Professional Documents

Culture Documents

Canning

Canning

Uploaded by

Jatinder KumarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Canning

Canning

Uploaded by

Jatinder KumarCopyright:

Available Formats

Canning Process

Unit Operations

The typical unit operations in a canning plant

are as below.

Raw Material Cleaning

All food raw materials are cleaned before processing. The purpose is obviously

to remove contaminants, which range from innocuous to dangerous. It is important

to note that removal of contaminants is essential for protection of process equipment as well

as the final consumer. For example, it is essential to remove sand, stones or metallic particles

from wheat prior to milling to avoid damaging the machinery. The main contaminants are:

unwanted parts of the plant, such as leaves, twigs, husks;

soil, sand, stones and metallic particles from the growing area;

insects and their eggs;

animal excreta, hairs etc.;

pesticides and fertilisers;

mineral oil;

microorganisms and their toxins.

There are a number of cleaning methods available, classified into dry and wet methods, but a

combination would usually be employed for any specific material. Selection of the

appropriate cleaning regime depends on the material being cleaned, the level and type of

contamination and the degree of decontamination required.

Sorting and grading

All food products undergo some kind of sorting operation. There are a number of benefits,

including the need for sorted units in weight-filling operations and the aesthetic and

marketing advantages in providing units of uniform size or colour. In addition, it is much

easier to control processes such as sterilisation, dehydration or freezing in sorted food units;

and they are also better suited to mechanised operations such as size reduction, pitting or

peeling.

Peeling

Peeling of fruits and vegetables is frequently carried out in association with

cleaning. Mechanical peeling methods require loosening of the skin using one

of the following principles, depending on the structure of the food and the level

of peeling required

Steam is particularly suited to root crops. The units are exposed to high pressure

steam for a fixed time and then the pressure is released causing steam

to form under the surface of the skin, hence loosening it such that it can be

removed with a water spray.

Lye (12% alkali) solution can be used to soften the skin which can again be

removed by water sprays. There is, however, a danger of damage to the product.

Brine solutions can give a peeling effect but are probably less effective than

the above methods.

Abrasion peeling employs carborundum rollers or rotating the product in a

carborundum-lined bowl, followed by washing away the loosened skin. It is

effective but here is a danger of high product loss by this method.

Mechanical knives are suitable for peeling citrus fruits.

Flame peeling is useful for onions, in which the outer layers are burnt off

and charred skin is removed by high pressure hot water.

Blanching

Blanching is a mild heat treatment, but is not a method of preservation per se. It is a

pretreatment usually performed between preparation and subsequent processing. Blanching

consists of heating the food rapidly to a predetermined temperature, holding for a specified

time, then either cooling rapidly or passing immediately to the next processing stage.

Blanching is an important operation for vegetables in which air, water, or

steam can be used to heat the product to about 8899C, blanching is performed to:

1. inactivate enzymes responsible for quality degradation such as texture and color

changes,

2. remove air from the raw vegetables which results in better packing inside the can and

reduces chances of corrosion by reducing excess oxygen from the headspace;

3. prevent browning in certain products;

4. help to preheat the product before sealing;

5. soften the food and make it easier to fil in containers.

For blanching, the product can either be placed in hot water or be conveyed

through belt and exposed to hot water or steam. Blanching of vegetable soybean

at 100C for 90 seconds reduced the initial lipoxygenase activity by 99% (Mozzoni et al.

2009). However, the blanching operation produces the major portion of the effluent in a

canning plant. The use of microwave for blanching has potential to improve this situation.

Filling/Weighing

Prepared vegetables are placed into cans by means of a depositor. A depositor adds a

predetermined quantity of products in each can followed by the addition of brine (NaCl

and/or CaCl2). The can is not completely filled leaving about 1 inch of headspace is

important. Lower headspace can cause the ends of can to bulge and may also cause

understerilization.

Exhausting and Vacuum Closing

Exhausting is a key step to maintain vacuum. In this process, fille cans are passed through an

exhaust box containing water at about 90C so as to bring the temperature of the center of the

can to about 71C. The exhausting expands products and expels trapped air and gases.

Vacuum closing helps to retain the container shape and prevents distortion during retorting; it

maintains the concave position of the can and helps in reducing oxygen inside the can. Low

level of oxygen prevents discoloration that might happen due to oxidation of fats or vitamins;

it also reduces internal corrosion of the can. High-speed vacuum sealers draw the vacuum out

of the headspace of can. The firs step in this process is to clinch the lid on the can without an

air tight seal. Then the machine applies vacuum to remove air from the headspace of the

container and then it is finall sealed with the second press rollers to get a double air tight

seam.

Retort Process (Sterilisation)

Containers are sterilised in retorts, which are large pressure vessels. Batch and continuous

retorts are available and the heating medium is either steam, pressurised hot water, or

steam/air mixtures.

Sterilisation of foods by the application of heat can either be in sealed containers

or by continuous flow techniques. Whatever the process, the main concerns are with food

safety and quality. The most heatresistant pathogenic bacterium is Clostridium botulinum,

which does not grow below pH 4.5. On this basis, the simplest classification is to categorise

foods as either as acid foods (pH<4.5) or low-acid foods (pH>4.5). Note that a broader

classification has been used for canning: low-acid (pH>5.0), medium-acid (pH 4.55.0), acid

(pH 4.53.7), high-acid (pH<3.7). However, as mentioned earlier, the main concern is with

foods at pH>4.5. For such foods, the minimum recommended process is to achieve 12D

reductions for C. botulinum. This is known as the minimum botulinum cook. This requires

heating at 121 _C for 3 min, measured at the slowest heating point.

Static Retort: A static retort does not provide agitation to the can and they normally operate

at 115.6C to 121.1C (240F to 250F). The cans are kept inside the retort and the

retort is sealed. Pressure is build up in the retort for cooking after venting the air with steam. There is

continuous supply of steam during the duration of cook. Vertical steam retort is a good example of

static retort. Some retorts also use steam and air combination to achieve uniform temperature

distribution. Water spray retorts circulate the stored water through pumps and spray it on cans. The

water is then circulated through the heat exchanger where it is heated again by the steam.

Cascading water fl w retorts use continuous fl w of heated water throughout the retort to maintain

uniform temperature distribution.

Rotary Cookers: Rotating action or agitation to the can provides a better rate of heat transfer to the

product inside the can and hence significantl reduces process time. Cans inside the retort can be

rotated at a certain speed depending on the type of product.

There are three phases of can rotation:

(1) Fixed reel travelcans are carried on a central axis for a distance of about 220 degrees around

the periphery of the shell of retort;

(2) Free rotationcans roll freely on their central axis on a spiral tees at the lower

portion of the shell for a distance of about 100 degrees; and (3) Transitional phasethis is

the transition phase for the cans from free rotation to the fi ed reel travel.

Continuous retorts: In this type of retort, cans are carried from one end of the retort to the other end

along the surface of the retort. Sometimes agitation is also provided to improve heat transfer rate by

inducing forced convection in the product inside the can. This system has advantages over the static

or batch type systems in terms of time and energy. Steriflamm process is a continuous cooker and

utilizes direct flam (1093.3C, or 2000F) on rolling cans (80 rpm) for predetermined time. Cans are

packaged under high vacuum and are brought up to an initial temperature of 100C/212F before

processing with flame This system is suitable for processing small cans.

Hydrostatic pressure sterilizers: This is also a continuous type retort system in which steam

pressure is maintained by the water pressure. There are four chambers in hydrostatic cookers, a

come-up leg, sterilizing chamber, a hydrostatic come-down leg, and a cooling system. It uses large

columns of water as a feed system for cans inside the high pressure steam chamber of the cooker.

Cans are placed horizontally on a moving chain which carries cans through the legs into the

sterilization chamber. Processing time is determined by the chain speed and the temperature of the

chamber. This system is suitable for large volume productions and it can also handle various sizes of

cans and jars. The major advantages of such a system include savings in

floor space, high volume operation, and reduction in steam and water cost.

Cooling

is a very important operation and containers should be cooled as quickly as possible down to

a final temperature of 3540_C. As the product cools, the pressure inside the can falls and it

is important to ensure that the pressure in the retort falls at about the same rate. This is

achieved by using a combination of cooling water and compressed air to avoid a sudden fall

in pressure caused by steam condensation. Water quality is important and it should be

free of pathogenic bacteria. This can be assured by chlorination, but an excessive amount

should be avoided as this may cause container corrosion. It is also important to avoid too

much manual handling of wet cans to reduce the levels of ppc.

The containers are then labelled and stored. A small proportion may be incubated

at elevated temperatures to observe for blown containers.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Wire Rope Slings by Safety SlingDocument4 pagesWire Rope Slings by Safety SlingRajNo ratings yet

- EcosystemDocument14 pagesEcosystemanjuabraham129No ratings yet

- The Three Domain System: Prepared By: Marimar T. AbrigoDocument50 pagesThe Three Domain System: Prepared By: Marimar T. AbrigoCN TarlitNo ratings yet

- Understanding Ammonia SystemsDocument8 pagesUnderstanding Ammonia Systemshatassa100% (1)

- Trench SpecificationsDocument4 pagesTrench SpecificationsFatoni Gea AirlanggaNo ratings yet

- 3353, Brochure MBBR Pack EN 1115 PDFDocument6 pages3353, Brochure MBBR Pack EN 1115 PDFJulio TovarNo ratings yet

- Tecnología de La Elaboración de Vinagre de YucaDocument321 pagesTecnología de La Elaboración de Vinagre de YucaRobinson Chopra ChopraNo ratings yet

- D 102310 X 012Document8 pagesD 102310 X 012Peter BqkNo ratings yet

- Hog Scraper Catalog LongwoodDocument4 pagesHog Scraper Catalog LongwoodGeafir NicoletaNo ratings yet

- Operation Manual: For 1/2/4/6/8/10 Filling Nozzles Newest Model)Document5 pagesOperation Manual: For 1/2/4/6/8/10 Filling Nozzles Newest Model)Paula NovoaNo ratings yet

- 1 - Stoichiometry-01 - TheoryDocument42 pages1 - Stoichiometry-01 - TheoryRaju SinghNo ratings yet

- TVB445 - BrochureDocument2 pagesTVB445 - Brochurejibu3386No ratings yet

- Literature SurveyDocument14 pagesLiterature SurveyMukesh PatilNo ratings yet

- Pet Polycondensation Side ReactionsDocument6 pagesPet Polycondensation Side ReactionsGeorge MarkasNo ratings yet

- GATE Mining Engineering 2010Document16 pagesGATE Mining Engineering 2010Charan Reddy100% (1)

- Room Air Conditioner: Service ManualDocument70 pagesRoom Air Conditioner: Service ManualHa Bao AnhNo ratings yet

- Hydraulic Drives For Bridges Considering The New DIN Standard 19704Document13 pagesHydraulic Drives For Bridges Considering The New DIN Standard 19704Nguyen Cong Cuong100% (1)

- Properties of Sodium SoapDocument6 pagesProperties of Sodium SoapA MahmoodNo ratings yet

- Tapflo PT Hose Pumps Operation ManualDocument44 pagesTapflo PT Hose Pumps Operation ManualBoopyJoe100% (1)

- Role of A Novel Transdermal Patch For Both Antihypertensive and Antiparkinsonism ActivityDocument8 pagesRole of A Novel Transdermal Patch For Both Antihypertensive and Antiparkinsonism ActivityMr.S. p.royNo ratings yet

- Clean Technology in The Production of Epichlorohydrin: Jowi W. Bijsterbosch, A. Das and F.P.J.M. KerkhofDocument4 pagesClean Technology in The Production of Epichlorohydrin: Jowi W. Bijsterbosch, A. Das and F.P.J.M. KerkhofProton HutabaratNo ratings yet

- MMF 06 Februari 2023: NO Nama Stok KomposisiDocument148 pagesMMF 06 Februari 2023: NO Nama Stok KomposisiKlinikapotek KikiNo ratings yet

- R P & G F & H C R M P I: Estricted Rocter Amble Abric OME AREDocument3 pagesR P & G F & H C R M P I: Estricted Rocter Amble Abric OME AREIssam LahlouNo ratings yet

- Ubc 2001-0211Document151 pagesUbc 2001-0211cudynkNo ratings yet

- Cleaning Validation A Lifecycle Approach - 1Document50 pagesCleaning Validation A Lifecycle Approach - 1lounes.asma30No ratings yet

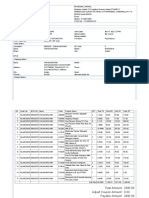

- Modicare - Order Preview-Sini 17032022Document3 pagesModicare - Order Preview-Sini 17032022Arjun SidharthNo ratings yet

- The Earth - S Water BudgetDocument33 pagesThe Earth - S Water BudgetKeysi02No ratings yet

- Prarancangan Pabrik Alumunium Klorida Dari Bauksit Dan HCL Dengan Kapasitas 35000 Ton Per TahunDocument49 pagesPrarancangan Pabrik Alumunium Klorida Dari Bauksit Dan HCL Dengan Kapasitas 35000 Ton Per TahunGhina Fatikah SalimNo ratings yet

- Geotechnical Engineering 1 (RMIT) Course RevisionDocument53 pagesGeotechnical Engineering 1 (RMIT) Course RevisionSaint123No ratings yet