Water Loop Calculations

Process Engineering

�WATER LOOP DISTRIBUTION

Simultaneous usage within a

minute

Need to identify users for a

distribution loop

Water quality

Temperature

�WATER DELIVERY OPTIONS

Basic Distribution

delivered/received at same

temperature as stored

Cool/Reheat

Point-of-use heat exchangers

Chase the tail

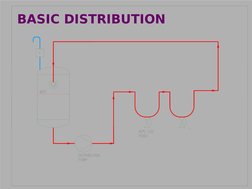

�BASIC DISTRIBUTION

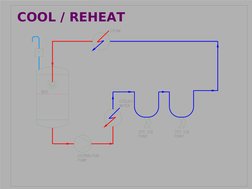

�COOL / REHEAT

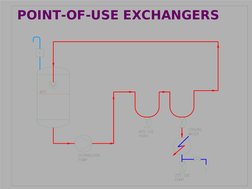

�POINT-OF-USE EXCHANGERS

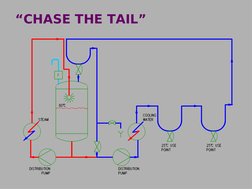

�CHASE THE TAIL

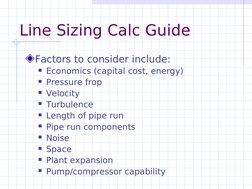

�Line Sizing Calc Guide

Factors to consider include:

Economics (capital cost, energy)

Pressure frop

Velocity

Turbulence

Length of pipe run

Pipe run components

Noise

Space

Plant expansion

Pump/compressor capability

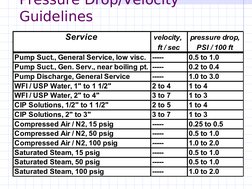

�Pressure Drop/Velocity

Guidelines

Service

velocity,

ft / sec

Pump Suct., General Service, low visc. ----Pump Suct., Gen. Serv., near boiling pt. ----Pump Discharge, General Service

----WFI / USP Water, 1" to 1 1/2"

2 to 4

WFI / USP Water, 2" to 4"

3 to 7

CIP Solutions, 1/2" to 1 1/2"

2 to 5

CIP Solutions, 2" to 3"

3 to 7

Compressed Air / N2, 15 psig

----Compressed Air / N2, 50 psig

----Compressed Air / N2, 100 psig

----Saturated Steam, 15 psig

----Saturated Steam, 50 psig

----Saturated Steam, 100 psig

-----

pressure drop,

PSI / 100 ft

0.5 to 1.0

0.2 to 0.4

1.0 to 3.0

1 to 4

1 to 3

1 to 4

1 to 3

0.25 to 0.5

0.5 to 1.0

1.0 to 2.0

0.5 to 1.0

0.5 to 1.0

1.0 to 2.0

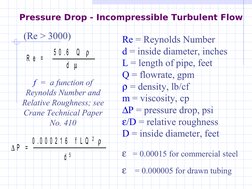

�Pressure Drop - Incompressible Turbulent Flow

(Re > 3000)

R e =

5 0 .6 Q

d

f = a function of

Reynolds Number and

Relative Roughness; see

Crane Technical Paper

No. 410

P =

0 .0 0 0 2 1 6 f L Q

d

Re = Reynolds Number

d = inside diameter, inches

L = length of pipe, feet

Q = flowrate, gpm

= density, lb/cf

m = viscosity, cp

P = pressure drop, psi

/D = relative roughness

D = inside diameter, feet

= 0.00015 for commercial steel

= 0.000005 for drawn tubing

�Line Sizing Guidelines

Maximum flow rate of 7-8 ft/sec

Maximum pressure drop of 2 lb per 100

feet

Evaluate the Equivalent Length

Minimum flow rate

3 ft/sec

Turbulent flow (Reynolds Number > 3000 is

turbulent. >10,000 15,000 is preferred)

�Line Loses - Equivalent

Length

Typically done when you can only

estimate the linear footage of the

system

Other resistances to be considered

include manual valves, elbows, tees,

reducers, entrances/exits, etc.

Difficult to tabulate the resistances at

this stage of design

Rule of thumb - allow the equivalent

length to be twice the linear footage for

the purpose of the initial pump head

calculation

�PUMP HEAD CALCULATION CONSIDERATIONS

(CIRCULATION LOOP)

c o n tr o l

v a lv e lo s s

s u c tio n

te r m in a l

p re s s u re

d is c h a r g e lin e

lo s s

d is c h a r g e

te r m in a l

p re s s u re

s p r a y b a ll

lo s s

exchanger

lo s s

s u c tio n

s ta tic

head

u s e p o in ts

m e te r

lo s s

FI

s u c tio n lin e lo s s

pum p w ear

lo s s

d is c h a r g e

s ta tic h e a d

N O T E : c o n s id e r d iffe r e n t flo w s c e n a r io s fo r

p r e s s u r e d r o p c a lc (n o u s e , p e a k u s e , e tc .)

�TYPICAL EQUIPMENT LOSSES

(for pump head calculations)

In-line filter - allow 3 to 5 psi

Flowmeter - allow 3 to 5 psi

Control valve - allow 10 psi

Heat exchanger - allow 3-5 psi shellside,

3-5 psi tubeside

Tank jacket - allow 5-10 psi

Sprayball - allow 25-30 psi

Pump wear - allow 5 psi

note: check these values as the vendor information comes in

�EVALUATE TWO

SCENARIOS

Hot WFI Loop

Ambient WFI Loop

�WATER USE-POINT

LAYOUT

QC Lab

A-10

Buffer Prep

Fractionation

A-6

Buffer Prep

Purification

A-9

Fractionation

A-4, A-5, A-12

C-1

Purification

A-7, A-8, A-13

H-1, H-2

Inactivation

A-1, A-2, A-3

C-2

Utility

WFI

CIP

A-11

H-3

Ambient Loop

Hot Loop

�HOT WFI LOOP

HWFI System Use-Point Matrix

Use

Room

Point

Name

H-1

Purification Autoclave

H-2

Purification Washer

H-3

CIP

Estimated

Use-Pt.

Temp.

80 Deg C

80 Deg C

80 Deg C

Maximum Possible Draw:

From

Tank

H-3

H-1 / 2

TOTAL

To

H-3

H-1 / 2

Tank

Estimated

Design

Peak

Flow

Daily Volume

Usage

5 gpm 150 gals

5 gpm

5 gpm 200 gals

5 gpm

10 gpm 500 gals

10 gpm

20 gpm

850 gals

Distance

20 ft

80 ft

120 ft

220 ft

20 gpm

�HOT WFI

CONSIDERATIONS

Maximum Demand - 20 GPM

Minimum Return Flow

Future Expansion

Storage Tank Sprayball flowrate (???)

2.5 - 3 GPM / ft of circumference

400 Gal Tk, 4 ft diameter -> 30 - 40 GPM

Economics

FDA Approval

�Service: HWFI

Line No.

INPUT

Flow

(GPM)

Pipe Length (feet)

Specific Gravity

Viscosity

(centipoise)

Roughness

(ft)

>>>>

Nominal

Size (in)

0.500

0.750

1.000

1.500

2.000

3.000

4.000

6.000

8.000

10.000

Actual ID

Reynolds

P

(inches)

Number Flow Region (psi/100ft)

0.37

473982 Turbulent 1,717.8892

0.62

282860 Turbulent

118.2286

0.87

201578 Turbulent

20.8810

1.37

128010 Turbulent

2.1202

1.87

93782

Turbulent

0.4538

2.87

61106

Turbulent

0.0559

3.83

45742

Turbulent

0.0138

5.78

30331

Turbulent

0.0019

7.98

21974

Turbulent

0.0004

10.02

17502

Turbulent

0.0001

note : Clean Tubing

Engineer:

20.00

440

0.97

0.35

0.00005

Velocity

(ft/sec)

59.68

21.25

10.79

4.35

2.34

0.99

0.56

0.24

0.13

0.08

Friction

Factor

0.0227

0.0207

0.0199

0.0195

0.0198

0.0208

0.0218

0.0237

0.0254

0.0269

�Service: HWFI

Line No.

Engineer:

INPUT

Flow

(GPM)

Pipe Length (feet)

Specific Gravity

Viscosity

(centipoise)

Roughness

(ft)

>>>>

Nominal

Size (in)

0.500

0.750

1.000

1.500

2.000

3.000

4.000

6.000

8.000

10.000

Actual ID

Reynolds

(inches)

Number Flow Region

0.37

1066459 Turbulent

0.62

636435 Turbulent

0.87

453551 Turbulent

1.37

288022 Turbulent

1.87

211011 Turbulent

2.87

137488 Turbulent

3.83

102919 Turbulent

5.78

68245

Turbulent

7.98

49441

Turbulent

10.02

39380

Turbulent

note : Clean Tubing

45.00

440

0.97

0.35

0.00005

P

(psi/100ft)

8,585.3781

581.2814

100.8326

9.9066

2.0675

0.2470

0.0598

0.0082

0.0017

0.0006

Velocity

(ft/sec)

134.28

47.82

24.29

9.79

5.26

2.23

1.25

0.55

0.29

0.18

Friction

Factor

0.0224

0.0201

0.0189

0.0180

0.0178

0.0181

0.0187

0.0199

0.0211

0.0222

�AMBIENT WFI LOOP

AWFI System Use-Point Matrix

Use

Room

Point

Name

A-1

Inactivation Wash Room CIP

A-2

Inactivation Wash Room

A-3

Inactivation Wash Sink

A-4

Fractionation Wash Room

A-5

Fractionation Wash Sink

A-6

Fractionation Buffer Prep

A-7

Purification Wash Room

A-8

Purification Wash Sink

A-9

Purification Buffer Prep

A-10

Q.C. Lab

A-11

CIP

A-12

Fractionation Diafiltration

A-13

Purification Diafiltration

C-2

Batching/Reactor Tanks

C-1

Fractionization Freezers

Estimated

Use-Pt.

Temp.

25 Deg C

25 Deg C

25 Deg C

25 Deg C

25 Deg C

25 Deg C

25 Deg C

25 Deg C

25 Deg C

25 Deg C

25 Deg C

25 Deg C

25 Deg C

2 Deg C

2 Deg C

Maximum Possible Draw:

Design

Flow

5 gpm

4 gpm

2 gpm

5 gpm

2 gpm

2 gpm

4 gpm

2 gpm

4 gpm

2 gpm

10 gpm

4 gpm

4 gpm

7 gpm

7 gpm

Estimated

Peak

Daily Volume Usage

200 gals

5 gpm

100 gals

4 gpm

50 gals

0 gpm

100 gals

5 gpm

50 gals

0 gpm

100 gals

2 gpm

50 gals

0 gpm

50 gals

0 gpm

200 gals

4 gpm

10 gals

0 gpm

500 gals

10 gpm

50 gals

4 gpm

50 gals

0 gpm

1000 gals

7 gpm

200 gals

7 gpm

64 gpm 2710 gals

48 gpm

From

To

Distance

Tank

A-11

20 ft

A-11

A-4 / 5 / 6

40 ft

A-4 / 5 / 6

C-1

10 ft

C-1

A-1 / 2 / 3

90 ft

A-1 / 2 / 3

C-2

10 ft

C-2

A-7 / 8 / 13

60 ft

A-7 / 8 / 13

A-9

30 ft

A-9

A-6

20 ft

A-6

A-10

40 ft

A-10

Tank

60 ft

TOTAL

380 ft

�AMBIENT WFI

CONSIDERATIONS

Maximum Demand - 48 GPM

Minimum Return Flow

Future Expansion

Storage Tank Sprayball flowrate

2.5 - 3 GPM / ft of circumference

1000 Gal Tk, 5.5 ft diameter -> 43 - 50 GPM

Economics

FDA Approval

�Service: AWFI

Line No.

INPUT

Flow

(GPM)

Pipe Length (feet)

Specific Gravity

Viscosity

(centipoise)

Roughness

(ft)

>>>>

Nominal

Size (in)

0.500

0.750

1.000

1.500

2.000

3.000

4.000

6.000

8.000

10.000

Actual ID

Reynolds

P

(inches)

Number Flow Region (psi/100ft)

0.37

692053 Turbulent 18,442.8108

0.62

412999 Turbulent 1,258.1437

0.87

294321 Turbulent

220.1296

1.37

186905 Turbulent

21.9881

1.87

136930 Turbulent

4.6502

2.87

89219

Turbulent

0.5652

3.83

66787

Turbulent

0.1383

5.78

44286

Turbulent

0.0191

7.98

32084

Turbulent

0.0041

10.02

25555

Turbulent

0.0014

note : Clean Tubing

Engineer:

65.00

760

1.00

0.80

0.00005

Velocity

(ft/sec)

193.96

69.08

35.08

14.15

7.59

3.22

1.81

0.79

0.42

0.26

Friction

Factor

0.0226

0.0203

0.0194

0.0187

0.0188

0.0194

0.0202

0.0218

0.0233

0.0245

�Service: AWFI

Line No.

INPUT

Flow

(GPM)

Pipe Length (feet)

Specific Gravity

Viscosity

(centipoise)

Roughness

(ft)

>>>>

Nominal

Size (in)

0.500

0.750

1.000

1.500

2.000

3.000

4.000

6.000

8.000

10.000

Actual ID

Reynolds

P

(inches)

Number Flow Region (psi/100ft)

0.37

180998 Turbulent 1,311.6706

0.62

108015 Turbulent

93.3924

0.87

76976

Turbulent

17.0159

1.37

48883

Turbulent

1.8080

1.87

35813

Turbulent

0.3980

2.87

23334

Turbulent

0.0506

3.83

17467

Turbulent

0.0127

5.78

11582

Turbulent

0.0018

7.98

8391

Turbulent

0.0004

10.02

6684

Turbulent

0.0001

note : Clean Tubing

Engineer:

17.00

760

1.00

0.80

0.00005

Velocity

(ft/sec)

50.73

18.07

9.17

3.70

1.99

0.84

0.47

0.21

0.11

0.07

Friction

Factor

0.0235

0.0221

0.0219

0.0225

0.0235

0.0254

0.0271

0.0300

0.0327

0.0348

�CONCLUSIONS

HWFI System

2 Line, 45 GPM (> 5 ft/sec)

AWFI System

2 Line, 65 GPM, Min Return Flow of 18 GPM

(2 ft/sec). May limit Expansion

3 Line if Expansion critical and Cost is not.

Tools: Pipe Sizing - Non Compressible

Fluids, Pipe Sizing - Matrix

Can use other tools for complicated

systems

Fluid Flow, Hydronet