Professional Documents

Culture Documents

Quality Assurance in Microbiology Labs

Uploaded by

giuseppegnr0 ratings0% found this document useful (0 votes)

36 views6 pagesThis document discusses quality assurance in microbiology laboratories. It outlines that quality assurance is a planned system to ensure analytical data produced is valid. It involves documenting and controlling all laboratory activities that affect data production, including sampling, methodology, environment, equipment, reagents, staff, reference materials, and internal/external quality control. Laboratory accreditation enables demonstrating ability to perform analytical work and produce valid data, giving credibility. The document then discusses specific quality assurance considerations for sampling, methodology, environment, equipment, reagents, staff, and reference materials in microbiology laboratories.

Original Description:

Original Title

s 007690050028

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses quality assurance in microbiology laboratories. It outlines that quality assurance is a planned system to ensure analytical data produced is valid. It involves documenting and controlling all laboratory activities that affect data production, including sampling, methodology, environment, equipment, reagents, staff, reference materials, and internal/external quality control. Laboratory accreditation enables demonstrating ability to perform analytical work and produce valid data, giving credibility. The document then discusses specific quality assurance considerations for sampling, methodology, environment, equipment, reagents, staff, and reference materials in microbiology laboratories.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

36 views6 pagesQuality Assurance in Microbiology Labs

Uploaded by

giuseppegnrThis document discusses quality assurance in microbiology laboratories. It outlines that quality assurance is a planned system to ensure analytical data produced is valid. It involves documenting and controlling all laboratory activities that affect data production, including sampling, methodology, environment, equipment, reagents, staff, reference materials, and internal/external quality control. Laboratory accreditation enables demonstrating ability to perform analytical work and produce valid data, giving credibility. The document then discusses specific quality assurance considerations for sampling, methodology, environment, equipment, reagents, staff, and reference materials in microbiology laboratories.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

Accred Qual Assur (1996) 1: 1823

Q Springer-Verlag 1996 GENERAL PAPER

Dermot Hayes Quality assurance in the microbiology

laboratory

Abstract The pertinent issues nec-

essary for the establishment of

quality assurance in the microbio-

logy laboratory are discussed.

Quality assurance is a planned sys-

tem of control measures that ena-

bles management to ensure that

the analytical data produced in the

laboratory are valid. To introduce

quality assurance, all activities in

the laboratory that affect the pro-

duction of analytical data must be

documented and controlled. These

include sampling, method selection,

laboratory environment, equip-

ment, reagents and media, staff,

reference materials and internal

and external quality control. Labo-

ratory accrediation in accordance

with EN45001 and ISO Guide 25

enables laboratories demonstrate

to an external agency their ability

to perform analytical work and

produce valid analytical data. This

gives creditability to the laboratory

and allows management to have

confidence in the data produced.

Key words Microbiology

laboratory 7 Sampling 7

Micro-organisms 7 Reference

materials 7 Quality control

external 7 Quality control internal 7

Accreditation

Received: 6 June 1995

Accepted: 3 July 1995

Dermot Hayes (Y)

State Laboratory,

Abbotstown, Dublin 15, Ireland

Introduction

Quality assurance has been defined as the total inte-

grated management programme for assuring the relia-

bility of data [1]. In the microbiology laboratory its ad-

option has been slower than in other disciplines. Many

microbiologists consider it an unnecessary time-con-

suming bureaucratic process that is not applicable to

microbiological analysis. They consider that the com-

plexity inherently associated with living organisms

makes the process of quality assurance wasteful in time

and money. On the contrary, however, a laboratory

quality assurance scheme can save time and money by;

(I) reducing the need for costly repeat analysis,

(II) providing quality data with documented fail-safe

practices that ensure the acceptability of the results,

(III) training the staff to avoid costly mistakes by forc-

ing the adoption of written procedures, (IV) identify-

ing the staff requirements and training necessary to

provide an efficient quality service, (V) ensuring credi-

tability which is particularly important when there are

legal implications.

Quality assurance encompasses all aspects of the mi-

crobiology laboratorys analytical activities. In common

with other analytical testing laboratories, particularly

chemical testing laboratories [2], the most important top-

ics are considered to be (a) sampling (sample selection

and sample handling), (b) methodology, (c) environ-

ment, (d) equipment, (e) reagents and media, (f) staff,

(g) reference materials, and (h) internal and external

quality control.

The sample matrix, size, stability, condition, and

storage time before analysis all have significant effects

on the microbiological analysis. When it is considered

that the doubling time for many micro-organisms, such

as bacteria, may be as little as 30 min, a delay in testing

a sample or storage of the sample under inappropriate

conditions may make the analysis meaningless.

19

The environment of the microbiological laboratory

has a profound effect on the quality of the analyses car-

ried out. The laboratory design should facilitate the

testing requirements within the laboratory. Depending

on the type of microbiological analysis being carried

out, it may be necessary to have sterile work rooms,

various classes of laminar flow cabinets, or non-sterile

work bench areas.

The detection and quantification of micro-organism

depend on the method used (e.g. MPN, membrane fil-

tration), so proper methodology selection is essential.

A method suitable for one particular process or opera-

tion may be totally inadequate for another application.

Also the expense of carrying out the method, or the

time required for the analysis, may make the applica-

tion of a particular technique unsuitable. The equip-

ment used to carry out the tests must be shown to be

working properly and to give the correct results. All

media and reagents used in the tests must be of proven

quality and adequate for the test.

The use of reference materials and certified refer-

ence materials is the norm in other disciplines, but the

difficulty of obtaining stable reference materials with

viable cultures of micro-organisms is a further difficulty

for the microbiological analyst. Very few reference ma-

terials are available, and certified reference materials

do not exist [3]. The use of pure reference cultures of

the micro-organism is necessary in so far as it gives in-

formation on the cultural characteristics that are under

investigation, but it does not take into account the af-

fects of the matrix and the difficulties that are caused

by coextractants from the matrix.

The use of internal and external quality control pro-

cedures will check that the procedures in use in the la-

boratory are under statistical control and that the data

are precise and accurate. It is of vital importance that a

laboratory implements such quality control proce-

dures.

With less restrictions on trade throughout the world

the comparability of data among testing laboratories

becomes all the more important. In the past the differ-

ences in quality programmes operated in laboratories

made this difficult. Laboratory accreditation to quality

standards such as EN 45000 series and ISO Guide 25

[4] has given creditability to data produced by laborato-

ries and has ensured wider acceptability of the data.

Many European countries with national accreditation

bodies now have multilateral recognition agreements.

Sampling

Sample selection

The test result obtained from a sample should be indi-

cative of the sample lot. Sampling has been defined by

Garfield [5] as selecting a representative portion of

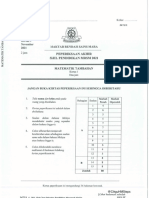

Fig. 1 Sampling in milk production may be at any of the critical

control points. Clinical samples may be taken to show the pres-

ence or absence of a pathogen

material, in some manner, to represent a larger body of

material, presumably for testing or analysis. The sam-

ple for analysis can only be representative when the

original bulk sample is homogeneous and stable. Also,

in discussing sampling Gy [6] explains homogeneous as

when all units are identical to one another.

Micro-organisms grow in discrete units and are not

spread throughout a bulk sample without thorough

mixing. With the exception of water, sample lots (such

as dense liquids, liquids with organic matter and foods)

do not readily mix, so the selection of a representative

sample is often very difficult.

The number of micro-organisms in a sample will

continuously change. If the sample is stored at P20 7C

before analysis, in order to prevent multiplication of

the micro-organisms, some will die or be injured. If the

sample is retained at higher temperatures, multiplica-

tion of the micro-organisms will inevitably occur. With

clinical samples, the need to maintain the samples at a

temperature as close as possible to 37 7C may be the

overriding consideration, particularly if one is trying to

isolate salmonellae or shigellae [7]. It may also be nec-

essary to maintain the samples in transport media while

awaiting laboratory analysis. The concepts more usual-

ly applied to analysis, such as trueness, bias, accuracy,

error, precision, uncertainty, proficiency testing, inter-

nal quality control, etc. can validly be applied to the

sampling process [8].

Sampling for microbiological analysis should be car-

ried out for a specific purpose (Fig. 1). If there is no

well-defined reason for the sampling, then the subse-

quent quality assurance of the analysis is to an extent

wasted.

On the production line, hazard analysis critical control

point (HACCP) analysis is used to identify sample

points which may show potential problems that require

continued monitoring.

20

Clinical samples are taken and tested to show the pres-

ence or absence of particular pathogens or their suscep-

tibility to chemotherapeutic agents. With certain clini-

cal samples such as those taken during surgery, it is

most unlikely that repeat samples can be obtained.

Thus it is essential that correct transport and storage of

these samples does not affect the viability of the micro-

organisms present.

Samples for regulatory purposes are drawn and tested

to show that the sample lot is safe or, if it is a foodstuff,

that it is fit for human consumption.

Samples that are taken which may involve litigation

should show an unbroken chain of custody from sample

point to laboratory and subsequently to the final report

from the laboratory. It is vital that this unbroken chain

is documented.

Sample handling

The microbiology laboratory should have a docu-

mented procedure for handling samples after delivery.

For example, (a) the sample should be given a unique

unambiguous identification code that traces the sample

from receipt to the end of the analysis, (b) the date and

time (if relevant) of receipt should be recorded togeth-

er with any identification number on the sample, and

(c) details of the sampling date and the condition of the

sample, including its temperature, and the name of the

sampler should be documented.

The sample used in the laboratory test may be pre-

pared by taking an aliquot, in the case of liquids, for

example, or may involve reconstitution and subcultur-

ing, for example in the case of dried products. Whatev-

er procedure is used to select the laboratory test sam-

ple, it must be shown to be representative of the sample

delivered to the laboratory.

Sample disposal

The safe retention and disposal of samples submitted

for laboratory analysis is essential, and in order to en-

sure this a procedure should be documented for de-

scribing their safe storage or disposal. It is important to

remember that certain samples may contain harmful

pathogens, which may require decontamination before

being discarded. It must also be remembered that even

non-pathogenic micro-organisms that have been cul-

tured on growth media may occur in such high numbers

that they are hazardous when released outside the labo-

ratory.

Methodology

Classical methods for the detection and enumeration of

micro-organisms depend on the ability of media to sup-

Fig. 2 As the selectivity of the medium (method) is increased, the

recovery of viable micro-organisms decreases

port the growth of the target organism. The choice of

medium is always a compromise between the ability of

the medium to inhibit the growth of non-target organ-

isms and the low recovery of target organisms in a high-

ly selective medium (Fig. 2).

Methods that differentiate organisms based on me-

tabolite production, or on the basis of cellular compo-

nents such as protein and fatty acid profiling, also de-

pend on the ability of the organisms to grow in a de-

fined culture medium and to show significant character-

istic differences. In general, immunological methods

(e.g. immunofluorescence, ELISA) depend on the

availability of antisera with high specificity. The more

recent molecular biology procedures such as polymer-

ase chain reaction (PCR) depend on the elucidation of

unique nucleic acid sequences that are specific for the

target organism.

The purpose for which the analysis is being perform-

ed will determine the choice of method. No method is

suitable for every purpose. It may be more appropriate

to try to detect a plant pathogen in a consignment of

potatoes by immunofluorescence microscopy, rather

than to attempt to culture the target pathogen on selec-

tive media. In a dairy, it may be more appropriate to

monitor contaminants by rapid conductance or impe-

dance procedures, while the official control laboratory

may use classical cultural methods.

The limit of detection, selectivity, time required to

carry out the tests and the number of tests that can be

carried out in a reasonable time all influence the choice

of procedure. Whatever the choice, the method should

be fully documented and be validated. Official methods

and methods from recognised national or international

organisations have already been validated and may not

require further validation. However, for all other meth-

ods, validation must be carried out and the data stored

for as long as is necessary.

Validation for quantitative and qualitative microbio-

logical test methods should estimate the specificity, re-

lative trueness, positive deviation, negative deviation,

limit of detection, limit of determination, matrix effect,

repeatability and reproducibility.

In microbiological tests the specificity refers to the

degree to which a method is affected by other compo-

nents (for example micro-organisms co-extracted) in

the sample. The relative trueness refers to the degree of

21

equivalence (for example the total count of micro-or-

ganisms) of the results of the method under investiga-

tion to those obtained using a reference method. The

positive and negative deviations refer to positive and ne-

gative results (e.g. the presence or absence of particular

micro-organisms) obtained with the method under in-

vestigation, while the reference method gives the oppo-

site result. The limit of detection refers to the lowest

number of micro-organisms that can be detected, but

they are too few in number to be estimated accurately.

The limit of determination refers to the lowest number

of micro-organisms with a defined variability that may

be determined under the experimental conditions of

the method under evaluation.

For validation of a microbiological method, natural-

ly contaminated products (if available) or products

spiked with various levels of micro-organisms should be

tested. It should be remembered that different sample

matrices can adversely effect the performance of a

method. Some international organisations, such as the

Association of Official Analytical Chemists (AOAC),

validate microbiological methods through collaborative

testing.

Environment

The microbiological analysis should be carried out in

facilities that do not adversely effect the result. Ideally,

the laboratory should be designed on a no way back

principle, but this is not always feasible, for example in

older buildings. In the design of the laboratory it is

preferable to have separate areas for (a) sample receipt

and storage, (b) sample preparation, (c) maintenance

of reference micro-organisms, and (d) sterilisation and

decontamination.

The laboratory floors, walls, ceiling and worktops

should be constructed of materials that are smooth and

easy to clean and disinfect.

Continuous documented monitoring of the laborato-

ry environment is essential, for example, by means of

contact plates and exposure plates [9]. Acceptable

background counts should be assigned and a docu-

mented procedure should be established to deal with

counts exceeding these limits. Analysts working in the

microbiology laboratory should wear protective cloth-

ing appropriate for the tests being carried out and

should remove them before leaving the area.

Equipment

All equipment used to carry out analyses must be kept

in good working order and the microbiology laboratory

must document and carry out a programme for mainte-

nance, calibration and performance verification of the

equipment. General service equipment, such as incuba-

tors, water baths, autoclaves, should be maintained by

cleaning and should be serviced regularly by trained

service engineers. Records of all cleaning and servicing

must be kept. A programme for calibration of the

equipment and verification of performance must also

be established; for example, thermometers in water

baths should be calibrated at least annually against a

reference thermometer at freezing point and at the

working temperature in the waterbath. The perform-

ance of equipment such as the autoclave should be de-

termined for a typical load, and it should be capable of

meeting the specified temperature at all points in the

typical load for sterilisation and/or decontamination.

The operation of the autoclave, including the tempera-

ture and time of each cycle, should be documented.

Thermocouples, maximum thermometers or visual ob-

servation of the maximum temperature achieved on the

autoclave temperature/pressure gauge should be used

to monitor the temperature. Chemical or biological in-

dicators may be used to check the effectiveness of the

autoclave. Autoclave tape should be used to indicate

that a batch has been processed; it should not be used

to indicate a successful sterilisation or decontamination

cycle.

Reagents

All reagents, media and solutions used to perform ana-

lytical tests in the microbiology laboratory should be

prepared according to documented procedures. Media

prepared in the laboratory should be checked to ensure

that they support the growth of specific microbial cul-

tures. Selective media should also be checked to ensure

that they inhibit the growth of non-target organisms.

All reagents must be used within their shelf-life. It

might be considered unnecessary to check media re-

ceived from reputable manufacturers, but Shanholtzer

et al. [10] concluded that the testing carried out by

manufacturers of media was not always adequate and

that failure of the media to recover significant patho-

gens would make the laboratorys skills in identification

irrelevant.

Staff

The microbiological tests must be carried out by or un-

der the direction of a person qualified in microbiology.

Staff performing the tests must have adequate training

for the techniques and instruments they use, and their

competence to carry out these tests should be contin-

ually monitored. They should be retrained if they fail to

achieve competence in the tests during subsequent

monitoring.

22

Fig. 3 The use of reference cultures of micro-organisms is similar

to the use of reference standards in chemical tests

Reference materials

The microbiological analyst is familiar with the use of

reference micro-organisms for control purposes in ex-

periments (Fig. 3). Reference strains give information

(a) on the cultural, biochemical and pathogenic charac-

teristics of the cultures under test, (b) on how the cul-

tures appear on different media and (c) on how they

behave at different incubation temperatures. They are

generally seen to be necessary for accurate comparative

work.

The use of reference micro-organisms in various ma-

trices is a relatively new concept. The use of micro-

organisms in this manner leads to consideration of tra-

ceability and uncertainty of measurement, which are

concepts not readily understood or used in microbio-

logical analyses. There is difficulty in obtaining such

reference materials and there are problems associated

with the stability of these materials, which need to be

overcome. Traceability of mass is readily understood

for physical measurements where mass is traceable

through an unbroken chain of comparisons to the pro-

totype kilogram (Bureau International des Poids et ei

Measures in Paris; BIPM). The mass measurement used

in the laboratory may be traceable to the prototype

kilogram, but the micro-organism isolated or quantified

is not traceable to some prototype micro-organism.

The solution proposed to solve this dilemma is simi-

lar to that established for chemical measurement [11],

i.e. the development of reference and certified refer-

ence materials. The materials used in chemical analysis

contain a guaranteed and predetermined level of ana-

lyte, with a given level of uncertainty (an estimate of

the range of values within which the true value lies).

To produce a similar type of reference material for

microbiological analyses it is necessary to inoculate var-

ious matrices with cultures of the micro-organisms that

are being tested and quantify the level through collabo-

rative studies. Such reference materials have been pro-

duced from spray dried milk and encapsulated with ge-

latin [12, 13]. Others have established similar materials

and stabilised them by freezing and freeze-drying [14].

The equivalent certified reference material have not

been produced, presumably because of the difficulty of

obtaining data with documented levels of uncertainty.

When using reference materials, the analyst assumes

that data obtained in from samples of a similar matrix are

correct if the data obtained using the reference material

are within the expected variation of the reference mate-

rial.

Since preparing reference materials is difficult in

many instances and impossible in others, it would be

preferable to add micro-organisms to the sample under

test and run this sample with the added micro-organ-

isms as a control sample. This could be routinely car-

ried out with bacteria, for example, by preparing stocks

of the pure culture and calculating the total viable

count in a dilution series. These diluted stocks could be

stored at P20 7C in 20% glycerol (or other cryo-protec-

tant) and used to spike samples. The viability of the di-

lution series of the pure cultures could be determined

regularly and the effect of the various matrices on their

recovery could be ascertained.

Internal / external quality control

The principle function of the microbiology laboratory is

to provide reliable data. Unreliable data can be danger-

ous, i.e. incorrect diagnosis of pathogens in clinical

samples or undetected pathogens in food and water

samples. An internal quality control programme in a la-

boratory covers the staff, methods, equipment, media

and reagents and is essential to the achievement of reli-

able data that are both precise and accurate.

Control charts are used in other disciplines to moni-

tor the day-to-day variation in the laboratory. In the

microbiology laboratory, a stable and homogeneous

quality control material may not always be available.

However, if spray-dried, freeze-dried or deep-frozen

reference material is available a portion of the material

can be analysed alongside each batch of samples. The

results of the analyses on the control material is plotted

on the ordinate of the control chart and the date plot-

ted on the abscissa. Lines representing acceptable re-

sults for the control material should be drawn. They are

usually set at the target value plus and minus 10%.

When the control material is outside these acceptable

limits the batch should be repeated. Control charts give

a rapid visual representation that the analyses are un-

der statistical control.

Participation in external quality control programmes

demonstrates the laboratorys ability to produce the

correct data, when testing for a specific analyte. Partici-

pation in proficiency testing schemes can be used by a

laboratory to ascertain its performance vis--vis other

laboratories. They have been used for the evaluation of

clinical laboratories for many years. Schemes for food

23

and water microbiology are also available, but unlike

clinical tests, these are often quantitative [15] and the

difficulty again arises for the distribution of stable ho-

mogeneous samples [16].

Accreditation

Accreditation bodies throughout the world have based

their assessment criteria on ISO/IEC Guide 25. In Eu-

rope, the European standard EN 45001 [17] is used and

is itself based on the ISO Guide 25. The microbiologi-

cal laboratories may be externally assessed by accredi-

tation bodies. A number of countries now have accredi-

tation bodies and there is mutual recognition between

most of these national accreditation organisations. Ac-

ceptance of analytical data between laboratories is fa-

cilitated by meeting accreditation requirements. The re-

quirements for accreditation cover all aspects of the

analytical work in the laboratory. Details concerning

every factor that influences the data are recorded and

documented and are available for inspection if neces-

sary. Among the topics covered in accreditation are;

(a) the laboratory management and organisation,

(b) the quality system in operation,

(c) audit and review procedures,

(d) the skills, experience and qualifications of the

staff,

(e) the calibration, performance checking and mainte-

nance of equipment,

(f) the methodology used,

(g) the laboratory environment,

(h) the handling and identification of samples,

(i) the recording of data and reporting of results.

These requirements for accreditation are written in

general terms and need interpretation for use in the mi-

crobiology laboratory. A guidance document that helps

this interpretation has been produced by EURA-

CHEM/EAL [18]. A laboratory may be accredited for a

specific test on a particular material, or it may be accre-

dited for techniques that are applicable in a number of

analytical areas. Before accreditation is granted, a labo-

ratory must demonstrate to the national accreditation

body that all the factors listed above that affect the

analysis are properly addressed.

Conclusion

In the majority of laboratories most of the elements of

a quality assurance programme are carried out, often

without a stated policy or without full documentation

of the process. Documenting the process may be time

consuming, but the pay-back is a more easily managed

laboratory where management can have confidence in

the data generated. When a laboratory gains accredita-

tion for its test procedures or techniques, it shows that

the practices used in the laboratory are managed to an

acceptable standard. The disadvantage of not gaining

accreditation is that results from a non-accredited labo-

ratory will be more liable to challenge. Since most of

the practices involved in a quality assurance pro-

gramme involve better management of laboratory re-

sources, it would be battling against the tide to resist

the introduction of such a programme.

References

1. Cross-Smiecinski A, Stetzenbach LD

(1994) Quality planning for the life

science researcher. CRC Press, Boca

Raton

2. Mesley RJ, Pocklington WD, Walker

RF (1991) Analyst 116: 975990

3. Maier EA, Griepink B, Int Veld PH,

Mooijman K, Havelaar AH (1993)

Fresenius J Anal Chem 354: 140143

4. ISO/IEC (1990) Guide 25 Interna-

tional Organisation for Standardisa-

tion, Geneva

5. Garfield FM (1989) J Assoc Off Anal

Chem 72: 405411

6. Gy PM (1995) Trends Anal Chem

14: 6776

7. Isenberg HD, Washington II JA, Ba-

lows A, Sonnenwirth AC (1985) In:

Lennette EH (ed) Manual of clinical

microbiology, 4th edn. American So-

ciety for Microbiology, Washington,

pp 7380

8. Thompson M, Ramsey MH (1995)

Analyst 120: 261270

9. Comar D (1988) Food Technol Aust

40: 214218

10. Shanholtzer CJ, Peterson MD (1987)

Am J Clin Pathol 210215

11. Reed WP (1980) (NBS special publi-

cation 582). US Department Com-

merce,

12. EUR (1992) bcr information devel-

opment of microbiological reference

materials Report EUR 14375 EN,

Brussels

13. Beckers HL, Leusden FM van,

Meijssen MJM (1985) J Appl Bacteri-

ol 59: 507512

14. Petrez M, Noorberg P (1983) J Assoc

Off Anal Chem 66: 15101513

15. Peterz M (1992) J Appl Bacteriol

73: 210216

16. Havelaar AH, Hogeboom WM, Sek-

huis VM, Erne EHW van (1987) J

Appl Bacteriol 62: 555564

17. EN 45001 (1989) General criteria for

the operation of testing laboratories.

CEN/Cenelec, Brussels

18. EUROCHEM/EAL (1995) Informa-

tion sheet no. 2 Accreditation guide

for laboratories performing microbio-

logical testing. (in press)

You might also like

- Auditing key aspects of the microbiology laboratoryDocument22 pagesAuditing key aspects of the microbiology laboratorymahesh nani33% (3)

- Annex 2: WHO Good Practices For Pharmaceutical Microbiology Laboratories BackgroundDocument25 pagesAnnex 2: WHO Good Practices For Pharmaceutical Microbiology Laboratories Backgroundamerican_guy10No ratings yet

- A Guide To Utilization of The Microbiology Laboratory For Diagnosis of Infectious Diseases: 2013Document18 pagesA Guide To Utilization of The Microbiology Laboratory For Diagnosis of Infectious Diseases: 2013Ridho WahyutomoNo ratings yet

- G-2308 Specific Criteria For Virology Section-Rev. No. 00Document3 pagesG-2308 Specific Criteria For Virology Section-Rev. No. 00Nazaqat FarooqNo ratings yet

- Appl. Environ. Microbiol. 2008 Budowle 5599 607Document10 pagesAppl. Environ. Microbiol. 2008 Budowle 5599 607humusdelombrizNo ratings yet

- WHO TRS 961 Eng-80-100Document21 pagesWHO TRS 961 Eng-80-100Valery LopezNo ratings yet

- Approaching Microbiological Method ValidationDocument18 pagesApproaching Microbiological Method ValidationPrashanth KumarNo ratings yet

- Validacio Microbio.Document15 pagesValidacio Microbio.cgannauNo ratings yet

- Validating Micro MethodsDocument19 pagesValidating Micro MethodsUjang KarnaNo ratings yet

- Approaching Microbiological Method Validation IVTDocument18 pagesApproaching Microbiological Method Validation IVTPiruzi MaghlakelidzeNo ratings yet

- Guide to Creating SOPs for Microbiology LabsDocument8 pagesGuide to Creating SOPs for Microbiology Labsmuni yasaswiNo ratings yet

- QC and QA in Molecular LaboratoryDocument20 pagesQC and QA in Molecular LaboratoryMd. Minhazul IslamNo ratings yet

- QC and QA in Molecular LaboratoryDocument20 pagesQC and QA in Molecular LaboratoryMd. Minhazul IslamNo ratings yet

- Microbiology Best Laboratory PracticesDocument47 pagesMicrobiology Best Laboratory PracticesQAV_CRS100% (1)

- Quality Assurance for Animal Feed Analysis LaboratoriesFrom EverandQuality Assurance for Animal Feed Analysis LaboratoriesNo ratings yet

- Alternative Micro Methods in Pharma: Need for New Micro CurriculumDocument9 pagesAlternative Micro Methods in Pharma: Need for New Micro Curriculumltrevino100No ratings yet

- Approaching Microbiological Method Validation-1Document19 pagesApproaching Microbiological Method Validation-1Apar DholakiaNo ratings yet

- Chpt13 Quality Control AssuranceDocument7 pagesChpt13 Quality Control Assurancevisini100% (1)

- Laboratory Methods For The Diagnosis of Meningitis - CHAPTER 13 - Quality Control - Quality AssuranceDocument7 pagesLaboratory Methods For The Diagnosis of Meningitis - CHAPTER 13 - Quality Control - Quality Assuranceselvalakshmi RNo ratings yet

- Wang - Microbiological Best Laboratory PracticesDocument47 pagesWang - Microbiological Best Laboratory PracticesGuna BabuNo ratings yet

- Quality in The Clinical Microbiology LaboratoryDocument43 pagesQuality in The Clinical Microbiology LaboratoryYemen IlimaneNo ratings yet

- Lab ManagementDocument19 pagesLab ManagementLaurice Nicole ConcepcionNo ratings yet

- Good Laboratory PracticesDocument52 pagesGood Laboratory Practicesankita pathania100% (1)

- The Other Side of Clinical Trial Monitoring Assuring Data Quality and Procedueral AdherenceDocument9 pagesThe Other Side of Clinical Trial Monitoring Assuring Data Quality and Procedueral AdherenceClarissa BC100% (1)

- Good Clinical Laboratory Practice (GCLP) : Quality Demanding From Clinical LaboratoriesDocument5 pagesGood Clinical Laboratory Practice (GCLP) : Quality Demanding From Clinical LaboratoriesJaneNo ratings yet

- Good Clinical Laboratory Practice GCLPDocument36 pagesGood Clinical Laboratory Practice GCLPPatrick Kosgei100% (1)

- Microbiological Testing of Fresh ProduceDocument18 pagesMicrobiological Testing of Fresh ProducerohishaakNo ratings yet

- Quality AssuranceDocument2 pagesQuality AssuranceAvi DhakalNo ratings yet

- Presentation 1Document17 pagesPresentation 1agreysonlameckNo ratings yet

- Rato - Quality of Specimen NotesDocument5 pagesRato - Quality of Specimen NotesAileen SacayNo ratings yet

- The Role of Technical Quality Control in Histology Laboratories 2157 7099.1000264Document5 pagesThe Role of Technical Quality Control in Histology Laboratories 2157 7099.1000264Chirag ChaudharyNo ratings yet

- Guideline For Ecoli Testing Cattle Swine Estab PDFDocument22 pagesGuideline For Ecoli Testing Cattle Swine Estab PDFTrelospapasse BaftisedenyparxeisNo ratings yet

- Quality Control and Assurance in Histopathology LabsDocument39 pagesQuality Control and Assurance in Histopathology LabsJanielle Medina FajardoNo ratings yet

- Annex 2: WHO Good Practices For Pharmaceutical Microbiology Laboratories BackgroundDocument24 pagesAnnex 2: WHO Good Practices For Pharmaceutical Microbiology Laboratories Backgroundanandhra2010No ratings yet

- 21_113205Document6 pages21_113205KAGOYA WHITNEYNo ratings yet

- LQMS 5-3 5-6 Sample Collection TransportDocument5 pagesLQMS 5-3 5-6 Sample Collection Transportahmed alghrablyNo ratings yet

- Quality Control in HistopathologyDocument30 pagesQuality Control in HistopathologyMuhammad Jamiu Bello78% (9)

- 58635 Ce(Ad) f(is) Pf1(Aka Ss) Pfa(Ss) Pn(Ss)Document4 pages58635 Ce(Ad) f(is) Pf1(Aka Ss) Pfa(Ss) Pn(Ss)marvel ecstasyNo ratings yet

- J PH & Bio AnalysisDocument9 pagesJ PH & Bio AnalysisMaría Belén OlivarezNo ratings yet

- Sampling Requirements of USP 43Document13 pagesSampling Requirements of USP 43cahayu andarupmNo ratings yet

- Measuring Lab Performance GuideDocument9 pagesMeasuring Lab Performance GuideJosé Hiram Sánchez GascaNo ratings yet

- The Evaluation of Quality Control and Laboratory Management in Microbiology Laboratories in Sudan Comparing To The International StandardsDocument7 pagesThe Evaluation of Quality Control and Laboratory Management in Microbiology Laboratories in Sudan Comparing To The International StandardsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Current and Future Challenges in Quality Assurance in Mo - 2021 - Clinica ChimicDocument8 pagesCurrent and Future Challenges in Quality Assurance in Mo - 2021 - Clinica ChimicAns Barrung100% (1)

- Quality Control in Histopathology - PPTX Edited - PPTX No 1Document30 pagesQuality Control in Histopathology - PPTX Edited - PPTX No 1Medicine 0786No ratings yet

- Proficiency Testing in The Food Microbiology Laboratory: EviewDocument11 pagesProficiency Testing in The Food Microbiology Laboratory: Eviewzilangamba_s4535No ratings yet

- Checklist of Pathology Laboratory and Its Quality Indicators For NABH Accreditation PreparationDocument3 pagesChecklist of Pathology Laboratory and Its Quality Indicators For NABH Accreditation PreparationQUALITY SIDARTH HOSPITALS100% (1)

- Practical Manual for Detection of Parasites in Feces, Blood and Urine SamplesFrom EverandPractical Manual for Detection of Parasites in Feces, Blood and Urine SamplesNo ratings yet

- Quality Control in MicrobiologyDocument5 pagesQuality Control in MicrobiologyDenySidiqMulyonoChtNo ratings yet

- Quality Assurance Lec 10Document42 pagesQuality Assurance Lec 10raju niraulaNo ratings yet

- Lot-To-Lot Variation and Verification - cclm-2022-1126Document8 pagesLot-To-Lot Variation and Verification - cclm-2022-1126Georgiana Daniela DragomirNo ratings yet

- Lesson 13 PDFDocument5 pagesLesson 13 PDFRaja SharmaNo ratings yet

- Lesson 13Document5 pagesLesson 13Mana DimanaNo ratings yet

- Checklist of Pathology Laboratory and Its Quality Indicators For NABH Accreditation PreparationDocument3 pagesChecklist of Pathology Laboratory and Its Quality Indicators For NABH Accreditation PreparationPayal Thakker100% (1)

- Good Laboratory PracticesDocument11 pagesGood Laboratory PracticesAkash GayanNo ratings yet

- Risk-Proportionate Clinical Trial Monitoring: An Example Approach From A Non-Commercial Trials UnitDocument10 pagesRisk-Proportionate Clinical Trial Monitoring: An Example Approach From A Non-Commercial Trials UnitAnton ChernetsovNo ratings yet

- ASSIGNMENTDocument7 pagesASSIGNMENTBENJAMIN MAWUENYEGAHNo ratings yet

- 5 Thomas Hammack PDFDocument38 pages5 Thomas Hammack PDFВіталій РоманNo ratings yet

- Auditing The Microbiology LaboratoryDocument68 pagesAuditing The Microbiology LaboratoryMohammed Yousffi94% (18)

- Quality Assurance in The Preanalytical PhaseDocument21 pagesQuality Assurance in The Preanalytical PhaseDaniel Huachani CoripunaNo ratings yet

- Evaluation of Five New Plating Media For Isolation of Salmonella Species.Document5 pagesEvaluation of Five New Plating Media For Isolation of Salmonella Species.giuseppegnrNo ratings yet

- Detection and Characterization of Virulence Factors in Lactose PositiveDocument5 pagesDetection and Characterization of Virulence Factors in Lactose PositivegiuseppegnrNo ratings yet

- Detection and Enumeration of Salmonella and Pseudomonas Aeruginosa from Water SamplesDocument10 pagesDetection and Enumeration of Salmonella and Pseudomonas Aeruginosa from Water SamplesgiuseppegnrNo ratings yet

- Calendario ATP 2016Document2 pagesCalendario ATP 2016Yo Soy BetoNo ratings yet

- Development of A New Culture Medium For The Rapid DetectionDocument5 pagesDevelopment of A New Culture Medium For The Rapid DetectiongiuseppegnrNo ratings yet

- Evaluation of Motility Enrichment On Modified Semi-SolidDocument7 pagesEvaluation of Motility Enrichment On Modified Semi-SolidgiuseppegnrNo ratings yet

- Establishment of A Real-Time PCR-BasedDocument7 pagesEstablishment of A Real-Time PCR-BasedgiuseppegnrNo ratings yet

- Efficiency of Different Enrichment and Isolation Procedures ForDocument8 pagesEfficiency of Different Enrichment and Isolation Procedures ForgiuseppegnrNo ratings yet

- Escherichia Coli Isolated From Seafood Toxicity and Plasmid ProfilesDocument4 pagesEscherichia Coli Isolated From Seafood Toxicity and Plasmid ProfilesgiuseppegnrNo ratings yet

- Methodology For Detection and Typing of Foodborne MicroorganismsDocument12 pagesMethodology For Detection and Typing of Foodborne MicroorganismsgiuseppegnrNo ratings yet

- Evaluation of New Culture Media For Rapid DetectionDocument4 pagesEvaluation of New Culture Media For Rapid DetectiongiuseppegnrNo ratings yet

- Ferrioxamine E-Supplemented Pre-Enrichment andDocument11 pagesFerrioxamine E-Supplemented Pre-Enrichment andgiuseppegnrNo ratings yet

- Impedance Microbiology Applications in Food HygieneDocument9 pagesImpedance Microbiology Applications in Food HygienegiuseppegnrNo ratings yet

- Impedance Microbiology-A Rapid Change For MicrobiologistsDocument11 pagesImpedance Microbiology-A Rapid Change For Microbiologistsgiuseppegnr100% (1)

- Incidence and Role of Salmonella in Seafood SafetyDocument9 pagesIncidence and Role of Salmonella in Seafood SafetygiuseppegnrNo ratings yet

- Improvement of Salmonella Detection On MotilityDocument13 pagesImprovement of Salmonella Detection On MotilitygiuseppegnrNo ratings yet

- New Developments in Chromogenic and Fluorogenic Culture Media PDFDocument14 pagesNew Developments in Chromogenic and Fluorogenic Culture Media PDFgiuseppegnrNo ratings yet

- Influence of Salts and Sodium Chloride On The RecoveryDocument6 pagesInfluence of Salts and Sodium Chloride On The RecoverygiuseppegnrNo ratings yet

- A Comparison of Six Different Plating Media UsedDocument13 pagesA Comparison of Six Different Plating Media UsedgiuseppegnrNo ratings yet

- Evaluation of Factors Affecting Survival of 5 PDFDocument5 pagesEvaluation of Factors Affecting Survival of 5 PDFgiuseppegnrNo ratings yet

- A Medium For The Cultivation of LactobacilliDocument6 pagesA Medium For The Cultivation of LactobacilligiuseppegnrNo ratings yet

- Selective Enumeration of LactobacillusDocument4 pagesSelective Enumeration of LactobacillusgiuseppegnrNo ratings yet

- In Situ Measurement and Statistical ModellingDocument11 pagesIn Situ Measurement and Statistical ModellinggiuseppegnrNo ratings yet

- Evaluation of Factors Affecting Survival ofDocument6 pagesEvaluation of Factors Affecting Survival ofgiuseppegnrNo ratings yet

- Influence of Prior Growth Conditions On Low Nutrient Response of Escherichia ColiDocument5 pagesInfluence of Prior Growth Conditions On Low Nutrient Response of Escherichia ColigiuseppegnrNo ratings yet

- Lysis of Escherichia Coli by Marine Micro-OrganismsDocument3 pagesLysis of Escherichia Coli by Marine Micro-OrganismsgiuseppegnrNo ratings yet

- Evaluation of Factors Affecting The Survival of Escherichia Coli in 6Document5 pagesEvaluation of Factors Affecting The Survival of Escherichia Coli in 6giuseppegnrNo ratings yet

- Marine Bacteria Which Produce TetrodotoxinDocument2 pagesMarine Bacteria Which Produce TetrodotoxingiuseppegnrNo ratings yet

- Mortality of Fecal Bacteria in SeawaterDocument4 pagesMortality of Fecal Bacteria in SeawatergiuseppegnrNo ratings yet

- Membrane Filter Method For Enumerating Escherichia ColiDocument7 pagesMembrane Filter Method For Enumerating Escherichia ColigiuseppegnrNo ratings yet

- Chapter 2 Skills Practice AnswersDocument3 pagesChapter 2 Skills Practice Answersafaflotfi_1556964590% (1)

- Beard & Ragheb (1983) - Measuring Leisure MotivationDocument11 pagesBeard & Ragheb (1983) - Measuring Leisure MotivationHuyen T. T. NguyenNo ratings yet

- Name:Mr - Sarawut Moontima ID:5631301107 Section:01 Date: DueDocument17 pagesName:Mr - Sarawut Moontima ID:5631301107 Section:01 Date: DuePongsatorn TammavaragornNo ratings yet

- Kath Murdoch S Inquiry Cycle PDFDocument1 pageKath Murdoch S Inquiry Cycle PDFSneha MishraNo ratings yet

- School Leadership and Management PracticesDocument114 pagesSchool Leadership and Management PracticesrandyNo ratings yet

- ExtenbeamDocument2 pagesExtenbeamthienthanh81No ratings yet

- GSI Survey and Drawing StandardsDocument79 pagesGSI Survey and Drawing StandardsTenson ChikumbaNo ratings yet

- SAP PP ConfigurationDocument25 pagesSAP PP ConfigurationRanjan100% (2)

- BROAD CRESTED WEIR LABORATORY EXPERIMENTDocument12 pagesBROAD CRESTED WEIR LABORATORY EXPERIMENTSyafiq Roslan75% (4)

- The manyfoot package guideDocument23 pagesThe manyfoot package guiderhonemaritimeNo ratings yet

- 4 1 e A SoftwaremodelingintroductionvideoDocument7 pages4 1 e A Softwaremodelingintroductionvideoapi-291536844No ratings yet

- C271M - 11Document4 pagesC271M - 11Luis HuayaneyNo ratings yet

- Erpia PDFDocument316 pagesErpia PDFJosuéLMNo ratings yet

- Prahlad ChhabriaDocument3 pagesPrahlad ChhabriaYogesh Jagpal SharmaNo ratings yet

- Solubility and dissolution factorsDocument20 pagesSolubility and dissolution factorsYuppie RajNo ratings yet

- BMR 1369.3 BMI: Pengiraan Basal Metabolic Rate (BMR) Bagi PerempuanDocument4 pagesBMR 1369.3 BMI: Pengiraan Basal Metabolic Rate (BMR) Bagi PerempuanIzzati LauNo ratings yet

- Reading the Problem and Developing Legal ArgumentsDocument2 pagesReading the Problem and Developing Legal ArgumentsSoumyaNo ratings yet

- Caco Cell LineDocument9 pagesCaco Cell Linedonaldozc07No ratings yet

- Kertas Trial Addmath MRSM K1 2021 SkemaDocument48 pagesKertas Trial Addmath MRSM K1 2021 SkemaRyan YongNo ratings yet

- ME FinalDocument81 pagesME FinalAnkit DahiyaNo ratings yet

- Me Lab Report 1 SilvaDocument18 pagesMe Lab Report 1 SilvaEthan SilvaNo ratings yet

- RRLDocument15 pagesRRLAyrish Septimo100% (4)

- Bourdieu FoucaultDocument33 pagesBourdieu FoucaultChristie DanielsNo ratings yet

- Low-Complexity Polytopic Invariant Sets For Linear Systems Subject To Norm-Bounded UncertaintyDocument6 pagesLow-Complexity Polytopic Invariant Sets For Linear Systems Subject To Norm-Bounded UncertaintyRoyalRächerNo ratings yet

- Horner Wadsworth Emmons ReactionDocument17 pagesHorner Wadsworth Emmons Reactiond1s7euu+rqc23kNo ratings yet

- Vibhuti Sharma ResumeDocument3 pagesVibhuti Sharma ResumeSharma AnkurNo ratings yet

- Structural Design Statement for LHOK NGA Cement Plant ReconstructionDocument17 pagesStructural Design Statement for LHOK NGA Cement Plant Reconstructionwhyme_bNo ratings yet

- Catia v5Document337 pagesCatia v5Saanaa100% (2)

- Empiricism Rationalism and PositivismDocument26 pagesEmpiricism Rationalism and PositivismammorahamNo ratings yet

- Classical Reports in Sap ABAPDocument14 pagesClassical Reports in Sap ABAPSaswat Raysamant0% (1)