Professional Documents

Culture Documents

Melting Point Depression of Ionic Liquids With CO2 Phase Equilibria

Uploaded by

cansuOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Melting Point Depression of Ionic Liquids With CO2 Phase Equilibria

Uploaded by

cansuCopyright:

Available Formats

Melting Point Depression of Ionic Liquids with CO

2

: Phase Equilibria

Aaron M. Scurto,*

,,

Elizabeth Newton,

,|

Ross R. Weikel,

,|

Laura Draucker,

,|

Jason Hallett,

,|

Charles L. Liotta,

,|,

Walter Leitner,

,#

and Charles A. Eckert

,|,

Institut fur Technische und Makromolekulare Chemie, RWTH Aachen, Worringerweg 1,

D-52074 Aachen, Germany, Department of Chemical & Petroleum Engineering and NSF-ERC Center for

EnVironmentally Beneficial Catalysis, UniVersity of Kansas, Lawrence, Kansas 66045, School of Chemical and

Biomolecular Engineering, Georgia Institute of Technology, Atlanta, Georgia 30332, School of Chemistry and

Biochemistry, Georgia Institute of Technology, Atlanta, Georgia 30332, Specialty Separations Center,

Georgia Institute of Technology, Atlanta, Georgia 30332, and Max-Planck-Institut fur Kohlenforschung,

Mulheim an der Ruhr, Germany

Development of ionic liquids for specific tasks is currently being pursued by many researchers as numerous

cation/anion combinations are theoretically possible. However, only a small fraction of these combinations

melt below 100 C. Recently, large melting point depressions of several ionic solids with compressed carbon

dioxide have been reported. This investigation details the melting point depression of a large number of ionic

organic compounds (ionic liquids) with gaseous, liquid, and supercritical CO

2

. Large and previously unreported

depressions were observed for some of the ionic solids. This methodology greatly expands the numbers of

compounds and functional groups that can be employed in an ionic liquid/compressed gas system for various

applications. Thermodynamic analysis indicates that even small amounts of CO

2

can lead to substantial melting

point depression, due to its very low melting temperature and negative deviations to Raoults law.

Introduction

Room-temperature ionic liquids (ILs) have been the subject

of intense focus due to their demonstrated usefulness as solvents

for extractions,

1

reactions,

2,3

and materials processing.

4,5

Pre-

liminary toxicology studies of ILs

6-8

indicate low to moderate

toxicity on average, and most ILs have no measurable vapor

pressure, thus eliminating air emissions; an advantage over any

other organic solvent. Due to these advantageous properties,

ILs have been touted as green solvents. In addition, biphasic

systems with ILs can be utilized for advanced reactions and

extractions. In particular, there has been significant research in

pairing CO

2

with ionic liquids.

9-11

Carbon dioxide is frequently

used in green processing due to its benign characteristics.

12

CO

2

has excellent solubility in many ILs, while ILs have little to no

solubility in CO

2

.

9

In addition, Scurto et al.

13,14

have used CO

2

pressure as a separation switch, to induce immiscibility in

ionic liquid solutions with organics and water. Brown et al.

15

have used supercritical CO

2

to extract products of a homoge-

neously catalyzed reaction from an IL. Leitner and co-workers

have performed a variety of reactions in CO

2

/IL biphasic

systems where the ionic liquid immobilizes a homogeneous

catalyst in a continuous process.

10,16,17

Sellin et al.

18,19

have also

used the IL to immobilize a homogeneous catalyst in an IL/

CO

2

biphasic system for hydroformylation reactions. Catalytic

reactions using enzymes have also been carried out in such

biphasic media.

11,20,21

A detailed overview of biphasic catalysis

in IL/CO

2

systems is available in the literature.

22,23

The present definition of an ionic liquid is an organic salt

that has a melting point below 100 C.

24

There are a myriad of

cation/anion combinations that can be molecularly engineered

with specific physical or chemical properties. However, design-

ing organic salts with particular properties and functional groups

that are also liquid near room-temperature is not a trivial task.

Of the estimated 10

18

possible cation-anion combinations (10

14

unique cations and anions),

25

only a very small fraction actually

melt below 100 C. Often useful functional groups yield solid

salts, such as those shown with metal-extracting ionic com-

pounds by Visser et al.,

26

chiral ionic liquids,

27,28

an IL that is

both solvent and catalyst,

29

etc. A methodology or process to

increase the range of ionic compounds for use as solvents would

be highly useful.

It has been long known that organic solids can undergo

melting below their normal melting points (melting point

depression) in the presence of a number of compressed gases.

30

Kazarian et al.

31

observed liquid-crystal transitions induced by

CO

2

for surfactant-like imidazolium salts. Recently, Scurto and

Leitner

32

have demonstrated that CO

2

can induce unprecedented

melting point depressions in some types of ionic salts. Moreover,

the induced melts can serve as an advantageous platform for

metal-complex catalysis. This contribution will present the

results for a larger variety of ionic solids and demonstrate the

effect of temperature, pressure, and composition on the melting

point. The melting point with composition data will be modeled

using an ideal and advanced activity-coefficient model.

Phase Behavior

Melting point depression is a thermodynamic condition that

can be represented by two different equilibria: solid-liquid and

solid-liquid-vapor (SLV). Figure 1 illustrates the phase

transitions with pressure and temperature of a typical highly

asymmetric system of a common organic solid with an ambient

gaseous component: naphthalene and ethane or carbon dioxide,

for example. In the presence of a second gaseous component,

the melting curve of the pure solute can be lowered as shown

* To whom correspondence should be addressed. E-mail: ascurto@

ku.edu. Phone: +1 (785) 864-4947. Fax: +1 (785) 864-4967.

Institut fur Technische und Makromolekulare Chemie.

University of Kansas.

School of Chemical and Biomolecular Engineering, Georgia

Institute of Technology.

|

Specialty Separations Center, Georgia Institute of Technology.

School of Chemistry and Biochemistry, Georgia Institute of

Technology.

#

Max-Planck-Institut fur Kohlenforschung.

493 Ind. Eng. Chem. Res. 2008, 47, 493-501

10.1021/ie070312b CCC: $40.75 2008 American Chemical Society

Published on Web 09/28/2007

by the dashed SLV curves labeled I and II. Solid-liquid-vapor

(SLV) equilibria for a binary system is obtained by starting with

higher molar loading of the compressed gas and maintaining

temperature (1a to 2 in Figure 1) or pressure (1b to 2 in Figure

1) and varying the other variable until the very first instance

that a solid, liquid, and vapor coexist in equilibria. The melting

point depression (T

m

) is thus T

m

minus T

SLV

. For nonionic

organic systems, the SLV line emanates from the triple point

of the solute and terminates at the upper critical endpoint

(UCEP). The SLV can proceed directly (curve I, e.g., naphtha-

lene and ethane

33

) to the UCEP, or the SLV curve can have a

minimum in temperature on a PT projection (curve II, e.g.,

naphthalene and carbon dioxide

34-36

). This implies that increas-

ing pressure along certain isotherms will first melt the solid

(SLV curve II) to produce vapor-liquid equilibrium and then

at higher pressures solidify the liquid phase, returning to solid-

fluid equilibrium. However, some gaseous components do not

induce much or any melting point depression and can actually

increase the melting point beyond that of the pure component.

This phenomenon is observed when naphthalene is exposed to

helium.

36

Solid-liquid-vapor equilibrium can also occur at

lower temperatures near the vapor pressure of the less volatile

component, as shown in Figure 1; however, this transition is

primarily the boiling point elevation of the liquefied gas in

the presence of the solute. At lower gas loading (moles gas:

solute) and pressures above the SLV pressure, the melting point

depression will be represented by solid-liquid equilibrium

(SLE). The inset in Figure 1 illustrates in a pressure-

composition plot for the phase behavior regions of both SLV

and SLE (P

2

represents point 2 (SLV) in the larger plot).

The melting point of naphthalene (T

m

) 80.1 C) has been

determined in the presence of a variety of gases: methane,

37

ethane,

33

ethylene,

38

carbon dioxide,

35

and xenon.

39

The largest

melting point depression was found in the presence of super-

critical xenon (T

m

) 37.5 C at 124 bar). Large melting point

depressions with CO

2

and inorganic minerals have also been

discovered, however at conditions in excess of 1000 K and 1000

bar.

40

CO

2

has been known for several decades to lower the

glass transition temperature of polymers.

41

Only more recently

has CO

2

been shown to lower the melting temperature of poly-

mers. Zhang and Handa

42

report that CO

2

lowers the melting

point of syndiotactic polystyrene (T

m

) 277 C) by approxi-

mately 12 C at 72 bar. Kishimoto and Ishii

43

found that CO

2

depressed the melting point of isotactic polypropene (T

m

)

180 C) by 11 C at 94 bar. Weidner and co-workers

44

deter-

mined the melting point depression of polyethylene glycol (PEG,

MW 1500, T

m

) 44.9 C) of approximately 16 C at 150 bar.

In attempt to perform electrochemistry in wet supercritical

carbon dioxide, Wightman and co-workers

45-47

used the ionic

solids tetrahexylammonium nitrate and hexafluorophosphate

([THexAm][PF

6

]) to aid in electrochemical oxidation. They

found that the CO

2

/H

2

O mixture induced a melting point in the

ionic solid (T

m

) 131 C of [THexAm][PF

6

]) to 40 to 50 C at

about 90 bar. This is not surprising considering the highly

hygroscopic nature of most quaternary ammonium salts. Ka-

zarian et al.

31

have used attenuated total reflection-infrared

(ATR-IR) to detect the formation of a liquid crystal phase

transition under 70 bar of pure CO

2

of a long-chain (C

16

) methyl-

imidazolium PF

6

; at ambient pressure, the ionic solid forms a

smectic A phase at 75 C and an isotropic liquid phase at

125 C. They also inferred from the IR spectra that the CO

2

has preferential interactions with the fluorinated anion in the

liquid crystal phase. However, the general trend or magnitude

of the melting point depression with compressed gases for the

vast majority of ionic solids has not been elucidated.

Thermodynamics and Modeling

Thermodynamic modeling of solid-liquid equilibria gives

the relationship for the mole fraction of the solid (2) in terms

of the melting point (T

m

), the triple point temperature (T

t

), the

enthalpy of fusion (h

fus

), the enthalpy of any solid-solid

transition (h

trans

), the temperature of that transition (T

trans

), and

the activity coefficient

2

. Neglecting second-order corrections,

the solid-liquid equilibrium is given by eq 1

48

This relationship can be used to make predictions of the

melting point curve, where the liquid may be either ideal or

nonideal, modeled by an expression for Gibbs excess free

energy/activity (g

EX

/). Deviations from Raoults law may be

both positive or negative, but unless there is a reasonably strong

compound formed (e.g., liquid metals), this procedure will give

a single eutectic and the predictions of the melting point curve

are generally quite accurate.

48-51

For ideal solutions, the activity

coefficient,

i

, is set equal to one. Modeling procedures are

discussed below.

Experimental Section

Materials. Naphthalene, [TBAm][BF

4

] and [THexAm][Br]

were purchased from Sigma-Aldrich at a purity of 99% or

greater. The solids were then further purified by drying at room

temperature under vacuum of 10

-3

Torr for 48 h and stored at

room temperature under a nitrogen atmosphere. Tetrabutylphos-

phonium bromide >99% ([TBP][Br]), tetrabutylammonium

bromide >99% ([TBAm][Br]), tetrabutylammonium tosylate

>99% ([TBAm][Tosyl]), tetrabutylammonium tetrafluoroborate

>99% ([TBAm][BF

4

]), tetrabutylammonium hexafluorophos-

phate >99% ([TBAm][PF

6

]), tetrapentylammonium bromide

>99% ([TPAm][Br]), tetrahexylammonium bromide >99%

([THexAm][Br]), tetraheptylammonium bromide ([THepAm]-

[Br]), tetraoctylammonium bromide >99% ([TOAm][Br]),

methyltrioctylammonium bromide >97% ([MTOAm][Br]), ben-

zyldodecyldimethylammonium bromide >99% ([BDMDDAm]-

[Br]), and 1-hexadecylpyrdinium chloride >98% ([HDPy][Cl])

were purchased from Sigma-Aldrich (Fluka). 1-Butyl-3-methyl-

imidazolium chloride 98% ([C

4

MIm][Cl]), 1-butyl-3-methyl-

imidazolium methanesulfonate 98% ([C

4

MIm][CH

3

SO

3

]), and

1-butyl-3-methyl-imidazolium tosylate 98% ([C

4

MIm][Tosyl])

Figure 1. Typical PT diagram of a highly asymmetric system for an organic

compound and compressed gas.

ln

1

x

2

)

h

fus

R

(T

m

- T)

T

t

T

+

h

trans

R

(T

trans

- T)

T

trans

T

- ln

2

(1)

494 Ind. Eng. Chem. Res., Vol. 47, No. 3, 2008

were generously donated by Solvent Innovation. 1,5-Diethyl-

2-methylpyridinium ethylsulfate ([EEMPy][EtSO

4

]), tetrabutyl-

ammonium trifluorotris(perfluoroethyl)phosphate ([TBAm]-

[TFEPF

3

]), (1S,2R)-1-hydroxy-N,N,N-trimethyl-1-phenylpro-

pan-2-ammonium triflate ([EP][Tfo]), (S)-1-hydroxy-N,N,N-

trimethylbutan-2-ammonium triflate ([AB][Tfo]), (S)-N-(1-hy-

droxybutan-2-yl)-N,N-dimethylbutan-1-ammonium +menthol-

sulfate ([MTOA][+MS]), (R)-1-methoxy-N,N,N-trimethylbutan-

2-ammonium bis(trifyl)imide ([IHETMAm][Tf

2

N]), methyl-

trioctylammonium triflate ([MTOAm][Tfo]), trimethylsulfonium

bis(trifyl)imide ([TMSfn][Tf

2

N]), tetraethylammonium bis(tri-

fyl)imide 99% ([TEAm][ Tf

2

N]), and methyl-tributylphospho-

nium triflate ([TBMP][Tfo]) were generously donated by Prof.

Dr. Peter Wasserscheidt and were all of 98%+ purity (NMR).

Methyl tributylammonium triflate ([TBMAm][Tfo]) and methyl-

tris(2-methyl-propyl)ammonium triflate ([TiBMAm][TFo]) were

synthesized by direct metathesis of the tributyl (isobutyl) amine

by dropwise addition of methyltriflate in dichloromethane as a

solvent. The reaction was allowed to finish overnight and was

evaporated and then dried under vacuum. Purity was confirmed

by NMR. All samples, regardless of source, were dried under

vacuum and stored under argon in Schlenk tubes. In addition,

each sample was dynamically extracted with supercritical CO

2

prior to measurement.

Two different methods were used: one to determine the

pressure and temperature at the SLV and the other to determine

solely the solid-liquid equilibrium (concentrations) at pressures

slightly above the SLV pressure, to prevent the formation of a

vapor phase. The melting point depressions (SLV) and the PT

projection of binary systems of ionic solid and compressed gas

were measured using a static high-pressure view cell. The so-

called first melting method was used here, where the solid

sample was slowly heated at constant pressure and visually

observed for the first signs of melting. This method is opposed

to the so-called first freezing method where the sample is

liquefied, cooled, and crystallization is observed.

The apparatus consists of a high-pressure view cell (autoclave)

and a compressor. Figure 2a is a diagram of the apparatus. An

air-operated compressor with back-pressure regulator was built

in-house for the compression of the gases. The autoclave design

is similar to that used by Leitner and co-workers

52

for reactions,

except using view-cell glass (KDH, GmbH, PN400.4462 B 02-

47) with a 400 bar pressure rating. Pressure was measured with

a pressure transducer (Wika, GmbH, ECO-1) with a maximum

pressure rating of 400 bar, with a nominal accuracy of 2 bar.

The temperature was maintained by a heating plate (Ika Werke,

GmbH, PN: RET Basic C) with electronic temperature control

(Ika Werke, GmbH, PN: IKATRON ETS-d4-fuzzy) using a

Pt-1000 RTD placed through the wall of the autoclave. The

precision is 0.1 C and was calibrated to an ice-bath and boiling

water adjusted for atmospheric pressure for a resultant accuracy

of approximately 0.2 C.

All samples were dried in vacuo (0.1 mbar) for ap-

proximately 48 h. Approximately 200 mg of the sample (most

were powders) were placed into a small sample vial capable of

fitting into the autoclave. The sample vial was placed in the

autoclave while under argon and sealed. The autoclave was

connected with the compressor and then purged with the desired

gas. For the CO

2

systems, the autoclave was then charged to

supercritical conditions (40-60 C and 150-200 bar) and

allowed to equilibrate for about 10 min. The system was then

dynamically extracted for about 5 min. This was to ensure

removal of any residual organic contaminants or water. The

system was depressurized and allowed to rest for approximately

10 min. After this purging process, the autoclave was pressurized

to the desired pressure and heated slowly. With the aid of a

background light, the solid sample was observed for any sign

of phase change while heating at a rate of roughly 2 C/min.

Once the first sign of melting occurred, the heating was stopped

and the autoclave depressurized to cool below this melting point.

The process was then repeated at a much slower heating rate

of approximately 0.05 C per minute; this was determined to

be sufficient to allow adequate time for thermal equilibrium

for the whole system. This was repeated for a total of three

times to ensure that the temperature of this solid-liquid-vapor

transition was reproducible to approximately 0.5 C (usually to

0.2 C). After each induced melting, the autoclave was turned

upright and shifted to spread the liquid over the bottom of the

sample vial containing the substance in the autoclave and then

depressurized to crystallize the material as a thin film. Upon

return of the autoclave to a horizontal position, the film of

material is now vertical and directly within the plane of the

light path, which allows easier detecting of the melting point.

As the material changes from a crystalline state to a liquid state,

the film evolved from an opaque solid to a clear liquid

accompanied by downward flow due to gravity. Many of the

studied materials are known to have solid-solid transitions,

amorphous, and liquid crystal phases. At times, some of these

materials became more transparent but did not flow within a

reasonable time-scale (10 min). Others began to flow before

becoming completely transparent. Only when transparency and

Figure 2. Experimental apparatus used in these experiments: (a) autoclave

for melting point depression data (SLV) [(1) heater/stirrer, (2) windowed

autoclave vessel, (3) valve, (T) RTD, (P) pressure transducer]; (b) solubility

at the melting point depression (SLE).

Ind. Eng. Chem. Res., Vol. 47, No. 3, 2008 495

flow are observed is the solid-liquid-vapor temperature taken

unless otherwise noted.

Solid-Liquid Equilibrium. In a separate experiment, the

solid-liquid equilibrium was determined at known compositions

of the liquid phase. A modest hydrostatic overpressure was used

to ensure our knowledge of liquid composition, but the

overpressures (tens of bars) are too small to have any measurable

effect on the melting point depression observed. All of these

measurements of CO

2

were carried out in a variable-volume

windowed vessel (1.59 cm i.d., 20 cm

3

maximum volume)

similar to that used by McHugh

53

which was used previously

to measure liquid-liquid equilibrium (LLE) systems.

54

A

schematic of this vessel is located in Figure 2b. The vessel

window and variable-volume piston were sealed with Buna-N

O-rings. Phase boundaries were measured by visually observing

the freezing point through a 2.54 cm diameter sapphire window

(1.27 cm viewable area) with a charge-couple device (CCD)

camera (Sony) mounted on a 0.635 cm borescope (Olympus).

The borescope and video camera not only allowed for safe

observation of the phase equilibria but also provided a significant

magnification of the viewable area. The binary mixtures were

stirred with a Teflon-coated stir bar coupled with an external

magnet. The entire cell was placed in a thermostated air bath

(modified Varian 3400 gas chromatograph) with temperature

control better than (0.5 K. Precise temperature control was not

required as freezing points were induced and observed while

cooling the vessel. The temperature was measured with a hand-

held readout (HH-22 Omega) and thermocouple (Omega type

K) inserted into the center of the phase equilibria vessel. The

thermocouple response time was on the order of seconds. The

combination of thermocouple and readout was accurate to (0.2

K and calibrated for each experiment against a platinum RTD

(Omega PRP-4) with a DP251 precision RTD bench-top

thermometer (DP251 Omega) accurate to (0.025 K and

traceable to NIST. Back-pressure was applied to the piston with

a syringe pump (ISCO 100D) operated at constant pressure. To

avoid any vapor phase, the pressure was held constant at 210

bar measured with a Druck DPI 260 gauge with a PDCR 910

transducer accurate to (0.1 bar.

To ensure that this method would be applicable to melting

point depression measurements, experimental data were taken

to compare with literature. Cheong et al.

34

measured the

temperature composition of naphthalene-CO

2

using what they

called the first freezing point method. This method involved

observing the initial appearance of solid, followed by sampling

from a high-pressure view cell. An equation of state, paired

with pressure, temperature, and volume data, provided the gas-

phase composition. Gravimetric measurement of the solid phase

after dissolution and drying gave the other compositions. Figure

3 shows the comparison of our data to the literature, where the

two methods show excellent correlation. Thus, our novel

freezing point method was validated, where the composition

could be determined without sampling.

First, a known mass of organic solid was loaded into a

variable-volume high-pressure view cell, and the pure solid

melting point was confirmed before adding any CO

2

. Then, the

cell with a known quantity of CO

2

from a syringe pump was

loaded and allowed to reach equilibrium with temperature and

pressure such that there was a single liquid phase. Next, the

mixture was cooled isobarically until the first crystal formed.

Generally, the entire contents froze quickly thereafter. The

composition of the single liquid phase is known since there are

only two components and one phase. The first crystal of pure

solid has a negligible impact on the overall composition, and

thus, the composition at the freezing point is known.

After one freezing point is measured, the system was reheated

back into one phase, and the process was repeated until two

consecutive data points were identical to ensure the system was

at equilibrium, which can take up to 24 h, depending on the

solid.

The high-pressure cell was also loaded under nitrogen

atmosphere, thus preventing air contamination of the solids.

After secondary purification, the ionic solids were tested for

water content. Samples were prepared by dissolving 1 g of solid

in 0.5 mL of methanol. Methyl alcohol, extra dry with molecular

sieves, <50 ppm water, was purchased from Acros Organics.

The water contents of both the methanol and the dissolved solids

were measured using a Karl Fisher titrator, model DL31 from

Mettler Toledo. Aquastar Combititrant 1 from EMD chemicals

was used for the titrant. Physical properties and modeling

parameters are listed in Table 1.

Results and Discussion

Initially, the melting point depression with CO

2

was measured

with common imidazolium and pyridinium cation classes. As

shown in Table 2, only moderate melting point depression data

were obtained for these compounds; the relative magnitude of

which is consistent with most organic compounds, e.g., naph-

thalene with CO

2

, etc. Interestingly, the long-alkyl chain

pyridinium compound, [HDPy][Cl], experiences a broader range

of melting point depression, consistent with solid-solid or

liquid-crystal transitions as observed by Kazarian et al.

31

Considerably larger and very pronounced melting point de-

pressions were observed for salts based on tetraalkyl ammonium

cations. Table 3 illustrates the profound influence of the anion

on the melting point depression with tetrabutylammonium

cations. [TBAm][BF

4

] has one of the largest melting point

depressions at 120 C of any organic compounds with CO

2

known to the authors. This is in contrast to the bromide, which

Figure 3. Temperature-composition (T-x) diagram for naphthalene-

CO2: experimental data compared to literature values (ref 34), ideal

solubility, and modeling.

Table 1. Physical and Model Properties of Select Ionic Solids

ionic solid

Tm

[C]

Hfus

[kJ/mol]

Ttrans

[C]

Htrans

[kJ/mol]

naphthalene

a

80.2 18.8

[TBAm][BF4]

b

160 10.5 68 2.5

[THexAm][Br]

b

100 15.9 32 2.5

a

Reference 34.

b

Reference 65.

496 Ind. Eng. Chem. Res., Vol. 47, No. 3, 2008

has only a moderate depression of roughly 20 C, and the

tosylate, with a depression of 34 C. The highly fluorinated

trifluorotris(perfluoroethyl)phosphate anion produces a tetrabu-

tylammonium compound with a normal melting point of 54 C

and T

m

of 37 C at only 35 bar of CO

2

pressure. Table 3 also

indicates that analogous phosphonium compounds (tetrabutyl

phosphonium vs ammonium bromides) seem to have larger

melting point depressions with CO

2

.

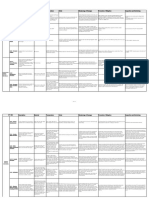

Table 2. Melting Point Depression of Imidazolium and Pyridinium Solids

a

Reference 32.

Table 3. Tetrabutyl Ammonium and Phosphonium Compounds

a

Refernce 32.

b

TSLV is beyond the upper temperature limitation of equipment (>100 C).

Table 4. Melting Point Depression of Quaternary Ammonium Bromide Compounds with CO2

a

Reference 32.

b

Possible solid-solid/liquid crystal transitions.

Ind. Eng. Chem. Res., Vol. 47, No. 3, 2008 497

For quaternary ammonium compounds, the cation may also

have a large effect on the SLV behavior. With a common

bromide anion, symmetric tetra-alkyl compounds (four equal

substituents) have rather similar normal melting points at

approximately 98 C (see Table 4), from tetrabutyl- to tetraoctyl-

ammonium bromide. However, the maximum T

m

occurs with

tetra-hexyl-ammonium bromide and CO

2

with a decrease of

71 C, while smaller and larger alkyl chains produce signifi-

cantly less-pronounced T

m

values at similar pressures. Replac-

ing one of the alkyl chains with a methyl group (methyl-trialky-

ammonium) seems to simultaneously decrease the normal

melting point and increase the degree of T

m

(see [MTOAm]-

[Br], [BDMDDAm][Br], and [MTOA][Br] in Table 4).

Table 5 illustrates various cations with fluorinated sulfonate

or bis(trifluorylmethysulfonyl)imide [Tf

2

N] anions. These cat-

ions include chiral ionic solids ([EP][Tfo], [AB][Tfo], [MTOA]-

[+MS], and [IHETMAm][Tf

2

N]) for potential use in chiral

reactions

55

and separations. Of special note is the relatively

simple ionic solid, tetraethylammonium [Tf

2

N]. This compound

has a normal melting point of 102 C but melts at 20 C with

only 35 bar of gaseous CO

2

. This T

m

at 82 C would probably

represent the largest melting point depression of all of the

compounds tested if cryogenic equipment were available to

permit measurement and comparison at 150 bar. This represents

an approximately 2.4 C depression per bar of CO

2

pressure.

Overall, several trends can be established to increase the

melting point depression with CO

2

and organic ionic solids.

Fluorinated anions universally increase the melting point

depression. This follows the observation of Kazarian et al.,

31

who found enhanced CO

2

interaction with fluorinated anions

by ATR-IR. Bis(trifyl)imide ([Tf

2

N]) anions always seem to

yield the highest melting point depressions, even considering

the usually lower normal melting points. Asymmetric am-

monium cations which have more nonequal substituents (e.g.,

methytributyl ammonium [TBMAm], trimethyl-hydroxyisobutyl

ammonium [AB][Tfo], etc.) tend to have lower melting points

with CO

2

pressure compared with equal substituents. Straight

chain alkyl groups tend to have lower T

m

values to a greater

extent than similar branched salts, e.g., [TBMAm][Tfo] vs

[TiBMAm][Tfo] in Table 5. For the more planar cations, i.e.,

imidazolium and pyridinium, the anion seems to have a much

greater effect than the cation.

SLV with Pressure and Temperature. The melting point

depression of several ionic solids was taken over larger pressure

ranges. Figure 4 and Table 6 illustrate the global phase behavior

of four ionic solids to 350 bar of CO

2

pressure. As seen from

Table 5. Various Cations with Sulfates or Bis(trifyl)imide Anions

a

Reference 32.

498 Ind. Eng. Chem. Res., Vol. 47, No. 3, 2008

the figure, the change in the SLV temperature of the ionic solids

with pressure is extremely large and negative in the lower

pressure range, i.e., P < 150 bar. [TBAm][BF

4

] shows the most

dramatic decrease, while [TOAm][Br] shows much more

moderate depression. At higher pressures, the increase in melting

point depression is minimal with added pressure. The melting

point depression of [TBAm][BF

4

] was also measured with

ethylene and found to be large compared with most nonionic

organics (naphthalene

35

and octacosane

34

with CO

2

), but still

much lower than the same salt with CO

2

. This difference is

almost surely due to variations in the solution behavior. The

phase behavior of CO

2

and the long-chain wax, octacosane (C

28

),

from the work of Cheong et al.

34

and the polyaromatic,

naphthalene, from the work of McHugh and Yogan

35

are shown

for comparison. Initially, both of the solids undergo moderate

melting point depression but not nearly to the same magnitude

as the ionic solids. Octacosane and naphthalene both have a

minimum in T

SLV

with pressure between 100 and 150 bar. After

this minimum, the trend reverses and the melting point increases

rather than decreases. At approximately 650 bar in the octa-

cosane/CO

2

system,

34

the T

SLV

equals T

m

, i.e., no melting point

depression, followed by a melting point elevation at higher

pressures. For the ionic solids, the largest rate in depression

occurs between 0 and 150 bar. After which, the depression

seems to level off approaching some asymptotic value. Whether

these ionic solids experience a minimum in T

SLV

similar to

octacosane and naphthalene is uncertain. This study was limited

to 400 bar.

Modeling Discussion Solid-Liquid Equilibrium. A number

of differences in the results can be shown to be a function of

solution nonideality. For example, the melting point depressions

observed for [TBAm][BF

4

] with ethylene were far less than

those for the same salt with CO

2

. Moreover, the melting point

depression for naphthalene in CO

2

is substantially less profound

than that of the ionic liquids in CO

2

. The reason is almost surely

due to specific interactions. Naphthalene interacts with CO

2

almost entirely by dispersion (van der Waals) forces, as does

ethylene with the ionic liquid. Such interactions always give

positive deviations from Raoults law ( > 1), and this term

would become important in eq 1. Conversely, CO

2

would

interact with the ionic liquids in a different way, with strong

unlike pair specific attractions due to the chemistry of CO

2

,

probably due to weak Lewis acid-Lewis base interactions of

the acidic carbon in CO

2

with basic moieties of the saltsand

similar interactions have been observed often in other situa-

tions.

56-58

These would give negative deviations from Raoults

law ( < 1), and this term would also become important

in eq 1.

As previously mentioned, Figure 3 shows a comparison of

literature results to model predictions for the composition versus

Figure 4. Experimental and modeling of the SLV of several ionic solids

and naphthalene (ref 35) and octacosane (ref 34) [smoothed data].

Table 6. SLV Equilibrium for Several Ionic Solids

[TBAm][BF4]/CO2 [TBAm][BF4]/Ethylene

TSLV [C] PSLV [bar] T [C] TSLV [C] PSLV [bar] T [C]

27.2 335 128.8 73 250 83

30.0 250 126 81.1 200 74.9

33.4 200 122.6 89.8 150 66.2

36.1 150 119.9 109 100 47

40.5 100 115.5 156.0 1 0

87.3 85 68.7

100.0 78 56

156.0 1 0

[TOAm][Br]/CO2 [TBMPhos][Tfo]/CO2

TSLV [C] PSLV [bar] T [C] TSLV [C] PSLV [bar] T [C]

59.4 350.0 38.1 33.1 350.0 85.9

60.3 300.0 37.2 35.0 300.0 84.0

61.3 250.0 36.2 36.7 250.0 82.3

61.6 200.0 35.9 38.8 200.0 80.2

61.8 150.0 35.7 40.4 150.0 78.6

64.3 125.0 33.2 44.3 125.0 74.7

66.8 100.0 30.7 52.5 100.0 66.5

71.7 86.0 25.8 68.0 90.0 51.0

75.5 75.0 22.0 77.5 80.0 41.5

97.5 1.0 0.0 119.0 1.0 0.0

Table 7. T-P-Composition Data of Melting Point Depression with

CO2

system

with CO2

T

[C]

P

[bar] xCO2

system

with CO2

T

[C]

P

[bar] xCO2

naphthalene -56.6 1 1 [TBAm][BF4] -56.6 1 1

55.5 172.4 0.838 28.1 102.9 0.539

59.0 181.3 0.556 45.6 239.3 0.504

59.4 222.6 0.549 59.5 232.7 0.458

59.7 241.3 0.536 73.9 102.9 0.393

60.0 195.2 0.498 120.1 198.4 0.244

60.1 77.6 0.438 140.1 116.9 0.145

60.8 215.8 0.528 144.1 168 0.097

61.6 195.1 0.448 160 1 0

63.2 137.9 0.365 [THexAm][Br] -56.6 1 1

63.7 174.6 0.371 34.7 231.8 0.569

66.1 139.9 0.311 50.4 177.5 0.412

67.2 105.0 0.262 64.8 136.8 0.286

68.5 105.1 0.239 79.2 202.9 0.171

69.5 153.8 0.239 100 1 0

69.7 105.1 0.239

70.8 105.1 0.203

73.3 84.3 0.143

73.5 105.3 0.154

74.3 77.1 0.098

76.1 77.2 0.062

77.1 181.3 0.096

80.3 1 0

Figure 5. T-x diagram for tetrabutyl ammonium tetrafluoroborate-CO2

with ideal solubility prediction.

Ind. Eng. Chem. Res., Vol. 47, No. 3, 2008 499

melting temperature and pressure for the naphthelene-CO

2

system. The pressure, temperature, and composition data are

listed in Table 7. Also included on this figure are the ideal

solution prediction and the MOSCED (modified separation of

cohesive energy density) prediction.

59,60

It is clear that the ideal

prediction (eq 1, with

2

set at unity) for this system is a poor

predictor for this system due to the large positive deviation from

ideality, as one would expect for CO

2

-naphthalene interactions.

The MOSCED model (eq 2), which has been recently shown

to work well at predicting solid solubility,

59,61

fits four

parameters (hydrogen bond acidity and bascity, polarizability,

and dipolarity) to experimental data to calculate infinite dilution

activity coefficients.

The calculated activity coefficients were used in the Wilson

equation

48

to predict the solubility line shown in Figure 3.

Several different modeling techniques have been used to

predict the interaction between CO

2

and ionic liquids, including

the tPC-SAFT equation of state,

62

the irregular ionic lattice

model,

63

and molecular dynamic simulations.

64

However, as with

most thermodynamic models, some experimental solubility data

are needed for parameter tuning. For the tPC-SAFT model,

vapor pressure data is needed; for the irregular ionic lattice

model, solubility data is needed. MOSCED model parameters

have been successfully regressed for a few ionic liquids in

various solvents.

59

However, there is currently insufficient data

for any of the ionic solids studied here to allow MOSCED

prediction with CO

2

. Future work in the area of thermodynamic

modeling of ionic liquids will require an extensive solubility

study over a wide range of ionic liquid solutes. Although no

modeling is reported for our CO

2

-IL data, the results were

compared to the ideal solubility.

CO

2

Solubility at the Melting Point. The results for [TBAm]-

[BF

4

] are shown in Figure 5 and listed in Table 7. The ideal

solubility, shown for reference, is calculated from eq 1 with

each of the respective activity coefficients set equal to 1. The

low-temperature region is enlarged to show the simple eutectic

behavior expected in a melting point depression T-x diagram.

The results show a melting point depression of 130 C at a mole

fraction near 0.5. The results seem to agree with the work of

Scurto and Leitner

32

and elucidate the effect the CO

2

has on

[TBAm][BF

4

]. Figure 6 (Table 7) demonstrates the results for

[THexAm][Br] which are very similar to that of [TBAm][BF

4

].

The ideal solubility is again included and it is clear that for

both ionic liquids, the T-x curve falls well below the ideal

solubility. This is in stark contrast to the naphthalene/CO

2

data,

where there are strong positive deviations from Raoults law.

Conclusions

Here, the melting point depression of a large variety of ionic

solids was measured. Some compounds represent some of the

largest melting point depressions known in the literature. As

shown from ideal modeling, negative deviations to Raoults law

exist, indicating specific interactions of the CO

2

with the ionic

solid. Understanding and controlling this induced melting will

allow a much greater number of ionic liquids to be utilized in

these biphasic processes. This is especially important when

designing task-specific ionic liquids.

Acknowledgment

We would like to thank the National Science Foundation

(USA) for a postdoctoral fellowship (NSF-IRFP for A.M.S.).

The Georgia Tech group also acknowledges support from the

donors of the J. Erskine Love, Jr., Institute Chair. W.L. thanks

the BMBF (Grant Numbers 03X2008D and 03X2012A) as well

as the Fonds der Chemischen Industrie for financial support.

Solvent Innovation (Cologne, Germany) and Peter Wassersc-

heidt (University of Erlangen) are thanked for generous donation

of samples.

Literature Cited

(1) Murugesan, S.; Linhardt, R. J. Ionic liquids in carbohydrate chemistry

- Current trends and future directions. Curr. Org. Synth. 2005, 2 (4), 437.

(2) Olivier-Bourbigou, H.; Magna, L. Ionic liquids: perspectives for

organic and catalytic reactions. J. Mol. Catal. A 2002, 419, 182-183.

(3) Welton, T. Room-Temperature Ionic Liquids. Solvents for Synthesis

and Catalysis. Chem. ReV. 1999, 99 (8), 2071.

(4) Barisci, J. N.; Wallace, G. G.; MacFarlane, D. R.; Baughman, R. H.

Investigation of ionic liquids as electrolytes for carbon nanotube electrodes.

Electrochem. Commun. 2004, 6 (1), 22.

(5) Lu, W.; Fadeev, A. G.; Qi, B. H.; Mattes, B. R. Fabricating

conducting polymer electrochromic devices using ionic liquids. J. Electro-

chem. Soc. 2004, 151 (2), H33.

(6) Bernot, R.; Brueseke, M.; Evans-White, M.; Lamberti, G. Acute and

chronic toxicity of imidazolium-based ionic liquids on Daphnia magna.

EnViron. Toxicol. Chem. 2005, 24 (1), 87.

(7) Gathergood, N.; Garcia, M.; Scammells, P. Biodegradable ionic

liquids: Part I. Concept, preliminary targets and evaluation. Green Chem.

2004, 6 (2), 166.

(8) Jastorff, B.; Stormann, R.; Ranke, J.; Molter, K.; Stock, F.;

Oberheitmann, B.; Hoffmann, W.; Hoffmann, J.; Nuchter, M.; Ondruschka,

B.; Filser, J. How hazardous are ionic liquids? Structure-activity relationships

and biological testing as important elements for sustainability evaluation.

Green Chem. 2003, 5 (2), 136.

(9) Blanchard, L. A.; Hancu, D.; Beckman, E. J.; Brennecke, J. F. Green

processing using ionic liquids and CO

2. Nature 1999, 399 (6731), 28.

(10) Bosmann, A.; Francio`, G.; Janssen, E.; Solinas, M.; Leitner, W.;

Wasserscheid, P. Activation, tuning, and immobilization of homogeneous

catalysts in an tonic liquid/compressed CO2 continuous-flow system. Angew.

Chem., Int. Ed. 2001, 40 (14), 2697.

(11) Lozano, P.; de Diego, T.; Carrie, D.; Vaultier, M.; Iborra, J. L.

Continuous green biocatalytic processes using ionic liquids and supercritical

carbon dioxide. Chem. Commun. 2002, (7), 692.

(12) Jessop, P. G.; Leitner, W. Chemical Synthesis Using Supercritical

Fluids; Wiley-VCH: Weinheim, 1999.

(13) Scurto, A. M.; Aki, S. N. V. K.; Brennecke, J. F. CO

2 as a

Separation Switch for Ionic Liquid/Organic Mixtures. J. Am. Chem. Soc.

2002, 124, 10276.

(14) Scurto, A. M.; Aki, S. N. V. K.; Brennecke, J. F. Carbon Dioxide

induced separation of ionic liquids and water. Chem. Commun. 2003, 572.

Figure 6. T-x diagram for tetrahexyl ammonium bromide-CO2 with ideal

solubility prediction.

ln

2

)

V

2

RT

[

(

1

-

2

)

2

+

q

1

2

q

2

2

(

1

-

2

)

2

1

+

(R

1

- R

2

)(

1

-

2

)

1

]

+ ln

(

V

2

V

1

)

aa

+ 1 -

(

V

2

V

1

)

aa

(2)

500 Ind. Eng. Chem. Res., Vol. 47, No. 3, 2008

(15) Brown, R. A.; Pollet, P.; McKoon, E.; Eckert, C. A.; Liotta, C. L.;

Jessop, P. G. Asymmetric Hydrogenation and Catalyst Recycling Using

Ionic Liquid and Supercritical Carbon Dioxide. J. Am. Chem. Soc. 2001,

123 (6), 1254.

(16) Ballivet-Tkatchenko, D.; Picquet, M.; Solinas, M.; Francio`, G.;

Wasserscheid, P.; Leitner, W. Acrylate dimerisation under ionic liquid-

supercritical carbon dioxide conditions. Green Chem. 2003, 5 (2), 232.

(17) Solinas, M.; Pfaltz, A.; Cozzi, P.; Leitner, W. Enantioselective

hydrogenation of imines in ionic liquid/carbon dioxide media. J. Am. Chem.

Soc. 2004, 126 (49), 16142.

(18) Sellin, M. F.; Bach, I.; Webster, J. M.; Montilla, F.; Rosa, V.;

Aviles, T.; Poliakoff, M.; Cole-Hamilton, D. J. Hydroformylation of alkenes

in supercritical carbon dioxide catalysed by rhodium trialkylphosphine

complexes. J. Chem. Soc., Dalton Trans. 2002, (24), 4569.

(19) Sellin, M. F.; Webb, P. B.; Cole-Hamilton, D. J. Continuous flow

homogeneous catalysis: hydroformylation of alkenes in supercritical fluid-

ionic liquid biphasic mixtures. Chem. Commun. 2001, (8), 781.

(20) Lozano, P.; De Diego, T.; Carrie, D.; Vaultier, M.; Iborra, J. L.

Lipase catalysis in ionic liquids and supercritical carbon dioxide at 150

degree C. Biotech. Prog. 2003, 19 (2), 380.

(21) Reetz, M. T.; Wiesenhofer, W.; Francio`, G.; Leitner, W. Continuous

Flow Enzymatic Kinetic Resolution and Enantiomer Separation using Ionic

Liquid/Supercritical Carbon Dioxide Media. AdV. Synth. Catal. 2003, 345,

1221.

(22) Leitner, W.; Scurto, A. M., Immobilization of Organometallic

Catalysis Using Supercritical Fluids. In Aqueous-Phase Organometallic

CatalysissConcepts and Applications; Cornils, B., Herrmann, W. A., Eds.;

Wiley-VCH: Weinheim, 2004.

(23) Ahosseini, A.; Ren, W.; Scurto, A. M. Homogeneous Catalysis in

Biphasic Ionic Liquids/CO

2 Systems. Chem. Today 2007, 25 (2), 40.

(24) Wasserscheid, P.; Keim, W. Ionic liquids - new solutions for

transition metal catalysis. Angew. Chem., Int. Ed. 2000, 39 (21), 3772.

(25) Holbrey, J. D.; Seddon, K. R. Ionic Liquids. Clean Prod. Process.

1999, 1 (4), 223.

(26) Visser, A. E.; Swatloski, R. P.; Reichert, W. M.; Mayton, R.; Sheff,

S.; Wierzbicki, A.; Davis, J. H.; Rogers, R. D. Task-specific ionic liquids

for the extraction of metal ions from aqueous solutions. Chem. Commun.

2001, (01), 135.

(27) Bao, W. L.; Wang, Z. M.; Li, Y. X. Synthesis of chiral ionic liquids

from natural amino acids. J. Org. Chem. 2003, 68 (2), 591.

(28) Wasserscheid, P.; Bosmann, A.; Bolm, C. Synthesis and properties

of ionic liquids derived from the chiral pool. Chem. Commun. 2002, (3),

200.

(29) Cole, A. C.; Jensen, J. L.; Ntai, I.; Tran, K. L. T.; Weaver, K. J.;

Forbes, D. C.; Davis, J. H. Novel bronsted acidic ionic liquids and their

use as dual solvent-catalysts. J. Am. Chem. Soc. 2002, 124 (21), 5962.

(30) Prins, A. Verslag Akad. Wetenschappen Amsterdam 1915, 17, 1095.

(31) Kazarian, S. G.; Sakellarios, N.; Gordon, C. M. High-pressure CO

2-

induced reduction of the melting temperature of ionic liquids. Chem.

Commun. 2002, (12), 1314.

(32) Scurto, A. M.; Leitner, W. Expanding the useful range of ionic

liquids: melting point depression of organic salts with carbon dioxide for

biphasic catalytic reactions. Chem. Commun. 2006, 3681.

(33) van Welie, G. S. A.; Diepen, G. A. M. The solubility of naphthalene

in supercritical ethane. J. Phys. Chem. 1963, 67, 755.

(34) Cheong, P. L.; Zhang, D.; Ohgaki, K.; Lu, B. C.-Y. High Pressure

Phase Equilibrium for Binary Systems Involving a Solid Phase. Fluid Phase

Equilib. 1986, 29, 555.

(35) McHugh, M. A.; Yogan, T. J. Three-phase solid-liquid-gas

equilibria for three carbon dioxide-hydrocarbon solid systems, two ethane-

hydrocarbon solid systems, and two ethylene-hydrocarbon solid systems.

J. Chem. Eng. Data 1984, 29 (2), 112.

(36) Wilken, M.; Fischer, K.; Gmehling, J., Transitiometry: PVT-

modulated calorimetry for simultaneous determination of thermal and

mechanical properties of materials. Chem. Ing. Tech. 2001, 73 (10), 1300.

(37) Van Hest, J. A. M.; Diepen, G. A. M. Symp. Soc. Chem. Ind. London

1963, 10.

(38) Diepen, G. A. M.; Scheffer, F. E. C. Critical phenomena of saturated

solutions in binary systems. J. Am. Chem. Soc. 1948, 70, 4081.

(39) Krukonis, V. J.; McHugh, M. A.; Seckner, A. J. Xenon as a

supercritical solvent. J. Phys. Chem. 1984, 88 (13), 2687.

(40) Wendlandt, R. F.; Mysen, B. O. Melting phase relations of natural

peridotite + carbon dioxide as a function of degree of partial melting at 15

and 30 kbar. Am. Mineralol. 1980, 65 (1-2), 37.

(41) Wang, W.-C. V.; Kramer, E. J.; Sachse, W. H. Effects of high-

pressure CO

2 on the glass transition temperature and mechanical properties

of polystyrene. J. Polym. Sci. B 1982, 20 (8), 1371.

(42) Zhang, Z.; Handa, Y. P. CO2-assisted melting of semicrystalline

polymers. Macromolecules 1997, 30 (26), 8505.

(43) Kishimoto, Y.; Ishii, R. Differential scanning calorimetry of isotactic

polypropene at high CO2 pressures. Polymer 2000, 41 (9), 3483.

(44) Weidner, E.; Wiesmet, V.; Knez, Z .; Skerget, M., Phase equilibrium

(solid-liquid-gas) in polyethyleneglycol-carbon dioixide systems. J. Super-

crit. Fluids 1997, 10, 139.

(45) Niehaus, D.; Philips, M.; Michael, A.; Wightman, R. M. Voltam-

metry of Ferrocene in Supercritical CO

2 Containing Water and Tetrahexy-

lammonium Hexafluorophosphate. J. Phys. Chem. 1989, 93 (16), 6232.

(46) Niehaus, D. E.; Wightman, R. M.; Flowers, P. A. Ionically Modified

Electrodes for Use in Nonpolar Fluids. Anal. Chem. 1991, 63 (17), 1728.

(47) Philips, M. E.; Deakin, M. R.; Novotny, M. V.; Wightman, R. M.

Effect of Added Water on Voltammetry in near-Critical Carbon-Dioxide.

J. Phys. Chem. 1987, 91 (15), 3934.

(48) Prausnitz, J. M.; Lichtenthaler, R. N.; Gomes de Azevedo, E.

Molecular Thermodynamics of Fluid-Phase Equilibria, 3rd ed.; Prentice

Hall: Upper Saddle River, NJ, 1999.

(49) Alger, M. M.; Eckert, C. A. Chemical Theory for the Thermody-

namics of Liquid Metal Solutions. High Temp. Sci. 1985, 19, 253.

(50) Stoicos, T.; Eckert, C. A. Nonideal Behavior in Liquid Metal

Solutions. 1. Physical Theory Model. Ind. Eng. Chem. Fundam. 1985, 24,

140.

(51) Stoicos, T.; Eckert, C. A. Nonideal Behavior in Liquid Metal

Solutions. 2. Chemical-Physical Theory Model. Ind. Eng. Chem. Fundam.

1985, 24, 147.

(52) Koch, D.; Leitner, W. Rhodium-Catalyzed Hydroformylation in

Supercritical Carbon Dioxide. J. Am. Chem. Soc. 1998, 120 (51), 13398.

(53) Kirby, C. F.; McHugh, M. A. Phase Behavior of Polymers in

Supercritical Fluids Solvents. Chem. ReV. 1999, 99, 565.

(54) Brown, J. S.; Hallett, J. P.; Bush, D.; A., E. C. Liquid-Liquid

Equilibria for Binary Mixtures of Water + Acetophenone, + 1-octanol, +

Anisole, and + Toluene from 370 K to 550 K. J. Chem. Eng. Data 2000,

45, 846.

(55) Gausepohl, R.; Buskens, P.; Kleinen, J.; Bruckmann, A.; Lehmann,

C. W.; Klankermayer, J.; Leitner, W. Highly enantioselective Aza-Baylis-

Hillman reaction in a chiral reaction medium. Angew. Chem., Int. Ed. 2006,

45 (22), 3689.

(56) Kazarian, S. G.; Brantley, N. H.; Eckert, C. A. Applications of

Vibrational Spectroscopy to Characterize Poly(ethylene terephthalate)

Processed with Supercritical CO

2. Vibrat. Spectrosc. 1999, 19, 277.

(57) Kazarian, S. G.; Vincent, M. F.; Bright, F. V.; Liotta, C. L.; Eckert,

C. A. Specific Intermolecular Interaction of Carbon Dioxide with Polymers.

J. Am. Chem. Soc. 1996, 118, 1729.

(58) Meridith, J. C.; Johnston, K. P.; Seminario, J. M.; Kazarian, S. G.;

Eckert, C. A. Quantitative Equilibrium Constants Between CO

2 and Lewis

Bases from FTIR Spectroscopy. J. Phys. Chem. 1996, 100, 10837.

(59) Lazzaroni, M. J.; Bush, D.; Eckert, C. A.; Frank, T. C.; Gupta, S.;

Olson, J. D. Revision of MOSCED Parameters and Extension to Solid

Solubility Calculations. Ind. Eng. Chem. Res. 2005, 44, 4075.

(60) Thomas, E. R.; Eckert, C. A. Prediction of Limiting Activity

Coefficients by a Modified Separation of Cohesive Energy Density Model

and UNIFAC. Ind. Eng. Chem. Des. DeV. 1984, 23, 194.

(61) Draucker, L. C.; Janakat, M.; Lazzaroni, M. J.; Bush, D.; Eckert,

C. A.; Frank, T. C.; Olson, J. D. Experimental Determination and Model

Prediction of Solid Solubility of Multifunctional Compounds in Pure and

Mixed Nonelectrolyte Solvents. Ind. Eng. Chem. Res. 2007, 46, 2198.

(62) Kroon, M. C.; Karakatsani, E. K.; Economou, I. G.; Witkamp, G.-

J.; Peters, C. J. Modeling of the Carbon Dioxide Solubility in Imidazolium-

Based Ionic Liquids with the tPC-SAFT Equation of State. J. Phys. Chem.

B 2006, 110, 9262.

(63) Ally, M. R.; Braunstein, J.; Baltus, R. E.; Dai, S.; DePaoli, D. W.;

Simonson, J. M. Irregular Ionic Lattice Model for Gas Solubilities in Ionic

Liquids. Ind. Eng. Chem. Res. 2004, 43, 1296.

(64) Cadena, C.; Anthony, J. L.; Shah, J. K.; Morrow, T. I.; Brennecke,

J. F.; Maginn, E. J. Why is CO

2 So Soluble in Imidazolium-Based Ionic

Liquids? J. Am. Chem. Soc. 2004, 126, 5300.

(65) Coker, T. G.; Ambrose, J.; Janz, G. J. Fusion Properties of Some

Ionic Quaternary Ammonium Compounds. J. Am. Chem. Soc. 1970, 92,

5293.

ReceiVed for reView March 1, 2007

ReVised manuscript receiVed May 18, 2007

Accepted May 24, 2007

IE070312B

Ind. Eng. Chem. Res., Vol. 47, No. 3, 2008 501

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- What Are AlkaloidsDocument29 pagesWhat Are AlkaloidsmhadhiehNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Anti-Dandruff Shampoo With Zinc Pyrithione: INCI Name, Trade Name Weight % FunctionDocument2 pagesAnti-Dandruff Shampoo With Zinc Pyrithione: INCI Name, Trade Name Weight % FunctionandreeaNo ratings yet

- Methanol CarbonylationDocument10 pagesMethanol CarbonylationhazimraadNo ratings yet

- 571 SummaryDocument3 pages571 SummarySimbu Arasan100% (1)

- A101 Design Calculation For Foundation of New VCM Storage TankDocument25 pagesA101 Design Calculation For Foundation of New VCM Storage TankzatenneNo ratings yet

- Science 7 ExamDocument5 pagesScience 7 Examangge21No ratings yet

- 16 PTIRecommendationsforStayCableDesignTestingandInstallationDocument23 pages16 PTIRecommendationsforStayCableDesignTestingandInstallationBeratErtekin100% (1)

- Ceramic Engineering: From Wikipedia, The Free EncyclopediaDocument6 pagesCeramic Engineering: From Wikipedia, The Free EncyclopediaFaiz AbdullahNo ratings yet

- Chemical Bonding ModuleDocument35 pagesChemical Bonding ModuleMark Paul Lipata Benitez100% (2)

- Compozitia Smaltului Si DemineralizareaDocument10 pagesCompozitia Smaltului Si DemineralizareaMadalina Elena TapeleaNo ratings yet

- POSS Review PDFDocument32 pagesPOSS Review PDFcansuNo ratings yet

- Self-Assembled Fernlike Microstructures of Polyhedral Oligomeric Silsesquioxane/Gold Nanoparticle HybridsDocument8 pagesSelf-Assembled Fernlike Microstructures of Polyhedral Oligomeric Silsesquioxane/Gold Nanoparticle HybridscansuNo ratings yet

- XRD Poss PDFDocument5 pagesXRD Poss PDFcansuNo ratings yet

- Carbohydrate Polymers: Kongliang Xie, Yanli Zhang, Yanhong YuDocument5 pagesCarbohydrate Polymers: Kongliang Xie, Yanli Zhang, Yanhong YucansuNo ratings yet

- Bifunctionalized Hybrid Silica Spheres by Hydrolytic Cocondensation of 3-Aminopropyltriethoxysilane and VinyltriethoxysilaneDocument6 pagesBifunctionalized Hybrid Silica Spheres by Hydrolytic Cocondensation of 3-Aminopropyltriethoxysilane and VinyltriethoxysilanecansuNo ratings yet

- The Effect of Hybrid Nanoparticle Additives On Epoxy-Nanocomposite Behavior and MorphologyDocument5 pagesThe Effect of Hybrid Nanoparticle Additives On Epoxy-Nanocomposite Behavior and MorphologycansuNo ratings yet

- 16 Deisik PDFDocument9 pages16 Deisik PDFcansuNo ratings yet

- Preparation and Characterization of Poss-Sio / Cyanate Ester Composites With High PerformanceDocument9 pagesPreparation and Characterization of Poss-Sio / Cyanate Ester Composites With High PerformancecansuNo ratings yet

- Hydrogen Bond Assisted Assembly of Well-Ordered Polyhedral Oligomeric Silsesquioxane Block Copolymer CompositesDocument7 pagesHydrogen Bond Assisted Assembly of Well-Ordered Polyhedral Oligomeric Silsesquioxane Block Copolymer CompositescansuNo ratings yet

- Low-K Periodic Mesoporous Organosilica With Air Walls: POSS-PMODocument4 pagesLow-K Periodic Mesoporous Organosilica With Air Walls: POSS-PMOcansuNo ratings yet

- 11 Guzel PDFDocument9 pages11 Guzel PDFcansuNo ratings yet

- Microporous and Mesoporous Materials: Wei Shan, Lei Chen, Yang Chu, Feipeng Zhao, Guozheng Liang, Aijuan Gu, Li YuanDocument10 pagesMicroporous and Mesoporous Materials: Wei Shan, Lei Chen, Yang Chu, Feipeng Zhao, Guozheng Liang, Aijuan Gu, Li YuancansuNo ratings yet

- Phosphorus, Sulfur, and Silicon and The Related Elements: Click For UpdatesDocument10 pagesPhosphorus, Sulfur, and Silicon and The Related Elements: Click For UpdatescansuNo ratings yet

- XRD PossDocument8 pagesXRD PosscansuNo ratings yet

- Unsteady Isothermal C STRDocument3 pagesUnsteady Isothermal C STRcansuNo ratings yet

- 0901 B 803808 e 4479Document7 pages0901 B 803808 e 4479SiddharthapachisiaNo ratings yet

- 19 Heat of Combustion MGDocument5 pages19 Heat of Combustion MGmanuelscribdgonzalesNo ratings yet

- To Run QC On Absolute Positions: Figure 9-49. Example For Template With Absolute SettingsDocument100 pagesTo Run QC On Absolute Positions: Figure 9-49. Example For Template With Absolute SettingsMaicol EligioNo ratings yet

- Dental Materials Reviewer Pt. 10Document5 pagesDental Materials Reviewer Pt. 10Ryo MiyataNo ratings yet

- Periodic Table Sig Fig B WDocument1 pagePeriodic Table Sig Fig B WRicardo VelozNo ratings yet

- Pgcca 2012 Winner Buckman InternationalDocument11 pagesPgcca 2012 Winner Buckman InternationalAnanyo BhattacharyyaNo ratings yet

- Iit Model Paper PDFDocument14 pagesIit Model Paper PDFstudysteps.in100% (2)

- Asahi KaseiDocument24 pagesAsahi KaseiRitam GhoshNo ratings yet

- Adsorption From Solutions, Acetic Acid On Charcoal: Lorenz John T. ChuDocument7 pagesAdsorption From Solutions, Acetic Acid On Charcoal: Lorenz John T. ChuZhu Chen ChuanNo ratings yet

- BTech (Mechanical With Specialization in Energy Engineering) Curriculum For AY2012-13Document8 pagesBTech (Mechanical With Specialization in Energy Engineering) Curriculum For AY2012-13Akshat GargNo ratings yet

- Source Machinery: REF: SOU/GEN/11-12/21 DATE: 12 December, 2011Document8 pagesSource Machinery: REF: SOU/GEN/11-12/21 DATE: 12 December, 2011Ravi k LavuNo ratings yet

- KLEN 2207 Cream CleanerDocument3 pagesKLEN 2207 Cream CleanerSneha Nagaokar100% (1)

- Pearson's Classification of Lewis Acids and Lewis Bases Into Hard and Soft - Acids and BasesDocument5 pagesPearson's Classification of Lewis Acids and Lewis Bases Into Hard and Soft - Acids and BasesThantea ChhakchhuakNo ratings yet

- Removal of Gaseous Chlorine From Cylinders and Ton ContainersDocument4 pagesRemoval of Gaseous Chlorine From Cylinders and Ton Containersmailmaverick8167No ratings yet

- Voe Main2Document4 pagesVoe Main2prevrtljivacNo ratings yet

- CO2 Cueva BulakDocument7 pagesCO2 Cueva BulakCristian RiveraNo ratings yet

- Melamine ProductionDocument49 pagesMelamine ProductionImtiaz HussainNo ratings yet

- 1980 - Roos - Chem Phys - A Complete Active Space SCF Method (CASSCF) Using A Density Matrix Formulated Super-CI ApproachDocument17 pages1980 - Roos - Chem Phys - A Complete Active Space SCF Method (CASSCF) Using A Density Matrix Formulated Super-CI Approachvitoribeiro90No ratings yet

- Ray OpticsDocument52 pagesRay OpticsJack LupinoNo ratings yet

- Improved Procedures For The Genetic Transformation of Rhodobacter CapsulatusDocument1 pageImproved Procedures For The Genetic Transformation of Rhodobacter CapsulatusSerena XuNo ratings yet