Professional Documents

Culture Documents

Tri Lift

Uploaded by

Drew GrahamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tri Lift

Uploaded by

Drew GrahamCopyright:

Available Formats

Tri-Lift

Quad-Lift

4-post Integrated

Parking Lift

1

HARDING STEEL, INC.

I

730 17th Street #650

I

Denver, CO 80202

I

(800) PARK-DBL

I

www.hardingsteel.com

Harding Steel's multi-vehicle stacking systems are a 4-post integrated parking lift designed for rugged

indoor or outdoor operation. Each system may be congured as a stand-alone lift or combined into rows of

lifts, with each pair of machines sharing a common set of posts. Each parking level of the lift is an all-steel

galvanized platform that will accommodate vehicles weighing up to 6000 pounds with overall heights of

approximately 75". Each vehicle platform is raised and lowered by a series of cables attached to the four

corners of each platform. A hydraulic cylinder on each machine controls the raising and lowering of the

platforms. Lifts are operated by a trained attendant who must be present at the control switch of each lift

during operation. Lifts are equipped with steel locking mechanisms that provide safety to both vehicles and

personnel.

Hydraulic Power System: Lifts are powered by an integrated power pack that consists of an electrical control

panel, hydraulic pump motor, and hydraulic uid tank. Power packs are sized to the specic application. Each

power pack can operate up to 20 lifts depending on conguration, layout, and other technical factors. Power

pack units each require their own dedicated 220V, 40 amp, 3-phase power circuit. Fluid tanks are equipped with

electric heaters.

Applications: Tri-Lifts are ideal for applications that require high density vehicle parking and storage. These lifts

are employed all over the world in applications that include commercial parking, retail auto dealerships, classic

car storage, residential parking, ofce parking, rental car agencies, and auto repair/service.

Tri-Lift

Quad-Lift

n

Commercial parking

n

Vehicle storage

n

Auto retail and service

n

Residentialmulti family

n

High security environments

n

Rental car agencies

n

Fabricated in the USA

n

All US hydraulic components

n

Hot dipped galvanized vehicle platforms now standard

n

Seismic Zone 4 approved

n

Two-position fail-safe locking mechanism

n

Custom enamel nishes for columns and beams

2

HARDING STEEL, INC.

I

730 17th Street #650

I

Denver, CO 80202

I

(800) PARK-DBL

I

www.hardingsteel.com

Tri-Lift

Quad-Lift

3

HARDING STEEL, INC.

I

730 17th Street #650

I

Denver, CO 80202

I

(800) PARK-DBL

I

www.hardingsteel.com

174

268

80

77-3/4

80

116

116

102

174

156

Heights of overall machine and individual stall heights may be customized by application.

Triple high units are now available in a 8 6 wide model

Tri-Lift

Quad-Lift

Toggle switches or

push button/key

locks are available.

FIG.

1

4

HARDING STEEL, INC.

I

730 17th Street #650

I

Denver, CO 80202

I

(800) PARK-DBL

I

www.hardingsteel.com

116 174

348-3/4

80

77-3/4

80

116

102

174

156

80

Heights of overall machine and individual stall heights may be customized by application.

Triple high units are now available in a 8 6 wide model

Tri-Lift

Quad-Lift

FIG.

2

5

HARDING STEEL, INC.

I

730 17th Street #650

I

Denver, CO 80202

I

(800) PARK-DBL

I

www.hardingsteel.com

156 CENTERS

(FRONT TO BACK)

110 OUTSIDE PLATES

174 OUTSIDE

OF BASE PLATES

116 OUTSIDE PLATES

102 CENTERS 96 CENTERS

86 PLATFORM WITH 86 PLATFORM WIDTH

Triple high units are also available in a 8 6 wide model (102 centers).

36 BUFFER AREA 36 BUFFER AREA

174 OUTSIDE

OF BASE PLATES

220 OVERALL

LENGTH WITH

36 IN. BUFFER

156 CENTERS

(FRONT TO BACK)

DIRECTION OF

VEHICLE ENTRY

TRI-LIFT and QUAD-LIFT SYSTEMS

(STANDARD) FOOTPRINT DIMENSIONS

(8 PRODUCT)

TRI-LIFT and QUAD-LIFT SYSTEMS

(WIDE) FOOTPRINT DIMENSIONS

(8 6 FOOT PRODUCT)

DIRECTION OF

VEHICLE ENTRY

Tri-Lift

Quad-Lift

FIG.

3

6

HARDING STEEL, INC.

I

730 17th Street #650

I

Denver, CO 80202

I

(800) PARK-DBL

I

www.hardingsteel.com

Tri-Lift

Quad-Lift

102 or 96

ON CENTER

102 or 96

ON CENTER

102 or 96

ON CENTER

Typical conguration. End leg is required to complete a row of lifts.

END

LEG

FIG.

4

7

HARDING STEEL, INC.

I

730 17th Street #650

I

Denver, CO 80202

I

(800) PARK-DBL

I

www.hardingsteel.com

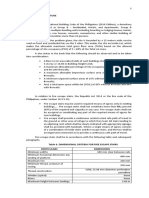

CAPACITY

The maximum lifting capacity is twelve thousand pounds for the Tri-Lift and 18,000

pounds for the Quad-Lift. Platforms are rated at six thousand (6,000) pounds each.

SITE REQUIREMENTS

n Lifts can be installed as single units, or in rows, sharing common posts between units.

n Surface must be level to within 2 inches per 8 feet (side-to-side or front-to-back).

n Surface under lifts should be standard commercial grade, 3000 psi reinforced concrete

at least 6" in depth. Footer details available on request

n Pier footers may be constructed in lieu of full concrete pads (see manufacturer for

specications)

n Lifts will be rmly bolted to concrete pad or footers

n Drainage should be such that standing water is eliminated under lift platforms

n Turning radius in front of machines no less than 19' (20'- 22' recommended).

CLEARANCES

n Clear ceiling height: 22' 6" minimum for standard height Tri-Lift, 29'6" for standard

height Quad-Lift. Custom heights are available for all model lifts.

n Distance at rear of lifts to nearest wall or obstruction: 36"

n Distance between two rows of lifts in tandem congurations: 60-72".

POWER REQUIREMENTS

n 220V, 40 amp, 3-phase for each hydraulic power pack unit

n Each power pack unit operates up to 20 lifts depending on conguration and layout

n Individual lifts are operated by 24 VDC (low voltage)

LOADINGS

There are no uplifting loads on the structure. All loading is downward and the center of

gravity is located within the lift structure. Base Plate loading is below AISC allowable

standards. When operated at full capacity as a stand-alone unit, the base plate loading is

17 psi (4284 lbs on base plate). When operated as a double unit in a row, the base plate

loading is 26 psi (6552 lbs on base plate).

WARRANTY

One year electrical, two year mechanical, ve year structural

SAFETY

n Key-operated control switch for security and safety

n Hydraulic velocity fuses on all cylinders

n Automatic shut-off if operator releases the key-switch

n Structure certied for seismic and wind loads

n Integrated anti-fall safety system

n Manually operated lock releases

n All platforms congured with wheel stops and certering guides

Tri-Lift

Quad-Lift

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Civil & Structural Designer'S Data Pack: Section 7: MasonryDocument5 pagesCivil & Structural Designer'S Data Pack: Section 7: MasonryMirea Florentin0% (1)

- 107 01 Covers and Side Doors A SideDocument38 pages107 01 Covers and Side Doors A Sideben vervuurtNo ratings yet

- Cloudworx Pdms UsDocument2 pagesCloudworx Pdms Usguru4lifegmailcomNo ratings yet

- Additional Material On CommunicationDocument15 pagesAdditional Material On CommunicationSasmita NayakNo ratings yet

- A Microscope For Christmas: Simple and Differential Stains: Definition and ExamplesDocument4 pagesA Microscope For Christmas: Simple and Differential Stains: Definition and ExamplesGwendolyn CalatravaNo ratings yet

- Experiment #3 Venturi Meter: Home Unquantized ProjectsDocument7 pagesExperiment #3 Venturi Meter: Home Unquantized ProjectsEddy KimathiNo ratings yet

- Rail Inspection Vehicle Using Ir Sensor and Spot Marking SystemDocument63 pagesRail Inspection Vehicle Using Ir Sensor and Spot Marking SystemNarayananNanuNo ratings yet

- Straightforward Pre-Intermediate Progress Test 4: Language Section VocabularyDocument8 pagesStraightforward Pre-Intermediate Progress Test 4: Language Section VocabularyStrange BrawlerNo ratings yet

- Literature Review Is The Backbone of ResearchDocument7 pagesLiterature Review Is The Backbone of Researchafmzweybsyajeq100% (1)

- Module-2: SolidificationDocument16 pagesModule-2: SolidificationSachin AgnihotriNo ratings yet

- MS Y7 Spelling Bee Memo & List 21 22Document9 pagesMS Y7 Spelling Bee Memo & List 21 22Muhammad Akbar SaniNo ratings yet

- Iphone 14 Pro Max Inspired Preset by Rey Dhen - XMPDocument3 pagesIphone 14 Pro Max Inspired Preset by Rey Dhen - XMPRizkia Raisa SafitriNo ratings yet

- A Research Paper On DormitoriesDocument5 pagesA Research Paper On DormitoriesNicholas Ivy EscaloNo ratings yet

- Briefing Evaluation: Yes / No High / Low Yes / No High / Low Good / Inferior Yes / NoDocument4 pagesBriefing Evaluation: Yes / No High / Low Yes / No High / Low Good / Inferior Yes / NoAmmarah AzharNo ratings yet

- 17 Safety InventoryDocument47 pages17 Safety Inventorymishrakanchan 2396No ratings yet

- Employment Under Dubai Electricity & Water AuthorityDocument6 pagesEmployment Under Dubai Electricity & Water AuthorityMominur Rahman ShohagNo ratings yet

- Seventh Pay Commission ArrearsDocument11 pagesSeventh Pay Commission Arrearssantosh bharathyNo ratings yet

- KIT REQUEST FORM - GradDocument2 pagesKIT REQUEST FORM - Graddamie aadamsNo ratings yet

- Dynamic Analysis of Synchronous Reluctance Motor Drives Based On Simulink and Finite Element ModelDocument5 pagesDynamic Analysis of Synchronous Reluctance Motor Drives Based On Simulink and Finite Element ModelenmnabilNo ratings yet

- Intro To Geometric Design and Vertical AlignmentDocument25 pagesIntro To Geometric Design and Vertical AlignmentAhsan ArfanNo ratings yet

- Serie 20 Sauer DanfossDocument18 pagesSerie 20 Sauer DanfossCristian100% (1)

- Entrepreneurial BehaviourDocument16 pagesEntrepreneurial Behaviournonalyn tomboconNo ratings yet

- Snap-Tite75 Series-Catalog 3800 - SectionBDocument3 pagesSnap-Tite75 Series-Catalog 3800 - SectionBfrancis_15inNo ratings yet

- Experiential MarketingDocument23 pagesExperiential Marketingambesh Srivastava100% (5)

- SIP Project ProposalDocument2 pagesSIP Project ProposalDeep SutariaNo ratings yet

- Catholic Social TeachingsDocument21 pagesCatholic Social TeachingsMark de GuzmanNo ratings yet

- 65° Panel Antenna: General SpecificationsDocument2 pages65° Panel Antenna: General SpecificationsAnnBliss100% (2)

- DOPE Personality TestDocument8 pagesDOPE Personality TestMohammed Hisham100% (1)

- Michael S. Lewis-Beck-Data Analysis - An Introduction, Issue 103-SAGE (1995)Document119 pagesMichael S. Lewis-Beck-Data Analysis - An Introduction, Issue 103-SAGE (1995)ArletPR100% (1)

- The Logistics of Harmonious Co-LivingDocument73 pagesThe Logistics of Harmonious Co-LivingKripa SriramNo ratings yet