (2).

Using the flat plate solutions in references [1 and 2], the stress

intensity magnification factor, MKS{6), was obtained for a pres-

surized semi-elliptical crack in a flat plate as shown in Figs. 4

i

eet'l -Pi

(Rp/r) +1

(R 0/R i)

2

-I

. 2

ZI <Y >"<W >

p, INNER PRESSURE

Ro/Rj =5/4

R0/R; = 7/6

R [/R j "10/9

20 40 60 80 100

C IRC ULAR A NGL E, 8 DEGREES

Fig. 9 Stress i ntensi ty m agni fi cati on factor of an outer sem i -el l i p-

ti cal crack i n a pressuriz ed cyl i nder

through,8. I n order to show the peculiarities of the two boundary

value problems considered in this paper, the . stress intensity

magnification factors are normalized with the local stress intensity

factor from the basic solution of a completely embedded elliptical

crack.

2

As a result, despite a dip in stress intensity magnifica-

tion factor, MKS(6), for crack aspect ratio of b/a = 0. 2, the actual

stress intensity factor exhibits a minimum value at the front

surface, 6 = 0 deg, and attains a maximum value at its deepest

penetration, 6 = 90 deg. For a near semi-circular crack with

crack aspect ratio of b/a = 0. 98, however, the maximum stress

!

E(k) which appears in F igs. 4 through 16 is the complete elliptic integral of

the second kind with i? = 1 (.b/a)'.

20 40 60 80

C IRC ULAR A NGL E, 6 DEGREES

Fig. 8 Stress i ntensi ty m agni fi cati on factor of an inner sem i-circular

crack in a pressuriz ed cyl i nder

R 0/R ;"3/2

0 20 40 60 80

C IRC ULAR A NGL E. fi DEGREES

Fig. 10 Stress intensity m agni fi cati on factor of an outer sem i -el l i p-

tical crack i n a pressuriz ed cylinder i

86 / FEB R UA R Y 1977 Transactions of the ASME

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 07/11/2014 Terms of Use: http://asme.org/terms

or

o

i -

o

<

7

O

C

A

T

u.

7

U)

<

s

I

T

Y

z

CO

. o

+

CO

c

N

k

^

t ?

. (Ro/rl'+l

9 9

'<R 0/R j)

2

-I

20 ' 40 60 80

C IRC ULAR A NGL E, 9 DEGREES

R 0/R j=3/2

R 0/R | = 5/4

R 0/R j=7/6

Ro/Ri = I O/9

K

O

N

F

A

C

T

T

I

O

<

z

<

1 -

co

z

H

Z

t o

CO

I d

C

jr

CO

CY

V )

o

u

+

CD

e

U)

"4

N ~

> | u

h

\

iC

Ji .

CD

100

Fig. 11 Stress

ti cal crack i n a

i ntensi ty m agni fi cati on factor of an outer sem i -el l i p-

pressuriz ed cyl i nder

R 0 / R ; - 3/ 2

R 0/R ; 5/4

R o/R j=I O /9

C IRC ULAR A NGL E, 9 DEGREES

Fig. 13 Stress i ntensi ty m agni fi cati on factor of an outer sem i -ci rcul ar

crack i n a pressuriz ed cyl i nder

intensity factors occur near the free surface and the actual stress

intensity factor continuously decreases with increasing 9 even

at the maximum crack depth of b/(B Bi) = 0. 8. A lso note

that the differences in M

K

s{6) at the front surface, 6 = 0 deg,

and the deepest penetration, 6 - 90 deg, are much larger than

those at the flat tension plate problem due to the stress gradient

in the hoop stress which attains a maximum value at the front

surface.

The stress intensity magnification factor, MK{6), for a pres-

surized inner semi-elliptical crack in a pressurized cylinder is thus

obtained from

M

K

{8) = M

c

(d) MKS{6)

(3)

V R | "3/ 2

Ro/Ri= 5/4

R o/ R i ' 7/ 6

Ro/R|> 10/9

l . 0

L

O 20 40 60 80 100

C IRC ULAR ANGLE ,8 DEGREES

Fig. 12 Stress i ntensi ty m agni fi cati on factor of an outer sem i -ci rcul ar

crack in a pressuriz ed cyl i nder

where the curvature correction, M

c

(d), which is taken from the

Fig. 2 for this problem, is a function of 6 and varies with the

local crack depth, b, along the crack periphery.

Unpressurized O uter Semi-Elliptical Crack in a P ressurized Cyl-

inder. For the unpressurized outer semi-elliptical crack in a

pressurized cylinder, the crack pressure represented by equation

(1) must be least square fitted to the hoop stress of

c(z, V) = Pi

R

2

/(R ~ Vf + 1

Ro^fR? - 1

(4)

where the origin of the coordinate system used in equation (4) is

now located on the external surface of the cylinder as shown in

Fig. 3.

A gain by the use of the flat plate solutions in references [1 and

2], the stress intensity magnification factor, MKS(9), is obtained

for an unpressurized outer semi-elliptical crack in a flat plate

shown in Figs. 9 through 13. The notable differences between

MRS values for the pressurized inner cracks and the outer cracks

are the increased MRS values at the front surface, 6 = 0 deg.

A lso the stacking sequences of the MKS curves for varying R

0

/Bi

ratios are reversed in the pressurized inner and outer crack

problems.

The actual stress intensity factor, MK{9), for the unpres-

surized outer semi-elliptical crack in a pressurized cylinder is

obtained from equation (3) using the appropriate curvature cor-

rection, M

c

{6), of Fig. 3 and the MKS(8) values in Figa. 9 through

13.

Discussion

The stress intensity magnification factors for a flat plate,

MKS(6), reported in this paper are for an oblong crack of b/a

= 0.2 and a nearly semicircular crack of b/a = 0. 98. For semi-

elliptical cracks with a crack aspect ratio of 0.2 < b/a < 0. 98,

a reasonable estimate of MKS value can be obtained by linear

interpolation of these two extreme values [15].

Using this interpolation procedure, the stress intensity mag-

nification factors, MK, can be compared with those obtained by

finite element analysis by Blackburn, et al. [7], who computed

Journal of Pressure Vessel Technology FEB R UA R Y 1977 / 87

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 07/11/2014 Terms of Use: http://asme.org/terms

o

V P|

S?ii

p, = INNER PRESSURE

R/ Ri - 3/ 2

^ "

) = P i

L ( V R ^ " l 'J

20 40 60 80

CIRCULAR ANGLE,S DEGREES

Fig. 14 Stress Intensity magnification factor of a pressurized inner

semi-elliptical crack in a pressurized cylinder

Itf-Ri*

P| INNER PRESSURE

R/Ri = 3/2

b/a 0.6

b/Q 0.98J

THIS PAPER

UNDERWOOD [ 5]

0 0.2 0.4 0.6 0.8

CRACK DEPTH , b/(R0-Rj)

Fig. 16 Stress intensity magnification factor of a pressurized inner

semi-elliptical crack in a pressurized cylinder

the stress intensity factors along the crack periphery of a pres-

surized inner semi-elliptical crack and an outer semi-elliptical

crack with a crack aspect ratio of b/a = 0.6 and a crack depth

b/(R Ri) = 0.4 in a pressurized cylinder of R

0

/Rt = 1.461

Figs. 14 and 15 show the interpolated MK{6) values for semi-

elliptical cracks with crack aspect ratios of b/a = 0. 2, 0. 4, 0. 6,

0. 8 and 0.98 at a crack depth of b/(R

0

.Ri) = 0.4 in a pressurized

cylinder of R/Ri = 3/ 2. MK{6) values obtained by Blackburn,

et al. [7], who considered a cylindrical geometry of R/Ri =

1.4615, differs from the R

0

/Ri = 1.5 used in Figs. 14 and 15,

(Rp/r) +1

Fig

ica!

20 40 60 80

2* CIRCULAR ANGLE.fi DEGREES

15 Stress intensity magnification factor of an outer semi-ellip-

crack in a pressurized cylinder

respectively. The higher finite element results in Fig. 14 could

be accounted for by this difference in cylindrical geometry.

The 15 percent higher finite element results at 6 = 0 deg in Fig.

15 could also be accounted for by this large difference in cylin-

drical geometries from which M

C

{B) was derived.

For a pressurized inner crack, the results in this paper at the

deepest crack penetration, i. e. B = 90 deg, can be compared

with the results of Underwood [5]. For R

0

/Ri = 1.5, the stress

intensity factor of the deepest penetration was computed follow-

ing Underwood's approximate formula and plotted in Fig. 16

together with the results of this paper. A lthough reasonable

agreement between the two results was expeoted for shallow

cracks, the large differences between the two results at deeper

crack depth demonstrates the importance of the back surface

correction in these deep surface flaw problems.

C onclusions

1 Using the procedure described in reference [4], the stress

intensity magnification factors were derived for pressurized

inner and unpressurized outer semi-elliptical cracks of b/a => 0.2

and 0.98 at crack depths of b/a = 0. 4, 0.6 and 0.8 in a pressurizod

cylinder of RJRi = 10/9, 7/6, 5/4 and 3/2 (inner crack only).

2 Good correlations were obtained with the stress intensity

factors obtained by Blackburn, et al. [7], who used three-dimen-

sional finite element analysis to analyze a pressurized inner

crack with b/a = 0.6 at a crack depth of b/(R Ri) = 0.4 in a

pressurized cylinder with R

a

/Ri = 1.461.

Ack nowledgment

The work reported in this paper is sponsored by the Electric

P ower Research I nstitute under C ontract N o. RP 231-0-0. The

authors wish to thank Drs. C onway C han and A . Gopalakrish-

nan of EP RI for their encouragement throughout the course of

this research program.

88 / FEB R UA R Y 1977 Transactions of the ASME

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 07/11/2014 Terms of Use: http://asme.org/terms

References

1 Kobayashi, A . S. , P olvanich, N . , Emery, A . F . , and L ove,

W. J. , "Stress I nt ensi t y F act or of a Surface C rack in a P res-

surized C ylinder," Computational Fracture Mechanics, E. F .

Rybicki and S. E. Bengley, eds. , A SME, 1975, pp. 121-132.

2 Kobayashi, A . S. , Emery, A . F . , P olvanich, N . , and L ove,

W. J. , "Surface F law in a Thermally Shocked H ollow C ylinder, "

Trans, of the 3rd Int. Conf. on Struc. Mech. in Reactor Tech.,

C EC A , C EE, C EEA , L uxembourg, 1975, P aper G 4/ 3.

3 Kobayashi, A . S. , Emery, A , F . , P olvanich, N . , and L ove,

W. J. , "C orner F law at t he Bore of a Rotating Disk," Journal

of Engineering for Power, TRA N S. A SME, V ol. 98, Ser. A , N o.

4, O ct. 1976, pp. 465-472.

4 Kobayashi, A . S. , Emery, A . F . , P olvanich, N . , and L ove,

W. J. , "Surface F law in a P ressurized and Thermally Shocked

H ollow C ylinder," to be published in t he Int. Journal of Pressure

Vessels and Pipings.

5 Underwood, J. H . , "Stress I nt ensi t y F actors for I nternally

P ressurized Thick-Wall C ylinder," Stress Analysis and Growth

of Crack, A STM STP 513, 1972, pp. 59-70.

6 Kobayashi, A . S. , "A Simple P rocedure for Est i mat i ng

Stress I nt ensi t y F actor in Region of H igh Stress G radi ent , "

Significance of Defects in Welded Structures, T. Kanazawa and

A . S. Kobayashi, eds. , University of Tokyo P ress, 1974, pp.

127-143.

7 Blackburn, W. S. , and H ellen, T. K. , "C alculation of

Stress I ntensity F actors for Elliptical and Semi-Elliptical C racks

in Blocks and C ylinders," C entral Electricity G enerating Board

Report N o. RD/ B/ N 3103, Jul y 1974.

(Abstracts cont'd from p. 82)

Moment C apability of V alves Using Semi-A nalytical Finite Element

A pproach (76-P et-38), by M. S. Kalsi, Manager, Design A nalysis

A ssoc. Mem. A SME, and B. L . McDougal, Engineer, Design

A nalysis, W-K-M V alve Division, A C F I ndustries, H ouston, Tex.

C omparison of test results with analysis shows t hat t he semi-

analytical finite-element technique can be used to accurately

predict t he behavior of thick axisymmetric structures under non-

axisymmetric loadings. The application of this method to a valve

subjected to pipe bending moment is presented.

High Notch Toughness Steel for Large LPG Tanks (76-Pet-57), by E.

V . Bravenec, Supervising Metallurgist, Quality A ssurance,

H ouston Works, Mem. A SME; and R. L . H artzell, Supervisor,

Technical Services, Mem. A SME, A rmco Steel C orp. , H ouston,

Tex. H igher C harpy V -notch impact (C V N ) energy t han is

normally exhibited by A STM A 537 C lass 2 plate was needed to

provide t he C V N energy of 35 ft-lb at -50 F (48 J at -46 C )

specified in the' heat-affected zones of t he weldments in large

L P G tanks exceeding 127,000-m

3

capacity. Using special process-

ing and rare eart h additions for sulfide shape control, plate was

produced with C V N values more than twice those of conventional

plate. The C V N values in the heat-affected zones were met and

exceeded in both t he longitudinal and transverse directions using

both t he shielded metal arc and t he submerged arc welding

processes.

Boreholes' Stability and I ts P rognosing in L edge Rock Masses (76-

P et-58), by I . A . Turchaninov, P rofessor, Director of Mining I n-

stitute of Kola Branch, of t he USSR A cademy of Sciences, R. V .

Medvedev, and E. V . Kasparjan, Senior Research Workers, Mi n-

ing I nstitute, S. M. Kirov Kola Branch of the USSR, A cademy of

Sciences, Murmansk Region, USSR. We suggest t he method

which permits to estimate and make prognosis of borehole stabil-

8 Bowie, O . L . , and F reese, C . E. , "Elastic A nalysis for

Radial C rack in a C ircular Ri ng, " Engineering Fracture Mechan-

, ics, V ol. 4, N o. 2, June 1972, pp. 315-322.

9 C lifton, R. J. , Simonson, E. R. , Jones, A . H . , and G reen,

S. J. , "Det ermi nat i on of t he C ritical Stress-I ntensity F act or

Kio from I nternally P ressurized Thick-Walled V essels," Ex-

; perimental Mechanics, V ol. 16, N o. 6, June 1976, pp. 233-238.

10 Emery, A . F . , and Segedin, C . M. , "The Eval uat i on of t he

' Stress I nt ensi t y F act or for C racks Subjected to Tension, Torsi on

and F lexion by an Efficient N umerical Technique, " Journal of

Basic Engineering, TRAN Si A SME, V ol. 94, Series D. , N o. 2,

June 1972, pp. 387-393.

11 Kobayashi, A . S. , "F ract ure Mechanics, " Experimental

Techniques in Fracture Mechanics, A . S. Kobayashi, ed. , I owa

J St at e University P ress, 1973, pp. 4-37.

6

12 Browning, W. M. , "The A nalysis of a Semi-C ircular

C rack Emanat i ng from a H ole in a P l at e, " P hD thesis, C olorado

r

St at e University, Dec. 1974.

i 13 G anong, G . C , "Quarter-Elliptical C racks Emanat i ng

from H oles in P l at es, " P hD thesis, C olorado St at e University,

, Jul y 1975.

' 14 Kobayashi, A . S. , and Enet anya, A . N . , "Stress I nt ensi t y

1 F act or of a C orner C rack, " Mechanics of Crack Growth, A STM

. STP 590, 1975, pp. 477-495.

15 Kobayashi , A . S. , Enet anya, A . N . , and Shah, R. C ,

E "Stress I nt ensi t y F actors of Elliptical C racks, " Prospects of

i Fracture Mechanics, G . C . Sih, H . C . van Elst, and D. Broek,

1 eds. , N oordhoff I nt ernat i onal P ublishing, L eyden, The N et her-

lands, 1975, pp. 525-544.

i t y in ledge rock masses on t he basis of complex determination o

rock properties by core tests and calculations of destruction by

t he theory of maxi mum equilibrium.

Well-H ole Temperature Distribution in the P resence of A quifers (76-

P et-59), by C . A . O ster, Battelle-N orthwest, and W. A . Scheffler,

Joi nt C enter for G raduat e Study, Mem. A SME, Battelle, P acific

N orthwest L aboratories, Richland, Wash. A method is described

for determining t he t emperat ure distribution in a circulating

drilling fluid when aquifers are present in t he formation. The

dept h of an aquifer relative t o t he well dept h is shown to be an

i mport ant parameter. A n aquifer near t he surface has much less

influence on t he t emperat ure distributions t han one located near

the well bot t om. I f t he drilling fluid has much greater density

t han t he entering formation water, then t he temperature dis-

tributions are altered significantly.

V ibration Energy: A Quick A pproach to Rotor Dynamic O ptimization

(76-P et-60), by H . R. Simmons, Senior Research Engineer, A pplied

P hysics Div. , Southwest Research I nstitute, San A ntonio, Tex.

Mem. A SME. A method is described for identifying the most

significant rotor part s contributing to a vibration problem and

for calculating critical speed changes due to structural modifica-

tion of those part s. A pplication of t he method, which is based

on t he principles used by Rayleigh, requires no more t han inspec-

tion of or direct hand calculations from tabulated energy distribu-

tion functions. Rotor optimization is accomplished by relating

t he potential critical speed benefit of a proposed fix with its real

cost and degree of difficulty. The computer technique for gen-

erating t he baseline critical speeds and energy distribution tables

has been adapt ed to a portable telephone computer terminal.

Thus, this technique is highly suitable for troubleshooting and

correcting field vibration problems.

(Abstracts cont'd on p. 99)

Journal of Pressure Vessel Technology

FEB R UA R Y 1977 / 89

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 07/11/2014 Terms of Use: http://asme.org/terms

You might also like

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Final Report ABAQUS Project: The Main Steps of Building A Model in ABAQUSDocument5 pagesFinal Report ABAQUS Project: The Main Steps of Building A Model in ABAQUSSandip PardeshiNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Cop 04Document26 pagesCop 04Pinto CarlosNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- FEM simulation of heat equation on cylindrical rodDocument19 pagesFEM simulation of heat equation on cylindrical rodMohammad Rizwan MalikNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 1 s2.0 S1877705815040795 MainDocument19 pages1 s2.0 S1877705815040795 Main882636013No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Buckling Analysis of Filament-Wound Thick Composite Cylinder Under Hydrostatic PressureDocument5 pagesBuckling Analysis of Filament-Wound Thick Composite Cylinder Under Hydrostatic Pressure882636013No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Journal of Sound and Vibration: Fabien TreyssedeDocument17 pagesJournal of Sound and Vibration: Fabien Treyssede882636013No ratings yet

- Buckling Analysis of a Thin-Shell CylinderDocument28 pagesBuckling Analysis of a Thin-Shell CylinderOmid BehniyaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 721 2714 1 PBDocument7 pages721 2714 1 PBalokanand1906No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- A Two-Stage Model For Predicting Crack Growth Due To Repeated Thermal ShockDocument10 pagesA Two-Stage Model For Predicting Crack Growth Due To Repeated Thermal Shock882636013No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Kirkhope1990+stress Intensity Factor Equations For Single and Multiple Cracked Pressurized Thick-Walled CylindersDocument9 pagesKirkhope1990+stress Intensity Factor Equations For Single and Multiple Cracked Pressurized Thick-Walled Cylinders882636013No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Thermal Fatigue Crack Growth Modelling and TestingDocument5 pagesThermal Fatigue Crack Growth Modelling and Testing882636013No ratings yet

- A Critical Plane Fatigue Model Applied To Out-Of-phase Bending and Torsion Load ConditionsDocument12 pagesA Critical Plane Fatigue Model Applied To Out-Of-phase Bending and Torsion Load ConditionsIndranil BhattacharyyaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- A Critical Plane Fatigue Model Applied To Out-Of-phase Bending and Torsion Load ConditionsDocument12 pagesA Critical Plane Fatigue Model Applied To Out-Of-phase Bending and Torsion Load ConditionsIndranil BhattacharyyaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Critical Plane Fatigue Model Applied To Out-Of-phase Bending and Torsion Load ConditionsDocument12 pagesA Critical Plane Fatigue Model Applied To Out-Of-phase Bending and Torsion Load ConditionsIndranil BhattacharyyaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Weight Functions and Stress Intensity Factors For Axial Cracks in Hollow Cylinders, C.-C.M, J.-I .Huang and C.-h.TsaiDocument8 pagesWeight Functions and Stress Intensity Factors For Axial Cracks in Hollow Cylinders, C.-C.M, J.-I .Huang and C.-h.Tsai882636013No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Dimensionless stress intensity factors for cracked thick cylindersDocument7 pagesDimensionless stress intensity factors for cracked thick cylinders882636013No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- ++effects of Thermal Gradients On Fracture Mechanics, Ognjen Ognjanovic, Katarina Maksimovic, Dragi StamenkovicDocument5 pages++effects of Thermal Gradients On Fracture Mechanics, Ognjen Ognjanovic, Katarina Maksimovic, Dragi Stamenkovic882636013No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Stress Intensity Factor For A Surface Crack Due To Moving Impact LoadingDocument10 pagesThe Stress Intensity Factor For A Surface Crack Due To Moving Impact Loading882636013No ratings yet

- 4 Fracture MechanicsDocument17 pages4 Fracture MechanicsSubhash AhujaNo ratings yet

- ASME+Inner and Outer Cracks in Internally Pressurized CylindersDocument7 pagesASME+Inner and Outer Cracks in Internally Pressurized Cylinders882636013No ratings yet

- STP381 ForewordDocument11 pagesSTP381 Foreword882636013No ratings yet

- MESHII Repository 10Document16 pagesMESHII Repository 10882636013No ratings yet

- Transient Thermal Contact Problem For Axial Crack in A Hollow Circular CylinderDocument13 pagesTransient Thermal Contact Problem For Axial Crack in A Hollow Circular Cylinder882636013No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Thermal Stress Intensity Factors For A Cracked Cylinder Under Transient Thermal LoadingDocument11 pagesThermal Stress Intensity Factors For A Cracked Cylinder Under Transient Thermal Loading882636013No ratings yet

- Multiaxial Stress in The Fatigue Life of Mechanical PartsDocument8 pagesMultiaxial Stress in The Fatigue Life of Mechanical Parts882636013No ratings yet

- FractureDocument16 pagesFractureElvis Osorio SantanderNo ratings yet

- LS-DYNA Tie-Break Contacts Modeling GuideDocument33 pagesLS-DYNA Tie-Break Contacts Modeling Guidemr.aikido100% (2)

- 04 PDFDocument42 pages04 PDFAla ThajilNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- PriceListHirePurchase NormalDocument54 pagesPriceListHirePurchase NormalAfzaal AwanNo ratings yet

- Patran PlateDocument6 pagesPatran PlateankitfgietNo ratings yet

- Assignment 2 - 2023 - SolutionsDocument23 pagesAssignment 2 - 2023 - SolutionsLinhan ChuNo ratings yet

- G38-01 (2013) Standard Practice For Making and Using C-Ring Stress-Corrosion Test SpecimensDocument8 pagesG38-01 (2013) Standard Practice For Making and Using C-Ring Stress-Corrosion Test SpecimensislamakthamNo ratings yet

- Richardson and ZakiDocument1 pageRichardson and ZakiMalik Saqib ShahzadNo ratings yet

- Solar Water HeatingDocument2 pagesSolar Water HeatingCatherine Diccion LaciapagNo ratings yet

- 3-Torsion of Circular Shafts PDFDocument28 pages3-Torsion of Circular Shafts PDFMohamad Zaid75% (4)

- HDD Design and MethodologyDocument14 pagesHDD Design and MethodologyVipin Gupta100% (4)

- 7 Ab Biomecanica IPRO 2021Document121 pages7 Ab Biomecanica IPRO 2021Mary SmileNo ratings yet

- States of Matter: Guided PracticeDocument18 pagesStates of Matter: Guided PracticeVICTOR AXEL GARRICO HERNANDEZNo ratings yet

- How to Separate Chemical MixturesDocument47 pagesHow to Separate Chemical MixtureschintanNo ratings yet

- ITG43r - 07 Report On Structural Design andDocument66 pagesITG43r - 07 Report On Structural Design andHarun AlrasyidNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Vignes H 2018Document9 pagesVignes H 2018Nguyễn TúNo ratings yet

- 12 - Deflection by Conjugate Beam MethodDocument7 pages12 - Deflection by Conjugate Beam MethodFrancis Ko Badongen-Cawi Tabaniag Jr.No ratings yet

- Exercise 2 - Embankment - PLAXIS Consolidation and Safety AnalysisDocument19 pagesExercise 2 - Embankment - PLAXIS Consolidation and Safety AnalysisRelu MititeluNo ratings yet

- PVT Properties of Crude Oils: Understanding Density, Viscosity & Phase BehaviorDocument121 pagesPVT Properties of Crude Oils: Understanding Density, Viscosity & Phase BehaviorRavi Shankar PatelNo ratings yet

- Definition, types and analysis of statically determinate and indeterminate beamsDocument47 pagesDefinition, types and analysis of statically determinate and indeterminate beamsJack PresadoNo ratings yet

- Blow-Through vs. Draw-Through Heating DesignsDocument1 pageBlow-Through vs. Draw-Through Heating DesignsAditya PatilNo ratings yet

- Experiment 3Document15 pagesExperiment 3Ashwin PurohitNo ratings yet

- The Diesel Effect in Hydraulic Systems - Material Damage Is The OutcomeDocument3 pagesThe Diesel Effect in Hydraulic Systems - Material Damage Is The Outcomeanil basnetNo ratings yet

- Rigid vs. Flexible Pile Caps - Case Study For 235 M. Delhi T.V. ToDocument6 pagesRigid vs. Flexible Pile Caps - Case Study For 235 M. Delhi T.V. ToPrashant MuleNo ratings yet

- Module 4. Lesson 2 Design Response SpectrumDocument6 pagesModule 4. Lesson 2 Design Response SpectrumRich Lenard L. MagbooNo ratings yet

- Designing Shotcrete As Primary Support in TunnelsDocument6 pagesDesigning Shotcrete As Primary Support in TunnelsAnonymous VkzquW39No ratings yet

- Stress-Strain Curve - WikipediaDocument3 pagesStress-Strain Curve - WikipediaTomy GeorgeNo ratings yet

- Two Phase Flow and Heat TransferDocument15 pagesTwo Phase Flow and Heat TransferRaghu Rambug100% (1)

- Co L, NP, AC, CGDocument8 pagesCo L, NP, AC, CGAnuj AroraNo ratings yet

- USFD in Rails & Welds DetectionDocument144 pagesUSFD in Rails & Welds DetectionLokeshwar YadagiriNo ratings yet

- Thermodynamics - MCQsDocument25 pagesThermodynamics - MCQsmujtabahassan100% (1)

- Weapons of Mass Instruction: A Schoolteacher's Journey Through the Dark World of Compulsory SchoolingFrom EverandWeapons of Mass Instruction: A Schoolteacher's Journey Through the Dark World of Compulsory SchoolingRating: 4.5 out of 5 stars4.5/5 (149)

- Summary: The 5AM Club: Own Your Morning. Elevate Your Life. by Robin Sharma: Key Takeaways, Summary & AnalysisFrom EverandSummary: The 5AM Club: Own Your Morning. Elevate Your Life. by Robin Sharma: Key Takeaways, Summary & AnalysisRating: 4.5 out of 5 stars4.5/5 (22)

- How to Talk to Anyone: Learn the Secrets of Good Communication and the Little Tricks for Big Success in RelationshipFrom EverandHow to Talk to Anyone: Learn the Secrets of Good Communication and the Little Tricks for Big Success in RelationshipRating: 4.5 out of 5 stars4.5/5 (1135)

- The 16 Undeniable Laws of Communication: Apply Them and Make the Most of Your MessageFrom EverandThe 16 Undeniable Laws of Communication: Apply Them and Make the Most of Your MessageRating: 5 out of 5 stars5/5 (72)

- Summary: Greenlights: by Matthew McConaughey: Key Takeaways, Summary & AnalysisFrom EverandSummary: Greenlights: by Matthew McConaughey: Key Takeaways, Summary & AnalysisRating: 4 out of 5 stars4/5 (6)

- Summary: It Didn't Start with You: How Inherited Family Trauma Shapes Who We Are and How to End the Cycle By Mark Wolynn: Key Takeaways, Summary & AnalysisFrom EverandSummary: It Didn't Start with You: How Inherited Family Trauma Shapes Who We Are and How to End the Cycle By Mark Wolynn: Key Takeaways, Summary & AnalysisRating: 5 out of 5 stars5/5 (3)