Professional Documents

Culture Documents

Articulo 1

Uploaded by

Oscar GarridoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Articulo 1

Uploaded by

Oscar GarridoCopyright:

Available Formats

Effective extraction of microalgae lipids from wet

biomass for biodiesel production

Hanifa Taher

a

, Sulaiman Al-Zuhair

a,

*, Ali H. Al-Marzouqi

a

, Yousef Haik

b

,

Mohammed Farid

c

a

Chemical and Petroleum Engineering Department, UAE University, Al-Ain, United Arab Emirates

b

Mechanical Engineering Department, UAE University, Al-Ain, United Arab Emirates

c

Chemical and Materials Engineering Department, University of Auckland, New Zealand

a r t i c l e i n f o

Article history:

Received 23 September 2013

Received in revised form

28 January 2014

Accepted 28 February 2014

Available online 20 March 2014

Keywords:

Enzymes

Cell disruption

Wet microalgae

Separation

Nitrogen starvation

Biodiesel

a b s t r a c t

Producing biodiesel from lipid extracted from microalgae is a promising approach for

sustainable fuel production. However, this approach is not yet commercialized due to the

high costs of upstream processes that are associated with the time consuming and/or

energy intensive drying, and lipid extraction processes. In this study, the possibility of

avoiding the drying process, and extracting the lipid directly from the wet concentrated

cells, using enzymatic disruption to enhance the extraction, has been tested. Results

showed that lysozyme and cellulase were both efcient in disrupting cell walls and

enhancing lipid extraction from wet samples, with highest lipid extraction yield of 16.6%

achieved using lysozyme. The applicability of using supercritical CO

2

(SC-CO

2

) in extracting

lipid from wet biomass was also tested and the highest yield of 12.5% was achieved using

lysozyme. In addition, a two-step culturing process was applied, using Scenedesmus sp., to

combine both high biomass growth and lipid content. The strain was able to increase its

biomass productivity in the rst stage, reaching 174 mg l

1

d

1

, with almost constant lipid

content. In the second stage, the lipid content was enhanced by six-fold after three weeks

of nitrogen starvation, but with lower biomass productivity.

2014 Elsevier Ltd. All rights reserved.

1. Introduction

Biodiesel, a series of mono-alkyl fatty acid esters, has received

an increasing attention, especially with the increasing energy

demand and inevitable depletion of fossil fuel reserves [1,2].

Conventionally, biodiesel is produced fromoils extracted from

oil crops. This is highly controversial and competes with their

use as a food stock. In addition, the oil crops require large

arable land development, fertilization, and fresh water

irrigation. These signicant drawbacks limit further industri-

alization and urge to nd new feedstocks. Waste cooking oils

and animal fats have been suggested as alternatives; however

the supply of such feedstocks is not consistent and cannot

satisfy the large demand for biodiesel production. In addition,

poor cold ow properties (cloud and pour points) of oils and

saturated fatty acid contents of animal fats reduce the quality

of produced biodiesel [3]. On the other hand, oil extracted

from microalgae has recently emerged as a potential alter-

native source due to the microalgae high growth rate, high

* Corresponding author. Tel.: 971 35319.

E-mail address: s.alzuhair@uaeu.ac.ae (S. Al-Zuhair).

Available online at www.sciencedirect.com

ScienceDirect

ht t p: / / www. el sevi er. com/ l ocat e/ bi ombi oe

b i o ma s s a nd b i o e ne r gy 6 6 ( 2 0 1 4 ) 1 5 9 e1 6 7

http://dx.doi.org/10.1016/j.biombioe.2014.02.034

0961-9534/ 2014 Elsevier Ltd. All rights reserved.

lipid content, and ability to grow in seawater. Furthermore,

they do not require development of agriculture lands. The

lipid productivity of microalgae is reported to be ten times

higher than that of the best oil crop, which makes it a prom-

ising alternative [1,3]. In spite of their obvious advantages over

oil crops, microalgae-biodiesel production processes are not

yet commercialized.

Generally, microalgae can produce both neutral lipids,

composed mainly of triglycerides, and polar lipids such as

phospholipids, which commonly produced in cellular mem-

brane, whereas the former usually accumulated as droplets in

the cytoplasm [4]. The biodiesel production process from

microalgae consists of biomass cultivation, harvesting, dry-

ing, and lipid extraction, followed by the conversion of

extracted lipids to biodiesel, and nally purication of the

produced biodiesel.

Among the main challenges in the biodiesel production

from microalgae are separating the cultivated biomass from

the growth media and extracting lipids from the harvested

biomass. The biomass concentration of Scenedesmus is re-

ported to be low in outdoor cultures, reaching 0.02e0.12 g l

1

[5] and increases to about 0.3e3.4 g l

1

[6] in photobioreactors.

The currently used harvesting methods are centrifugation,

sedimentation and occulation. These methods have been

proven to be effective but are costly, representing 20e35% of

total biomass production cost [7].

On the other hand, a drying step is usually required prior to

lipid extraction from the harvested microalgae cells. Sun

drying is the most commonly used method, as it directly uti-

lizes the solar energy. However, it is a time consuming process

and the drying rate remains the main challenge of such pro-

cess. Other faster processes are energy intensive and/or can

alter the lipid structure and the protein rich leftover biomass,

which affects their quality. It has been reported that the dry-

ing step accounts for 89% of the required energy input [8], and

70e75% of total processing cost [9]. Thus, it is considered as

the major bottleneck of algae based biodiesel production [10].

Therefore, positive net energy from microalgae biodiesel

could be obtained if wet extraction is used. It would be

economically favorable to avoid the drying step while main-

taining an effective lipid extraction from the wet biomass.

Indeed, it has been estimated that the energy required to

produce 1 kg of biodiesel from dried biomass is 4000 times

more than that from wet biomass [11]. This requires expen-

sive and high energy consumption in both the up- and down-

stream processes in order to get high quality biodiesel.

It is vital therefore to develop a cost and energy effective

processes, which is green and environmental friendly, which

can overcome the main technical and economical barriers of

the conventional techniques. In addition, for microalgae uti-

lization process to be feasible, the extraction process should

not negatively affect the de-lipidated leftover biomass to allow

it to be used in useful applications, or its conversion to a

valuable product.

Several extraction methods can be used to extract the lipid

from dried microalgae biomass. Among the common used

techniques are Folch [12], Bligh and Dyer [13], and Soxhlet [14].

However, these techniques are complicated and time

consuming, requiring about 1e3 days for completion. In

addition, an extra solvent evaporation unit is required to

separate the extracted lipid from the solvent. Furthermore,

contamination of the de-lipidated with traces of solvent is

inevitable, which limits their further uses. Recently, super-

critical CO

2

(SC-CO

2

) received considerable attention due to its

tunable solvation power, mild operating conditions, and

environmental benign features. In addition, the process is

fast, and extraction that requires 24 h using conventional

techniques is completed with 30e60 min. This technique also

does not require solvent separation, as CO

2

is separated from

the extracted lipid by simple depressurization. Furthermore,

there is no contamination of the leftover biomass with the

extraction solvent.

On the other hand, the rigid and tough cell walls of

microalgae cells hinder the extraction of the cells lipids. These

cell walls are mainly composed of 24e74% neutral sugars,

1e24% uronic acids, 2e16% protein, and 0e15% glucosamine

[15]. In addition, the presence of water in wet harvested

biomass forms a lmpreventing the solvent fromreaching the

lipid, which further prevents efcient lipid extraction. Thus,

for an efcient extraction of the lipid, the microalgae cells

have to be disrupted to liberate the lipid and allow them to

come into contact with the solvent. This is conventionally

done using wet milling [16], ultrasonication [17,18], bead-

beating [14], microwaves [18], autoclaving at a high tempera-

ture and pressure, and osmotic disruption by treatment with

sodium chloride [19]. All these processes however, are energy

intensive and may affect the properties of the triglycerides

causing downstream difculties in their transesterication to

biodiesel. Inaddition, mechanical disruptionusually results in

excessive heat generation, which requires cooling.

Another technique, which is commonly used is acid

treatment [20]. Usually, this is performed by soaking the

biomass in diluted acid, commonly sulfuric acid, and then

heating it at high temperature for a certain time. In many

cases, this is followed by alkaline addition, commonly sodium

hydroxide, thus leading to pores swelling and decreasing in

cellulose crystallinity. Although this process is efcient in

lignocellulose degradation, sulfuric acid is toxic and corrosive,

which makes this process not recommended, neither for fuel

production nor for the left biomass applications. Freeze drying

has also been suggested [18], wherein harvested cells are

lyophilized, resulting in dried powder, prior to lipid extraction.

Lyophilization, however, is an energy intensive process that is

not justied in energy production processes.

For an-economical and effective lipid production, efcient

cell disruption, mild extraction conditions, and leftover

biomass utilization are essential. Some enzymes have the

potential to facilitate the cell disruption. They can operate at

low temperatures with high selectivity and fewer side prod-

ucts. Utilizing enzymes for cell disruption is expected to

enhance the efciency of lipid extraction at mild conditions.

Operation at mild conditions is less energy intensive and also

has a minimum effect on the triglycerides structure or the

leftover residual biomass that can be utilized in pharmaceu-

tical, food and fuel applications.

Several lysis enzymes can be used, such as cellulase that

can effectively hydrolyze the cellulosic structure of the cell

walls, and lysozyme that can hydrolyze the linkage between

peptidoglycan residues in the cell walls. Specically, it de-

grades polymers containing N-acetylglucosamine, which is a

b i oma s s a nd b i oe ne r g y 6 6 ( 2 0 1 4 ) 1 5 9 e1 6 7 160

derivative of glucosamine, major component of cell wall. The

enzymes have been tested on Chlorella species and outer cell

wall disruption was observed [21e24]. In this work, the two

enzymes were tested to disrupt cell wall, and liberate the lipid,

which would enhance the extraction process.

To the best of our knowledge, enzymatic disruption com-

bined with SC-CO

2

extraction has not been reported in liter-

ature. The use of such process is less time consuming than

conventional solvent extraction processes, avoids the use of

toxic chemicals, and does not require solvent separation unit.

In addition, the process allows the utilization of the protein

rich leftover biomass.

In additionto the extraction challenges, the lipid content of

the microalgae cells is important. The overall effectiveness of

biodiesel production from microalgae depends on the lipid

productivity, which is a combined effect of biomass produc-

tivity and lipid content. The reported lipid content of micro-

algae is in the range of 20e30% (dry basis) when the

microalgae are grown under controlled conditions with suf-

cient nutrients. However, under stress conditions, microalgae

may accumulate larger lipid content [25e28]. The primary

stress applied to green microalgae is nitrogen deciency,

where accumulations of more than 50% (dry basis) have been

reported [1,29]. This is mainly due to the lack of nitrogen

required for protein synthesis, and the excess carbon from

photosynthesis is then diverted into lipid production pathway

[30].

The objective of this study is to assess the effectiveness of

using enzymes for cell disruption and compare it conven-

tional methods. In addition, investigate the possibility of

extracting lipids fromwet biomass using SC-CO

2

, avoiding the

high organic solvent consumption, the time consuming dry-

ing step and the energy intensive mechanical cell disruption.

In addition, lipid enhancement by nitrogen starvation, com-

bined with efcient biomass production is also studied to

conrm Scenedesmus sp. applicability for biodiesel production.

The success of this work adds great enhancement to the

extraction process, which in turn has a positive effect on the

overall algae biodiesel production process.

2. Materials and methods

2.1. Chemicals and enzymes

n-Hexane, methanol, acetone, sulfuricacid, sodiumhydroxide,

HEPES (4-(2-hydroxyethyl)-1-piperazineethanesulfonic acid),

14% boron tetraouridemethanol mixture, Nile Red (9-

diethylamino-5-benzo[a] phenoxazinone), dimethyl sulfoxide

(DMSO), were purchased from SigmaeAldrich Inc., USA. Liq-

ueed CO

2

with a purity of 99.95% was supplied by Abu-Dhabi

Oxygen Company, UAE. Ultra high purity helium and zero-air

were supplied by Air Product Company, UAE. Lysozyme from

chicken egg white (activity > 40,000 U mg

1

, according to the

suppliers denition) and cellulase from Trichoderma long-

ibrachiatum (activity 1.0 U mg

1

, according to the suppliers

denition) were purchased fromSigmaeAldrichInc., USA, and

stored below 8

C and above 0

C according to the suppliers

instructions, respectively. Standard of high purity fatty acid

methyl esters (FAMEs), used for gas chromatography (GC)

calibration and fatty acid compositional analysis, comprised

of; 3.9% myristic acid methyl ester (C14:0), 9.9% palmitic acid

methyl ester (C16:0), 6.0%stearic acid methyl ester (C18:0), 10%

elaidic acid methyl ester (C18:1), 24.8%cis-9-oleic methyl ester

(C18:1), 36.1% linoleic acid methyl ester (C18:2n6c), 1.9% lino-

lelaidic acid methyl ester (C18:2), 2.1% arachidic acid methyl

ester (C20:0), and 2.1% behenic acid methyl ester (C22:0) were

obtained from Sigma Aldrich, USA.

2.2. Strains and culture medium

Scenedesmus sp. culture was obtained fromAlgal Oil Company,

Philippines, and cultivated in a modied bassel medium(3N-

BBM) for two weeks, followed by three weeks of stressing in

nitrogen-deprivation medium (N-BBM). The modied me-

dium, 3N-BBM, comprised of (in mM); 8.82 NaNO

3

, 0.17

CaCl

2

$2H

2

O, 0.3 MgSO

4

$7H

2

O, 1.29 KH

2

PO

4

, 0.43 K

2

HPO

4

, 0.43

NaCl, 1 ml l

1

of Vitamine B

12

, and 6 ml l

1

of P-IVsolution that

consisted of 2 Na

2

EDTA$2H

2

O, 0.36 FeCl

3

$6H

2

O, 0.21

MnCl

2

$4H

2

O, 0.37 ZnCl

2

, 0.0084 CoCl

2

$6H

2

O, and 0.017

Na

2

MoO

4

$2H

2

O. In N-BBM, the nitrate source (NaNO

3

) was

removed.

2.3. Growth experiments

For an economical biodiesel production frommicroalgae, high

biomass productivity and lipid content are important. These

two factors are difcult to achieve simultaneously, as condi-

tions favoring high biomass productivity usually result in low

lipid accumulation, and vice versa. To overcome this, a two

stage cultivation approach has been used, wherein the rst

stage, the cells were allowed to grow in a nutrient rich me-

dium (3N-BBM) for two weeks to enhance the biomass pro-

ductivity, and in the second stage cells in their exponential

growth phase were transferred to a nitrogen-decient me-

dium (N-BBM) for three weeks to enhance the lipid accu-

mulation. The cultivations in both stages were done in a 5 l

bubble column photobioreactor with an internal illumination.

All cultivations in this work were autotrophic, with CO

2

naturally present in air bubbled through the system being the

sole carbon source.

Prepared media were sterilized in autoclave (Hirayama HV-

50, Japan) at 121

C for 15 min and cooled to roomtemperature

prior to use. The microalgae was rst grown in 200 ml of 3N-

BBM placed in 500 ml Erlenmeyer asks with ltered air

bubbling at a constant temperature of 25 1

C under light

intensity of 75 mmol m

2

s

1

determined using a light meter

(model 472990, Extech Instruments, Massachusetts) with an

initial cell concentration of 3.2 10

4

cells ml

1

. Details about

cell concentration determination are mentioned later. After 11

days of growth, the culture was transferred to the photo-

bioreactor, where the growth was monitored with time. The

photobioreactor was illuminated with one 50 cm, 60 W, white

uorescent light at a light intensity of 120 mmol m

2

s

1

,

measured using the light meter under 12 h light/dark photo-

period automatically controlled by 24 h timer (S2402, China).

The photobioreactor had an outer diameter of 10 cm, an inner

diameter of 5 cm and 40 cm height.

The cell growth was monitored daily by measuring the

optical density at 680 nm using a spectrophotometer

b i o ma s s a nd b i o e ne r gy 6 6 ( 2 0 1 4 ) 1 5 9 e1 6 7 161

(Shimadzu UVe1800 UV, Kyoto, Japan). The samples were

measured twice and the average values were considered. The

cell concentration (cells ml

1

) at any given cultivation time

was calculated from a pre-prepared calibration curve of the

optical density at 680 nm versus cell concentration deter-

mined using Neubauer Hemocytometer, placed on a micro-

scope (Eclipse LV100 Pol, Nikon, Japan). The dry weight of algal

biomass was also determined by ltering the algal suspension

using a, prewashed and dried Whatman lter paper, dried

overnight at 105

C in an oven (Memmert, Germany) until

constant weight.

On day 14, while cells were still in their exponential growth

phase, they were allowed to settle at the bottom of the pho-

tobioreactor, and were then concentrated by centrifugation at

3000 r min

1

for 15 min using multispeed centrifuge (IEC CL31,

Thermo Scientic, USA), and washed twice with distilled

water. Concentrated microalgae cells, after centrifugation,

were cultivated back in a similar photobioreactor in N-BBM

medium to enhance the lipid accumulation. Samples were

collected at regular intervals, centrifuged and re-diluted in

distilled water to obtain a 4 ml of cell suspension. For lipid

testing, the accumulations were monitored by staining the

constant concentration samples (1.5 10

6

cells ml

1

) with Nile

Red that emits a yellow uorescent signal in the presence of

the lipid, and the uorescents were visualized using uores-

cence microscope (Olympus). The Nile Red stock solution was

prepared as described by Siaut et al. [31], by dissolving 0.1 mg

of Nile Red in 1 ml acetone, and the solution was stored in the

dark at 4

C. Culture samples (500 ml) were placed in an

eppendorf tube, span in a centrifuge (Sigma 113, Germany) for

30 s at 4000 r min

1

and 410 ml of the supernatant were taken.

DMSO (10 ml) was then added to promote the accessibility of

Nile Red into the cells. The culture was then vortexed and 1 ml

of Nile Red solution was added followed by 20 min incubation

in the dark. The lipid accumulations were then quantied

using Multi-label Plate Reader (PerkineElmer, Boston) with

black 96-well plates. Fluorescences were measured before and

after Nile Red staining and for Nile Red stained N-BBM me-

dium. The intensity was considered after subtracting the

stained medium and sample before staining intensities from

the stained sample intensity at excitation and emission

wavelengths of 485 and 590 nm, respectively.

2.4. Cells disruptions

Wet cell biomass samples (1 g containing 6.8% solids) were

subjected to three different disruption methods, namely: (1)

lyophilization, (ii) enzymatic disruption and (iii) acid treat-

ment. The lyophilization was carried out in a freeze drier

(Telstar, Terrassa, Spain) operated at 54

C and 0.02 mbar for

6 h. The enzymatic pre-treatments were carried as follow;

3.25 ml of 10 mg ml

1

of enzymatic (lysozyme or cellulase)

solution was added to the wet biomass in the presence of

7.5 ml HEPES buffer solution (pH 7.48). This corresponds to

lysozyme and cellulase loadings of 1.92 10

4

and 0.48 U mg

1

dry biomass, respectively, with 6.78 g l

1

biomass loading. The

mixtures were then incubated in SI-300 Shaker at 37

C and

100 r min

1

for 30 min. The acid treatment was done by adding

1 ml of sulfuric acid (1 M) to the wet biomass and heated to

90

C for 30 min in shaking water bath (LabTech, Daihan

LabTech Co., Ltd., Korea), followed by addition of 1 ml sodium

hydroxide (5 M) solution and further incubation at 90

C for

30 min [20].

2.5. Lipid extraction

Microalgae lipids were extracted using two extraction sol-

vents, namely n-hexane and SC-CO

2

. In the static n-hexane

extraction, where no continuous ow or circulation of the

extraction solvent was employed compared to Soxhlet, 30 ml

of n-hexane was added to 1 g (containing 6.8% solids) of the

disrupted biomass (wet basis), incubated in an SI-300 Bench-

top Shaker at 50

C and 100 r min

1

overnight. The total lipid

content of the biomass was determined from lyophilized

biomass, as a base line, by Soxhlet extraction using n-hexane

for 8 h. The wet samples had a water content of 93.2% deter-

mined by drying a pre-weighed sample on a pre-dried What-

man lter paper and drying overnight at 60

C until a constant

weight was reached. For the enzymatic and acidic treated

samples, n-hexane solvent was added directly to the treated

sample, without removing the treating solutions. The mixture

was then centrifuged at 3000 r min

1

for 5 min. The upper n-

hexane layer containing the lipid was collected and the lipid

content was determined gravimetrically after solvent evapo-

ration. Same approach was carried out with lyophilized

samples, where lyophilized cells were extracted directly

without any additional cell disruption step, as lyophilization

can simultaneously dry and disrupt the cell. The extraction

was performed in a duplicate and average values were

considered.

The SC-CO

2

extractions were conducted at a pressure of

500 bar, temperature of 50

C and 3 ml min

1

owof solvent in

ISCO supercritical extraction unit (SFX-220, USA), which are

the optimal operating conditions determined in our previous

study [32]. The high pressure used was to ensure highest lipid

extraction. Unlike in the static n-hexane extraction, in the SC-

CO

2

extraction, separating the wet biomass from the enzyme

solution, prior to extraction, was required. After incubation in

the enzymatic solution for the desired time, the sample was

centrifuged at 3000 r min

1

for 5 min. The supernatant was

removed and residual treated biomass was collected. The

disrupted wet biomass was placed in 10 ml extraction cell

with glass wool placed in bothextractionvessel sides. CO

2

was

pressurized to the operation pressure using a high-pressure

syringe pump (Model 260D, ISCO, USA), and the pressurized

CO

2

was then heated to the operation temperature and

pumped into the extraction vessel. The extract was collected

in a vial after depressurization via micro-metering valve (HIP

15-12AF1-V), and lipid content was determined gravimetri-

cally after solvent evaporation. Further details about SC-CO

2

extraction procedure were reported elsewhere [32,33].

2.6. Fatty acid methyl ester (FAME) prole

To quantify the fatty acids present in the extracted lipid,

which affects the properties of the produced FAMEs and their

applicability to replace petroleumfuel, lipids were esteried to

FAME using 14% boron tetraourideemethanol mixture as

described by Rule [34]. FAME were identied and quantied by

GC (Varian, CP-3800, USA), tted with CP-Sil 88 FAME capillary

b i oma s s a nd b i oe ne r g y 6 6 ( 2 0 1 4 ) 1 5 9 e1 6 7 162

column (100 m 0.25 mm 0.2 mm, Varian, USA), ame

ionization detector (FID) and equipped with auto-injector (CP

8410. Varian, USA). The oven initial temperature was held at

150

C for 1 min and then increased to 250

C at 4

C min

1

.

Helium and zero air were used as the carrier gases with a split

ratio of 40:1. Both the injector and the detector temperatures

were set at 260

C.

2.7. Statistical analysis

Experiments were conducted with at least duplicate treat-

ments. The data were analyzed using one-way (unstacked)

analysis of variance (ANOVA) followed by Fishers Least Sig-

nicant Differences (LSD). p-Value 5% was considered as

signicant, and data were presented as mean standard

deviation.

3. Results and discussion

3.1. Strain growth and productivity

Scenedesmus sp. cultivation was carried in two stages; in the

rst the cells were allowed to grow in a nutrient rich media

(3N-BBM) for 14 d to enhance the biomass productivity, and

in the second the cells were transferred to nitrogen decient

medium (N-BBM) to enhance the lipid accumulation. Fig. 1

shows the growth and the correspondence time course of

lipid accumulation in the two cultivation stages. The gure

shows that the lag phase was short, and the growth entered

the exponential growth phase almost immediately. As ex-

pected, the lag phase was short as the inoculum into the

photobioreactor was fromthe stock broth of cells grown in the

same medium. In stage 1, the specic growth rate was

0.195 d

1

, determined from the slope of the logarithmic

growth line (not shown here). The lipid content was deter-

mined at the beginning and end of this stage and found to

remain almost constant at 12.6 0.8% (dry basis). The lipid

content was determined after cells lyophilization at 54

C

and 0.02 mbar for 6 h in the freeze drier followed by SC-CO

2

extraction at 50

C, 500 bars and 3 ml min

1

with 100 ml total

CO

2

passed. Multiplying the biomass productivity, determined

fromthe slope of the growth curve, by lipid content resulted in

overall lipid productivity of 19.5 mg l

1

d

1

. Similar lipid

content was also reported in the work of Rodol et al. [35] done

on a strain of a genus similar to the one used in this work. The

exact species of the strainused in this work was not identied.

However, slightly higher biomass productivity was obtained

by Rodol et al. [35], which resulted in higher overall lipid

productivity. This is mainly because the cultivation was done

with 5%CO

2

enrichment, whereas in this work, the cultivation

was autotrophic with CO

2

being the sole carbon source. In

addition, this slightly higher productivity is due to the pref-

erable illumination intensity and duration, which were in this

work 120 mmol m

2

s

1

under 12 h light/dark photoperiod,

respectively, compared to 100 mmol m

2

s

1

under continuous

illumination applied in Ref. [35]. These results are also com-

parable to those found by Ren et al. [36] for the same strain but

grown heterotrophically.

3.2. Effect of nitrogen stressing on lipid productivity

In the second stage, cells were grown in a nitrogen decient

medium (N-BBM), which resulted in a sharp drop in the

specic growth rate to 0.0165 d

1

, as shown in Fig. 1. The slight

drop in biomass concentration observed at the beginning of

the second stage was due to loss of some cells during the

harvesting, after collecting the cells and re-culturing them in

the new medium. However, having grown in stage 1 to a

sufcient concentration, the accumulation of lipid was the

main objective of this stage. This reduces the net energy and

increases biodiesel productivity [8]. Real outdoor cultivations

may have lower growth rates due to self-shading and other

effects. However, even if lower growth rates are, the proposed

technique will still be applicable. The total lipid content in the

rst day of starvation was 12.6% based on dried cell weight.

The lipid accumulation was monitored by staining with Nile

Red. Fig. 2 shows the uorescence microscopic images in

different days after starvation, where the brightness in the

photos indicates the amount of lipids. It is clearly shown that

by day 11, cells started to accumulate the lipid, which

enhanced further until day 23. This has been also proven by

quantitative measurements using micro-plate reader as

shown in Fig. 3. The lipid content was also determined

gravimetrically by Soxhlet extraction from lyophilized sam-

ples and a calibration curve between the uorescence in-

tensity and lipid content was prepared. The results shown in

Fig. 3 further conrmed that lipid accumulation started after

day 11 of starvation and increased exponentially thereafter.

After 3 weeks of starvation, a six-fold increase in lipid content

Fig. 1 e Cell growth (CD3N-BBM and B LN-BBM) and lipid

content (-) curves of Scenedesmus sp. grown in 5 l

photobioreactor

b i o ma s s a nd b i o e ne r gy 6 6 ( 2 0 1 4 ) 1 5 9 e1 6 7 163

was observed, reaching 73% on a dry weight basis. The pro-

posed two step process results in lowering the harvesting and

lipid extraction costs.

Table 1 shows the FAME compositions of extracted lipid,

after SC-CO

2

extraction, rapid transesterication to FAME, and

analysis using GC-FID, from the growth in nitrogen sufcient

(3N-BBM) and nitrogen decient (N-BBM) media. The re-

sults show that the compositions of the extracted lipid were

almost similar, but the triglycerides content (fatty acid con-

tents) was higher in the lipid extracted from cells grown in

N-BBM conrming that the natural lipid are accumulated by

starvation.

3.3. Pretreatment effect on lipid extraction yield

The use of chemical solvents, such as n-hexane, has several

drawbacks, which include the leftover biomass contamina-

tion with the solvent, long extraction time and the need of

additional separation units. These drawbacks can be over-

come by using SC-CO

2

extraction. It was also assumed that

operating at the supercritical conditions may allow the sol-

vent (CO

2

) to penetrate through the water lm and reach the

lipid. Therefore, SC-CO

2

was tested with both lyophilized and

wet samples. The results, shown in Fig. 4, indicated that the

extraction yield from wet and lyophilized samples was close

to those obtained using n-hexane. The reproducibility of the

results was conrmed by doing the experiments in at least in a

duplicate, and the results presented in Fig. 4 are the average

values with the error bars representing the respective stan-

dard deviations.

As mentioned earlier, drying is a time consuming step and

in many cases an energy intensive process. Avoiding this step

would signicantly enhance the microalgae-biodiesel pro-

duction process. Thus, in this study, at rst, the lipid

extracted from lyophilized cells was compared to that

extracted from wet biomass. Soxhlet extraction from lyoph-

ilized biomass using n-hexane was used to determine the

total lipid content in the biomass. It was found that the total

lipid content was 21.1 1.5%. The lipid extraction was also

performed using static n-hexane, as a solvent and left over-

night in an incubator at 50

C. Fig. 4 shows the lipid extrac-

tion yield expressed as percentage of lipid extracted per dry

biomass weight. As shown in the gure, lipid extraction yield

from wet sample was only 4% compared to 12.6% achieved

from lyophilized sample. The lower lipid extraction yield

from the wet sample is due to the water lm formed over the

lipid, which prevents the solvent from contacting it. In

addition to the drying effect that enhanced the extraction

yield, lyophilization also disrupts algal cell and makes cell

walls more porous [37].

3.4. Lipid extraction from pre-treated wet biomass

Microalgal cell wall rigidity and toughness is the main barrier

to microalgal lipid extraction, and cell walls need to be dis-

rupted in order to enhance the extraction. The main param-

eters that determine disruption method suitability are process

cost, scalability and product contamination with other cell

components. Lyophilization is the most commonly used

technique, and as shown in Fig. 4, the lipid yield increased

from only 4% using wet biomass to 12.6% from lyophilized

sample. However this technique requires high energy to

freeze the samples and its operation and maintenance costs

are relatively high, which is usually not justied in energy

production processes.

Acid treatment has also been suggested to disrupt the cells

and liberate the lipid [20]. Pretreatment using diluted sulfuric

acid was tested and resulted in a lipid extraction yield of 10%.

However, using acids is neither recommended in fuel pro-

duction nor for the leftover biomass applications. In addition,

using acids require special materials of construction, which is

not economical for large-scale applications.

Fig. 2 e Fluorescence microscopy images of Scenedesmus sp. cells stained with Nile Red and showing lipid accumulation

after 1 (a), 11 (b), 14 (c), 20 (d) and 23 (e) days of nitrogen starvation in cultures. The brightness in the photos indicates the

amount of lipids.

Fig. 3 e Relative uorescence intensity (C) determined

using micro-plate reader and lipid content in dry weight

basis (B) in the nitrogen starvation stage.

b i oma s s a nd b i oe ne r g y 6 6 ( 2 0 1 4 ) 1 5 9 e1 6 7 164

To test enzymatic treatment, two enzymes have been

tested, namely lysozyme, naturally used to disrupt bacterial

cell walls, and cellulase, which catalyzes the hydrolysis of

cellulose. The latter was tested to disrupt the cellulosic

structure of the cell walls. Fig. 4 shows that lipid extraction

yields from wet samples using both enzymes, separately,

resulted in a better yield than even the lyophilized samples,

with values of 16.6 and 15.4% using lysozyme and cellulase,

respectively. This is a signicant nding as it shows that using

either enzyme, with lysozyme showing slightly better results,

lipid can be extracted from wet sample without the need for

the time consuming and energy intensive drying step. The

result of this work clearly shows the superiority of using

lysozyme, or cellulase, in the extraction of lipid from wet

microalgae, while avoiding the drying step. The synergic effect

of both enzymes was then tested using 50% mixture of lyso-

zyme and cellulase; however lower yield of 12% was achieved.

This could be due to the formation of a product from one

enzymatic reaction that inhibits the other enzymatic reaction.

Cellulase, from the same source as the one used in this study,

was also tested by Liang et al. [38] to assist lipid extraction

from pre-ultrasonicated wet cells of Chlorella vulgaris and

compared to extraction from lyophilized cells using Bligh and

Dyer method. It was found that the lipid extraction yield

increased with the addition of the enzyme. However the

highest lipid recovery (lipid extracted to actual lipid content)

was 49%, which was signicantly lower than the one obtained

in this study, which reached 72%. In addition, the solid con-

centration was signicantly higher, where the solids were

concentrated to 18% compared to only 6.8% in this work.

Furthermore, Liang et al. ultra-sonicated the lyophilized

biomass, which was shown in this work to be not required.

The one-way ANOVA proved that there is a signicant

difference in the yield with p-value equal to 0.038 between

treatments and the Fishers (95% condence intervals) multi-

ple comparison demonstrated that the yield of individual

enzyme use is close, while the enzyme mixture yield is not.

Although the use of the enzymes has shownto be effective,

their industrial implementation for low-value products is

often limited due to their high cost. It is worth mentioning

though that the price of lysozyme is relatively not expensive,

compared to other enzymes [39]. In addition, it can be

repeatedly used for many cycles without any signicant lose

of activity when used in an immobilized forms. Lysozyme

immobilized on extrudate-shaped NaY zeolite has been suc-

cessfully used for 12 cycles [40]. Immobilization of the enzyme

also has the advantage of enhancing the recovery and puri-

cation steps.

Due to SC-CO

2

advantages over conventional solvent

extraction, the application of enzymatic treatment with SC-

CO

2

extraction fromwet cells using lysozyme has been tested.

The lipid extraction yield was 12.5%, which is almost 75% of

that extracted using n-hexane. The signicant difference in

the yield was also conrmed by one way ANOVA, where a p-

value of 0.033 was obtained. This relatively lower yield can be

attributed to some free lipid that may have been lost in the

enzymatic aqueous solution during the disruption step after

centrifugation. This did not occur with n-hexane extraction,

as the solvent was added before the centrifugation, which was

not possible in the SC-CO

2

extraction. Nevertheless, due to its

T

a

b

l

e

1

e

F

a

t

t

y

a

c

i

d

c

o

m

p

o

s

i

t

i

o

n

(

%

w

/

w

)

o

f

t

h

e

l

i

p

i

d

e

x

t

r

a

c

t

e

d

u

s

i

n

g

S

C

-

C

O

2

a

n

d

n

-

h

e

x

a

n

e

w

i

t

h

d

i

f

f

e

r

e

n

t

d

i

s

r

u

p

t

i

o

n

m

e

t

h

o

d

s

.

F

a

t

t

y

a

c

i

d

n

-

H

e

x

a

n

e

e

x

t

r

a

c

t

i

o

n

d

S

C

-

C

O

2

e

x

t

r

a

c

t

i

o

n

d

L

y

o

p

h

i

l

i

z

a

t

i

o

n

a

W

e

t

A

c

i

d

t

r

e

a

t

m

e

n

t

L

y

s

o

z

y

m

e

C

e

l

l

u

l

a

s

e

L

y

o

p

h

i

l

i

z

a

t

i

o

n

a

W

e

t

L

y

s

o

z

y

m

e

L

y

o

p

h

i

l

i

z

a

t

i

o

n

b

C

1

4

:

0

3

.

2

0

0

.

4

6

.

1

0

0

.

8

7

.

5

0

0

.

5

7

.

5

0

.

7

6

.

0

0

0

.

4

3

.

5

0

0

.

1

5

.

7

0

0

.

6

7

.

0

0

0

.

2

3

.

2

0

0

.

0

5

C

1

6

:

0

2

1

.

0

0

.

0

9

1

2

.

2

0

.

5

1

5

.

1

0

.

2

1

6

.

4

0

.

0

8

1

1

.

9

0

.

3

1

6

.

5

0

.

4

1

4

.

3

0

.

3

1

8

.

6

0

.

2

1

7

.

4

0

.

7

C

1

8

:

0

8

.

1

0

0

.

5

8

.

2

0

0

.

8

1

1

.

3

0

.

4

1

3

.

4

0

.

1

1

3

.

1

0

.

7

4

.

7

0

0

.

6

5

.

7

0

0

.

9

9

.

3

0

0

.

6

6

.

3

0

0

.

4

C

1

8

:

1

1

2

.

9

0

.

1

2

.

0

0

0

.

9

e

6

.

0

0

.

7

4

.

8

0

0

.

9

1

1

.

8

0

.

5

4

e

4

.

7

0

0

.

1

1

2

.

1

0

.

9

C

1

8

:

1

(

t

r

a

n

s

-

9

)

8

.

1

0

0

.

4

1

2

.

2

0

.

7

9

.

4

0

0

.

7

7

.

5

0

.

9

6

7

.

1

0

0

.

4

9

.

4

0

0

.

1

1

1

.

4

0

.

4

e

8

.

2

0

0

.

5

C

1

8

:

2

1

.

6

0

0

.

6

2

.

0

0

0

.

0

3

1

.

9

0

0

.

2

4

.

5

0

.

8

6

.

0

0

0

.

8

e

2

.

9

0

0

.

5

7

.

0

0

0

.

4

0

.

6

0

0

.

7

C

1

8

:

2

(

n

6

)

4

3

.

5

0

.

9

5

3

.

1

0

.

7

5

0

.

9

0

.

2

4

1

.

8

0

.

1

4

5

.

2

0

.

9

4

4

.

7

0

.

6

5

4

.

3

0

.

1

4

1

.

9

0

.

2

4

0

.

7

0

.

6

C

1

8

:

3

(

n

3

)

e

4

.

1

0

0

.

4

e

e

2

.

4

0

0

.

1

7

.

1

0

0

.

2

2

.

9

0

0

.

3

4

.

7

0

0

.

7

8

.

4

0

0

.

8

C

2

0

:

0

e

e

1

.

9

0

0

.

8

e

3

.

6

0

0

.

4

e

2

.

9

0

0

.

6

4

.

7

0

0

.

3

1

.

2

0

0

.

6

C

2

2

:

0

1

.

6

0

0

.

1

e

1

.

9

0

0

.

1

3

.

0

0

.

6

e

2

.

4

0

0

.

4

e

2

.

3

0

0

1

1

.

9

0

0

.

0

2

T

o

t

a

l

f

a

t

t

y

a

c

i

d

s

8

4

.

3

7

6

.

9

7

9

.

7

8

2

.

2

7

9

.

0

6

9

.

6

7

3

.

5

7

6

.

1

7

8

.

2

U

/

S

c

2

.

0

2

.

8

1

.

7

1

.

5

1

.

9

2

.

7

2

.

5

1

.

4

2

.

3

a

E

x

t

r

a

c

t

i

o

n

f

r

o

m

l

y

o

p

h

i

l

i

z

e

d

c

e

l

l

g

r

o

w

n

i

n

3

N

-

B

B

M

.

b

E

x

t

r

a

c

t

i

o

n

f

r

o

m

l

y

o

p

h

i

l

i

z

e

d

c

e

l

l

g

r

o

w

n

i

n

N

-

B

B

M

.

c

U

n

s

a

t

u

r

a

t

i

o

n

r

a

t

i

o

.

d

T

h

e

s

t

a

n

d

a

r

d

d

e

v

i

a

t

i

o

n

.

b i o ma s s a nd b i o e ne r gy 6 6 ( 2 0 1 4 ) 1 5 9 e1 6 7 165

favorable features, the successful use of SC-CO

2

with wet

biomass is still a major nding.

Both operation time and cost are critical parameters in

process commercialization. SC-CO

2

approach has a shorter

extraction time with less solvent consumption compared to

organic solvents extraction. Although the operation cost

might be higher, associated to the pumping cost, this will be

counterbalanced by lower down-streaming cost, as no solvent

recovery unit is required and the solvent can be separated by

simple depressurizing and recycled back.

Using this environmental friendly and recycled approSC-

CO

2

was also tested with lyophilized biomass and compared

to n-hexane. It was found that the difference in yield was

insignicant compared to n-hexane (p-value 0.724).

3.5. Analysis of extracted lipid

Complete analysis of the fatty acid composition of the

extracted lipid by n-hexane and SC-CO

2

was carried out using

GC-FID analysis, as shown in Table 1. Mass fractions are

normalized according to the total fatty acids found in the GC

analysis. It is clearly shown that the extracts were mainly

composed of linoleic acid (42e55%), palmitic acid (12e19%)

and oleic acid (7e12%). The obtained unsaturation ratio was in

the range of 1.5e3. No signicant change in composition was

observed by using different treatments and extraction tech-

niques. However, the total fatty acid of the lipid extracted by

SC-CO

2

was slightly lower in all treatments, which is mainly

due to the solubility of other pigments in SC-CO

2

. When

considering the extract yield, quality, costs and environ-

mental impacts of using chemical solvents, the enzymatic

disruption followed by SC-CO

2

extraction could probably be

the most efcient for biodiesel production from wet biomass.

This is especially true if the leftover, protein rich, biomass

after lipid extraction is used in pharmaceutical or food

industries.

4. Conclusion

The work looked at the possibility of extracting lipid from

microalgae, while avoiding the time consuming and energy

intensive drying step. It was shown that by using enzymatic

cell disruption, using lysozyme or cellulase, the lipid extrac-

tion was achieved from the wet sample that contained 93%

water. The highest lipid extraction yield of 16.6%was obtained

from enzymatically disrupted cells using lysozyme. The SC-

CO

2

extraction was also successful in extracting lipid from

enzymatic disrupted biomass, but with a slightly less yield

compared to n-hexane. In addition, the study also shows that

lipid content was enhanced in nitrogen starvation medium.

Acknowledgment

The authors would like to express their sincere appreciation to

Prof. Kourosh Salehi-Ashtiani, Associate Professor of Biology

at New York University Abu Dhabi, for his valuable assistance

in visualizing the lipid accumulationof the microalgae strains.

r e f e r e n c e s

[1] Chisti Y. Biodiesel from microalgae. Biotechnol Adv 2007;294.

[2] Maggio G, Cacciola G. When will oil, natural gas, and coal

peak? Fuel 2012;111.

[3] Ahmad AL, Yasin NHM, Derek CJC, Lim JK. Microalgae as a

sustainable energy source for biodiesel production: a review.

Renew Sustain Energy Rev 2011;584.

[4] Olmstead ILD, Hill DRA, Dias DA, Jayasinghe NS, Callahan DL,

Kentish SE, et al. A quantitative analysis of microalgal lipids

for optimization of biodiesel and omega-3 production.

Biotechnol Bioeng 2013;2096.

[5] Makareviciene V, Andrulevi ci ut _ e V, Skorupskait _ e V,

Kasperovi cien_ e J. Cultivation of microalgae Chlorella sp. and

Scenedesmus sp. as a potential biofuel feedstock. Environ Res

Eng Manage 2011;21.

[6] Sa nchez JF, Ferna ndez-Sevilla JM, Acie n FG, Cero n MC, Pe rez-

Parra J, Molina-Grima E. Biomass and lutein productivity of

Scenedesmus almeriensis: inuence of irradiance, dilution rate

and temperature. Appl Microbiol Biotechnol 2008;719.

[7] Gudin C, Thepenier C. Bioconversion of solar energy into

organic chemicals by microalgae. Adv Biotechnol Process

1986;73.

[8] Sander K, Murthy G. Life cycle analysis of algae biodiesel. Int

J Life Cycle Assess 2010;704.

[9] Mohn HF. Improved technologies for harvesting and

processing of microalgae and their impact on production

costs. Arch Hydrobiol Beih Ergeb Limnol 1978;228.

[10] Razon LF, Tan RR. Net energy analysis of the production of

biodiesel and biogas from the microalgae: Haematococcus

pluvialis and Nannochloropsis. Appl Energy 2011;3507.

Fig. 4 e Yield of extracted lipid by n-hexane and SC-CO

2

with different treatments.

b i oma s s a nd b i oe ne r g y 6 6 ( 2 0 1 4 ) 1 5 9 e1 6 7 166

[11] Lardon L, He lias A, Sialve B, Steyer J, Bernard O. Life-cycle

assessment of biodiesel production from microalgae.

Environ Sci Technol 2009;6:475.

[12] Folch J, Lees M, Sloane Stanley GH. A simple method for the

isolation and purication of total lipids from animal tissues. J

Biol Chem 1957;497.

[13] Bligh EG, Dyer WJ. A rapid method of total lipid extraction

and purication. Can J Biochem Physiol 1959;911.

[14] Ryckebosch E, Muylaert K, Foubert I. Optimization of an

analytical procedure for extraction of lipids from microalgae.

J Am Oil Chem Soc 2012;189.

[15] Blumreisinger M, Meindl D, Loos E. Cell wall composition of

chlorococcal algae. Phytochemistry 1983;1603.

[16] ShenY, Pei Z, YuanW, Mao E. Effect of nitrogenandextraction

method on algae lipid yield. Int J Agric Biol Eng 2009;51.

[17] Suarsini E, Subandi S. Utilization ultrasonic to increase the

efciency of oil extraction for microalgae indigenous isolates

from pond gresik, east java. In: Clean Energy and Technology

(CET), 2011 IEEE First Conference on; 2011. p. 275.

[18] Sostaric M, Klinar D, Bricelj M, Golob J, Berovic M, Likozar B.

Growth, lipid extraction and thermal degradation of the

microalga Chlorella vulgaris. Nat Biotechnol 2012;325.

[19] Lee J-Y, Yoo C, Jun S-Y, Ahn C-Y, Oh H-M. Comparison of

several methods for effective lipid extraction from

microalgae. Bioresour Technol 2010;S75.

[20] Sathish A, Sims RC. Biodiesel from mixed culture algae via a

wet lipid extraction procedure. Bioresour Technol 2012;643.

[21] Cho H-S, Oh Y-K, Park S-C, Lee J-W, Park J-Y. Effects of

enzymatic hydrolysis on lipid extraction from Chlorella

vulgaris. Renew Energy 2013;156.

[22] Chuchird N, Hiramatsu S, Sugimoto I, Fujie M, Usami S,

Yamada T. Digestion of Chlorella cells by chlorovirus-encoded

polysaccharide degrading enzyme. Microbes Environ

2001;206.

[23] Fu C-C, Hung T-C, Chen J-Y, Su C-H, Wu W-T. Hydrolysis of

microalgae cell walls for production of reducing sugar and

lipid extraction. Bioresour Technol 2010;8750.

[24] Gerken HG, Henri GG, Bryon D, Eric PK. Enzymatic cell wall

degradation of Chlorella vulgaris and other microalgae for

biofuels production. Planta 2013;239.

[25] Zemke PE, Wood BD, Dye DJ. Considerations for the

maximum production rates of triacylglycerol from

microalgae. Biomass Bioenergy 2010;145.

[26] Liu Z-Y, Wang G-C, Zhou B-C. Effect of iron on growth and

lipid accumulation in Chlorella vulgaris. Bioresour Technol

2008;4717.

[27] Converti A, Casazza AA, Ortiz EY, Perego P, Del Borghi M.

Effect of temperature and nitrogen concentration on the

growth and lipid content of Nannochloropsis oculata and

Chlorella vulgaris for biodiesel production. Chem Eng Process

2009;1146.

[28] Hsieh C-H, Wu W-T. Cultivation of microalgae for oil

production with a cultivation strategy of urea limitation.

Bioresour Technol 2009;3921.

[29] Tornabene TG, Holzer G, Lien S, Burris N. Lipid composition

of the nitrogen starved green alga Neochloris oleoabundans.

Enzyme Microb Technol 1983;435.

[30] Amaro HM, Guedes AC, Malcata FX. Advances and

perspectives in using microalgae to produce biodiesel. Appl

Energy 2011;3402.

[31] Siaut M, Cuine S, Cagnon C, Fessler B, Nguyen M, Carrier P,

et al. Oil accumulation in the model green alga

Chlamydomonas reinhardtii: characterization, variability

between common laboratory strains and relationship with

starch reserves. BMC Biotechnol 2011;7.

[32] Taher H, Al-Zuhair S, AlMarzouqi A, Haik Y, Farid M, Tariq S.

Supercritical carbon dioxide extraction of microalgae lipid:

process optimization and laboratory scale-up. J Supercrit

Fluids; 2014:86.

[33] Taher H, Al-Zuhair S, AlMarzouqui A, Hashim I. Extracted fat

from lamb meat by supercritical CO

2

as feedstock for

biodiesel production. Biochem Eng J 2011;23.

[34] Rule DC. Direct transesterication of total fatty acids of

adipose tissue, and of freeze-dried muscle and liver with

boron-triuoride in methanol. Meat Sci 1997;23.

[35] Rodol L, Chini Zittelli G, Bassi N, Padovani G, Biondi N,

Bonini G, et al. Microalgae for oil: strain selection, induction

of lipid synthesis and outdoor mass cultivation in a low-cost

photobioreactor. Biotechnol Bioeng 2009;100.

[36] Ren H-Y, Liu B-F, Chao Ma LZ, Ren N-Q. A new lipid-rich

microalga Scenedesmus sp. strain R-16 isolated using Nile red

staining: effects of carbon and nitrogen sources and initial

pH on the biomass and lipid production. Biotechnol Biofuels

2013;143.

[37] Wiltshire K, Boersma M, Moller A, Buhtz H. Extraction of

pigments and fatty acids from the green alga Scenedesmus

obliquus (Chlorophyceae). Aquat Ecol 2000;119.

[38] Liang K, Zhang Q, Cong W. Enzyme-assisted aqueous

extraction of lipid from microalgae. J Agric Food Chem

2012;11771.

[39] Kubiak-Ossowska K, Mulheran PA. Mechanism of hen egg

white lysozyme adsorption on a charged solid surface.

Langmuir 2010;15954.

[40] Chang YK, Chu L. A simple method for cell disruption by

immobilization of lysozyme on the extrudate-shaped NaY

zeolite. Biochem Eng J 2007;37.

b i o ma s s a nd b i o e ne r gy 6 6 ( 2 0 1 4 ) 1 5 9 e1 6 7 167

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Multiplayer Dialogue: Heroes VillainsDocument67 pagesMultiplayer Dialogue: Heroes VillainsOscar GarridoNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- IAFID1QMS EMS Codes20140610 PDFDocument8 pagesIAFID1QMS EMS Codes20140610 PDFJohn RajeshNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Multiplayer Dialogue: Heroes VillainsDocument67 pagesMultiplayer Dialogue: Heroes VillainsOscar GarridoNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Biodisel Mustard OilDocument28 pagesBiodisel Mustard OilOscar GarridoNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- GEJ 001-002-007 Campbell Biodiesel From AlgaeDocument6 pagesGEJ 001-002-007 Campbell Biodiesel From AlgaeRizki Nur Fitri IskandarNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Biodiesel SeedDocument11 pagesBiodiesel SeedOscar GarridoNo ratings yet

- DaviviendaDocument2 pagesDaviviendaOscar GarridoNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- DaviviendaDocument2 pagesDaviviendaOscar GarridoNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Environmental Building News: BiodieselDocument10 pagesEnvironmental Building News: BiodieselOscar GarridoNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Solution Manual Himmelblau Basic Principles and Calculations in Chemical EngineeringDocument244 pagesSolution Manual Himmelblau Basic Principles and Calculations in Chemical EngineeringNilson BispoNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- DaviviendaDocument2 pagesDaviviendaOscar GarridoNo ratings yet

- Yay OFFLINEDocument6 pagesYay OFFLINEmichellaineNo ratings yet

- 759-Article Text-1948-1-10-20150627Document6 pages759-Article Text-1948-1-10-20150627hayet debbichNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hot Isostatically-Pressed Stainless Steel Flanges, Fittings, Valves, and Parts For High Temperature ServiceDocument11 pagesHot Isostatically-Pressed Stainless Steel Flanges, Fittings, Valves, and Parts For High Temperature ServiceProduction DepartmentNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- 245 Bergander Rev5Document8 pages245 Bergander Rev5mariodalNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Lab Report Belt FrictionDocument8 pagesLab Report Belt Frictionasnaliffah94No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Problem Set 1Document15 pagesProblem Set 1YanYan Carpio25% (4)

- Asme Section 1 - PmiDocument3 pagesAsme Section 1 - PmiArul Edwin Vijay0% (1)

- Effect of Water Content and Tween 80 To The Stability of Emulsified BiodieselDocument7 pagesEffect of Water Content and Tween 80 To The Stability of Emulsified BiodieselTaurusVõNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- To Determine Vapor Pressure of Gasoline Sample Using Reid Method Astm D323 ObjectiveDocument3 pagesTo Determine Vapor Pressure of Gasoline Sample Using Reid Method Astm D323 ObjectiveFAH MANNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- TS NEET-2019 QP Test-07 (PMTcorner - In) PDFDocument15 pagesTS NEET-2019 QP Test-07 (PMTcorner - In) PDFhuylimala0% (1)

- 2014 BookDocument92 pages2014 Bookbrian delgado de lucioNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- cls9 qp1Document22 pagescls9 qp1Shebin PaulNo ratings yet

- RadioactivityDocument15 pagesRadioactivityBenjamin Teo0% (2)

- Lecture - Electron DiffractionDocument12 pagesLecture - Electron DiffractionOlivia WahyudiNo ratings yet

- Shuaiba Transition Zone Fields: From Laboratory Scal Experiments To Field Development ChallengesDocument12 pagesShuaiba Transition Zone Fields: From Laboratory Scal Experiments To Field Development Challengesari_siNo ratings yet

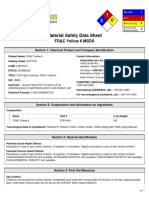

- FD&C Yellow 6 MSDS: Section 1: Chemical Product and Company IdentificationDocument5 pagesFD&C Yellow 6 MSDS: Section 1: Chemical Product and Company Identificationzubair1951No ratings yet

- SP 5160Document2 pagesSP 5160Dileepa DissanayakeNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- CHEM 241 SyllabusDocument2 pagesCHEM 241 SyllabusBob MillerNo ratings yet

- Organometallic Reactions and Catalysis - 2Document34 pagesOrganometallic Reactions and Catalysis - 2Irma AlfaBetNo ratings yet

- Experimental Thermal and Fluid Science: M.R. SalimpourDocument5 pagesExperimental Thermal and Fluid Science: M.R. Salimpourmartin sabusNo ratings yet

- SOP Medium MSMDocument2 pagesSOP Medium MSMFarah GlavanaNo ratings yet

- Single Sphere Flows in Stokes RegimeDocument46 pagesSingle Sphere Flows in Stokes RegimeqoberifNo ratings yet

- Zonasi Reservoir Dan Estimasi Penentuan Titik Bor Panas Bumi Dengan Analisis Rotasi Tensor Data Magnetotellurik (Studi Kasus Lebak, Banten)Document7 pagesZonasi Reservoir Dan Estimasi Penentuan Titik Bor Panas Bumi Dengan Analisis Rotasi Tensor Data Magnetotellurik (Studi Kasus Lebak, Banten)Karlina DewiNo ratings yet

- Exam t3 2011.12 Physics f4 p2Document10 pagesExam t3 2011.12 Physics f4 p2asjawolverineNo ratings yet

- VMC AitsDocument25 pagesVMC AitsPrateek Madaan100% (1)

- Velasc0 E-PortfolioDocument8 pagesVelasc0 E-PortfolioAngelyn Nicole MagsanoNo ratings yet

- Viscosity measurement using concentric cylindersDocument1 pageViscosity measurement using concentric cylindersKranthi ReddyNo ratings yet

- FY20-006-DPA-S - LC-MSMS Method For The Determination of NDMA in Ranitidine Dak PDFDocument7 pagesFY20-006-DPA-S - LC-MSMS Method For The Determination of NDMA in Ranitidine Dak PDFTony Cogliano Allechi SpencerNo ratings yet

- What Is Boiler Corrosion?Document4 pagesWhat Is Boiler Corrosion?Viola ZakariaNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 9 Science TP 12 1Document5 pages9 Science TP 12 1SaurabhNo ratings yet