Professional Documents

Culture Documents

Exposure Hazard Analysis in Cement Fiber Sheet

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Exposure Hazard Analysis in Cement Fiber Sheet

Copyright:

Available Formats

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

_______________________________________________________________________________________________

Volume: 03 Special Issue: 11 | NCAMESHE - 2014 | Jun-2014, Available @ http://www.ijret.org 76

EXPOSURE HAZARD ANALYSIS IN CEMENT FIBER SHEET

MANUFACTURING INDUSTRY

M. Rajesh Kumar

1

, K. N. Karthick

2

, T. Dheenathayalan

3

, K. Visagavel

4

1

PG Scholar, Industrial Safety Engineering, Knowledge Institute of Technology, Salem, India

2

Assistant Professor, Department of Mechanical Engineering, Knowledge Institute of Technology, Salem, India.

3

Assistant Professor, Department of Mechanical Engineering, Knowledge Institute of Technology, Salem, India

4

Professor, Department of Mechanical Engineering, Knowledge Institute of Technology, Salem, India

Abstract

Asbestos a collective name given to six type of naturally occurring fiber, well known human carcinogen. Undesirable health

effects of asbestos lead to prohibition in most of developed countries but still some developing countries tend to use it in various

commercial form. The objective of this study is to estimate the occupational asbestos exposure level and to predict the health risk

if the level of exposure exceeds the recommended standard limit. One of the asbestos cement (AC) sheet manufacturing industry is

selected to conduct study similar to general cross-sectional study. The main operation of the industry is to manufacture AC sheet

in continuous basic that mean production is done round the clock. Both personal sample and static sample were collected in

regular operational day by following BIS 11450:2006 as standard procedure for collecting air samples and fiber counting.

Location for sampling were selected by considering staff suggestion and by visual observation made around the occupancy area.

From twenty-four collected samples twenty-two were sampled, the personal sample taken from wet ball mill area shown 0.0690

fiber per cubic centimetre (f/cc) which was highest among overall collected sample and lowest concentration 0.0195 f/cc was

found from personal testing fiber sheet. From the obtained fiber concentration result it shows that asbestos exposure at

occupational area were maintained within the permissible limit also no history of asbestos related diseases (ARD) was found

among employees which hypothesis the progressive safety system in working environment. Unless until the use of asbestos is

completely prohibited, a finest control system should be followed to avoid the occurrence of ARD from both occupational and

public zone.

Key Words: Asbestos, fiber concentration, occupational asbestos exposure and sampling.

--------------------------------------------------------------------***----------------------------------------------------------------------

1. INTRODUCTION

Asbestos is universally recognized as human carcinogenic

that can result in chronic disease such as mesothelioma, lung

cancer, chromosomal alteration and [1]-[5]. Asbestos are

mainly categorised as two types amphiboles (Actinolite,

Amosite, Anthophyllite, Crocidolite, tremolite) and

serpentine (Chrysotile) [2], [6], [7]. This fiber can be found

as natural rock in certain parts of the world, among world

countries Russia and Canada are the largest exporters[6] of

asbestos fiber especially chrysotile, commercially termed as

white fiber. Chrysotile can be found in many different

commercial products that include cement products,

automobile brake lining [6]. There were few studies which

show non-significant [8], [9] health effect of chrysotile fiber

but numerous show significant association with asbestos

related diseases. Although all types of asbestos are health

hazardous this white fiber is proved as less hazardous than

its other types [10]. But in recent years chrysotile fiber has

become a threat to human health. Various studies has been

done in aspect of risk assessment, occupational exposure

and mortality rate determination which are now used as tool

to create awareness and this current study follows same

way.

Each country has set of protocol to assess the occupational

exposure level, in India Bureau of Indian standard (BIS)

11450 is used to assess the airborne asbestos fibre

concentration in work environment by light microscopy

[11]. Because of higher mortality rate and by evidence of

ARD [12] from occupational and non-occupational asbestos

exposure many countries had banned the use of asbestos. By

economic consideration some countries still manufacture

and uses asbestos based product [13], in those industry it is

mandatory to assess the level of exposure and to maintain

safe working condition.

This study will help to reveal the actual asbestos exposure

level in an AC sheet manufacturing industry.

2. METHOD AND MATERIALS

2.1 Manufacturing Process

A cement fiber sheet manufacturing industry was selected to

carry out this study. Here the AC sheet are produced by

following well known Hatscheck process which is carried

out in wet condition. The raw material for the process

involves cement, fly ash, chrysotile asbestos fiber and water.

Each raw material are separately mixed with water to form

unique slurry then they are stored in separate silo on

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

_______________________________________________________________________________________________

Volume: 03 Special Issue: 11 | NCAMESHE - 2014 | Jun-2014, Available @ http://www.ijret.org 77

requirement those slurry is fed to series of rotating hallow

cylindrical vat attached with endless felt and sheet making

machine. When expected thickness is achieved the sheet is

automatically cut off into moving conveyor then sheet are

corrugated by the standard profile. The sheet along with

template are sent to heating chamber for initial curing that

takes from 8 to 22 hrs. After initial curing sheet are switched

to MS pallet for final curing at maturing bay by water

showering for 15 days and they are shifted to open space for

another 10 days for final maturing.

2.2 Study Area

Although cement sheet manufacturing process mostly

follows same principle the sampling area/process was

selected based on staff suggestion factor. Both personal

sampling and static sampling are done for one hour

constantly, personal sampling is made for workers at edge

runner mill area, personal on fiber testing, moulded goods

filling area, salvaging area, forklift driver on carrying fiber

bags. Static sampling is made at fiber storage area and fiber

stack. Personal samples are collected at the breathing zone

of personal. Fig 1 shows the picture taken at sample time.

2.3 Fiber Monitoring Procedure

BIS 11450:2006 is followed for air sampling, asbestos air

monitoring was done with help of personal sampler APM

800 manufactured by Envirotech Instruments private

Limited it is capable of sampling air at flow rate rages from

0.5 to 2 Liquid Per Minutes (LPM) here 1 LPM was

maintained as content flow rate, ester cellulose filter of 25

mm diameter (0.8-1.2 m pore size) is used as sampling

medium [11].Total of 24 samples was collected in which

two sample was rejected one because of damage on handling

and another due to atmospheric disturbance

(contaminations), so 22 sample were found suitable for fiber

count valuation.

2.4 Laboratory Analysis

The sampled filter were carefully stored in separate sealed

box by upright position and they labelled accordingly, in

laboratory Acetone-Triacetin mounting procedure is

followed for slide preparation and each slide were labelled.

Phase contract light microscope (PCM) [14], [15] is the

conventional equipment used to measure airborne particle

here asbestos fibers are counted. Technically fiber with

length greater than 5 m and width less than 3 m of aspect

ratio greater than 3:1 were counted as single fiber. PCM

AXIOSKOP 40 by magnification at x400 with Walton-

Becket graticule G-22 was used for fiber counting.

Minimum of one hundred graticule area were counted by

following standard procedure. Fig.2 was taken during fiber

counting using PCM AXIOSKOP 40.

2.5 Calculation

Fiber concentration C (f/cc) for each sample were calculated

using formula

C = (A/a)*(N/n)*(1/r)*(1/t)

To illustrate the estimation of fiber concentration one of

sample from Moulded goods filling area is evaluated, with

values from table 1, here the total number of fiber counted

6.5 is applied that gives

C = (385.38*6.5)/ (0.007857*100*1*1000*60)

= 0.053 f/cc.

Table -1: Values Used In Formula

Notation Value

A-effective filter area 385.38 mm2

a-graticule counting area 0.007857 mm2

N-total number of fiber counted Vary

n-number of graticule area observed 100

r-flow rate of air through filter 1 LPM

t-single sample duration 60 minutes

2.6 Picture

Fig 1 and Fig 2 shows the pictures taken at study time while

performing personal sampling and fiber counting

respectively.

Fig -1: Edge runner mill area

Personal samples were collected during the workers

performing their regular work, Fig -1 was taken at edge

runner mill area while the worker supposed to loads asbestos

bags in belt conveyor.

Fiber counting is most predominant work in fiber

concentration estimation hence it is conducted in control

environment which can be seen in fig -2.

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

_______________________________________________________________________________________________

Volume: 03 Special Issue: 11 | NCAMESHE - 2014 | Jun-2014, Available @ http://www.ijret.org 78

Fig -2: PCM

3. RESULTS

Table 2 shows the fiber concentration in geometric mean for

individual personal sample, they were in the range of

minimum 0.0195 f/cc and maximum 0.069 f/cc fiber sheet

testing personal and wet ball mill respectively. Number of

samples taken in each process/area are three but only one

sample was taken at wet ball mill and main machine area.

Sample at personal testing the sheet shows lowest

concentration which holds various reason in that process.

When compared to other personal samples wet ball mill area

sample shows greater level of fiber concentration because in

this area various activities like forklift movement, manual

handling of sheet, rejects handling are carried out this may

have influenced the concentration of fiber level.

Table 3 shows the results of individual static sample fiber

concentration in geometric mean, in particular the static

sampling at fiber stack is done at flow rate of 10 LPM for

duration 10 minutes.

Table -2: Fiber Concentration Observed By Personal

Sampling

S No. Process/Area (Samples)

Concentration,

f/cc

1 Edge runner mill area (3) 0.0395

2 Fiber sheet testing personal (3) 0.0195

3 Moulded goods filling area (3) 0.0581

4 Salvaging area (3) 0.0315

5

Forklift driver on carrying fiber

bags (3)

0.0207

6 Wet ball mill (1) 0.0690

TABLE -3: Fiber Concentration Observed By Static

Sampling

S No. Process/Area (Samples) Concentration, f/cc

1 Fiber storage area (3) 0.0250

2 Fiber stack (3) 0.0659

3 Main machine area (1) 0.0280

Due to high flow rate the fiber concentration was higher at

stack but other static samples yield very negligible values.

From table 2 and table 3 it reveals that results of no sample

value exceeds the standard U.S. Environmental Protection

Agency (0.1 fiber/cc), Occupational Safety and Health

Administration (OSHA) Permissible Exposure Limit (0.1

fiber/cc), National Institute for Occupational Safety and

Health (NIOSH) Recommended Exposure Limit (0.1

fiber/cc), American Conference of Governmental Industrial

Hygienists (ACGIH) Threshold Limit Value (0.1 fiber/cc)

[7], [15].

4. DISCUSSION

In this current study the overall airborne asbestos

concentration tends to remain in lower level which shows

the factorys safety performance to employee health. Safety

precaution such as training program, protective clothing,

statutory warning sign, smoking prohibition were observed

during study period also no evidence of occupational ARD

were found. Due to single sample representation, condition

of area while sampling and by other discussed reasons wet

ball mill area shows higher concentration, to obtain reliable

result for this particular area more number of sampling is

recommended. In future same study can be performed with

advance technology involving high-resolution computed

tomography (HRCT) [16], transmission electron microscope

(TEM) [17].

Significant health risk can be found in smoker than non-

smokers because smoking act as catalyst for developing

ARD so it is advised to cease smoking or never smoke [18],

[19]. Nolan RP et al concluded that exposure to high level of

asbestos might cause increase in kidney cancer [5].

India has banned the mining of asbestos fiber but not the

manufacturing of asbestos containing materials (ACM),

India import asbestos without warning sign but make export

to Canada with warning sign indicating hazardous material

[20], as most of developed countries has banned the

manufacturing and use of asbestos and ACM, some

developing countries like India had become the place of

manipulating asbestos materials [14].

However the manufacture of AC is permitted the risk is

unavoidable. If not, the safe control measure are followed

throughout the life cycle of ACM starting from mining

process to final disposal stage [21]. Our previous paper have

immense detail about asbestos and its risk witnessed by

various author from various period [22].

This study concludes that the level of fiber concentration

observed from occupational exposure at cement sheet

manufacturing was below the current standard limit, also

worker are aware of asbestos.

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

_______________________________________________________________________________________________

Volume: 03 Special Issue: 11 | NCAMESHE - 2014 | Jun-2014, Available @ http://www.ijret.org 79

ACKNOWLEDGEMENT

Authors wish to thanks the affiliated institution and AC sheet

manufacturing industry. M. Rajesh Kumar author morally

thank internal and external supportive member for their

guidance in various aspects.

REFERENCES

[1] Lee, H. J., Park, E. K., Wilson, D., Tutkun, E., &

Oak, C. (2013). Awareness of Asbestos and Action

Plans for Its Exposure can Help Lives Exposed to

Asbestos. Safety and health at work, 4(2), 84.

[2] Villeneuve, P. J., Parent, M. ., Harris, S. A., &

Johnson, K. C. (2012). Occupational exposure to

asbestos and lung cancer in men: evidence from a

population-based case-control study in eight Canadian

provinces. BMC cancer,12(1), 595.

[3] Bianchi, C., & Bianchi, T. (2009). Malignant pleural

mesothelioma in Italy.Indian journal of occupational

and environmental medicine, 13(2), 80.

[4] Dopp, E., & Schiffmann, D. (1998). Analysis of

chromosomal alterations induced by asbestos and

ceramic fibers. Toxicology letters, 96, 155-162.

[5] Sali, D., & Boffetta, P. (2000). Kidney cancer and

occupational exposure to asbestos: a meta-analysis of

occupational cohort studies. Cancer Causes &

Control, 11(1), 37-47.

[6] Khan, A. H., Ansari, F. A., Misra, D., & Bhargava,

S. K. (2006). Study of asbestos fibre levels in and

around a brake-lining industry. JOURNAL OF

SCIENTIFIC AND INDUSTRIAL RESEARCH, 65(5),

437.

[7] Nolan, R. P., Langer, A. M., & Wilson, R. (1999). A

risk assessment for exposure to grunerite asbestos

(amosite) in an iron ore mine. Proceedings of the

National Academy of Sciences, 96(7), 3412-3419.

[8] Wollmer, P., Eriksson, L., Jonson, B., Jakobsson,

K., Albin, M., Skerfving, S., & Welinder, H. (1987).

Relation between lung function, exercise capacity, and

exposure to asbestos cement. British journal of

industrial medicine, 44(8), 542-549.

[9] Lee, R. J., & Van Orden, D. R. (2008). Airborne

asbestos in buildings.Regulatory Toxicology and

Pharmacology, 50(2), 218-225.

[10] Huncharek, M. (1987). Chrysotile asbestos

exposure and mesothelioma. British journal of

industrial medicine, 44(4), 287.

[11] Bureau of Indian Standards, IS-11450, 1986.

Method for determination of air borne asbestos fibres

concentration in work environment by light microscopy

(Membrane filter method). Bureau of Indian Standard.

New Delhi.

[12] Frost, G., Harding, A. H., Darnton, A., McElvenny,

D., & Morgan, D. (2008). Occupational exposure to

asbestos and mortality among asbestos removal

workers: a Poisson regression analysis. British journal

of cancer, 99(5), 822-829.

[13] Baas, P., van't Hullenaar, N., Wagenaar, J.,

Kaajan, J. P. G., Koolen, M., Schrijver, M., ... &

Burgers, J. A. (2006). Occupational asbestos

exposure: how to deal with suspected mesothelioma

casesthe Dutch approach. Annals of

oncology, 17(5), 848-852.

[14] Kakooei, H., & Marioryad, H. (2010). Evaluation of

exposure to the airborne asbestos in an automobile

brake and clutch manufacturing industry in

Iran.Regulatory Toxicology and Pharmacology, 56(2),

143-147.

[15] Jafari, M., Karimi, A., & Bardshahi, A. M. (2010).

Prediction of cancer mortality by evaluation of

asbestos fibers concentrations in an asbestos-cement

products factory. Iranian Journal of Environmental

Health Science & Engineering, 7(2).

[16] Vierikko, T., Jrvenp, R., Uitti, J., Virtema, P.,

Oksa, P., Jaakkola, M. S., ... & Vehmas, T. (2008).

The effects of secondhand smoke exposure on HRCT

findings among asbestos-exposed

workers. Respiratory medicine, 102(5), 658-664.

[17] Loomis, D., Dement, J., Richardson, D., & Wolf, S.

(2010). Asbestos fibre dimensions and lung cancer

mortality among workers exposed to

chrysotile.Occupational and environmental

medicine, 67(9), 580-584.

[18] Jones, R. N., Hughes, J. M., & Weill, H. (1996).

Asbestos exposure, asbestosis, and asbestos-

attributable lung cancer. Thorax, 51(Suppl 2), S9-15.

[19] Erdin, M., Erdin, E., ok, G., & Polatli, M.

(2003). Respiratory impairment due to asbestos

exposure in brake-lining workers. Environmental

research,91(3), 151-156.

[20] Ramanathan, A. L., & Subramanian, V. (2001).

Present Status of Asbestos Mining and Related Health

Problems in India- A Survey. Industrial health, 39(4),

309-315.

[21] Phanprasit, W., Phanprasit, W., Sujirarat, D.,

Sujirarat, D., Chaikittiporn, C., & Chaikittiporn, C.

(2009). Health risk among asbestos cement sheet

manufacturing workers in Thailand.

[22] M. Rajesh Kumar, R. Suresh, K. N. Karthick, & H.

Abdul Zubar, A systematic literature review for

statistical evaluation of asbestos exposure level,

unpublished.

BIOGRAPHIES

Mr. M. Rajesh Kumar was born in

Namakkal city, Tamil nadu, India in

1991. He received the B.E. degree in

Electronics and Communication

Engineering from Paavai College of

Engineering, Namakkal, Tamil

Nadu, India, in 2012. He is currently

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

_______________________________________________________________________________________________

Volume: 03 Special Issue: 11 | NCAMESHE - 2014 | Jun-2014, Available @ http://www.ijret.org 80

pursuing the M.E. degree in Industrial Safety Engineering at

Knowledge Institute of Technology, Salem, Tamil Nadu,

India.

Mr. K. N. Karthick received the

B.E. degree in mechanical

engineering from K. S. Rangasamy

College of Technology, Namakkal,

Tamil Nadu, India, in 2010 and

M.E. degree in Manufacturing

Systems and Management from

College of Engineering, Guindy,

Anna University, Chennai, Tamil

Nadu, India, in 2013. Since 2013, he has been an assistant

professor with the Department of Mechanical Engineering at

Knowledge Institute of Technology.

Mr. T.Dheenathayalan received the

B.E. degree in Mechanical

Engineering from Annamalai

University, Chidambaram, Tamil

Nadu, India, in 2007 and the M.E.

degree in Industrial Safety

Engineering from K. S. Rangasamy

Institute of Technology, Namakkal,

Tamil Nadu, India, in 2009. He

received the MBA degree from Annamalai University

Distance Education, Chidambaram, Tamil Nadu, India, in

2011. Since July 2010, he has been an assistant professor

with the Department of Mechanical Engineering at

Knowledge Institute of Technology.

Dr. K. Visagavel received the B.E.

and M.E. degree in Mechanical

Engineering and Thermal Power

Engineering from Annamalai

University, Chidambaram, Tamil

Nadu, India, in 1996 and 1998,

respectively, and the Ph.D. degree in

Heat Transfer and CFD from Anna

University, Tamil Nadu, India, in

2009. From 1998 to 2009, he served as lecture, assistant

professor, professor and Head in the Department of

Mechatronics Engineering. Since April 2009, he has been a

Professor, Head of the Mechanical Engineering department

and Vice principal at Knowledge Institute of Technology.

He is the author of three books, more than 41 articles. His

research interests lie in thermal engineering.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Government College of Engineering SALEM 636011.: Electronics and Communication Engineering Curriculum and SyllabusDocument111 pagesGovernment College of Engineering SALEM 636011.: Electronics and Communication Engineering Curriculum and SyllabusSalma Mehajabeen ShajahanNo ratings yet

- Aes MatlabDocument32 pagesAes MatlabbalajithrillerNo ratings yet

- Cummins ECM Reference NotesDocument11 pagesCummins ECM Reference NotesjuanNo ratings yet

- NDT NablDocument3 pagesNDT NablPrabir KumarNo ratings yet

- GEK 116403 Ge File. Performance TestsDocument54 pagesGEK 116403 Ge File. Performance TestsSulaiman JafferyNo ratings yet

- Railway-4 Permanent Way & Alignment (Lecture-4)Document17 pagesRailway-4 Permanent Way & Alignment (Lecture-4)OBIDUR RAHMAN 1701085No ratings yet

- REERTRDocument4 pagesREERTRvgteeNo ratings yet

- The Scientist PDFDocument68 pagesThe Scientist PDFPetcu Adrian100% (1)

- Assault RiflesDocument203 pagesAssault Riflessadfafgdsg100% (1)

- (W. Wireline) Motor PGM365 DatasheetDocument7 pages(W. Wireline) Motor PGM365 Datasheetgonzalo andres HernandezNo ratings yet

- Ems2348x User Manual Id IdDocument104 pagesEms2348x User Manual Id IdGod GamerNo ratings yet

- Simple Free-Energy InformationDocument11 pagesSimple Free-Energy InformationDrago MelovNo ratings yet

- LEGRAND Main Price List April 2012Document124 pagesLEGRAND Main Price List April 2012Ajay SinghNo ratings yet

- Fdot Precast Bent Cap Development and Implementation: AbstractDocument10 pagesFdot Precast Bent Cap Development and Implementation: AbstractCongOanh PHANNo ratings yet

- Scope of Work Diesel Fuel Tank For The Rifle-Garfield County Regional Airport Fuel Farm IFB-GC-AP-01-14 - Diesel Fuel TankDocument4 pagesScope of Work Diesel Fuel Tank For The Rifle-Garfield County Regional Airport Fuel Farm IFB-GC-AP-01-14 - Diesel Fuel TankMSNo ratings yet

- Whirlpool SPIW318A2WF Air ConditionerDocument324 pagesWhirlpool SPIW318A2WF Air ConditionerAxxNo ratings yet

- Chapter 1 Introduction To PSoCDocument32 pagesChapter 1 Introduction To PSoCtptuyen2246No ratings yet

- PS2 VerilogDocument11 pagesPS2 Veriloglizhi0007No ratings yet

- 94-0518-4 Mini-RadaScan Engineers and Service GuideDocument15 pages94-0518-4 Mini-RadaScan Engineers and Service GuideAlex Sandoval100% (1)

- ECS Florida SOQ - 2018 - FT MyersDocument11 pagesECS Florida SOQ - 2018 - FT MyersPaul BenvieNo ratings yet

- Thesis Report Vishal Part 1Document9 pagesThesis Report Vishal Part 1vishal infantrajNo ratings yet

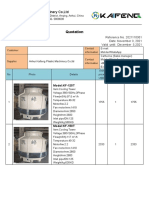

- KAIFENG Quotation For 150T Cooling TowerDocument13 pagesKAIFENG Quotation For 150T Cooling TowerEslam A. FahmyNo ratings yet

- TORONTO01Document2 pagesTORONTO01itrcentre07No ratings yet

- Brosur Hari GuruDocument8 pagesBrosur Hari GuruFitri SharifNo ratings yet

- Revised Runway Length Discussion (20171206) - 201712211212022318Document3 pagesRevised Runway Length Discussion (20171206) - 201712211212022318Ilham RaffiNo ratings yet

- 2012-13 Waste CalendarDocument2 pages2012-13 Waste CalendarOmar9998No ratings yet

- Current Volt Meter Ina219Document40 pagesCurrent Volt Meter Ina219sas999333No ratings yet

- Community Building PDFDocument2 pagesCommunity Building PDFLauren100% (1)

- Hong Kong International Airport Instrument Approach ChartDocument21 pagesHong Kong International Airport Instrument Approach ChartThamaroj ChansawangNo ratings yet

- Lexus Brand BrochureDocument40 pagesLexus Brand Brochurejammypops100% (1)