Professional Documents

Culture Documents

Pre104015 1003

Uploaded by

elibeyfelipesalomeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pre104015 1003

Uploaded by

elibeyfelipesalomeCopyright:

Available Formats

E

R

D

E

BOMAG -40 single drum rollers.

Robust technology with low running costs.

S

O

I

L

BOMAG single drum rollers set the standards in soil compaction.

The unrivalled expertise and experience of the world market leader

has been channelled into the -40 series. The result: hard wearing

machine technology and low running costs. In brief: these BOMAG

single drum rollers are the true benchmarks for soil compaction.

22

n

Profit. Lowest costs per cubic metre: BOMAG

single drum rollers demonstrate how efficient

soil compaction is done.

n

Power. Maximum compaction using high linear

loads and amplitudes.

n

Resale value. Quality without compromise:

BOMAG rollers offer a longer working life.

n

Handling. Easy operation ... and fast servicing

as well.

Single drum rollers play a key role in construction engineering. They create the sound basis, in every

sense, on which further work rests. There is no room for compromise, so BOMAG single drum rollers

consistently exceed the targets of modern project specifications by the use of high performance

technology.

3

n

Durablility. Tough TIER2 engines, durable hoods,

top-quality components.

n

Reliability: for extreme hot and cold conditions

the BOMAG cooling system plus a host of other

features.

n

Innovation. E

VIB

measuring technology for

greater reliability and efficiency.

n

Flexibility. The widest choice of options.

BOMAG - 4 0 s i n g l e d r u m r o l l e r s

BOMAG single drum rollers on site in St. Petersburg.

No compromises.

4

Drum and frame: Robust and well designed.

The conventional smooth drum-key features: the

edges are tapered for a smooth surface. Double

scrapers keep drums clean. Contact scrapers are

available for those really tough jobs.

PD models with pad foot drums are suitable for

cohesive soils. The cleverly shaped pad foot

penetrates deep into the soil and imparts a powerful

kneading effect. The wide clearance between drum

and frame prevents clogging, whilst the scraper

tooth profile minimises friction losses. Tooth caps

are made from wear-resistant manganese steel and

can be replaced separately.

Smooth drums can be easily converted to pad foot

roller drums using a segmented shell. This signifi-

cantly expands the rollers scope of use. The

three-part shape allows full adjustment and easy

assembly. The segments can be quickly fitted with-

out having to dismantle the frame.

Advantages at a glance:

n

Tapered drum edges

n

Two scrapers

n

Contact scrapers (optional)

n

Wide clearance between drums and frame

n

Exchangeable caps for scraper teeth

n

Three-part pad foot segmented shell allows

optimum adjustment

n

Segments can be fitted without dismantling the

frame

Easy assembly: Three-part pad foot segments.

Drum specifications are designed to meet on-site requirements. Two types are available.

Smooth drum for sandy soil.

5

Workplace and rear frame.

Theres nothing difficult about operating BOMAG -40

single drum rollers, even for new drivers. Coherently

labelled, durable switches and clearly arranged

displays make operation highly intuitive.

There is a wide selection of attachments for the

drivers platform, including simple rails and solid

sun roof, right up to the ROPS/FOPS roof. The cab

provides extra comfort with its air conditioning

unit. The drivers platform on all models is vibration

insulated for fatigue-free work. All-round visibility is

superb, especially to the wheels.

The rear frame features a fully enclosed pan. The

robust engine hood completely protects the engine

compartment, so all components are well protected

against damage and vandalism. And if an accident

does happen: the sheet steel hood is very easy to

repair.

Simple and clear layout: The workplace. There is a wide choice of attachments for the -40 single drum rollers.

Customised for individual site work: totally enclosed engine

compartment.

Advantages at a glance:

n Easy operation

n Vibration insulated drivers platform

n Outstanding all-round visibility

n Fully enclosed rear frame protecting all

components

n Robust, wrap-around sheet steel hood

BOMAG - 4 0 s i n g l e d r u m r o l l e r s

Te c h n o l o g y

6

The vibration system: the power base.

The BW 218 D-40 compacts layers up to 1.30 m.

Vibration is at the heart of the roller. And it beats powerfully on these BOMAG single drum rollers.

All BOMAG -40 rollers have two amplitudes and

two frequencies. The high amplitudes up to 2.2 mm

and well balanced parameters, such as centrifugal

force, oscillating mass and static load, provide

optimum depth effect and compaction output. The

result of 50 years technical leadership. And of

course BOMAG exciters are exceptionally durable

and low-maintenance. Integrated fan cooling max-

imises service life.

The -40 series features models with operating

weights from 9.5 to 18 t. With the right roller for

virtually any application. Some models can be fitted

with extra ballast options and even higher compac-

tion forces. For example, powerful amplitudes of

2.2 mm are available with the BW 211 and BW 212.

This means 25 % more depth effect.

The BW 218 D-40 shows just how efficient compac-

tion can be: the top model in the -40 series can

compact layers of up to 1.30 m of consolidated

rock.

Advantages at a glance:

n

Circular exciter with high compaction force

n

Up to 2.2 mm amplitude for maximum depth

effect

n

Two amplitudes and frequencies

n

Optimum vibration rating

n

Long service life with fan cooling

n

Wide choice of models and options: the right

roller for almost every application

Power and endurance: vibration with high amplitudes, sealed

bearings and internal cooling.

BF 6 0 0 F i n i s h e r

7

E

VIB

measuring technology: hitting the target

each time.

Combines BCM 05 positioning and BOMAG

StarFire: surface covering compaction map.

BOMAG E

VIB

measuring technology controls compaction during the rolling process. Surface-covering

and precise.

E

VIB

measures soil stiffness precisely and continu-

ously during compaction, and advises when further

compaction is no longer possible. It also identifies

weak spots.

The driver sees the E

VIB

results either on a BEM

round gauge or on the BTMprof display. BTMprof

also has a printer which documents each track.

The BCM 05 is a step up, saving E

VIB

results for the

entire site. GPS data creates accurate compaction

maps, without input from the driver. And the best

part is: the BOMAG StarFire GPS receiver achieves

precision down to 10 cm without a local reference

station. It could not be more flexible, accurate or

easy!

Basic model: BOMAG BEM E

VIB

meter. Up and running anywhere: BOMAG StarFire GPS receiver.

E

VIB

advantages at a glance:

n

E

VIB

values in MN/m

2

for surface covering con-

trol

n

No excess passes

n

Optimum accuracy with two sensors

n

High sampling frequency for comprehensive

analysis of weak spots

n

Integrated printer for immediate documentation

n

BCM 05 either track-bound or with GPS

n

StarFire GPS without local station for greater

flexibility

n

Retrofitting and upgrades possible at any time

BOMAG - 4 0 s i n g l e d r u m r o l l e r s

88

Power on gradients: with no-spin and manual slip control. Dust and heat: not a problem for a BOMAG -40.

The drive system: full power permanently!

The drive on BOMAG single drum rollers has been

designed for performance and long life. The eco-

nomical TIER2 engines with robust, mechanical

injection systems, turbochargers and intercoolers

are resistant to variable fuel quality.

The cooling system is a key feature and the BOMAG

system offers major advantages: cooling air is taken

in where it is cleanest and coolest above and in

front of the engine. This makes -40 single drum

rollers capable of use in temperatures of up to

54C with no difficulty! This design also keeps the

coolers clean. Exhaust air is conducted away from

the machine to prevent dust pollution.

The engine is protected by a two-stage fuel filter.

The air filter is a four-stage filter: two precleaners

and two filter cartridges enhance reliability on

-40 models.

Drum drive and no-spin differential are standard

features. No-spin means automatic locking up to

100%. If one wheel lifts, the other still drives the

roller forwards. The driver can control the torque

between drum and axle using manual slip control

so the machine will still move even under tough

conditions. The machine is capable of tackling

inclines of up to 54%.

In tight areas, BOMAG single drum rollers are

highly mobile with a 35 steering angle. And the

generous ground clearance also boosts rough-

terrain performance.

Advantages at a glance:

n

Robust engines for top reliability

n

BOMAG cooling system: Trouble-free use in

temperatures up to 54C

n

BOMAG cooling system: Less maintenance with

a clean cooler

n

Multi-stage fuel and air filtering

n

No-spin axles with 100% automatic lock

n

Manual slip control for extra traction

n

Outstanding mobility with 35 steering angle

n

High ground clearance of 490 mm

9

Servicing. Less is more.

All service points accessible from the ground and hood opens

manually.

Fewer service requirements means less downtime, less risk and lower costs. BOMAG leads the way

with reduced servicing. Its called: BOMAG Easy Service.

Grease nipples? None! All bearings are filled with

high-performance lubricants and sealed to last the

machine life. Dirt cannot penetrate and lubricant

cannot leak, maximising service life.

The hood can be easily opened fully by hand,

giving clear access to the engine compartment.

Drain valves are attached to the outside of the

frame for all fluids.

Suction for cooling and combustion air is cleverly

arranged so that the cooler remains clean and the

service life of the air filters is greatly increased.

The rubber buffers on the drum can be replaced

individually without dismantling the frame.

And if an accident happens, the front frame on the

-40 single drum rollers offers a major advantage: all

components are bolted, not welded, making repair

work far easier.

Advantages at a glance:

n

No grease nipples

n

Sealed bearings for maximum service life

n

Hood can be opened manually

n

All service points accessible from the ground

n

Drain valves for all fluids on the frame

n

Low-dust cooler

n

Individually exchangeable rubber buffers

n

Bolted (not welded) front frame for quick repairs

Easy Service no grease nipples on -40 single drum rollers.

BOMAG - 4 0 s i n g l e d r u m r o l l e r s

10

BOMAG ROPS/FOPS roof. Lozenge tyres or tractor profiles.

A wide range of options.

BOMAG has the answer to every job situation.

A wide range of models from BW 211 to BW 218

ensure the right choice is available. These single

drum rollers can be individually customised using

many options. Here is a selection:

n

Sun roof

n

ROPS/FOPS

n

ROPS/FOPS cab

n

Deluxe seat

n

Air conditioning unit

n

Work and road traffic lights

n

Extra ballast

n

Higher amplitude

n

Pad foot shell

n

Polyurethane or sheet metal contact scrapers

n

Choice of operating displays

n

Choice of tyre profiles (tractor profile)

n

Special paint finishes

n

Flashing beacon

n

Theft protection

and much more.

If you need a special solution for your next job,

BOMAG is the right partner for you. Flashing beacon.

Federal motor safety standard lighting for safe use on roads.

Deluxe seat.

Quality: no compromises.

BOMAG single drum rollers are always designed for

a long operating life. The result: maximum up-time

and high resale values. A BOMAG machine is an

investment which always adds value. The key factor

for profitability is not the purchase price but costs

over the machine operating life.

These features keep BOMAG at the forefront

for quality:

n

Fan-cooled exciter

n

BOMAG cooling system: for tropical conditions

n

Covered wiring harnesses

n

Sealed central electrics

n

Powder coating

n

Effective hose protection

n

UV-resistant hydraulic hoses

n

Enclosed rear frame to protect all components

n

Robust sheet steel hoods

n

Encased HD articulated joint

n

Multi-stage air and fuel filters

n

Electrical engine control

n

Plastic diesel tank to prevent corrosion

n

Vandal-protection

Customers throughout the world trust the

BOMAG name.

The company has been part of the FAYAT

Group since 2005. BOMAG has six branches

in Germany, twelve independent subsidiary

companies and four production units across

the globe. More than 500 dealers in over

120 countries offer distribution and support

for BOMAG products.

BOMAG quality management is certified according

to ISO 9001. Components have proven reliability

with extensive trials and tests. And BOMAG has

experience on sites all over the world. The -40

single drum rollers are designed for use under the

toughest conditions. BOMAG customer and parts

supply services are always on hand. And as the

expert in compaction technology, BOMAG offers

skilled advice on any application question: our

expert teams are happy to advise and offer sup-

port on site wherever needed.

11

BOMAG -40 series single drum rollers: 100 percent BOMAG quality.

BOMAG - 4 0 s i n g l e d r u m r o l l e r s

0

3

/

1

0

P

R

E

1

0

4

0

1

5

www.bomag.com

Head Office / Hauptsitz:

BOMAG

Hellerwald

56154 Boppard

GERMANY

Tel. +49 6742 100-0

Fax +49 6742 3090

info@bomag.com

BOMAG Maschinen-

handelsgesellschaft m.b.H.

Porschestrae 9

1230 Wien

AUSTRIA

Tel. +43 1 69040-0

Fax +43 1 69040-20

austria@bomag.com

BOMAG (CANADA), INC.

3455 Semenyk Court

Mississauga, Ontario L5C 4P9

CANADA

Tel. +1 905 361 9961

Fax +1 905 361 9962

canada@bomag.com

BOMAG (CHINA)

Compaction Machinery Co. Ltd.

No. 2808 West Huancheng Road

Shanghai Comprehensive

Industrial Zone (Fengxian)

Shanghai 201401

CHINA

Tel. +86 21 33655566

Fax +86 21 33655508

china@bomag.com

BOMA Equipment

Hong Kong LTD

Room 1003, 10/F Cham Centre

700, Castle Peak Road

Kowloon

HONG KONG

Tel. +852 2721 6363

Fax +852 2721 3212

bomahk@bomag.com

BOMAG France S.A.S.

2, avenue du Gnral de Gaulle

91170 Viry-Chtillon

FRANCE

Tel. +33 1 69578600

Fax +33 1 69962660

france@bomag.com

BOMAG (GREAT BRITAIN), LTD.

Sheldon Way

Larkfield, Aylesford

Kent ME20 6SE

GREAT BRITAIN

Tel. +44 1622 716611

Fax +44 1622 718385

gb@bomag.com

BOMAG Italia Srl.

Via Roma 50

48011 Alfonsine

ITALY

Tel. +39 0544 864235

Fax +39 0544-864367

italy@bomag.com

FAYAT BOMAG Polska Sp. z o.o.

Ul. Szyszkowa 52

02-285 Warszawa

POLAND

Tel. +48 22 482 0400

Fax +48 22 482 04 01

poland@bomag.com

FAYAT BOMAG RUS OOO

141400, RF, Moscow region

Khimki, Klayazma block, h. 1-g

RUSSIA

Tel. +7 (495) 287 92 90

Fax +7 (495) 287 92 91

russia@bomag.com

BOMAG GmbH

300 Beach Road

The Concourse, #18-06

Singapore 199555

SINGAPORE

Tel. +65 6 294 1277

Fax +65 6 294 1377

singapore@bomag.com

BOMAG Americas, Inc.

2000 Kentville Road

Kewanee, Illinois 61443

U.S.A.

Tel. +1 309 8533571

Fax +1 309 8520350

usa@bomag.com

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- BW138AD Operation Maintenance PDFDocument86 pagesBW138AD Operation Maintenance PDFelibeyfelipesalome67% (3)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Engine Electrical 1999 - GMC C Series - C7Document402 pagesEngine Electrical 1999 - GMC C Series - C7elibeyfelipesalome100% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Service Manual: (Before Serial Number 1090)Document229 pagesService Manual: (Before Serial Number 1090)elibeyfelipesalome100% (1)

- C7-C9 Electrical Electronic GuideDocument204 pagesC7-C9 Electrical Electronic GuideElibey Cuadros Berbesi93% (41)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- IU IIDC Time Management and Organizational SkillsDocument40 pagesIU IIDC Time Management and Organizational SkillsAsger HamzaNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Hume 100 ReviewerDocument7 pagesHume 100 ReviewerShai GaviñoNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Practicewith Argument Athletesas ActivistsDocument30 pagesPracticewith Argument Athletesas ActivistsRob BrantNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- I. Objectives Ii. Content Iii. Learning ResourcesDocument13 pagesI. Objectives Ii. Content Iii. Learning ResourcesZenia CapalacNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- World Trends in Municipal Solid Waste ManagementDocument11 pagesWorld Trends in Municipal Solid Waste ManagementNeima EndrisNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Ship Recognition Manual TOSDocument138 pagesShip Recognition Manual TOSCody Lees94% (17)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Harriet Tubman Lesson PlanDocument7 pagesHarriet Tubman Lesson PlanuarkgradstudentNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Drilling Jigs Italiana FerramentaDocument34 pagesDrilling Jigs Italiana FerramentaOliver Augusto Fuentes LópezNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- 1.2 The Basic Features of Employee's Welfare Measures Are As FollowsDocument51 pages1.2 The Basic Features of Employee's Welfare Measures Are As FollowsUddipta Bharali100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- 3DD5036 Horizontal.2Document6 pages3DD5036 Horizontal.2routerya50% (2)

- CTRLX Automation BrochureDocument60 pagesCTRLX Automation BrochureNinja do SofáNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- AMiT Products Solutions 2022 1 En-SmallDocument60 pagesAMiT Products Solutions 2022 1 En-SmallMikhailNo ratings yet

- S25580 MSDS Corn Starch FisherchiDocument6 pagesS25580 MSDS Corn Starch FisherchiProcurement ProlineNo ratings yet

- Human Development and Performance Throughout The Lifespan 2nd Edition Cronin Mandich Test BankDocument4 pagesHuman Development and Performance Throughout The Lifespan 2nd Edition Cronin Mandich Test Bankanne100% (28)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Skirmishes Graham Harman PDFDocument383 pagesSkirmishes Graham Harman PDFparaiaNo ratings yet

- A First Etymological Dictionary of BasquDocument29 pagesA First Etymological Dictionary of BasquDaily MailNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- SemDocument583 pagesSemMaria SantosNo ratings yet

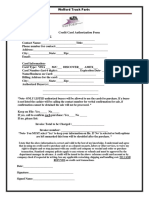

- Credit Card Authorization Form WoffordDocument1 pageCredit Card Authorization Form WoffordRaúl Enmanuel Capellan PeñaNo ratings yet

- Number CardsDocument21 pagesNumber CardsCachipún Lab CreativoNo ratings yet

- Diltoids Numberletter Puzzles Activities Promoting Classroom Dynamics Group Form - 38486Document5 pagesDiltoids Numberletter Puzzles Activities Promoting Classroom Dynamics Group Form - 38486sinirsistemiNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Toftejorg TZ-75 Rotary Jet Head - Portable: Fast, Effective Impact CleaningDocument3 pagesToftejorg TZ-75 Rotary Jet Head - Portable: Fast, Effective Impact CleaningSamo SpontanostNo ratings yet

- Ib Psychology - Perfect Saq Examination Answers PDFDocument2 pagesIb Psychology - Perfect Saq Examination Answers PDFzeelaf siraj0% (2)

- "Large Quote Goes Here.": Title or Heading HereDocument2 pages"Large Quote Goes Here.": Title or Heading HereHesti RianaNo ratings yet

- PH-01 (KD 3.1) Filling Out Forms (PG20) - GFormDocument4 pagesPH-01 (KD 3.1) Filling Out Forms (PG20) - GFormLahita AzizahNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Thesis - A Surlyn® Ionomer As A Self-Healing and Self-Sensing Composite - 2011 - UKDocument194 pagesThesis - A Surlyn® Ionomer As A Self-Healing and Self-Sensing Composite - 2011 - UKAhmedNo ratings yet

- WSI - Catalogue of O-Ring PDFDocument37 pagesWSI - Catalogue of O-Ring PDFyearetg100% (1)

- Angle ModulationDocument26 pagesAngle ModulationAtish RanjanNo ratings yet

- Application Letter For Promotion T2 T3Document24 pagesApplication Letter For Promotion T2 T3FGacadSabadoNo ratings yet

- Operation and Service 69UG15: Diesel Generator SetDocument72 pagesOperation and Service 69UG15: Diesel Generator Setluis aguileraNo ratings yet

- Cambridge IGCSE ™: Combined ScienceDocument11 pagesCambridge IGCSE ™: Combined ScienceAhmed Jomaa Salem0% (1)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)