Professional Documents

Culture Documents

QB Art Xiv PDF

Uploaded by

Andri NurdiansyahOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QB Art Xiv PDF

Uploaded by

Andri NurdiansyahCopyright:

Available Formats

01

01

ARTICLE XIV

BRAZING DATA

QB-400 VARIABLES

QB-401 General

QB-401.1 Each brazing variable described in this

Article is applicable as an essential or nonessential

variable for procedure qualication when referenced in

QB-250 for each specic process. Essential variables

for performance qualication are referenced in QB-350

for each specic brazing process. A change from one

brazing process to another brazing process is an essential

variable and requires requalication.

QB-402 Base Metal

QB-402.1 A change from a base metal listed under

one P-Number in QW/QB-422 to any of the following:

(a) a metal listed under another P-Number;

(b) any other base metal not listed in QW/QB-422;

(c) as permitted in QW-420.2 (for S-Numbers).

The brazing of dissimilar metals need not be requali-

ed if each base metal involved is qualied individually

for the same brazing ller metal, ux, atmosphere, and

process. Similarly, the brazing of dissimilar metals

qualies for the individual base metal brazed to itself

and for the same brazing ller metal, ux, atmosphere,

and process, provided the requirements of QB-153.1(a)

are met.

QB-402.2 A change from a base metal listed under

one P-Number in QW/QB-422 to any of the following:

(a) a metal listed under another P-Number;

(b) any other metal not listed in QW/QB-422;

(c) as permitted in QW-420.2 (for S-Numbers).

The brazing of dissimilar metals need not be requali-

ed if each base metal involved is qualied individually

for the same brazing ller metal, ux, atmosphere, and

process. Similarly, the brazing of dissimilar metals

qualies for the individual base metal brazed to itself

and for the same brazing ller metal, ux, atmosphere,

and process.

QB-402.3 A change in base metal thickness beyond

the range qualied in QB-451.

215

QB-403 Brazing Filler Metal

QB-403.1 A change from one F-Number in QB-432

to any other F-Number, or to any other ller metal

not listed in QB-432.

QB-403.2 A change in ller metal from one product

form to another (for example, from preformed ring to

paste).

QB-404 Brazing Temperature

QB-404.1 A change in brazing temperature to a

value outside the range specied in the BPS.

QB-406 Brazing Flux, Fuel Gas, or

Atmosphere

QB-406.1 The addition or deletion of brazing ux

or a change in AWS classication of the ux. Nominal

chemical composition or the trade name of the ux

may be used as an alternative to the AWS classication.

QB-406.2 A change in the furnace atmosphere from

one basic type to another type. For example:

(a) reducing to inert

(b) carburizing to decarburizing

(c) hydrogen to disassociated ammonia

QB-406.3 A change in the type of fuel gas(es).

QB-407 Flow Position

QB-407.1 The addition of other brazing positions

than those already qualied (see QB-120 through QB-

124, QB-203 for procedure, and QB-303 for per-

formance).

(a) If the brazing ller metal is preplaced or facefed

from outside the joint, then requalication is required

in accordance with the positions dened in QB-461

under the conditions of QB-120 through QB-124.

(b) If the brazing ller metal is preplaced in a

joint in a manner that major ow does occur, then

requalication is required in accordance with the posi-

01

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

QB-407.1 2001 SECTION IX QB-410.5

tions dened in QB-461 under the conditions of QB-

120 through QB-124.

(c) If the brazing ller metal is preplaced in a joint

so that there is no major ow, then the joint may be

brazed in any position without requalication.

QB-408 Joint Design

QB-408.1 A change in the joint type, i.e., from a

butt to a lap or socket, from that qualied. For lap or

socket joints, an increase in lap length of more than

25% from the overlap used on the brazer performance

qualication test coupon.

QB-408.2 A change in the joint clearances to a value

outside the range specied in the BPS and as recorded

in the PQR.

QB-408.3 A change in the joint clearances to a value

outside the range specied in the BPS.

QB-408.4 A change in the joint type, e.g., from a

butt to a lap or socket, from that qualied. For lap

and socket joints, a decrease in overlap length from

that qualied.

QB-409 Postbraze Heat Treatment

QB-409.1 A separate procedure qualication is re-

quired for each of the following conditions.

(a) For P-No. 101 and P-No. 102 materials, the

following postbraze heat treatment conditions apply:

(1) no postbraze heat treatment;

(2) postbraze heat treatment below the lower trans-

formation temperature;

(3) postbraze heat treatment above the upper trans-

formation temperature (e.g., normalizing);

(4) postbraze heat treatment above the upper trans-

formation temperature followed by heat treatment below

216

the lower transformation temperature (e.g., normalizing

or quenching followed by tempering);

(5) postbraze heat treatment between the upper

and lower transformation temperatures.

(b) For all other materials, the following post weld

heat treatment conditions apply:

(1) no postbraze heat treatment;

(2) postbraze heat treatment within a specied

temperature range.

QB-409.2 A change in the postbraze heat treatment

(see QB-409.1) temperature and time range requires

a PQR.

The procedure qualication test shall be subjected

to postbraze heat treatment essentially equivalent to that

encountered in the fabrication of production brazements,

including at least 80% of the aggregate time at tempera-

ture(s). The postbraze heat treatment total time(s) at

temperature(s) may be applied in one heating cycle.

QB-409.3 For a procedure qualication test coupon

receiving a postbraze heat treatment in which the upper

transformation temperature is exceeded, the maximum

qualied thickness for production brazements is 1.1

times the thickness of the test coupon.

QB-410 Technique

QB-410.1 A change in the method of preparing the

base metal, i.e., method of precleaning the joints (for

example, from chemical cleaning to cleaning by abrasive

or mechanical means).

QB-410.2 A change in the method of postbraze

cleaning (for example, from chemical cleaning to clean-

ing by wire brushing or wiping with a wet rag).

QB-410.3 A change in the nature of the ame (for

example, a change from neutral or slightly reducing).

QB-410.4 A change in the brazing tip sizes.

QB-410.5 A change from manual to mechanical torch

brazing and vice versa.

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

QB-420 BRAZING DATA QB-432

QB-420 P-NUMBERS

(See Part QW, Welding QW-420)

QB-430 F-NUMBERS

QB-431 General

The following F-Number grouping of brazing ller

metals in QB-432 is based essentially on their usability

characteristics, which fundamentally determine the abil-

QB-432

F-NUMBERS

Grouping of Brazing Filler Metals for Procedure and Performance Qualication SFA-5.8

QB F-No. AWS Classication No.

432.1 101 BAg-1

BAg-1a

BAg-8

BAg-8a

BAg-22

BAg-23

BVAg-0

BVAg-8

BVAg-8b

BVAg-30

432.2 102 BAg-2

BAg-2a

BAg-3

BAg-4

BAg-5

BAg-6

BAg-7

BAg-9

BAg-10

BAg-13

BAg-13a

BAg-18

BAg-19

BAg-20

BAg-21

BAg-24

BAg-26

BAg-27

BAg-28

BAg-33

BAg-34

BAg-35

BAg-36

BAg-37

BVAg-6b

BVAg-18

BVAg-29

BVAg-31

BVAg-32

(QB-432 continues on next page)

217

ity of brazers and brazing operators to make satisfactory

brazements with a given ller metal. This grouping is

made to reduce the number of brazing procedure and

performance qualications, where this can logically be

done. The grouping does not imply that ller metals

within a group may be indiscriminately substituted for

a ller metal which was used in the qualication test

without consideration of the compatibility from the

standpoint of metallurgical properties, design, mechani-

cal properties, postbraze heat treatment, and service

requirements.

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

QB-432 2001 SECTION IX

QB-432

F-NUMBERS (CONTD)

Grouping of Brazing Filler Metals for Procedure and Performance Qualication SFA-5.8

QB F-No. AWS Classication No.

432.3 103 BCuP-1

BCuP-2

BCuP-3

BCuP-4

BCuP-5

BCuP-6

BCuP-7

432.4 104 BAlSi-2

BAlSi-3

BAlSi-4

BAlSi-5

BAlSi-7

BAlSi-9

BAlSi-11

432.5 105 BCu-1

BVCu-1x

BCu-1a

BCu-2

432.6 106 RBCuZn-A

RBCuZn-B

RBCuZn-C

RBCuZn-D

432.7 107 BNi-1

BNi-1a

BNi-2

BNi-3

BNi-4

BNi-5

BNi-5a

BNi-6

BNi-7

BNi-8

BNi-9

BNi-10

BNi-11

432.8 108 BAu-1

BAu-2

BAu-3

BAu-4

BAu-5

BAu-6

BVAu-2

BVAu-4

BVAu-7

BVAu-8

432.9 109 BMg-1

432.10 110 BCo-1

432.11 111 BVPd-1

218

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

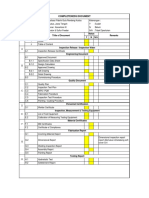

QB-450 BRAZING DATA QB-451.3

QB-450 SPECIMENS

QB-451 Procedure Qualication Specimens

QB-451.1

TENSION TESTS AND TRANSVERSE-BEND TESTS BUTT AND SCARF JOINTS

Range of Thickness of Type and Number of Test Specimens Required

Materials Qualied by Test

First Surface Second Surface

Plate or Pipe, in. (mm)

Thickness T of Test Coupon as Tension, QB- Bend, QB- Bend, QB-

Brazed, in. (mm) Min. Max. 462.1 462.2(a) 462.2(a)

Less than

1

8

(3.2) 0.5T 2T 2 2 2

1

8

to

3

8

(3.2 to 10), incl.

1

16

(1.6) 2T 2 2 2

Over

3

8

(10)

3

16

(4.8) 2T 2 [Note (1)] 2 2

NOTE:

(1) See QB-151 for details on multiple specimens when coupon thicknesses are over 1 in. (25 mm).

QB-451.2

TENSION TESTS AND LONGITUDINAL BEND TESTS BUTT AND SCARF JOINTS

Type and Number of Test Specimens Required

Range of Thickness of

First

Materials Qualied by Test

Surface Second

Plate or Pipe, in. (mm)

Thickness T of Test Coupon as Tension, Bend, Surface Bend,

Brazed, in. (mm) Min. Max. QB-462.1 QB-462.2(b) QB-462.2(b)

Less than

1

8

(3.2) 0.5T 2T 2 2 2

1

8

to

3

8

(3.2 to 10), incl.

1

16

(1.6) 2T 2 2 2

Over

3

8

(10)

3

16

(4.8) 2T 2 [Note (1)] 2 2

NOTE:

(1) See QB-151 for details on multiple specimens when coupon thicknesses are over 1 in. (25 mm).

QB-451.3 01

TENSION TESTS AND PEEL TESTS LAP JOINTS

Type and Number of

Test Specimens Required

Range of Thickness of Materials

Peel

Qualied by Test Plate or Pipe, in. (mm)

Thickness T of Test Coupon as Tension, QB-462.3

Brazed, in. (mm) Min. Max. QB-462.1 [Notes (1) and (2)]

Less than

1

8

(3.2) 0.5T 2T 2 2

1

8

to

3

8

(3.2 to 10), incl.

1

16

(1.6) 2T 2 2

Over

3

8

(10)

3

16

(4.8) 2T 2 2

NOTES:

(1) For a joint brazed with a ller metal having a tensile strength equal to or greater than that of the metal being joined, the specimens shall

be sectioned as shown in QB-462.4.

(2) The overlap length must be equal to or greater than the overlap length of the Tension Test specimen.

219

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

QB-451.4 2001 SECTION IX QB-451.5

QB-451.4

TENSION TESTS AND SECTION TESTS RABBET JOINTS

Range of Thickness of Type and Number of

Materials Qualied by Test Specimens Required

Test Plate or Pipe,

Thickness T of Tension, Section,

in. (mm)

Test Coupon as QB-462. QB-462.

Brazed, in. (mm) Min. Max. 1 4

Less than

1

8

(3.2) 0.5T 2T 2 2

1

8

to

3

8

(3.2 to 10), incl.

1

16

(1.6) 2T 2 2

Over

3

8

(10)

3

16

(4.8) 2T 2 2

QB-451.5

SECTION TESTS WORKMANSHIP COUPON JOINTS

Range of Thickness

of Materials Qualied by Type and Number of

Test Plate or Pipe, Test Specimens Required

Thickness T of

in. (mm)

Test Coupon as Section,

Brazed, in. (mm) Min. Max. QB-462.5 [Note (1)]

Less than

1

8

(3.2) 0.5T 2T 2

1

8

to

3

8

(3.2 to 10), incl.

1

16

(1.6) 2T 2

Over

3

8

(10)

3

16

(4.8) 2T 2

NOTE:

(1) This test in itself does not constitute procedure qualication but must be validated by conductance of tests of butt or lap joints as appropriate.

For joints connecting tension members, such as the stay or partition type in QB-462.5, the validation data may be based upon butt joints;

for joints connecting members in shear, such as saddle or spud joints, the validation data may be based on lap joints.

220

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

QB-452.1 BRAZING DATA QB-452.2

QB-452.1

PEEL OR SECTION TESTS BUTT, SCARF, LAP, RABBET JOINTS

Range of Thickness of Type and Number of

Materials Qualied by Test Specimens Required

Thickness T of

Test Plate or Pipe, in. (mm)

Test Coupon as Peel, QB-462.3

Brazed, in. (mm) Min. Max. [Note (1)]

Less than

1

8

(3.2) 0.5T 2T 2

1

8

to

3

8

(3.2 to 10), incl.

1

16

(1.6) 2T 2

Over

3

8

(10)

3

16

(4.8) 2T 2

NOTE:

(1) For a joint brazed with a ller metal having a tensile strength equal to or greater than that of the metal being joined, the specimens shall

be sectioned as shown in QB-462.4.

QB-452.2

SECTION TESTS WORKMANSHIP SPECIMEN JOINTS

Range of Thickness of Materials Type and Number of

Qualied by Test Plate or Test Specimens Required

Thickness T of Test

Pipe, in. (mm)

Coupon as Brazed, Section,

in. (mm) Min. Max. QB-462.5

Less than

1

8

(3.2) 0.5T 2T 1

1

8

to

3

8

(3.2 to 10), incl.

1

16

(1.6) 2T 1

Over

3

8

(10)

3

16

(4.8) 2T 1

221

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

QB-460 2001 SECTION IX QB-461

QB-460 GRAPHICS

QB-461 TEST FLOW POSITIONS

222

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

QB-462.1(a) BRAZING DATA QB-462.1(b)

10 in. (254 mm)

approx. [Note (1)]

2 in.

(51 mm) R

Edge of joint

This section machined,

preferably by milling

NOTE:

(1) Length may vary to fit testing machine.

1

/

4

in. (6 mm)

1

/

4

in. (6 mm)

1

/

4

in. (6 mm)

3

/

4

in. (19 mm)

QB-462.1(a) TENSION-REDUCED SECTION FOR BUTT AND SCARF JOINTS PLATE

10 in. (254 mm)

approx. [Note (1)]

2 in.

(51 mm) R

Edge of joint Machine the minimum amount

needed to obtain plane parallel

faces over the

3

/

4

in. (19 mm)

wide reduced section

This section machined,

preferably by milling

NOTE:

(1) Length may vary to fit testing machine.

1

/

4

in. (6 mm) 1

/

4

in. (6 mm)

1

/

4

in. (6 mm)

3

/

4

in. (19 mm)

QB-462.1(b) TENSION-REDUCED SECTION FOR BUTT AND SCARF JOINTS PIPE

223

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

QB-462.1(c) 2001 SECTION IX

This section machined,

preferably by milling

NOTE:

(1) Length may vary to fit testing machine.

X

T

T min.

X X

X X

X

T

T

T

T min.

3

/

4

in. (19 mm)

1

/

4

in. (6 mm)

1

/

4

in. (6 mm) 1

/

4

in.

(6 mm)

10 in. (254 mm) approx. [Note (1)]

1

/

4

in. (6 mm)

2 in. (51 mm) R

As specified

by design

As specified

by design

As specified

by design

X = 4T min. or as specified by design

For Rabbet Joints

Alternate Designs

For Lap Joints

T

T

QB-462.1(c) TENSION FULL SECTION FOR LAP AND RABBET JOINTS PLATE

224

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

BRAZING DATA QB-462.1(e)

QB-462.1(e) TENSION FULL SECTION FOR LAP AND BUTT JOINTS SMALL DIAMETER PIPE

225

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

QB-462.1(f) 2001 SECTION IX

Jaws of testing machine

Front View

Restrainer Bars GENERAL NOTE: The restraining fixture is intended to provide a snug

fit between the fixture and the contour of the tension specimen. The

fixture shall be tightened, but only to the point where a minimum of

0.001 in. (0.03 mm) clearance exists between the sides of the fixture

and the tension specimen.

Side View

3

3

2

4

4

1

1

1

Spacers 2

Reduced-Section Tension Specimen 3

Bolts, Body-Bound 4

4 Locknuts 5

4 Nuts 6

2

6

5

3

QB-462.1(f) SUPPORT FIXTURE FOR REDUCED-SECTION TENSION SPECIMENS

226

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

QB-462.2(a) BRAZING DATA QB-462.2(b)

GENERAL NOTE: For the first surface bend specimens,

machine from the second surface as necessary until the

required thickness is obtained. For second surface bend

specimens, machine from the first surface as necessary

until the required thickness is obtained.

6 in. (152 mm) min.

y

y, in. (mm)

T, in. (mm)

All ferrous and nonferrous materials

3

/

8

(10) >

3

/

8

( >10)

1

/

16

3

/

8

(1.610) T

y

T

T

Plate

y

T

y

T

Pipe

1

1

/

2

in. (38 mm)

QB-462.2(a) TRANSVERSE FIRST AND SECOND SURFACE BENDS PLATE AND PIPE

y, in. (mm)

T, in. (mm)

All ferrous and nonferrous materials

3

/

8

(10) >

3

/

8

( >10)

1

/

16

3

/

8

(1.610) T

6 in. (152 mm) min.

T

R

y

y

T

1

1

/

2

in.

(38 mm)

T

R =

1

/

8

in.

(3.2 mm) max.

y

y

T

GENERAL NOTE: For the first surface bend specimens,

machine from the second surface as necessary until the

required thickness is obtained. For second surface bend

specimens, machine from the first surface as necessary

until the required thickness is obtained.

QB-462.2(b) LONGITUDINAL FIRST AND SECOND SURFACE BENDS PLATE

227

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

QB-462.3 2001 SECTION IX QB-462.4

GENERAL NOTES:

(a) Flange Y may be omitted from Section B when peeling is to be accomplished in a

suitable tension machine.

(b) Specimen shall be brazed from side marked Z.

NOTE:

(1) Length may vary to fit testing machine.

10 in. (254 mm) approx.

[Note (1)]

Section A

Approximately, or sufficient

for peeling purposes

Fulcrum point

T

X

Z

Y

1

1

/

2

in. (38 mm)

Section B

X = 4T min. or as

required by design

QB-462.3 LAP JOINT PEEL SPECIMEN

GENERAL NOTE: Specimen shall be brazed from the side marked Z.

Section A

Discard

Section

Discard

this piece

specimen

this piece

T

X

Z

1

/

3

W

1

/

3

W

1

/

3

W

W = 1

1

/

2

in.

(38 mm)

1

1

/

2

in. (38 mm)

Alternate for Rabbet Joint

Section B

X = 4T min. or as required by design

QB-462.4 LAP JOINT SECTION SPECIMEN (See QB-181)

228

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

BRAZING DATA QB-462.5

QB-462.5 WORKMANSHIP COUPONS

229

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

QB-463 2001 SECTION IX QB-463.1(b)

QB-463 Order of Removal

QB-463.1(a) PLATES PROCEDURE QUALIFICATION

230

QB-463.1(b) PLATES PROCEDURE QUALIFICATION

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

BRAZING DATA QB-463.1(c)

NOTES:

(1) Required for rabbet joints.

(2) The sectioning specimen in this view may be used as

an alternate to sectioning the peel test specimens of

QB-463.1(d) when the peel test cannot be used. This

section test specimen should be approximately

1

/

2

in.

(13 mm) wide.

Discard this piece

specimen

Reduced section

tensile

Alternate Lap Joint

[Note (2)]

Rabbet Joint

Alternate Lap Joint

[Note (2)]

Alternate Lap Joint

[Note (2)]

[Note (1)]

specimen

Reduced section

tensile

Sectioning specimen

Sectioning specimen

Discard this piece

QB-463.1(c) PLATES PROCEDURE QUALIFICATION

231

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

QB-463.1(d) 2001 SECTION IX

QB-463.1(d) PLATES PROCEDURE QUALIFICATION

232

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

BRAZING DATA QB-463.1(e)

GENERAL NOTES:

(a) Figure shown is for coupons over 3 in. (76 mm) O.D.

(b) For coupons 3 in. (76 mm) O.D. or less, two coupons are

required for peel or section tests. One specimen

shall be removed from each coupon. For coupons

under 1 in. (25 mm) O.D., the specimen width shall be a

one-half section of the test coupon.

(c) Location specimens to be:

(1) Second surface bend specimens for butt and scarf joints

(2) Peel or sectioning specimens for lap joints

(3) Sectioning specimens for rabbet joints

45 deg

First surface bend test

(if required)

First surface bend test

(if required)

Reduced-section tensile

Reduced-section tensile

Horizontal plane (when pipe is brazed

in horizontal-flow position)

1

1

1

QB-463.1(e) PIPE PROCEDURE QUALIFICATION

233

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

QB-463.2(a) 2001 SECTION IX

NOTES:

(1) Required for rabbet joints.

(2) The sectioning specimen in this view may be used as

an alternate to sectioning the peel test specimens of

QB-463.2(b) when the peel test cannot be used. This

section test specimen should be approximately

1

/

2

in.

(13 mm) wide.

Alternate Lap Joint

[Note (2)]

Alternate Lap Joint

[Note (2)]

Alternate Lap Joint

[Note (2)]

Rabbet Joint

[Note (1)]

Alternate Scarf Joint

[Note (2)]

Alternate Butt Joint

[Note (2)]

Discard this piece

Sectioning specimen

Discard this piece

Sectioning specimen

Discard this piece

QB-463.2(a) PLATES PERFORMANCE QUALIFICATION

234

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

BRAZING DATA QB-463.2(b)

QB-463.2(b) PLATES PERFORMANCE QUALIFICATION

235

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

QB-463.2(c) 2001 SECTION IX

GENERAL NOTES:

(a)

(b)

(c)

(d)

For coupons over 3 in. (76 mm) O.D., one specimen

shall be removed from each location shown.

For coupons 3 in. (76 mm) O.D. and smaller, two

coupons shall be brazed and one specimen

shall be removed from each coupon. If brazed in

the horizontal flow position, the specimen shall

be taken at specimen location No. 1. Alternatively,

each coupon shall be cut longitudinally and the

specimen shall be both sides of one half-section

of each coupon.

When the coupon is brazed in the horizontal flow position,

specimen locations shall be as shown relative to the

horizontal plane of the coupon. For half-section

specimens, plane of cut shall be oriented as shown

relative to the horizontal plane of the coupon.

When both ends of a coupling are brazed, each end

is considered a separate test coupon.

Top

Bottom

Specimen

location No. 1

Specimen location No. 2

Plane of

cut for

half-section

specimens

Horizontal plane

QB-463.2(c) PIPE PERFORMANCE QUALIFICATION 01

236

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

QB-466 BRAZING DATA QB-466.1

QB-466 Test Jigs

As required

As required

Tapped hole to suit

testing machine

Hardened rollers 1

1

/

2

in. (38.1 mm) diameter

may be substituted for jig shoulders

Shoulders hardened

and greased

3

/

4

in. (19 mm)

3

/

4

in. (19 mm)

3

/

4

in. R

B R

D R C

A

3

/

4

in. (19 mm)

7

1

/

2

in. (190.5 mm)

9

in. (228.6 mm)

3

/

4

in. (19 mm)

1

/

2

in. (12.7 mm)

1

1

/

8

in. (28.6 mm)

1

/

8

in. (3.2 mm)

6

3

/

4

i

n

.

(

1

7

1

.

4

m

m

)

3

i

n

.

m

i

n

.

(

7

6

.

2

m

m

)

2

i

n

.

m

i

n

.

(

5

0

.

8

m

m

)

3

/

4

in. (19 mm)

1

1

/

8

in. (28.6 mm)

3

7

/

8

in. (98.4 mm)

2

in. (50.8 mm)

1

/

4

in. (6.4 mm)

Yoke

Plunger

(19 mm)

Thickness of

Specimen, A, B, C, D,

in. (mm) in. (mm) in. (mm) in. (mm) in. (mm)

3

8

(9.5) 1

1

2

(38.1)

3

4

(19) 2

3

8

(60.3) 1

3

16

(30.2)

t 4t 2t 6t + 3.2 3t + 1.6

QB-466.1 GUIDED-BEND JIG

237

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

QB-466.2 2001 SECTION IX QB-466.3

Notes (1), (2)

Note (3)

Notes (4), (5)

C

A

R

min.

R

min.

=

3

/

4

in. (19 mm)

B =

1

/

2

A

Thickness of A, B, C,

Specimen, in. (mm) in. (mm) in. (mm) in. (mm)

3

8

(9.5) 1

1

2

(38.1)

3

4

(19) 2

3

8

(60.3)

t 4t 2t 6t +

1

8

(3.2)

GENERAL NOTE: The braze joint in the case of a transverse bend

specimen shall be completely within the bend portion of the specimen

after testing.

NOTES:

(1) Either hardened and greased shoulders or hardened rollers free

to rotate shall be used.

(2) The shoulders of rollers shall have a minimum bearing surface

of 2 in. (51 mm) for placement of the specimen. The rollers shall

be high enough above the bottom of the jig so that the specimens

will clear the rollers when the ram is in the low position.

(3) The ram shall be tted with an appropriate base and provision

made for attachment to the testing machine, and shall be of a

sufciently rigid design to prevent deection and misalignment

while making the bend test. The body of the ram may be less

than the dimensions shown in column A.

(4) If desired, either the rollers or the roller supports may be made

adjustable in the horizontal direction so that specimens of t thick-

ness may be tested on the same jig.

(5) The roller supports shall be tted with an appropriate base de-

signed to safeguard against deection or misalignment and

equipped with means for maintaining the rollers centered mid-

point and aligned with respect to the ram.

QB-466.2 GUIDED-BEND ROLLER JIG

238

A

T

T +

1

/

16

in. (1.6 mm) max.

B =

1

/

2

A

Roller

Thickness of A, B,

Specimen, in. (mm) in. (mm) in. (mm)

3

8

(9.5) 1

1

2

(38.1)

3

4

(19)

t 4t 2t

GENERAL NOTES:

(a) Dimensions not shown are the option of the designer. The essential

consideration is to have adequate rigidity so that the jig parts

will not spring.

(b) The specimen shall be rmly clamped on one end so that there

is no sliding of the specimen during the bending operation.

(c) Test specimens shall be removed from the jig when the outer roll

has been removed 180 deg from the starting point.

QB-466.3 GUIDED-BEND WRAP AROUND JIG

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CementDocument15 pagesCementMohammedAbbasNo ratings yet

- Specification Tuyauterie q3622011 02 220 Pe SPC 00001 - BDocument96 pagesSpecification Tuyauterie q3622011 02 220 Pe SPC 00001 - BLAKHTIRINo ratings yet

- Die PreparationDocument6 pagesDie PreparationEllen Kay CacatianNo ratings yet

- Deep DrawDocument4 pagesDeep DrawBalvinder PrajapatiNo ratings yet

- Casting and Forging and Technology Assignment: 01: Subject: Gated PatternDocument7 pagesCasting and Forging and Technology Assignment: 01: Subject: Gated PatternTejas AmareshNo ratings yet

- Sa 537Document6 pagesSa 537Mauricio Carestia100% (1)

- P.E.S College of Engineering, Mandya: Report On Recent Technologies in Workholding Device"Document17 pagesP.E.S College of Engineering, Mandya: Report On Recent Technologies in Workholding Device"kiran kumarNo ratings yet

- Galvanised Steel: From Ancient Alchemy To The Infrastructure of The FutureDocument5 pagesGalvanised Steel: From Ancient Alchemy To The Infrastructure of The FuturekhurshedlakhoNo ratings yet

- HELLER - 5 Axis Machining Centres F - ENDocument8 pagesHELLER - 5 Axis Machining Centres F - ENRajiv GandhiNo ratings yet

- Lab ReportDocument16 pagesLab ReportFgj Jhg100% (1)

- Aws Brazing Handbook PDFDocument22 pagesAws Brazing Handbook PDFHARISH PNo ratings yet

- 660.502 A02 Process Clean (Class B) Inspection and Acceptance RequirementsDocument4 pages660.502 A02 Process Clean (Class B) Inspection and Acceptance Requirementspuwarin najaNo ratings yet

- EPIGEN 1311 HB Epoxy CoatingDocument2 pagesEPIGEN 1311 HB Epoxy CoatingtirtharchuNo ratings yet

- Stingblade: Id: 66842A0101 Er: 26946 FeaturesDocument1 pageStingblade: Id: 66842A0101 Er: 26946 FeaturesKhairatul Nada Burhanuddin100% (1)

- Review Dokumen PG. RendengDocument10 pagesReview Dokumen PG. RendengFarhan PutraNo ratings yet

- What Is Stellite SteelDocument11 pagesWhat Is Stellite SteelRathnakrajaNo ratings yet

- Markal-Laco-Tempil 2019Document46 pagesMarkal-Laco-Tempil 2019Adelina EstrellaNo ratings yet

- Plywood PlanbookDocument162 pagesPlywood PlanbookPaul Hutchinson86% (7)

- Festo PSI PUN-H Vs PEN EN142609 202211Document2 pagesFesto PSI PUN-H Vs PEN EN142609 202211frfNo ratings yet

- Operating Procedure For Water Tight GRP Manhole CoversDocument7 pagesOperating Procedure For Water Tight GRP Manhole CoversBipin SasikumarNo ratings yet

- BASF R5-12 Loading ProcedureDocument3 pagesBASF R5-12 Loading ProcedureNGUYỄN HOÀNG LINHNo ratings yet

- Cepheid SampleDocument15 pagesCepheid SampleguiNo ratings yet

- 1916 Boren 1st Submission 8-8-22Document195 pages1916 Boren 1st Submission 8-8-22TomNo ratings yet

- Jigs and Fixtures - Mechanical Engineering (MCQ) Questions and AnswersDocument2 pagesJigs and Fixtures - Mechanical Engineering (MCQ) Questions and AnswersPrashant SinghNo ratings yet

- Key Statistics 2011 FINALDocument32 pagesKey Statistics 2011 FINALFelipe Augusto Diaz SuazaNo ratings yet

- 1 - Heat TreatmentDocument61 pages1 - Heat TreatmentMohamed Karim MohamedNo ratings yet

- A Project of Volunteers in AsiaDocument98 pagesA Project of Volunteers in AsiaMbah DukNo ratings yet

- POLYCASA PC - Solid Polycarbonate Sheets - Technical-Manual - EN PDFDocument25 pagesPOLYCASA PC - Solid Polycarbonate Sheets - Technical-Manual - EN PDFArnold TunduliNo ratings yet

- Notes On Shipbuilding MaterialDocument16 pagesNotes On Shipbuilding MaterialAnkit MauryaNo ratings yet

- #0000, #000 and #00 Thread DimensionsDocument1 page#0000, #000 and #00 Thread DimensionsTheodor EikeNo ratings yet