Professional Documents

Culture Documents

Tabel Baja Garuda

Uploaded by

Andre WibowoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tabel Baja Garuda

Uploaded by

Andre WibowoCopyright:

Available Formats

NU

U

G

.

PT

RU

A

G

NG

DA

PRODUCT CATALOGUE

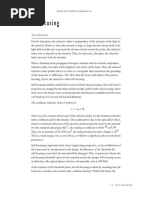

DE FLANGE SHAPE

wire NAIL

wire rod

h-beam

ROUND t-beam

BAR

KING

CROSS CROS

QUEEN

HONEY COMB

cell form

rectangularHOLLOW

hollow section SECTION

SQUARE

ix

Cx

plateplate

ey

r1

B

2

B

Y

Y

B

X

stiffener

iffener

B

ix

iy

r2

iy

90

t

Dbflange

Dc

Cy

Iy

X

Ix

t1

Cy

wirewire

mesh

H

2

iu

r

Sx

r2

iv

iy

X S.C.

iu

ix

iv

L EQUAL

ANGLE ANGLE

iy

ix

t2

t1

Sx

b

FLOOR DECK

roof & wall sheeting

LIPPED wire

CHANNEL

fence

eave strut

gutter & downspout

sagrod

ng stirrup

gabion

BOLT & NU

SCRAP TO BUILDING / DOWN STREAM TO UP STREAM

SCRAP

RAW

MATERIAL

By:

MELTING

PIG IRON

LIQUID STEEL

BLOOM

BEAM BLANK

HOT ROLL MILL

BILLET

- WIRE MESH

- WIRE FENCE

- NAIL WIRE

- ANCHOR BOLT

- CASTELLATED

BEAM

- KING CROSS

- QUEEN CROSS

- LIP CHANNEL

- Z-SECTION

- SQUARE PIPE

- CUTTING

- DRILLING

- PUNCHING

DESIGN

SHOP DRAWING

DETAILED

CONTRACTOR

APPLICATION

- WIDE PLATE

- HOT ROLLED

- COIL

- DEFORM BAR

- WIRE ROD

- ANGLE

- ROOF& WALL SHEETING

- FLOOR

- CAPPING, FLASHING

& TRIM

- ETC

STANDARD

COMPONENT

& ACCESSORIES

FOR STEEL

STRUCTURAL

- COPING / NOTCHING

- BENDING

- STIRRUP

WORKSHOP

ENGINEERING

SERVICE

CENTER

By :

SSC

COLD FORMED / FOLDING

FABRICATED SECTION

MEDIUM / SECOND PRODUCT

MACHINERYHOME INDUSTRY

FINISH

GOOD

By :

- IWF / H BEAM

- T BEAM

- ROUND BAR

SLAB

BUY OUT

- PAINTING

- GALVANIZING

- SHOT BLASTING

- ASSEMBLING & DRAWING

FABRICATION

SEARCHING PROJECT

TRANSPORTATION

ERECTION

FACTORIES,

STAY HOME,

TRANSMISSION TOWER,

HIGH RISE BUILDING,

WIRE MESH,

WAREHOUSE,

VILLA,

CRANE TOWER,

CAR PARKING SYSTEM,

STIRRUP WIRE,

POWER PLANT,

(CUT TO LENGTH)

SPORT HALL,

BUNGALOW,

STEEL STRUCTURE,

SUPERMARKET,

SIMPLE HOUSE

TELECOMMUNICATION,

WORKSHOP,

GIRDER BRIDGE,

SHOP HOUSE,

RIGID BRIDGE,

APARTMENT

CHEMICAL PLANT,

CEMENT PLANT

PRODUCT CATALOGUE

www.grdsteel.com

PRODUCT

and

COMPONENT

APPLICATION IN BUILDING

4

9

10

11

12

13

23

30

22

29

26

22

28

27

19

25

14

24

15

23

16

22

21

20

sig

nb

yA

ba

17

di

18

19

WALL PANEL

De

ROOF SHEETING

INSULATION

VENTILATOR

10

RAFTER

PURLIN

CLEAT

INSULATION

ROOF MONITOR

11

12

SKYLIGHT

CRANE SYSTEM

CLEAT

GUTTER AND DOWNSPOUT

14

15

16

ROOF EXTENSION

PERSONNEL DOOR

CANOPY AND FASCIA

SLIDING DOOR

20

21

22

23

13

ROOF EXTENSION

STIFFENER

RIDGE VENTILATOR

17

WALL

SHEETING

STIFFENER

18

END PLATE

SAGROD

19

WIND BRACING

PURLIN

BASE PLATE

RAFTER

BRICK

WALL

RAFTER

PURLIN

COLUMN

ANCHOR

BOLT

GIRT

FLANGE BRACE

BRICK WALL

24

PURLIN AND SAGROD

GIRT AND BRACING

EAVE STRUTH

FLANGE BRACE

25

26

27

28

CAP

PLATE

BASE PLATE AND ANCHOR BOLT

29

RIGID FRAME

30

END

WALL

COLUMN

COLUMN

LOUVER

ROLLING DOOR

STAIRS

END WALL COLUMN

PRODUCT CATALOGUE

CAP PLATE

WINDOW

www.grdsteel.com

DOUBLE PERSONNEL DOOR

P R O D U C T

S E C T I O N

BEAMS

WIDE FLANGE SHAPE

ACCORDING JIS G3192

198 x 99

200 x 150

194 x 150

METRIC SIZE

4.5

11

23.18

18.20

1580

114

8.26

2.21

160

23.0

5.5

11

27.16

21.30

1840

134

8.24

2.22

184

26.8

12

38.80

30.60

2675

507

8.30

3.60

275.8

67.6

continue .......>>

JURNAL BESI BAJA INDONESIA

www.jurnalbesibaja.com

P R O D U C T

S E C T I O N

CHANNELS

WIDE FLANGE SHAPE (2)

SPECIFICATION FOR WIDE FLANGE SHAPED ( HOT ROLLED )

DIMENSIONAL TOLERANCE

ACCORDING JIS G3192

+ 40 (1.575)

0

CHEMICAL COMPOSITION

CORRESPONDING SPECIFICATION

MECHANICAL PROPERTIES

Thickness of Steel Product (mm)

> 16 up to 40

> 6 up to 50

min

min

min

min

min

min

min

min

min

min

JURNAL BESI BAJA INDONESIA

www.jurnalbesibaja.com

P R O D U C T

S E C T I O N

BEAMS

T-BEAM

CUT FROM HOT ROLLED WIDE FLANGE SHAPE

B

t2

r

t1

STANDARD SECTIONAL DIMENSION

METRIC SIZE

INFORMATIVE REFERENCE

DEPTH OF WIDTH OF THICKNESS CORNER

SECTIONAL SECTION SECTION

Web Flange RADIUS

INDEX

SECTIONAL

AREA

UNIT

CENTER OF GEOMETRICAL

WEIGHT

MOMENT OF

GRAVITY

INERTIA

t1

t2

mm

mm

mm

mm

mm

mm

cm2

T 50 x 100

50.00

100

10

10.95

8.60

40.0

16

T 62.5 x 125

62.50

125

6.5

10

15.16

11.90

50.6

35

T 75 x 75

75.00

75

8.93

7.00

57.0

42

T 75 x 150

75.00

150

10

11

20.07

15.75

61.3

66

T 100 x 100

100.00

100

5.5

11

13.58

10.65

71.7

T 99 x 100

99.00

100

4.5

11

11.59

9.10

78.1

T 87.5 x 175

87.50

175

7.5

11

12

25.61

20.10

T 100 x 200

100.00

200

12

13

31.77

24.95

T 125 x 125

125.00

125

12

18.83

14.80

kg/m

RADIUS OF

GYRATION

OF AREA

MODULUS OF

SECTION

Ix

Iy

ix

iy

Zx

Zy

mm

cm4

cm4

cm

cm

cm3

cm3

67

1.20

2.47

4.0

13.4

147

1.51

3.11

6.9

23.5

25

2.18

1.67

7.4

6.6

282

1.81

3.75

10.8

37.6

114

67

2.90

2.22

14.8

13.4

94

58

2.84

2.25

12.0

11.7

72.0

114

492

2.11

4.38

15.8

56.2

82.7

184

801

2.41

5.02

22.2

80.1

97.2

248

147

3.63

2.79

25.5

23.5

T 124 x 124

124.00

124

12

16.34

12.85

97.7

207

127

3.56

2.79

21.2

20.5

T 125 x 250

125.00

250

14

16

46.09

36.20

104.2

411

1,825

2.98

6.29

39.4

146.0

T 150 x 150

150.00

150

6.5

13

23.39

18.35

115.9

463

254

4.45

3.29

39.9

33.8

T 149 x 149

149.00

149

5.5

13

20.40

16.00

116.4

393

221

4.39

3.29

33.7

29.6

T 150 x 300

150.00

300

10

15

18

59.90

47.00

125.3

796

3,378

3.64

7.51

63.5

225.2

T 175 x 175

175.00

175

11

14

31.57

24.80

137.5

814

492

5.08

3.95

59.2

56.3

T 173 x 174

173.00

174

14

26.34

20.70

136.0

678

396

5.07

3.88

49.9

45.5

T 175 x 350

175.00

350

12

19

20

86.95

68.85

146.4

1,515

6,794

4.17

8.84

103.5

388.2

T 200 x 200

200.00

200

13

16

42.06

33.00

157.7

1,395

868

5.76

4.54

88.5

86.8

T 198 x 199

198.00

199

11

16

36.08

28.30

156.3

1,193

723

5.75

4.48

76.3

72.7

T 200 x 400

200.00

400

13

21

22

109.35

86.00

167.9

11,207

4.75

10.12

147.1

560.4

T 225 x 200

225.00

200

14

18

48.38

38.00

173.5

2,470

2,155

936

6.67

4.40

124.2

93.6

T 250 x 200

250.00

200

10

16

20

57.10

44.80

190.5

3,210

1,071

7.50

4.33

168.5

107.1

T 300 x 200

300.00

200

11

17

22

67.20

53.00

221.6

5,786

1,139

9.29

4.12

261.9

113.9

T 294 x 300

294.00

300

12

20

28

96.25

75.50

233.2

6,695

4,509

8.34

6.84

295.3

300.6

T 350 x 300

T 400 x 300

350.00

400.00

300

300

13

14

24

26

28

28

117.75

133.70

92.50

105.00

274.5

308.3

12,015

18,787

5,412

5,866

10.10

11.85

6.78

6.62

447.3

609.5

360.8

391.1

NOTE : - Material specification refer to Wide Flange Shape.

- Tolerance H = + 2 mm.

- T 350 x 300, T 400 x 300 and T 200 x 400 are import product.

JURNAL BESI BAJA INDONESIA

www.jurnalbesibaja.com

P R O D U C T

S E C T I O N

BEAMS

KING CROSS

Y

B

t2

t1

H

2

t1

H

X

t2

r

METRIC SIZE

STANDARD SECTIONAL DIMENSION

INFORMATIVE REFERENCE

SECTIONAL

UNIT

AREA

DEPTH OF FLANGE THICKNESS CORNER

SECTION

WEIGHT

SECTION WIDTH WEB FLANGE RADIUS

INDEX

t1

t2

mm

mm

mm

mm

mm

mm

cm2

kg/m

GEOMETRICAL

MOMENT OF INERTIA

RADIUS OF

GYRATION

OF AREA

MODULUS OF

SECTION

IX

Iy

ix

iy

Zx

Zy

cm4

cm4

cm

cm

cm3

cm3

K 150 x 75

150

75

5.0

35.70

28.0

716

767

4.48

4.64

95.4

99.1

K 200 x 100

200

100

5.5

11

54.32

42.6

1,974

2,095

6.03

6.21

197.4

203.9

K 198 x 99

198

99

4.5

11

46.36

36.4

1,694

1,778

6.04

6.23

171.1

175.6

K 250 x 125

250

125

12

75.32

59.2

4,344

4,567

7.59

7.79

347.5

356.9

K 248 x 124

248

124

12

65.36

51.4

3,765

3,924

7.59

7.75

303.6

310.2

K 300 x 150

300

150

6.5

13

93.56

73.4

7,718

8,073

9.08

9.29

514.5

526.9

K 298 x 149

298

149

5.5

13

81.60

64.0

6,762

7,024

9.10

9.28

453.8

462.9

K 350 x 175

350

175

11

14

126.28

99.2

14,554

15,128

10.75

10.95

831.7

847.5

K 346 x 174

346

174

14

105.36

82.8

11,892

12,321

10.62

10.62

687.4

700.0

K 400 x 200

400

200

13

16

168.24

132.0

25,440

26,519

12.30

12.55

1,272.0

1,299.9

K 396 x 199

396

199

11

16

144.32

113.2

21,450

22,267

12.19

12.19

1,083.3

1,105.1

K 450 x 200

450

200

14

18

193.52

152.0

35,370

36,851

13.52

13.52

1,572.0

1,605.7

K 500 x 200

500

200

10

16

20

228.40

179.2

49,940

52,189

14.79

15.17

1,997.6

2,046.6

K 600 x 200

600

200

11

17

22

268.80

212.0

79,880

83,229

17.24

17.24

2,662.7

2,724.4

K 588 x 300

588

300

12

20

28

385.00

302.0

127,020

132,585

18.16

18.16

4,320.4

4,419.5

K 700 x 300

700

300

13

24

28

471.00

369.7

211,800

220,791

21.21

21.65

6,051.4

6,193.3

K 800 x 300

800

300

14

26

28

534.80

419.8

303,700

315,027

23.83

24.27

7,592.5

7,740.2

NOTE :

- h = H/2 = height of T-Beam.

- Tolerance, h = + 2 mm.

- Material specification refer to Wide Flange Shape.

- Welded specification as per AWS E - 6013.

- K 700 x 300 and K 800 x 300 are made from IWF import.

JURNAL BESI BAJA INDONESIA

www.jurnalbesibaja.com

P R O D U C T

S E C T I O N

BEAMS

QUEEN CROSS

Y

B

t2

t1

B

H

y

t2

r

x

h

METRIC SIZE

STANDARD SECTIONAL DIMENSION

DEPTH OF FLANGE

SECTION WIDTH

SECTION

INDEX

INFORMATIVE REFERENCE

SEC.

THICKNESS CORNER AREA

UNIT

WEIGHT

RADIUS

WEB FLANGE

t1

t2

CENTER OF

GRAVITY

GEOMETRICAL

MOMEN

OF INERTIA

IX

Iy

RADIUS OF

GYRATION

OF AREA

MODULUS OF

SECTION

ix

Zx

iy

Zy

21.0

57.3

310

3.40

53.99

32.0

76.6

848

4.56

110.72

27.3

76.1

44.4

95.9

1,844

5.71

192.34

1,637

722

6.86

4.56

165.3

94.86

38.5

95.4

1,599

5.71

167.62

55.1

114.7

3,260

6.82

284.16

48.1

114.2

2,842

6.81

248.76

74.4

134.5

6,096

8.02

62.1

133.3

11,496

4,978

7.94

99.1

153.9

24,570

10,661

9.19

692.79

85.0

152.8

20,725

8,984

9.11

588.07

114.0

159.3

14,572

10.02

914.48

134.5

165.2

20,386

10.91

1,234.37

1,826.74

158.3

175.7

32,097

12.62

226.7

229.7

53,713

13.64

453.30

664.5

373.37

2,338.03

Q 700 x 300

700

300

13

24

28

353.25

277.4

243.7

350.0

206,406 86,629

24.17

15.66

5,897.1

3,555.30

Q 800 x 300

800

300

14

26

28

401.10

315.0

255.1

400.0

297,859 121,518

27.25

17.41

7,446.3

4,763.91

NOTE :

- h = H/2 = height of T-Beam.

- Tolerance, h = + 2 mm.

- Material specification refer to Wide Flange Shape.

- Welded specification as per AWS E - 6013.

- Q 700 x 300 and Q 800 x 300 are import product.

JURNAL BESI BAJA INDONESIA

www.jurnalbesibaja.com

P R O D U C T

S E C T I O N

BEAMS

HONEY COMB

0.25Ds

0.29Ds

0.25Ds

0.54Ds

0.29Ds

CASTELLATED SHAPE HONEY COMB

Ds

r

X

t1

Dbflange

Dc

Dtee

t2

WASTE LENGTH

Iy

X

Ix

1.08Ds

ORIGINAL SECTION

CASTELLATED SECTION

WEIGHT

METRIC SIZE

SECTIONAL INDEX

DEPTH OF

SECTION

WIDTH

CORNER DEPTH

DEPTH DEPTH

OF THICKNESS RADIUS OF CASTEL- OF CASTEL- BETWEEN

SECTION

LATED

LATED

HOLE

TEE FLANGES

Web Flange

Original Castellated

Original Castellated

mm

mm

100 X 100 150 X 100

150 X 75 225 X 75

150 X 150 225 X 150

300 X 100

200 X 100

297 X 99

200 X 200 300 X 200

375 X 125

250 X 125

372 X 124

250 X 250 375 X 250

450 X 150

300 X 150

447 X 149

300 X 300 450 X 300

525 X 175

350 X 175

519 X 174

350 X 350 525 X 350

600 X 200

400 X 200

594 X 199

450 X 200 675 X 200

500 X 200 750 X 200

600 X 200 900 X 200

600 X 300 882 X 300

400 X 400 600 X 400

700 X 300 1050 X 300

800 X 300 1200 X 300

Dc

kg/m

mm

mm

mm

17.2

14.0

31.5

21.3

18.2

49.9

29.6

25.7

72.4

36.7

32.0

94.0

49.6

41.4

137

66.0

56.6

76.0

89.6

106

151

172

185

210

100

150

150

200

198

200

250

248

250

300

298

300

350

346

350

400

396

450

500

600

588

400

700

800

150

225

225

300

297

300

375

372

375

450

447

450

525

519

525

600

594

675

750

900

882

600

1050

1200

100

75

150

100

99

200

125

124

250

150

149

300

175

174

350

200

199

200

200

200

300

400

300

300

t1

t2

Ds

Dtee

mm mm

mm

mm

mm

mm

6

5

7

5.5

4.5

8

6

5

9

6.5

5.5

10

7

6

12

8

7

9

10

11

12

13

13

14

10

8

11

11

11

13

12

12

16

13

13

18

14

14

20

16

16

18

20

22

28

22

28

28

105

154

154

205

202

205

254

253

254

305

302

305

354

350

354

405

401

454

505

605

593

405

705

805

22.5

35.5

35.5

47.5

47.5

47.5

60.5

59.5

60.5

72.5

72.5

72.5

85.5

84.5

85.5

97.5

96.5

110.5

122.5

147.5

144.5

97.5

172.5

197.5

134

211

205

284

283

276

357

356

347

432

431

420

503

501

487

574

572

647

718

866

842

558

1002

1148

DIMENSIONAL TOLERANCE

Flange width (B)

(mm)

+ 3.0

SS 400

Under 400

400 - 600

600& over

+ 4.0

+ 5.0

+ 6.0

+ 3.0

RADIUS OF

GYRATION

MODULUS OF

SECTION

Min

Net

Ix

Iy

ix

iy

Zx

Zy

cm 2

cm 2

cm 4

cm 4

cm

cm

cm 3

cm 3

24.90

21.60

45.39

32.66

27.64

71.53

45.16

38.88

103.43

56.53

49.00

134.80

75.39

63.06

194.90

100.12

86.02

117.01

139.20

167.40

227.78

244.70

281.00

323.40

18.57

13.85

34.54

21.36

18.50

55.09

29.86

26.21

80.48

36.67

32.33

104.25

50.54

42.00

152.30

67.68

57.92

76.06

88.65

100.80

156.56

191.99

189.29

210.63

905.3

1579.7

3889.6

4306.8

3643.9

11139.0

9491.5

8189.6

25477.5

16895.1

14664.0

47854.8

31847.5

25819.2

95013.1

55683.6

46656.1

78747.4

112855.7

184103.0

274532.9

156913.2

473222.7

690341.9

134.0

49.5

563.0

134.0

114.0

1600.1

294.1

255.0

3650.2

508.1

442.0

6750.3

984.1

792.1

13600.6

1740.2

1450.1

1870.3

2140.5

2280.8

9021.0

22400.8

10801.5

11702.2

7.0 2.7 120.7

10.7 1.9 140.4

10.6 4.0 345.7

14.2 2.5 287.1

14.0 2.5 245.4

14.2 5.4 742.6

17.8 3.1 506.2

17.7 3.1 440.3

17.8 6.7 1358.8

21.5 3.7 750.9

21.3 3.7 656.1

21.4 8.0 2126.9

25.1 4.4 1213.2

24.8 4.3 995.0

25.0 9.4 3619.5

28.7 5.1 1856.1

28.4 5.0 1570.9

32.2 5.0 2333.3

35.7 4.9 3009.5

42.7 4.8 4091.2

41.9 7.6 6225.2

28.6 10.8 5230.4

50.0 7.6 9013.8

57.2 7.5 11505.7

Si

-

Mn

-

P

0.05 max

S

0.05 max

JURNAL BESI BAJA INDONESIA

Classification

26.8

13.2

75.1

26.8

23.0

160.0

47.0

41.1

292.0

67.7

59.3

450.0

112.5

91.0

777.2

174.0

145.7

187.0

214.0

228.1

601.4

1120.0

720.1

780.1

JIS G 3101 SS 400

Yield Point

N / mm 2

Thickness (mm)

Elongation %

Tensile

Thickness (mm)

Strength

2

16 or Under Over 16 N / mm 5 or Under 5 to 16 Over 16

245

235

400 - 510

21

WELDING

As per AWS

Welding material: E 6013

Chemical Composition (%)

C

-

MOMENT

OF INERTIA

MECHANICAL PROPERTIES

Depth of

cell form

hole (Ds)

(mm)

Depth (Dc)

(mm)

CHEMICAL COMPOSITION

GRADE

Max

Dbflange Gross

8

7

10

8

7

12

9

8

14

9

8

15

11

9

19

13

11

14

16

17

20

21

24

26

SECTION

AREA

www.jurnalbesibaja.com

17

21

P R O D U C T

S E C T I O N

BEAMS

HONEY COMB

r

Dtee

0.29 (Ds-Dadd)

60

iy

Ds

D_add

Dc

t1

Dbflange

WASTE LENGTH

0.25 (Ds-Dadd)

0.25 (Ds-Dadd)

0.54 (Ds-Dadd)

t2

0.29 (Ds-Dadd)

CASTELLATED SHAPE (HONEY COMB + ADDING PLATES)

ix

ORIGINAL SECTION

1.08 (Ds-Dadd)

CASTELLATED SECTION

WEIGHT

METRIC SIZE

SECTIONAL INDEX

Original

Castellated

mm

mm

100 X 100 200 x 100

150 X 75 300 x 75

150 X 150 300 x 150

400 x 100

200 X 100

396 x 99

200 X 200 400 x 200

500 x 125

250 X 125

496 x 124

250 X 250 500 x 250

600 x 150

300 X 150

596 x 149

300 X 300 600 x 300

700 x 175

350 X 175

692 x 174

350 X 350 700 x 350

800 x 200

400 X 200

792 x 199

450 X 200 900 x 200

500 X 200 1000 x 200

600 X 200 1200 x 200

600 X 300 1176 x 300

400 X 400 800 x 400

700 X 300 1400 x 300

800 X 300 1600 x 300

DEPTH DEPTH DEPTH DEPTH

DEPTH OF WIDTH

OF

OF BETWEEN SECTION

SECTION

OF THICKNESS CORNER OF

AREA

ADDED CASTEL- CASTELSECTION

RADIUS

PLATE LATED LATED FLANGES

Web Flange

Original Castellated

Min

HOLE

TEE

Max

H

Dc

D add

Ds

Dtee

kg/m

mm

mm

mm

mm mm

mm

mm

mm

mm

mm

18.55

15.50

33.60

23.50

19.90

53.00

32.50

28.10

76.80

40.50

35.20

99.90

54.40

45.40

141.62

72.30

62.10

83.90

99.50

118.50

165.00

177.50

191.10

218.00

100

150

150

200

198

200

250

248

250

300

298

300

350

346

350

400

396

450

500

600

588

400

700

800

200

300

300

400

396

400

500

496

500

600

596

600

700

692

700

800

792

900

1000

1200

1176

800

1400

1600

100

75

150

100

99

200

125

124

250

150

149

300

175

174

350

200

199

200

200

200

300

400

300

300

6

5

7

5.5

4.5

8

6

5

9

6.5

5.5

10

7

6

12

8

7

9

10

11

12

13

13

14

8

7

10

8

7

12

9

8

14

9

8

15

11

9

19

13

11

14

16

17

20

21

24

26

10

8

11

11

11

13

12

12

16

13

13

18

14

14

20

16

16

18

20

22

28

22

28

28

50

75

75

100

99

100

125

124

125

150

149

150

175

173

175

200

198

225

250

300

294

200

350

400

156

231

231

306

303

306

381

378

381

456

453

456

531

525

531

606

600

681

756

906

888

606

1056

1206

22.0

34.5

34.5

47.0

46.5

47.0

59.5

59.0

59.5

72.0

71.5

72.0

84.5

83.5

84.5

97.0

96.0

109.5

122.0

147.0

144.0

97.0

172.0

197.0

184

286

280

384

382

376

482

480

472

582

580

570

678

674

662

774

770

872

968

1166

1136

758

1352

1548

t1

t2

DIMENSIONAL TOLERANCE

Flange width (B)

(mm)

+ 3.0

Under 400

400 - 600

600& over

Depth of

cell form

hole (Ds)

(mm)

+ 4.0

+ 5.0

+ 6.0

+ 3.0

Depth (Dc)

(mm)

CHEMICAL COMPOSITION

GRADE

SS 400

Chemical Composition (%)

C

-

Si

-

Mn

-

P

0.05 max

S

0.05 max

JURNAL BESI BAJA INDONESIA

Dbflange Gross

2

cm

27.90

25.35

50.64

38.16

32.09

79.53

52.66

45.08

114.68

66.28

57.19

149.80

87.64

73.44

215.90

116.12

99.88

137.26

164.20

200.40

263.06

270.70

326.50

379.40

Net

2

cm

18.54

13.80

34.47

21.33

18.46

55.05

29.80

26.18

80.39

36.64

32.28

104.20

50.47

41.94

152.18

67.64

57.88

75.97

88.60

100.74

156.50

191.92

189.22

210.56

MOMENT

OF INERTIA

Ix

4

cm

1712

3022

7308

8216

6917

20867

18055

15523

47611

32198

27846

89361

60394

48949

177408

105531

88376

150151

216055

355610

519725

292713

898606

1317191

RADIUS OF MODULUS OF

GYRATION

SECTION

Iy

ix

iy

Zx

Zy

cm 4

cm

cm

cm 3

cm 3

134

49

563

134

114

1600

294

255

3650

508

442

6751

984

792

13602

1740

1450

1871

2141

2282

9023

22403

10805

11707

9.61 2.69 171.2

26.8

14.80 1.88 201.5

13.1

14.56 4.04 487.2

75.1

19.63 2.51 410.8

26.8

19.36 2.49 349.3

23.0

19.47 5.39 1043.4 160.0

24.61 3.14 722.2

47.0

24.35 3.12 625.9

41.1

24.34 6.74 1904.4 292.0

29.64 3.72 1073.3

67.7

29.37 3.70 934.4

59.3

29.28 8.05 2978.7 450.1

34.59 4.42 1725.5 112.5

34.16 4.35 1414.7

91.0

34.14 9.45 5068.8 777.3

39.50 5.07 2638.3 174.0

39.08 5.01 2231.7 145.7

44.46 4.96 3336.7 187.1

49.38 4.92 4321.1 214.1

59.41 4.76 5926.8 228.2

57.63 7.59 8838.9 601.5

39.05 10.80 7317.8 1120.2

68.91 7.56 12837.2 720.3

79.09 7.46 16464.9 780.5

MECHANICAL PROPERTIES

Yield Point

N / mm 2

Classification

Thickness (mm)

Elongation %

Tensile

Thickness (mm)

Strength

2

16 or Under Over 16 N / mm 5 or Under 5 to 16 Over 16

JIS G 3101 SS 400

245

235

400 - 510

21

17

WELDING

As per AWS

Welding material: E 6013

www.jurnalbesibaja.com

21

P R O D U C T

S E C T I O N

BEAMS

CELL FORM

t2

Ds

Ds

t1

Dc

Dbflange

Dtee

iy

ix

Ds

0.25 Ds

ORIGINAL SECTION

CELL FORM SECTION

SECTIONAL INDEX

WEIGHT

SECTION PROPERTIES OF CELL-FORM

Original

Cell-Form

mm

mm

kg/m

mm mm

100 X 100

150 X 75

150 X 150

150 x 100

225 x 75

225 x 150

300 x 100

300 x 99

300 x 200

375 x 125

375 x 124

375 x 250

450 x 150

450 x 149

450 x 300

525 x 175

525 x 174

525 x 350

600 x 200

600 x 199

675 x 200

750 x 200

900 x 200

900 x 300

600 x 400

1050 x 300

1200 x 300

16.27

12.78

29.75

19.44

16.54

47.10

26.98

23.33

68.32

33.55

29.17

88.76

45.11

37.65

129.25

59.94

51.37

68.66

80.28

94.11

136.46

162.21

165.42

185.76

100 150

150 225

150 225

200 300

198 300

200 300

250 375

248 375

250 375

300 450

298 450

300 450

350 525

346 525

350 525

400 600

396 600

450 675

500 750

600 900

588 900

400 600

700 1050

800 1200

200 X 100

200 X 200

250 X 125

250 X 250

300 X 150

300 X 300

350 X 175

350 X 350

400 X 200

450

500

600

600

400

700

800

X

X

X

X

X

X

X

200

200

200

300

400

300

300

METRIC SIZE

DEPTH

DEPTH OF WIDTH

THICKNESS CORNER OF

SECTION

OF

RADIUS CELL

SECTION

FORM

Web Flange

Original Cell Form

HOLE

H

Dc

t1

SECTION AREA

Max

Ds

Dtee Dbflange Gross

mm mm mm

mm

mm

mm

mm

100

75

150

100

99

200

125

124

250

150

149

300

175

174

350

200

199

200

200

200

300

400

300

300

10

8

11

11

11

13

12

12

16

13

13

18

14

14

20

16

16

18

20

22

28

22

28

28

103

155

155

206

210

206

258

262

258

309

313

309

361

369

361

412

421

464

515

618

643

412

722

825

23

35

35

47

45

47

59

57

59

70

68

70

82

78

82

94

90

106

117

141

128

94

164

188

134

211

205

284

286

276

357

359

347

432

434

420

503

507

487

574

578

647

718

866

860

558

1002

1148

6

5

7

5.5

4.5

8

6

5

9

6.5

5.5

10

7

6

12

8

7

9

10

11

12

13

13

14

t2

DEPTH DEPTH

OF BETWEEN

CELL

FORM

TEE FLANGE

8

7

10

8

7

12

9

8

14

9

8

15

11

9

19

13

11

14

16

17

20

21

24

26

cm

25.0

21.7

45.6

32.8

27.9

71.8

45.4

39.2

103.8

56.8

49.4

135.3

75.8

63.8

195.5

100.6

86.9

117.6

140.0

168.4

231.1

245.5

282.4

325.1

MOMENT

OF INERTIA

RADIUS OF

GYRATION

MODULUS OF

SECTION

Min

Net

Ix

Iy

ix

iy

Zx

Zy

cm 2

18.8

14.0

34.7

21.5

18.4

55.3

29.9

26.1

80.6

36.7

32.2

104.3

50.5

41.6

152.3

67.6

57.4

75.9

88.4

100.4

153.9

191.9

188.6

209.7

cm 4

908.9

1586.2

3897.8

4322.8

3732.3

11159.9

9516.5

8351.7

25510.2

16943.9

14905.3

47919.5

31912.4

26499.6

95108.4

55799.0

47743.1

78909.5

113123.5

184605.2

286789.2

157075.6

473991.0

691563.8

cm 4

cm

cm

cm 3

cm 3

134.0

49.5

563.0

134.0

114.0

1600.0

294.0

255.0

3650.0

508.0

442.0

6750.0

984.0

792.0

13599.9

1740.0

1450.0

1870.0

2140.0

2279.9

9019.9

22399.9

10799.9

11699.8

7.0 2.7 121.2

26.8

10.7 1.9 141.0

13.2

10.6 4.0 346.5

75.1

14.2 2.5 288.2

26.8

14.2 2.5 248.8

23.0

14.2 5.4 744.0 160.0

17.8 3.1 507.5

47.0

17.9 3.1 445.4

41.1

17.8 6.7 1360.5 292.0

21.5 3.7 753.1

67.7

21.5 3.7 662.5

59.3

21.4 8.0 2129.8 450.0

25.1 4.4 1215.7 112.5

25.2 4.4 1009.5

91.0

25.0 9.5 3623.2 777.1

28.7 5.1 1860.0 174.0

28.8 5.0 1591.4 145.7

32.2 5.0 2338.1 187.0

35.8 4.9 3016.6 214.0

42.9 4.8 4102.3 228.0

43.2 7.7 6373.1 601.3

28.6 10.8 5235.9 1120.0

50.1 7.6 9028.4 720.0

57.4 7.5 11526.1 780.0

continue .......>>

JURNAL BESI BAJA INDONESIA

www.jurnalbesibaja.com

P R O D U C T

S E C T I O N

BEAMS

CELL-FORM (2)

DIMENSIONAL TOLERANCE

Flange width (B)

(mm)

+ 3.0

Under 400

400 - 600

600& over

Depth of

cell form

hole (Ds)

(mm)

+ 4.0

+ 5.0

+ 6.0

+ 3.0

Depth (Dc)

(mm)

MECHANICAL PROPERTIES

Classification

Yield Point

N / mm 2

Thickness (mm)

Elongation %

Tensile

Thickness (mm)

Strength

2

16 or Under Over 16 N / mm 5 or Under 5 to 16 Over 16

JIS G 3101 SS 400

245

235

400 - 510

21

17

21

CHEMICAL COMPOSITION

GRADE

SS 400

Chemical Composition (%)

C

-

Si

-

Mn

-

P

0.05 max

S

0.05 max

WELDING

As per AWS

Welding material: E 6013

JURNAL BESI BAJA INDONESIA

www.jurnalbesibaja.com

P R O D U C T

S E C T I O N

ANGLES

EQUAL ANGLE

r2

ex

H

2

iu

ix

Cx

iu

r2

r1

iv

iv

90

B

2

Cy

iy

Y

V

ey

METRIC SIZE

STANDARD

SECTIONAL

DIMENSIONS

H x

SECTION

AREA

r 1 r2

mm x mm

mm mm mm

25 x 25

3 4 2

UNIT

WEIGHT

CENTER

OF

GRAVITY

Cx = C y

INFORMATIVE REFERENCE

GEOMETRICAL MOMENT

OF INERTIA

Max Iu

Min Iv

MODULUS

OF SECTION

ix = iy

Max iu

Min iv

cm2

1.427

kg/m

1.12

cm

0.719

cm4

0.797

cm4

1.26

cm4

0.332

cm

0.747

cm

0.94

cm

0.48

cm3

0.448

1.36

1.83

0.844

1.090

1.420

3.530

2.26

5.60

0.590

1.460

0.908

1.230

1.14

1.55

0.58

0.79

0.661

1.210

Ix = Iy

RADIUS OF GYRATION

OF AREA

Zx = Zy

30 x

40 x

30

40

3 4 2

3 4.5 2

1.727

2.336

40 x

40

4 4.5 2

2.336

1.83

1.090

3.530

5.60

1.460

1.230

1.55

0.79

1.210

40 x

45 x

40

45

5 4.5 3

5 6.5 3

3.755

4.302

2.95

3.38

1.170

1.280

5.420

7.910

8.59

12.50

2.250

3.290

1.200

1.360

1.51

1.71

0.77

0.87

1.910

2.460

45 x

45

4 6.5 3

3.492

2.74

1.240

6.500

10.30

2.700

1.360

1.72

0.88

2.000

50 x

50

4 6.5 3

3.892

3.06

1.370

9.060

14.40

3.760

1.530

1.92

0.98

2.490

50

50

60

60

x

x

x

x

50

50

60

60

5

6

4

5

3

4.5

3

3

4.802

5.644

4.692

5.802

3.77

4.43

3.68

4.55

1.410

1.440

1.610

1.660

11.100

12.600

16.000

19.600

17.50

20.00

25.40

31.20

4.580

5.230

6.620

8.090

1.520

1.500

1.850

1.840

1.91

1.88

2.33

2.32

0.98

0.96

1.19

1.18

3.080

3.550

3.660

4.520

60 x

65 x

65 x

60

65

65

6 8 4

5 8.5 3

6 8.5 4

6.910

6.367

7.527

5.40

5.00

5.91

1.700

1.770

1.810

22.790

25.300

29.400

36.16

40.10

46.60

9.420

10.500

12.200

1.820

1.990

1.980

2.29

2.51

2.49

1.17

1.28

1.27

5.280

5.350

6.260

65 x

65

8 8.5 6

9.761

7.66

1.880

36.800

58.30

15.300

1.940

2.44

1.25

7.960

70 x

75 x

75 x

70

75

75

6 8.5 4

6 8.5 4

9 8.5 6

8.127

8.727

12.690

6.38

6.85

9.96

1.930

2.060

2.170

37.100

46.100

64.400

58.90

73.20

102.00

15.300

19.000

26.700

2.140

2.300

2.250

2.69

2.90

2.84

1.37

1.48

1.45

7.330

8.470

21.100

75 x

75

12 8.5 6

6

6

7

10

13

7

13

6.5

6.5

6.5

6.5

16.560

13.00

2.290

81.900

129.00

34.500

2.220

2.79

1.44

15.700

8.5

10

10

10

10

10

10

4

5

5

7

7

5

7

9.230

10.550

12.220

17.000

21.710

13.620

24.310

7.32

8.28

9.59

13.30

17.00

10.70

19.10

2.180

2.420

2.460

2.570

2.690

2.710

2.940

56.400

80.700

93.000

125.000

156.000

129.000

220.000

89.60

128.00

148.00

199.00

248.00

205.00

348.00

23.200

33.400

38.300

51.700

65.300

53.200

91.100

2.460

2.770

2.760

2.710

2.680

3.080

3.000

3.10

3.48

3.48

3.42

3.38

3.88

3.78

1.58

1.78

1.77

1.74

1.73

1.98

1.94

9.700

12.300

14.200

19.500

24.800

17.700

31.100

100 x 100

120 x 120

10 10

8 12

7

5

19.000

18.760

14.90

14.70

2.820

3.240

175.000

258.000

278.00

410.00

72.000

106.000

3.040

3.710

3.83

4.67

1.95

2.38

24.400

29.500

120 x 120

11 13 6.5

25.370

19.90

3.300

340.000

541.00

140.000

3.660

4.62

2.35

39.360

120 x 120

130 x 130

12 13 6.5

9 12 6

27.540

22.740

21.60

17.90

3.400

3.530

367.000

366.000

583.00

583.00

151.000

150.000

3.650

4.010

4.60

5.06

2.35

2.57

42.680

38.700

130 x 130

130 x 130

150 x 150

15 12 8.5

12 12 8.5

12 14 7

36.750

29.760

34.770

28.80

23.40

27.30

3.760

3.640

4.140

568.000

467.000

740.000

902.00

743.00

1,180.00

234.000

192.000

304.000

3.930

3.960

4.610

4.95

5.00

5.82

2.53

2.54

2.96

41.600

49.900

68.100

150

150

175

175

200

x

x

x

x

x

150

150

175

175

200

15

19

12

15

15

14

14

15

15

17

10

10

11

11

12

42.740

53.380

40.520

50.210

57.750

33.60

41.90

31.80

39.40

45.30

4.240

4.400

4.730

4.850

5.460

888.000

1,090.000

1,170.000

1,440.000

2,180.000

1,410.00

1,730.00

1,860.00

2,290.00

3,470.00

365.000

451.000

480.000

589.000

891.000

4.560

4.520

5.380

5.350

6.140

5.75

5.69

6.78

6.75

7.75

2.92

2.91

3.44

3.48

3.93

103.000

91.800

114.000

150.000

200

200

250

250

x

x

x

x

200

200

250

250

20

25

35

25

17

17

24

24

12 76.000

12 93.750

18 162.600

12 119.400

59.70

73.60

128.00

93.70

5.670

5.860

7.450

7.100

2,820.000

3,420.000

9,110.000

6,950.000

4,490.00

5,420.00

14,400.00

11,000.00

1,160.000

6.090

6.040

7.490

7.630

7.68

7.61

9.42

9.62

3.90

3.88

4.83

4.89

197.000

242.000

519.000

388.000

80

90

90

90

90

100

100

NOTE :

x 80

x 90

x 90

x 90

x 90

x 100

x 100

Available ready stock

JURNAL BESI BAJA INDONESIA

1,410.000

3,790.000

2,860.000

82.600

continue .......>>

www.jurnalbesibaja.com

P R O D U C T

S E C T I O N

ANGLES

EQUAL ANGLE (2)

SPECIFICATION FOR WIDE FLANGE SHAPED ( HOT ROLLED )

ACCORDING JIS G 3192

METRIC SIZE

DIMENSION

TOLERANCE

REMARK

mm

Under 50 in depth

50 or over to and excl. 100

100 or over to and excl. 200

200 or over

1.5

2.0

3.0

4.0

For leg length

A (B for T

Section) :

130 or over

in depth

0.7

0.8

1.0

0.7

0.8

B

2

1.0

1.2

1.5

ACCORDING JIS G 3101, G 3106

CHEMICAL COMPOSITION

SYMBOL

OF GRADE

t

t

Thickness

t,

A

2

0.6

Under 6.3

6.3 or over

to and excl. 10

10 or over to

and excl.16

16 or over

Under 6.3

6.3 or over to

and excl. 10

10 or over to

and excl. 16

16 or over to

and excl. 25

25 or order

For leg length

A (B for T

Section) or

under 130

in depth

Leg length

(A or B)

CHEMICAL COMPOSITION (%)

Si

Mn

0.050 max

SS 400

0.050 max

CORRESPONDING SPECIFICATION

TYPE OF

MATERIAL

General Structure

CLASSIFICATION

JIS G3101 SS400

CLASSIFIED BY TENSILE STRENGTH

Tensile strength

class (N/mm)2

SPECIFICATIONS

Special

Specification

400

YIELD POINT

N/mm2

Thickness (mm)

16 or under

over 16

245

235

JIS

ASTM

BS 4360

DIN

G 3101 SS 400

A 36

Gr. 43A

St 33

ELONGATION, %

TENSILE

STRENGTH

N/mm2

JURNAL BESI BAJA INDONESIA

400-510

Thickness (mm)

5 or under

5 to 16

over 16

21

17

21

www.jurnalbesibaja.com

P R O D U C T

S E C T I O N

ANGLES

EQUAL ANGLE

COLD FORMED

Y

V

Cx

Cy

Y

V

B

METRIC SIZE

STANDARD

SECTIONAL

DIMENSIONS

H

mm x mm

20 x 20

25 x 25

30 x 30

35 x 35

40 x 40

50 x 50

60 x 60

70 x 70

80 x 80

100 x 100

120 x 120

150 x 150

SECTION

AREA

+ 0.5

CENTER

OF

GRAVITY

GEOMETRICAL MOMENT

OF INERTIA

RADIUS OF GYRATION

OF AREA

MODULUS

OF SECTION

Cx = Cy

Ix = Iy

Max Iu

Min Iv

ix = iy

Max iu

Min iv

mm

cm2

kg/m

cm

cm4

cm4

cm4

cm

cm

cm

cm3

1.2

1.5

1.6

2.0

2.5

3.0

1.6

2.0

2.5

3.0

1.5

1.6

2.0

2.5

3.0

2.5

2.0

2.5

3.0

2.0

2.5

3.0

4.0

5.0

2.0

2.5

3.0

4.0

5.0

6.0

3.0

3.5

4.0

5.0

6.0

3.0

3.5

4.0

5.0

6.0

3.0

3.5

4.0

5.0

6.0

3.0

3.5

4.0

5.0

6.0

3.0

3.5

4.0

5.0

6.0

0.45

0.56

0.59

0.72

0.90

1.05

0.75

0.92

1.13

1.32

0.86

0.91

1.12

1.38

1.62

1.63

1.52

1.88

2.25

1.92

2.38

2.85

3.74

4.59

2.32

2.88

3.45

4.54

5.59

6.61

4.05

4.70

5.34

6.59

7.81

4.65

5.40

6.14

7.59

9.01

5.85

6.80

7.74

9.59

1.41

7.05

8.20

9.34

11.58

13.81

8.85

10.30

11.74

14.59

17.41

0.35

0.44

0.46

0.57

0.70

0.83

0.59

0.72

0.89

1.04

0.68

0.71

0.88

1.08

1.27

1.28

1.19

1.47

1.77

1.51

1.87

2.24

2.93

3.60

1.82

2.26

2.71

3.56

4.39

5.19

3.18

3.69

4.19

5.17

6.13

3.65

4.24

4.82

5.96

7.07

4.59

5.34

6.07

7.53

8.96

5.54

6.44

7.33

9.10

10.84

6.95

8.08

9.21

11.45

13.67

0.56

0.57

0.58

0.60

0.62

0.64

0.70

0.72

0.75

0.77

0.82

0.83

0.85

0.87

0.90

1.00

1.10

1.12

1.14

1.35

1.74

1.39

1.43

1.48

1.60

1.62

1.64

1.68

1.73

1.78

1.89

1.91

1.93

1.98

2.03

2.14

2.16

2.18

2.23

2.28

2.64

2.66

2.68

2.73

2.78

3.14

3.16

3.18

3.23

3.28

3.89

3.91

3.93

3.98

4.02

0.18

0.22

0.23

0.28

0.34

0.38

0.46

0.56

0.68

0.79

0.77

0.82

1.00

1.21

1.41

1.97

2.44

2.98

3.52

4.85

5.95

7.05

9.08

10.95

8.48

10.44

12.39

16.05

19.49

22.72

19.92

22.96

25.92

31.60

36.99

30.02

34.65

39.17

47.91

56.26

59.39

68.69

77.83

95.63

112.79

103.50

119.89

136.05

167.64

198.30

203.89

236.52

268.77

332.15

394.04

0.29

0.36

0.38

0.46

0.55

0.63

0.76

0.92

1.12

1.30

1.25

1.33

1.63

1.98

2.32

3.21

3.96

4.86

5.71

7.87

9.43

11.41

14.74

17.85

13.74

16.95

20.02

26.02

31.68

37.00

32.15

37.10

41.93

51.26

60.14

48.38

55.91

63.29

77.60

91.31

95.58

110.67

125.52

154.51

182.57

166.42

192.93

219.11

270.43

320.40

327.50

380.17

432.29

534.93

635.43

0.07

0.08

0.08

0.10

0.12

0.14

0.17

0.20

0.24

0.28

0.30

0.30

0.37

0.44

0.50

0.72

0.91

1.10

1.33

1.83

2.47

2.69

3.41

4.06

3.22

3.93

4.76

6.09

7.31

8.43

7.70

8.82

9.90

11.95

13.84

11.65

13.38

15.05

18.23

21.21

23.19

26.72

30.15

36.75

43.00

40.59

46.85

52.99

64.85

76.20

80.27

92.87

105.25

129.36

152.64

0.63

0.62

0.63

0.62

0.61

0.60

0.79

0.78

0.78

0.77

0.95

0.95

0.94

0.94

0.93

1.10

1.27

1.26

1.25

1.59

1.58

1.57

1.56

1.55

1.91

1.90

1.89

1.88

1.87

1.85

2.22

2.21

2.20

2.19

2.18

2.54

2.53

2.53

2.51

2.50

3.19

3.18

3.17

3.16

3.14

3.83

3.82

3.82

3.80

3.79

4.80

4.79

4.79

4.77

4.76

0.80

0.80

0.80

0.80

0.78

0.77

1.01

1.00

1.00

0.99

1.20

1.21

1.21

1.20

1.19

1.40

1.61

1.61

1.59

2.02

1.99

2.00

1.99

1.97

2.43

2.43

2.41

2.39

2.38

2.37

2.82

2.81

2.80

2.79

2.78

3.22

3.22

3.21

3.20

3.18

4.04

4.03

4.03

4.01

4.00

4.86

4.85

4.84

4.83

4.82

6.08

6.08

6.07

6.06

6.04

0.38

0.38

0.38

0.37

0.37

0.37

0.48

0.47

0.46

0.46

0.59

0.58

0.57

0.57

0.56

0.66

0.77

0.77

0.77

0.98

1.02

0.97

0.96

0.94

1.18

1.17

1.17

1.16

1.14

1.13

1.38

1.37

1.36

1.35

1.33

1.58

1.57

1.57

1.55

1.53

1.99

1.98

1.97

1.96

1.94

2.40

2.39

2.38

2.37

2.35

3.01

3.00

2.99

2.98

2.96

0.12

0.15

0.16

0.20

0.24

0.28

0.26

0.32

0.39

0.46

0.36

0.38

0.46

0.60

0.67

0.71

0.84

1.04

1.23

1.33

1.64

1.95

2.55

3.11

1.93

2.39

2.84

3.72

4.57

5.38

3.90

4.51

5.12

6.30

7.44

5.12

5.93

6.73

8.30

9.83

8.07

9.36

10.64

13.15

15.61

11.68

13.56

15.43

19.11

22.73

18.35

21.33

24.29

30.14

35.90

TOLERANCE (mm)

t

UNIT

WEIGHT

INFORMATIVE REFERENCE

H, B

+2

Zx = Zy

TECHNICAL SPECIFICATION

Material

Symbol

Chemical Component

: JIS G3350

: SSC 41

: C. 0.25% (Maximum)

P. 0.05% (Maximum)

S. 0.05% (Maximum)

Technical data

Standard length

: Yield point : 25 kg/mm2 (minimum)

Tensile Strength 41-55 kg/mm2

: 6.00 m

1. Non standard length is available request subject to minimum quantity 2. We provide additional services for standard drilling and punching (for detail, please refer to standard drilling / punching for lip channel

data sheet) 3. Shot blasting, painting and galvanizing are available on request

JURNAL BESI BAJA INDONESIA

www.jurnalbesibaja.com

P R O D U C T

S E C T I O N

ANGLES

UNEQUAL ANGLE

COLD FORMED

Y

V

H

Cx

Cy

V

B

METRIC SIZE

STANDARD

SECTIONAL

DIMENSIONS

H x

mm x mm

80 x 60

100 x 60

100 x 80

150 x 60

150 x 80

120 x 80

SECTION

UNIT

AREA

WEIGHT

INFORMATIVE REFERENCE

CENTER

OF

GRAVITY

GEOMETRICAL MOMENT

OF INERTIA

RADIUS OF GYRATION

OF AREA

Cx

Cy

Ix

Iy

Min Iu

Min Iv

ix

iy

mm

cm2

kg/m

cm

cm

cm4

cm4

cm4

cm4

cm

cm

cm

cm

3.0

4.05

3.18

2.43

1.42

27.29 13.53

33.99

6.83

2.60

1.83

2.90

3.5

4.70

3.69

2.46

1.44

31.47 15.57

39.22

7.82

2.59

1.82

2.89

4.0

5.34

4.19

2.48

1.46

35.54 17.56

44.32

8.78

2.58

1.81

5.0

6.59

5.17

2.53

1.51

43.38 21.37

54.16

10.59

2.57

3.0

4.56

3.65

3.28

1.25

50.04 14.37

56.20

8.21

3.5

5.40

4.24

3.30

1.28

57.79 16.56

64.93

4.0

6.14

4.82

3.33

1.30

65.37 18.68

5.0

7.59

5.96

3.38

1.34

6.0

9.01

7.07

3.44

3.0

5.25

4.12

3.5

6.10

4.0

5.0

Min iu Min iv

MODULUS

OF SECTION

Zx

Zy

cm3

cm3

1.30

4.90

2.95

1.29

5.68

3.42

2.88

1.28

6.44

3.87

1.80

2.87

1.27

7.93

4.76

3.28

1.76

3.51

1.33

7.44

3.03

9.42

3.27

1.75

3.47

1.32

8.63

3.50

73.46

10.59

3.26

1.74

3.46

1.31

9.80

3.97

80.05 22.76

89.99

12.82

3.25

1.73

3.44

1.30

12.10

4.89

1.38

94.09 26.63

105.82

14.90

3.23

1.72

3.43

1.29

14.33

5.77

2.92

1.91

55.25 32.12

71.79

15.58

3.24

4.27

3.70

1.72

7.80

5.27

4.79

2.95

1.93

63.87 37.10

83.05

17.92

3.24

2.47

3.69

1.71

9.05

6.11

6.94

5.45

2.97

1.95

72.32 41.97

94.10

20.19

3.23

2.46

3.68

1.71

10.29

6.94

8.59

6.74

3.02

2.00

88.75 51.40

115.61

24.54

3.21

2.45

3.67

1.69

12.71

8.57

6.0 10.21

8.01

3.07

2.04 104.53 60.43

136.32

28.64

3.20

2.43

3.65

1.67

15.08

10.15

3.0

6.15

4.83

5.53

0.98 149.61 15.77

155.08

10.30

4.93

1.60

5.02

1.29

15.79

3.14

3.5

7.15

5.61

5.56

1.01 173.18 18.17

179.50

11.85

4.92

1.59

5.01

1.29

18.34

3.64

4.0

8.14

6.39

5.58

1.03 196.36 20.52

203.53

13.35

4.91

1.59

5.00

1.28

20.86

4.13

5.0 10.09

7.92

5.64

1.07 241.58 25.05

250.39

16.24

4.89

1.58

4.98

1.27

25.81

5.08

6.0 12.01

9.43

5.70

1.11 285.26 29.36

295.64

18.98

4.87

1.56

4.96

1.26

30.67

6.01

3.0

6.75

5.30

5.05

1.52 165.42 35.75

179.67

21.50

4.95

2.30

5.16

1.78

16.62

5.52

3.5

7.85

6.16

5.08

1.54 191.65 41.31

208.17

24.79

4.94

2.29

5.15

1.78

19.31

6.40

4.0

8.94

7.02

5.10

1.56 217.49 46.77

236.26

28.00

4.93

2.29

5.14

1.77

21.97

7.27

5.0 11.09

8.70

5.16

1.60 268.05 57.38

291.24

34.19

4.92

2.27

5.12

1.76

27.23

8.97

6.0 13.21

10.37

5.21

1.65

317.11 67.57

344.60

40.08

4.90

2.26

5.11

1.74

32.39

10.64

4.0 10.94

8.59

7.37

1.31 472.85 49.83

490.14

32.54

6.58

2.13

6.69

1.72

37.44

7.45

5.0 13.59

10.67

7.43

1.36 584.12 61.17

605.45

39.84

6.56

2.12

6.67

1.71

46.46

9.21

6.0 16.21

12.72

7.48

1.40 692.66 72.11

717.94

46.83

6.54

2.11

6.66

1.70

55.34

10.92

TOLERANCE (mm)

t

H, B

+ 0.5

+2

TECHNICAL SPECIFICATION

Material

Symbol

Chemical Component

: JIS G3350

: SSC 41

: C. 0.25% (Maximum)

P. 0.05% (Maximum)

S. 0.05% (Maximum)

Technical data

Standard length

: Yield point : 25 kg/mm2 (minimum)

Tensile Strength 41-55 kg/mm2

: 6.00 m

1. Non standard length is available request subject to minimum quantity 2. We provide additional services for standard drilling and punching (for detail, please refer to standard drilling / punching for lip channel

data sheet) 3. Shot blasting, painting and galvanizing are available on request

JURNAL BESI BAJA INDONESIA

www.jurnalbesibaja.com

P R O D U C T

S E C T I O N

CHANNELS

LIPPED CHANNEL

B

ix

C

H

iy

X S.C.

Cy

Cy

Sx

Sx

METRIC SIZE

DIMENSION

THICKNESS

SECTION. CENTER OF

AREA

GRAVITY

CENTER OF

SHEAR

MOMENT OF

INERTIA

RADIUS OF

GYRATION

MODULUS OF

SECTION

Cx

Cy

Sx

Sy

IX

Iy

ix

iy

Zx

Zy

kg/m

cm2

cm

cm

cm

cm

cm4

cm4

cm

cm

cm3

cm3

2.3

4.06

5.17

1.86

4.4

81

19

3.95

1.92

16.1

6.06

2.8

2.3

4.87

6.21

1.88

4.3

100

23

3.96

1.91

20.0

7.44

3.2

5.50

7.01

1.86

4.4

107

25

3.90

1.87

21.3

7.81

2.3

4.51

5.75

1.69

4.1

137

21

4.88

1.89

21.9

6.22

3.2

6.13

7.81

1.68

4.0

181

27

4.82

1.85

29.0

8.02

2.3

4.96

6.32

1.55

3.8

210

22

5.77

1.86

28.0

6.33

3.2

6.76

8.61

1.54

3.8

280

28

5.71

1.81

37.4

8.19

2.3

5.50

7.01

2.12

5.2

248

41

5.94

2.42

33.0

9.37

3.2

7.51

9.57

2.11

5.1

332

54

5.89

2.37

44.3

12.2

3.2

9.27

11.81

2.19

5.4

716

84

7.79

2.67

71.6

15.8

4.0

11.4

14.55

2.19

5.3

871

100

7.74

2.62

87.1

18.9

HxBxC

mm

mm

C 100 x 50 x 20

UNIT

WEIGHT

C 125 x 50 x 20

C 150 x 50 x 20

C 150 x 65 x 20

C 200 x 75 x 20

TECHNICAL SPECIFICATION

Material

Symbol

Chemical Component

: JIS G3350

: SSC 41

: C. 0.25% (Maximum)

P. 0.05% (Maximum)

S. 0.05% (Maximum)

Technical data

Standard length

2

: Yield point : 25 kg/mm (minimum)

2

Tensile Strength 41-55 kg/mm

: 6.00 m

Non standard length is available on request subject to minimum quantity

We provide additional services for standard drilling and punching (for detail, please refer to standard drilling / punching for lip channel data sheet)

Shot blasting, painting and galvanizing are available on request

JURNAL BESI BAJA INDONESIA

www.jurnalbesibaja.com

P R O D U C T

S E C T I O N

BEAMS

C-CHANNEL

Y

Cy

Cy

t2

H Sc

CG

Sx Sx

METRIC SIZE

DIMENSION THICK

NESS

UNIT

WEIGHT

SECTION.

AREA

CENTER OF

GRAVITY

CENTER OF

SHEAR

CX

SX

Cy

t1

mm x mm

mm

kg/m

cm2

cm

cm

80 x 35

80 x 40

80 x 40

80 x 40

80 x 40

80 x 40

80 x 45

80 x 45

80 x 45

80 x 50

80 x 50

80 x 50

80 x 50

80 x 50

80 x 55

80 x 60

80 x 60

80 x 60

80 x 60

80 x 65

80 x 70

80 x 80

80 x 80

80 x 80

80 x 85

90 x 35

90 x 40

90 x 45

90 x 50

90 x 50

90 x 55

90 x 75

100 x 35

100 x 40

100 x 40

100 x 40

100 x 40

4.0

2.0

2.5

3.0

4.0

5.0

3.0

4.0

5.0

2.5

3.0

4.0

5.0

5.5

4.0

2.5

3.0

4.0

5.0

4.0

5.0

3.0

4.0

5.0

4.0

4.0

4.0

4.0

4.0

5.0

4.0

4.0

4.0

2.5

3.0

4.0

5.0

4.30

2.41

2.98

3.54

4.61

5.63

3.77

4.93

6.03

3.37

4.01

5.24

6.42

6.99

5.55

3.76

4.48

5.87

7.20

6.18

7.99

5.42

7.12

8.77

7.44

4.61

4.93

5.24

5.55

6.81

5.87

7.12

4.93

3.37

4.01

5.24

6.42

5.47

3.07

3.79

4.50

5.87

7.18

4.80

6.27

7.68

4.29

5.10

6.67

8.18

8.91

7.07

4.79

5.70

7.47

9.18

7.87

10.18

6.90

9.07

11.18

9.47

5.87

6.27

6.67

7.07

8.68

7.47

9.07

6.27

4.29

5.10

6.67

8.18

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

1.00

1.09

1.11

1.14

1.18

1.23

1.33

1.38

1.43

1.51

1.53

1.58

1.63

1.66

1.79

1.93

1.95

2.00

2.05

2.22

2.49

2.83

2.88

2.94

3.11

0.94

1.12

1.31

1.50

1.55

1.70

2.55

0.90

1.00

1.02

1.07

1.11

HxB

TOLERANCE (mm)

t

H, B

+ 0.5

+2

GEOMETRICAL

MOMENT OF

INERTIA

Sy

IX

Iy

cm

cm

cm4

cm4

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

2.04

2.49

2.48

2.47

2.46

2.44

2.91

2.89

2.88

3.35

3.35

3.34

3.32

3.32

3.79

4.25

4.25

4.24

4.23

4.70

5.16

6.11

6.10

6.10

6.58

1.94

2.35

2.78

3.21

3.19

3.65

5.47

1.85

2.27

2.27

2.25

2.24

49.74

30.85

37.57

43.92

55.52

65.72

48.37

61.30

72.76

45.08

52.82

67.08

79.80

85.61

72.87

52.59

61.72

78.65

93.89

84.43

107.97

79.51

101.77

122.05

107.55

66.16

73.56

80.96

88.36

105.51

95.76

125.37

85.51

63.43

74.41

94.73

112.97

6.14

4.90

5.99

7.03

8.97

10.73

9.76

12.50

15.00

11.09

13.07

16.78

20.19

21.78

21.86

18.27

21.56

27.81

33.60

34.67

51.52

47.24

61.27

74.45

72.31

6.38

9.34

13.03

17.50

21.10

22.83

53.66

6.60

6.42

7.55

9.67

11.6

RADIUS OF

GYRATION

ix

MODULUS OF

SECTION

iy

Zx

Zy

cm

cm

cm3

cm3

3.01

3.17

3.15

3.12

3.07

3.03

3.17

3.13

3.08

3.24

3.22

3.17

3.12

3.10

3.21

3.31

3.29

3.24

3.20

3.27

3.26

3.39

3.35

3.30

3.37

3.36

3.42

3.48

3.53

3.49

3.58

3.72

3.69

3.84

3.82

3.77

3.72

1.06

1.26

1.26

1.25

1.24

1.22

1.43

1.41

1.40

1.61

1.60

1.59

1.57

1.56

1.76

1.95

1.94

1.93

1.91

2.10

2.25

2.62

2.60

2.58

2.76

1.04

1.22

1.40

1.57

1.56

1.75

2.43

1.03

1.22

1.22

1.20

1.19

12.44

7.71

9.39

10.98

13.88

16.43

12.09

15.33

18.19

11.27

13.20

16.77

19.95

21.40

18.22

13.15

15.43

19.66

23.47

21.11

26.99

19.88

25.44

30.51

26.89

14.70

16.35

17.99

19.64

23.45

21.28

27.86

17.10

12.69

14.88

18.95

22.59

2.45

1.68

2.08

2.46

3.19

3.88

3.08

4.01

4.88

3.18

3.77

4.91

5.99

6.51

5.89

4.48

5.33

6.96

8.51

8.10

11.42

9.13

11.97

14.71

13.41

2.50

3.25

4.08

5.01

6.12

6.01

10.84

2.53

2.14

2.54

3.30

4.02

TECHNICAL SPECIFICATION

Material

Symbol

Chemical Component

: JIS G3350

: SSC 41

: C. 0.25% (Maximum)

P. 0.05% (Maximum)

S. 0.05% (Maximum)

Technical data

Standard length

: Yield point : 25 kg/mm2 (minimum)

Tensile Strength 41-55 kg/mm2

: 6.00 m

1. Non standard length is available request subject to minimum quantity 2. We provide additional services for standard drilling and punching (for detail, please refer to standard drilling / punching for lip channel

data sheet) 3. Shot blasting, painting and galvanizing are available on request

JURNAL BESI BAJA INDONESIA

www.jurnalbesibaja.com

P R O D U C T

S E C T I O N

CHANNELS

U-CHANNEL

Cy bf - t1

t2

t1

r1

Sbfx

t2

METRIC SIZE

AxB

t1

mm x mm

mm

GEOMETRICAL

MOMENT OF

INERTIA

SECTIONAL

AREA

UNIT

MASS

CENTER OF

GRAVITY

t2

Cy

IX

Iy

mm

cm2

kg/m

cm

cm4

cm4

STANDARD SECTIONAL

DIMENSION

RADIUS OF

GYRATION

ix

MODULUS OF

SECTION

iy

Zx

Zy

cm

cm

cm3

cm3

4.54

75 x 40

8.818

6.92

1.27

75.9

12.4

2.93

1.19

20.2

100 x 50

7.5

11.92

9.36

1.55

189

26.9

3.98

1.50

37.8

7.82

125 x 65

17.11

13.40

1.94

425

65.5

4.99

1.96

68.0

14.40

150 x 75

6.5

10

23.71

18.60

2.31

864

122.0

6.04

2.27

115.0

23.60

150 x 75

12.5

30.59

24.00

2.31

1050

147.0

5.86

2.19

140.0

28.30

180 x 75

10.5

27.20

21.40

2.15

1380

137.0

7.13

2.24

150.0

25.50

200 x 70

10

26.92

21.10

1.85

1620

113.0

7.77

2.04

162.0

21.80

200 x 80

7.5

11

31.33

24.60

2.24

1950

177.0

7.89

2.38

195.0

30.80

200 x 90

13.5

38.65

30.30

2.77

2490

286.0

8.03

2.72

249.0

45.90

250 x 90

13

44.07

34.60

2.43

4180

306.0

9.74

2.64

335.0

46.50

250 x 90

11

14.5

51.17

40.20

2.39

4690

342.0

9.57

2.58

375.0

51.70

300 x 90

10

15.5

55.74

43.80

2.33

7400

373.0

11.50

2.54

494.0

56.00

300 x 90

12

16

61.90

48.60

2.25

7870

391.0

11.30

2.51

525.0

57.90

380 x 100

10.5

16

69.39

54.50

2.41

14500

557.0

14.50

2.83

762.0

73.30

380 x 100

13

16.5

78.96

62.00

2.29

15600

584.0

14.10