Professional Documents

Culture Documents

Ocean Ee Ring

Uploaded by

Nurul HudaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ocean Ee Ring

Uploaded by

Nurul HudaCopyright:

Available Formats

OCEANEERING INTERNATIONAL, INC.

Advancing off shore oil and gas exploration with SolidWorks Enterprise PDM

As the search for oil and gas reserves increasingly requires off shore deepwater

exploration,

Oceaneering International, Inc., has become a leading provider of subsea technic

al solutions.

The company designs and manufactures a variety of engineered off shore products,

including

remotely operated vehicles (ROVs), mobile off shore production systems, and buil

t-to-order

specialty subsea hardware. Oceaneerings expertise has enabled the company to grow

into a

globally diversifi ed manufacturer of advanced technology applications with reve

nues of more

than $1.9 billion a year.

The companys rapid growthwith thousands of employees working out of 66 locations i

n

18 countrieshas created a range of product development challenges. At its Deepwat

er

Technical Solutions (DTS) division, engineers use SolidWorks 3D design and simula

tion

technologies as part of their eff orts to streamline development and control cos

ts. However,

to truly maximize its productivity gains, DTS needed a product data management (

PDM)

system that could integrate its globally dispersed product development operation

s,

according to John Mullen, PDM implementation manager.

We needed to implement a PDM system that our employees would actually use in ord

er

to save time and money, Mullen explains. In addition to connecting DTS engineering

locations in the United States, Canada, Brazil, Norway, Scotland, India, and Sin

gapore, we

wanted to extend access to design data to other departments as well as integrate

it with

our PeopleSoft enterprise resource planning (ERP) system. We believed that by pr

oviding

everyone connected with the business with managed access to design data, we woul

d realize

substantial improvements in effi ciency.

Aft er researching PDM solutions, Oceaneering chose SolidWorks Enterprise PDM,

implementing 200 seats at DTS worldwide. The company chose SolidWorks Enterprise

PDM

because it is easy to use and administer, requires minimal training, and costs a

fraction of

the price of most PDM solutions.

C A S E S T U D Y

Challenge:

Connect the design, engineering, and

business operations of the Deepwater

Technical Solutions division to improve the

quality of off shore oil and gas products,

eliminate unnecessary development costs,

and accelerate product delivery.

Solution:

Implement SolidWorks design, simulation,

and PDM solutions to improve communication,

minimize rework, encourage design reuse and

standardization, accelerate time-to-market,

and reduce development costs.

Results:

Shortened design cycles by 40 percent

Cut time-to-market by 50 percent

Reduced development costs by 30 percent

Increased design reuse by 40 percent

eff Using SolidWorks integrated

design, simulation, and PDM

solutions, Oceaneering effff ectively

overcomes the challenges of a

globally dispersed product

development organization.

The way that SolidWorks Enterprise PDM is set up is phenomenal, Mullen stresses. It

does

not require teams of people to manage or implement. I can sit in my office in Ho

uston and

implement vaults anywhere in the world. DS SolidWorks has made this software so

easy to

implement and use that our team became proficient and began using it after only

three hours

of training, compared to weeks of training with other PDM applications.

Compressing development cycles

Since implementing SolidWorks Enterprise PDM, Oceaneering DTS has reduced its de

sign

cycles by 40 percent and cut time-to-market by 50 percent through greater design

reuse

(a 40-percent increase), tighter revision control, automated workflows, and dram

atically

improved design search capabilities. For example, DTS engineers used to spend up

to

four hours searching for a particular design file, a circumstance that led to a

great deal of

geometry re-creation and related inconsistencies. Now, an engineer can find a sp

ecific file in

just seconds.

By installing SolidWorks Enterprise PDM, we keep the work flowing, which is how w

e make

money, Mullen notes. We are able to find designs more quickly, use what others hav

e

already made more frequently, and move quality product out the door more consist

ently.

Squeezing out unnecessary costs

In addition to time savings, the tighter revision control, improved workflows, a

nd greater

standardization afforded by SolidWorks Enterprise PDM have resulted in significa

nt cost

reductions at DTS related to less scrap and rework, fewer mistakes, and more eff

icient

throughput.

We have saved money by going paperless, using the PDM system to drive workflows,

and giving manufacturing personnel access to the latest model revisions, Mullen p

oints

out. PDM has enabled us to reduce our development costs by 30 percent and complet

ely

eliminate ECOs. Instead of issuing an ECR, we roll to a new revision. With PDM,

there are no

longer questions about the correct revision or unauthorized part modifications,

which results

in far less rework.

Integrating development and business operations

SolidWorks Enterprise PDM also pays dividends for DTS outside of engineering and

manufacturing through integration with other business operations. Purchasing age

nts can

place accurate orders when they make sense. Project managers have greater insigh

t into

design progress. Marketing and sales personnel can update their presentations an

d materials

with the latest revision information.

PDM makes design data available to whoever needs it in the appropriate form, Mulle

n

explains. Everything is available to engineers, and other business functions can

access

data in the format that meets their needs. This degree of integration results in

improved

communication and feedback, which helps every aspect of our business run more ef

ficiently.

SolidWorks is a registered trademark of Dassault Systmes SolidWorks Corp. All oth

er company and product names are trademarks

or registered trademarks of their respective owners. 2010 Dassault Systmes. All ri

ghts reserved. MKOCECSENG1110

By installing SolidWorks

Enterprise PD M, we kee p

the work flowing, which

is how we make money.

John Mullen

PDM Implementation Manager

With SolidWorks Enterprise PDM, Oceaneering

saves time and money through tighter revision

control. improved workflows, and greater

standardization.

Dassault Systmes

SolidWorks Corp.

300 Baker Avenue

Concord, MA 01742 USA

Phone: 1 800 693 9000

Outside the US: +1 978 371 5011

Email: info@solidworks.com

www.solidworks.com

Oceaneering, Deepwater

Technical Solutions

11915 FM 529

Houston, TX 77041 USA

Phone: +1 832 467 7812

www.oceaneering.com

VAR: Progression Technologies,

Houston, Texas USA

You might also like

- Elastic BeaconsDocument9 pagesElastic BeaconsNurul HudaNo ratings yet

- Analysis and Design of Marine Structures V Digital PDFDocument4 pagesAnalysis and Design of Marine Structures V Digital PDFNurul Huda0% (1)

- Designmodeler: Workshop 5.1 3D CurveDocument8 pagesDesignmodeler: Workshop 5.1 3D CurveNurul HudaNo ratings yet

- 25 Abaqus ODBDocument6 pages25 Abaqus ODBNurul HudaNo ratings yet

- Steel Pipes - Pipe Schedule ChartDocument3 pagesSteel Pipes - Pipe Schedule ChartNurul HudaNo ratings yet

- Asme B30Document1 pageAsme B30Nurul Huda100% (1)

- Fatigue Analysis Tool 1.0Document2 pagesFatigue Analysis Tool 1.0Nurul HudaNo ratings yet

- Spring Analysis Tool3Document4 pagesSpring Analysis Tool3Nurul HudaNo ratings yet

- Response Spectra GenerationDocument16 pagesResponse Spectra GenerationNurul HudaNo ratings yet

- 3.4 Finite Element Analysis of Wind Induced Buckling of Steel TankDocument4 pages3.4 Finite Element Analysis of Wind Induced Buckling of Steel TankNurul HudaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- AMULDocument11 pagesAMULkeshav956No ratings yet

- Building Services Planning Manual-2007Document122 pagesBuilding Services Planning Manual-2007razanmrm90% (10)

- Contents EEMUA Publication 190 Edition1 May 2015Document4 pagesContents EEMUA Publication 190 Edition1 May 2015Aditya JainNo ratings yet

- Chhay Chihour - SS402 Mid-Term 2020 - E4.2Document8 pagesChhay Chihour - SS402 Mid-Term 2020 - E4.2Chi Hour100% (1)

- EPAS 11 - Q1 - W1 - Mod1Document45 pagesEPAS 11 - Q1 - W1 - Mod1Alberto A. FugenNo ratings yet

- Performance Task 1Document3 pagesPerformance Task 1Jellie May RomeroNo ratings yet

- Congenital Cardiac Disease: A Guide To Evaluation, Treatment and Anesthetic ManagementDocument87 pagesCongenital Cardiac Disease: A Guide To Evaluation, Treatment and Anesthetic ManagementJZNo ratings yet

- Training For Humans Guide: FAQ's How Many Sets/reps Should I Do Per Exercise?Document28 pagesTraining For Humans Guide: FAQ's How Many Sets/reps Should I Do Per Exercise?Paulo Pires100% (1)

- In Flight Fuel Management and Declaring MINIMUM MAYDAY FUEL-1.0Document21 pagesIn Flight Fuel Management and Declaring MINIMUM MAYDAY FUEL-1.0dahiya1988No ratings yet

- Miniature Daisy: Crochet Pattern & InstructionsDocument8 pagesMiniature Daisy: Crochet Pattern & Instructionscaitlyn g100% (1)

- SLA in PEGA How To Configue Service Level Agreement - HKRDocument7 pagesSLA in PEGA How To Configue Service Level Agreement - HKRsridhar varmaNo ratings yet

- IMCI Chart BookletDocument43 pagesIMCI Chart Bookletmysticeyes_17100% (1)

- Synthesis, Analysis and Simulation of A Four-Bar Mechanism Using Matlab ProgrammingDocument12 pagesSynthesis, Analysis and Simulation of A Four-Bar Mechanism Using Matlab ProgrammingPedroAugustoNo ratings yet

- How To Block HTTP DDoS Attack With Cisco ASA FirewallDocument4 pagesHow To Block HTTP DDoS Attack With Cisco ASA Firewallabdel taibNo ratings yet

- DBMS Lab ManualDocument57 pagesDBMS Lab ManualNarendh SubramanianNo ratings yet

- 40 People vs. Rafanan, Jr.Document10 pages40 People vs. Rafanan, Jr.Simeon TutaanNo ratings yet

- PDFDocument10 pagesPDFerbariumNo ratings yet

- Development Developmental Biology EmbryologyDocument6 pagesDevelopment Developmental Biology EmbryologyBiju ThomasNo ratings yet

- Lesson 6 - Vibration ControlDocument62 pagesLesson 6 - Vibration ControlIzzat IkramNo ratings yet

- (Jones) GoodwinDocument164 pages(Jones) Goodwinmount2011No ratings yet

- Delusion in SocietyDocument2 pagesDelusion in SocietyGasimovskyNo ratings yet

- ASHRAE Journal - Absorption RefrigerationDocument11 pagesASHRAE Journal - Absorption Refrigerationhonisme0% (1)

- Genetics Icar1Document18 pagesGenetics Icar1elanthamizhmaranNo ratings yet

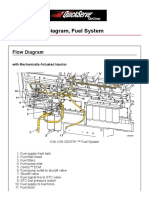

- Cummin C1100 Fuel System Flow DiagramDocument8 pagesCummin C1100 Fuel System Flow DiagramDaniel KrismantoroNo ratings yet

- KsDocument5 pagesKsnurlatifahNo ratings yet

- PMP Assesment TestDocument17 pagesPMP Assesment Testwilliam collinsNo ratings yet

- What Are The Spacer Bars in RC Beams - QuoraDocument3 pagesWhat Are The Spacer Bars in RC Beams - QuoradesignNo ratings yet

- Kiritsis SolutionsDocument200 pagesKiritsis SolutionsSagnik MisraNo ratings yet

- LP For EarthquakeDocument6 pagesLP For Earthquakejelena jorgeoNo ratings yet

- Interlocking Block TechnologyDocument15 pagesInterlocking Block TechnologyChaula Trivedi100% (5)