Professional Documents

Culture Documents

Steel Blue Cs Precise 04022014 Web

Uploaded by

Dinesh KhadkaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steel Blue Cs Precise 04022014 Web

Uploaded by

Dinesh KhadkaCopyright:

Available Formats

PRECISE BUSINESS SOLUTIONS Success Story

Steel Blue

Company Facts

Locaton: Perth, Australia

Industry: Manufacturing

Website: www.steelblue.com.au

Daniella Halikis, IT Operatons Manager | Steel Blue

Customer Profle

Steel Blue is Australias largest manufacturer of safety footwear. The company

has experienced strong growth since operations began in 1995 with the

launch of the first Steel Blue products. More recently the company has intro-

duced the Howler brand of footwear into Asia and South Africa.

Steel Blues goal is to manufacture and market the most comfortable safety

footwear and safety boots in the world. The company prioritises the research

and development of new cutting edge products, technology and customer

service to expand the business into a world-class company.

In 2001, the company moved to larger premises in Malaga, Perth, to meet the

growing demand for their products as they expanded their national and export

markets and increased their local market share.

We produce around 180 to 200 pairs of boots a day in our Malaga factory in

Perth, said Daniella Halikis, IT Operations Manager. We went live two years

ago with Epicor ERP for Manufacturing. Although Epicor is only implemented

in Perth, we also have a number of factories in Jakarta. We sell into the Aus-

tralian, New Zealand and Asian markets, and we are about to enter the South

African market.

Case Study Highlights

Soluton

Epicor next-generaton ERP

Benefts

MRP allowing for beter planning and

scheduling of jobs

Accurate data leading to beter infor-

maton and improved processes

Increased visibility across the supply chain

Reduced shipping costs

Improved 3PL and supplier management

We manage our 3PL relatonship through Epicor and it

helps us to cut costs with shipping. It has saved us a lot of

tme and improved efciency.

Precise Business Solutons, Level 1, 116 Hobart Street, Mt. Hawthorn, Western Australia - 6016

+61 8 9242 5933 solutons@precisebusiness.com.au www.precisebusiness.com.au

Customer Case Study - STEEL BLUE

The product described above has not been produced by or for Epicor Software Corporation. All information contained in this publication has been furnished by the third party software provider and

Epicor undertakes no responsibility for the representation of such information. The software product described in this publication operates in connection with certain Epicor software products. Epicor

assumes no responsibility for any integration with third part products except as otherwise agreed in writing. Epicor Enterprise, iScala, Clientele, Vantage, Vista, Manage2000, Avante, ManFact, and Data-

Flo and their related logos are registered trademarks of Epicor Software Corporation in the United Sates and/or other countries.

Precise Business Solutons Implementaton Project

Steel Blue used the services of Precise Business Solutions for the

rollout and Implementation of the Epicor project. Daniella Halikis

said Precise have assisted us in implementing many proactive

projects and their consultants increasing abilities to get the job

done and work side by side with Epicor Australia has been benefi-

cial. They always ensure the clients are getting the best possible

service.

Precise Business Solutions is a Western Australian-based company

that has been providing ERP solutions since 1989. With a project

of this scope using a locally based business with this level of expe-

rience is pivotal to assure a smooth roll out, Daniella explained. It

has been helpful and beneficial to have this service available in

the same time zone and only a phone call away.

Using Epicor Material Requirements Planning to In-

crease Efciencies in Producton

The Epicor enterprise resource planning (ERP) solution for manu-

facturing features strong material requirements planning (MRP),

capabilities and enables an organisation to plan, schedule, exe-

cute and monitor its entire manufacturing business. From raw

materials to final product, Epicor ERP provides a greater level of

flexibility and agility.

Apart from the core production management manufacturing

module we use Epicor ERP for finance, sales and material manage-

ment, said Halikis. We manufacture a range of boots with dif-

ferent styles and classes. Based on colour and size we have

around 8,000 SKUs (stock keeping units). Each boot has a different

bill of material (BOM) and that is where our costs are captured by

Epicor.

Daniella explained Steel Blues manufacturing process through

Epicor. We use MRP to create the demand Epicor prints out the

job traveller which goes to the floor and goes through the manu-

facturing process from start to finish. Once the boots are boxed

we go into time and expense entry and submit and close the job

ticket. Our manufacturing manager uses Epicor to run dashboards

and reports to manage materials and BOMs. We run MRP once a

week and it allows us to plan our production seven days ahead. It

makes the system and so our operations more efficient.

Cutng Costs and Saving Time through Supply Chain

and Third-Party Logistcs Management

One of the biggest benefits identified by Steel Blue is the role Epi-

cor plays in supporting the companys on-going supply chain man-

agement. Epicor helps achieve supply chain visibility and remove

processes that do not add value. It equips manufacturers to meet

customer demands for faster delivery and lower cost by synchro-

nising processes within and outside the company.

Halikis discussed managing the companys third-party logistics

(3PL) provider with Epicor ERP. Manufacturing is a large part of

what we do; however, from a logistics point of view we are also a

distributor so the material management functionality provided by

the system is very important. We have a lot of stock in Perth and

we opened up a 3PL in Brisbane to service our East coast custom-

ers. We manage our 3PL relationship through Epicor and it helps

us to cut costs with shipping. It has saved us a lot of time and im-

proved efficiency. It used to take us five to seven days to get stock

from Perth to Brisbane, whereas now it takes us two to four days.

We also use Epicor to manage our stock levels and get insight

into what type of stock is coming out of Brisbane to our East coast

customers, continues Halikis.

Additionally, Epicor integrates with Steel Blues 3PL warehouse

partners for outsourced warehouse management.

We created a new plant in Epicor for the 3PL and we put a couple

of BPMs (business process management workflows) into the sys-

tem based on where the customer is located and which of our

plants the stock will come from. We then run the fulfilment work-

bench process, reserve and release for pending orders and the

Epicor system automatically sends out an EDI (electronic data in-

terchange) order to our 3PL provider. They pick it, pack and send

the orders appropriately. Epicor creates an invoice and sends it

straight to the customer via email, says Halikis.

With Epicor ERP, Steel Blue has streamlined manufacturing, sup-

plier relatonships, gained efciencies and increased visibility

across the organisaton. With the ongoing support of Precise

Business Solutons, Steel Blue has consistently evolved our ERP

capabilites to aid and in line with the businesss changing needs

and expansion, Daniella said. We appreciate the services from

Precise and look forward to having an ongoing relatonship with

them as our business grows.

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Emotional LabourDocument13 pagesEmotional LabourDinesh KhadkaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Name PYP Group Date: Interview Preparation QuestionsDocument4 pagesName PYP Group Date: Interview Preparation QuestionsDinesh KhadkaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Q.No.1 Statutory InterpretationDocument6 pagesQ.No.1 Statutory InterpretationDinesh KhadkaNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Swot AnalysisDocument4 pagesSwot AnalysisDinesh Khadka100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Value Chain AnalyisDocument27 pagesValue Chain AnalyisDinesh KhadkaNo ratings yet

- Qantas AirwaysDocument51 pagesQantas AirwaysDinesh KhadkaNo ratings yet

- Taboos: Break The Shackles For Better Nepal: SisterDocument1 pageTaboos: Break The Shackles For Better Nepal: SisterDinesh KhadkaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Particle Packing in Concrete 30-04-20Document49 pagesParticle Packing in Concrete 30-04-20b ramachandraNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Revised Syllabus Filipino 2 PAGSASALINDocument8 pagesRevised Syllabus Filipino 2 PAGSASALINErza Scarler100% (4)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Block Diagram: PowerDocument96 pagesBlock Diagram: PowerBrennan GriffinNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Melt ManualDocument32 pagesMelt ManualSaikat ChakrabortyNo ratings yet

- Na Edifact Desadv SpecificationsDocument17 pagesNa Edifact Desadv Specificationsrajendra2505No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Abstract Superstructure Conc - Frame WestgateDocument2 pagesAbstract Superstructure Conc - Frame WestgateTashamiswa MajachaniNo ratings yet

- 28L059 PDFDocument9 pages28L059 PDFone_blanche6175No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Vacuum WordDocument31 pagesVacuum Wordion cristian OnofreiNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Project Goals/ ObjectivesDocument51 pagesProject Goals/ ObjectivesJoyce Abegail De PedroNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- TELEC-Dwg-Al Khater Plastic FactoryDocument8 pagesTELEC-Dwg-Al Khater Plastic FactoryRENJITH K NAIRNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Your Profile 16personalitiesDocument3 pagesYour Profile 16personalitiesapi-583293897No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On The Job Winter 2013Document3 pagesOn The Job Winter 2013alanhynesNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Um0244 01 GBDocument84 pagesUm0244 01 GBnetharafernando1No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Electrical Design Checklist v1.2Document39 pagesElectrical Design Checklist v1.2huangjlNo ratings yet

- ASME B16.47 Series A FlangeDocument5 pagesASME B16.47 Series A FlangePhạm Trung HiếuNo ratings yet

- Macmillan English Grammar in Context Advanced PDFDocument3 pagesMacmillan English Grammar in Context Advanced PDFAnonymous l1MDLhBFXNo ratings yet

- XMEye Android User ManualDocument32 pagesXMEye Android User Manualaxelkal ck50% (2)

- IJV MARLEY AutomotiveDocument6 pagesIJV MARLEY AutomotiveUmer HamidNo ratings yet

- Web Service Integration With SAPDocument7 pagesWeb Service Integration With SAPJoy PatelNo ratings yet

- Journal Approval WorkflowDocument46 pagesJournal Approval Workflowvarachartered283No ratings yet

- PrePeg XC110 210g 450gDocument3 pagesPrePeg XC110 210g 450gPrakashChouhanNo ratings yet

- Kirsten Koyle Grade 5 Science and Technology Understanding Matter and EnergyDocument10 pagesKirsten Koyle Grade 5 Science and Technology Understanding Matter and Energyapi-311535995No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Pump Primer 1 AssDocument34 pagesPump Primer 1 AssGkou DojkuNo ratings yet

- Waterjet CutterDocument4 pagesWaterjet CutterCarlos RamirezNo ratings yet

- 1-18 Easy Fix Double Glazing Counter Price ListDocument16 pages1-18 Easy Fix Double Glazing Counter Price ListChris PaceyNo ratings yet

- Advantages of Group Decision MakingDocument1 pageAdvantages of Group Decision MakingYasmeen ShamsiNo ratings yet

- Chapter 4 (Digital Modulation) - Review: Pulses - PAM, PWM, PPM Binary - Ask, FSK, PSK, BPSK, DBPSK, PCM, QamDocument7 pagesChapter 4 (Digital Modulation) - Review: Pulses - PAM, PWM, PPM Binary - Ask, FSK, PSK, BPSK, DBPSK, PCM, QamMuhamad FuadNo ratings yet

- Hyperloop 170201003657Document29 pagesHyperloop 170201003657RafaelLazoPomaNo ratings yet

- Retail Generation ZDocument24 pagesRetail Generation ZSomanNo ratings yet

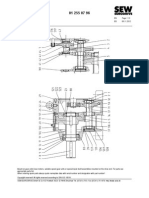

- Parts List 01 255 07 96: Helical Gear Unit R107Document3 pagesParts List 01 255 07 96: Helical Gear Unit R107Parmasamy Subramani50% (2)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)