Professional Documents

Culture Documents

Study Guide 6

Uploaded by

Aaron Merrill0 ratings0% found this document useful (0 votes)

182 views9 pagesmechatronics

Original Title

Study guide 6

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentmechatronics

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

182 views9 pagesStudy Guide 6

Uploaded by

Aaron Merrillmechatronics

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 9

NATIONAL LEVEL PAPER PRESENTATION

AURORA’S ENGG. COLLEGE, BHONGIR,

NALGONDA( A.P.).

"ENQUESTA-2005"

PAPER

On

“MECHATRONICS”

By

SHEREKAR BHASKAR V. GAIKWAD DILIP M.

B.E.(MECH) B.E.(MECH)

RAHUL B. DARKUNDE

B.E.(MECH)

Of

GOVERNMENT COLLEGE OF ENGG.

JALGAON

ABSTRACT

“MECHATRONICS MANIA OF THE MILLENIUM”

Today innovations are evolving from combination of different technologies.

Microelectronics mechanics, optics and software interact when technical systems of our

times become reality.

Mechatronics word originated in Japan, a senior engineer of a company, Yaskawa

in 1969 coined it as,

“ MECHATRONICS is the synergistic integration of mechanical engineering with

electronics and intelligent computer control ion the design and manufacture of products

and processes”. The advent of mechatronics, a synergistic blend of mechanics marks the

dazzling technological advances in precision engineering, control systems, computers

sensors actuators fields helping to design innovative products & processes.

Mechatronics is an indisciplinary fusion used to produce & enhance products & systems,

like computer disk drives, photo copier, fax machine, CNC machine, modern car HMD,

cave & so on. Some features are quick response, precision & robustness as in C.D. drive

of Seagate technology. These concepts & devises used in robotics.

The paper covers development of mechatronics, general structure & design of

mechatronics systems, advance approaches, applications and advantages. It covers

importance to needs and evaluation of mechatronics has taken place from the

indesciplinary fields. It also covers a brief review of the application for which this field is

completely devoted. A case study is reveled to understand the concepts of mechatronics

by study of electronic control module (ECM) use in different injection system. The ECM

can regarded as the brain which controls the injection system with the variable inputs

given through sensors

INTRODUCTION:-

A senior engineer of a Japanese company first coined the word mechatronics;

Yaskawa, in 1969, as a combination of "mecha" of mechanisms and "tronics" of

electronics and the company was granted the trademark rights on the word in 1971. The

word soon received broad acceptance in industry. The word has taken a wider meaning

since then and is now widely being used as a technical jargon to describe a philosophy in

engineering technology, more than the technology itself.

For this wider concept of mechatronics, a number of definitions have been

proposed in the literature but the most commonly used one is,

Mechatronics is the synergistic integration of mechanical engineering with

electronics and intelligent computer control in the design and manufacture of products

and processes.

Mechatronics is the interdisciplinary fusion of Mechanics, Electronics and

Information Technology, as shown in the Ven diagram.

DEFINITIONS OF "MECHATRONICS"

Chico State University

"Mechatronics is a field of study that combines the fundamentals of Mechanical,

Electrical, and Computer Engineering."

Clemson University

"Mechatronics is the blending of software, hardware for the design and analysis of

advanced control techniques."

Mechatronics - Electronic Control Systems in Mechanical Engineering

(book)

"Mechatronics is integration of electronics, control engineering and mechanical

engineering"

Figure 1: The interdisciplinary nature of Mechatronics

DEVELOPMENT OF MECHATRONICS: -

The development of mechatronics has gone through three stages.

[1] The first stage corresponds to the years around the introduction of the word. During

this stage, technologies used in mechatronics systems developed rather independently of

each other and individually.

[2] With the start of the eighties, a synergistic integration of different technologies started

taking place, the notable example being in optoelectronics (i.e. an integration of optics

and electronics). The concept of hardware/software co-design also started in these years.

[3] The third and the last stage, starts with the early nineties, can also be considered as

the start of the mechatronics age. The most notable aspect of the third stage is the

increased use computational intelligence in mechatronics products and systems. It is due

to this development that we can now talk about Machine Intelligence Quotient (MIQ).

The functional diagram of Semiosis

Fig. 3. The six-box diagram of behavior formation

Fig. 4 The

GENERAL STRUCTURE OF MECHATRONICS SYSTEM: -

A mechatronics system has two main components as shown in Fig. 4

[1] CONTROLLED SYSTEM: -

The controlled system is the mechanical process that is in contact with the world

with all of its sensors and actuators.

[A] MECHANICAL SYSTEMS: -

Mechanical systems are concerned with the behavior of matter under the action of forces.

Such systems are categorized as, Rigid, Deformable, and Fluid in nature.

Newtonian mechanics provides the basis for most mechanical systems and

consists of 3 independent and absolute concepts: space, time, mass and also force

concept.

[B] SENSORS: -

Sensor is used for an element, which produces a signal relating to the quantity

being measured. Sensors are required to monitor the performance of machines and

processes. Using more no of sensors, we can monitor more no of variables in process

such as: Surface quality, Speed, feed, force, temperature, torque, acceleration, vibrations

and flow rate of cutting fluid, etc.

Sensing system can also be used to evaluate operation, inspect the work in

progress and identify parts ad tools.

[C] ACTUATORS: -

Actuators are meant for opening and closing of the final control elements in an

instrument and control system. The actuators receives signal from controller and acts in

the process.

Types of actuators: -

Actuators may be analogous or digital.

[a] Electromagnetic Actuators:

Ex. A.C. and D.C. electric motor, Stepper motors, Electromagnets, etc.

[b] Fluid Power Actuators:

Ex. Hydraulic Actuators & Pneumatic Actuators etc.

[c] Unconventional Actuators:

Ex. Piezoelectric, Magnetostrictrive, Memory metal.

[2] CONTROLLING SYSTEM: -

The controlling systems have the three sub-systems and are used for perception,

knowledge representation and planning and control. The intelligence is usually embedded

in the planning and control sub-system. Here, based on the information gathered from the

sensors, computational intelligence methodologies are exploited to plan a course of action

that will enable the controlled system to achieve the given tasks. Conventional

microprocessors, artificial neural networks, fuzzy logic and probabilistic reasoning are

among the tools used in the sub-system for information processing and decision-making.

[A] INFORMATION SYSTEM: -

Information systems include all aspects of information transmit ion from signal

processing

to control system to analysis techniques. In Mechatronics applications, the information is

most concerned with modeling, simulation, automatic control and numerical methods for

optimization.

Modeling: -

It is the process of representing the behavior of real system by collection of

mathematical equations and logic.

Simulation: -

It is process of solving the model and is performed on computer. Process of

simulation can be divided into 3 sections viz, Initialization, Iteration and Termination.

ADVANCED APPROACHES IN MECHATRONICS:-

Intelligent manufacturing is a recent development in mechatronics. This

manufacturing has broader area of control for plant management; especially in the area of

sensor-based manufacturing, which significantly influenced the approaches like,

intelligent autonomous inspection system & intelligent decision making systems.

These performs task automatically without human intervention, by adapting to

the changes in the environment.

In intelligent inspection system, real time control is introduced during the

process of manufacturing to provide an increase in machining quality &productivity.

SOME OTHER APPLICATIONS OF MECHATRONICS ARE:-

1. Autonomous production cells with image based object orientation.

2. Monitoring & control of welding process.

3. Mechatronics systems with off –time programming that automatically

program a robot after receiving CAD data.

4. Integrated supervisory systems with multi- process control capability &

shared data basis from CAD drawings.

ADVANTAGES OF MECHATRONICAL SYSTEMS: -

1. In mechatronical machine we get controlled and/or coordinated motion of

one or more machine elements. The generation and coordination of the

required motions, such that the increasingly growing performance and

accuracy requirements are satisfied by mechatronics.

2. Mechatronical mechanisms are not limited in their flexibility in generating

a wide variety of motions, as in case of traditional mechanisms.

CONCLUSION:-

Mechatronics involves the bringing together of a no. of technologies: mechanical

engineering, electrical engineering, computer technology and control engineering. This

can be considered as the application of computer based digital control techniques,

through electronics & electrical interfaces to mechanical engineering problems.

Mechatronics provides an opportunity to take a new look at problem, with

mechanical engineers not just seeing a problem in terms of mechanical principles but

having to see it in terms of a range of technologies. The electronics, etc. should not be

seen as a bolt on item to existing mechanical hardware. A Mechatronics approach needs

to be adopted right from the design phase. There needs to be a complete rethink of the

requirements in terms of what an item is required to do.

REFERENCES: -

1. MECHTRONICS By W. BOLTON

2. www.google.com

3. www.scitech.com

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Tamil Nadu 12th Standard HistoryDocument194 pagesTamil Nadu 12th Standard HistoryIndia History Resources88% (8)

- Business Mathematics in English 2Document217 pagesBusiness Mathematics in English 2Sundhar SubramanianNo ratings yet

- Std12 Phy Vol 1Document237 pagesStd12 Phy Vol 1Aaron Merrill50% (2)

- Std12 Phy EM 2Document256 pagesStd12 Phy EM 2Gimel SteephanNo ratings yet

- Std10 Maths EMDocument241 pagesStd10 Maths EMAaron Merrill100% (2)

- An Introduction To Mathematical Methods in CombinatoricsDocument100 pagesAn Introduction To Mathematical Methods in Combinatorics@bhiNo ratings yet

- Hamming Codes: 4.1 BasicsDocument14 pagesHamming Codes: 4.1 BasicsRajat RanjanNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Single Minute Exchange Dies (S.M.E.D)Document4 pagesSingle Minute Exchange Dies (S.M.E.D)K Srinivasa SagarNo ratings yet

- Types of Testing: (Static Testing - 2 Marks Dynamic Testing - 2 Marks)Document15 pagesTypes of Testing: (Static Testing - 2 Marks Dynamic Testing - 2 Marks)Jayesh DeshmukhNo ratings yet

- Approximation of FIR by IIR Digital FiltersDocument11 pagesApproximation of FIR by IIR Digital FiltersKirti Deo MishraNo ratings yet

- Seminar PPT On FSM Based Vending MachineDocument13 pagesSeminar PPT On FSM Based Vending MachinePratik PatilNo ratings yet

- Objectives:: The General Form of The Yokogawa Cs3000 and Centumvp Pid ControllersDocument2 pagesObjectives:: The General Form of The Yokogawa Cs3000 and Centumvp Pid ControllersSudeep MukherjeeNo ratings yet

- 3.chaos AnatomyDocument7 pages3.chaos AnatomyJavier AntaNo ratings yet

- Role of Strategy Implementation On Governance of Counties in KenyaDocument18 pagesRole of Strategy Implementation On Governance of Counties in Kenyamariam yanalsNo ratings yet

- EE 515 Nonlinear Systems: Stability and Control: Uddipan Barooah (S19026)Document9 pagesEE 515 Nonlinear Systems: Stability and Control: Uddipan Barooah (S19026)johncena3No ratings yet

- PID Control System Analysis & DesignDocument11 pagesPID Control System Analysis & DesignNAYEEMNo ratings yet

- LARSEN-FREEMAN (1997) Chaos and Complexity TheoryDocument25 pagesLARSEN-FREEMAN (1997) Chaos and Complexity TheoryLucian Craciunescu100% (2)

- Heizer 17Document33 pagesHeizer 17Peter_Phee_341No ratings yet

- UNIT #07: Software Development LifecycleDocument7 pagesUNIT #07: Software Development LifecycleUltra ChannelNo ratings yet

- NP Otan Bi SC Knowledge DevelopmentDocument45 pagesNP Otan Bi SC Knowledge DevelopmentCosti MarisNo ratings yet

- Homomorphic Filtering and Speech Processing Using Cepstrum AnalysisDocument22 pagesHomomorphic Filtering and Speech Processing Using Cepstrum Analysissaurabh8435100% (2)

- Unit-1 - Introduction To Software and Software EngineeringDocument4 pagesUnit-1 - Introduction To Software and Software EngineeringShivaranjiniNo ratings yet

- PID Trajectory Tracking Control For Mechanical SystemsDocument1 pagePID Trajectory Tracking Control For Mechanical SystemsLordOfSpooksNo ratings yet

- Butterfly Effects PDFDocument3 pagesButterfly Effects PDFpablofaure1No ratings yet

- Sheet 3Document4 pagesSheet 3Bahaa RaghebNo ratings yet

- Control SystemsDocument8 pagesControl Systemsvasantha_btechNo ratings yet

- Comparison Between Conventional PID and Fuzzy Logic ControllerDocument5 pagesComparison Between Conventional PID and Fuzzy Logic ControllerSidiNo ratings yet

- SAP Logistics ExecutionDocument1 pageSAP Logistics Executionbiltex50% (2)

- GoodtechPCS7 enDocument1 pageGoodtechPCS7 enDhp CiaNo ratings yet

- P. Karelovic - CEP 2015Document12 pagesP. Karelovic - CEP 2015Jose Pablo Yevenes AinzuaNo ratings yet

- Agile & JunitDocument44 pagesAgile & JunitRoger KingNo ratings yet

- (22051) Sheet 0 Thermodynamics and Thermochemistry TH and Ex BDocument120 pages(22051) Sheet 0 Thermodynamics and Thermochemistry TH and Ex Bjust danceNo ratings yet

- R 740Document1 pageR 740Jose LuisNo ratings yet

- EE3302Document2 pagesEE3302ashishNo ratings yet

- Agile Life CycleDocument41 pagesAgile Life Cyclestudboy100% (2)

- Apqp Activities MatrixDocument7 pagesApqp Activities MatrixPk Nimiwal100% (1)

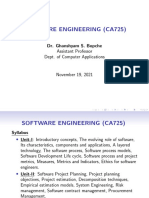

- Draft: Software Engineering (Ca725)Document55 pagesDraft: Software Engineering (Ca725)Amit kumarNo ratings yet