Professional Documents

Culture Documents

Omnia 46

Uploaded by

Enescu MirceaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Omnia 46

Uploaded by

Enescu MirceaCopyright:

Available Formats

Liability: All information in this data sheet is based on the best available knowledge, is subject to change without notice

and can

only be considered as suitable for general guidance Fumes: Consult information on Welding Safety Sheet, available upon request

www.lincolnelectric.eu

S

M

A

W

Omnia

46

Rutile electrode

Classification

AWS A5.1 : E6013

ISO 2560-A : E 38 0 R 11

General description

Rutile general purpose, all positions electrode

Applicable for clean structural steel

Smaller diameters excellent for hobby market

Very suitable for low open circuit voltage transformers

Welding positions

ISO/ASME PA/1G PB/2F PC/2G PF/3Gup PG/3Gdown PE/4G PF/5Gup PG/5Gdown

Current type

AC / DC -

Approvals

ABS BV DNV GL LR TV

2 2 2 2 2 +

Chemical composition (w%), typical, all weld metal

C Mn Si

0.06 0.5 0.45

Mechanical properties, all weld metal

Condition Yield strength Tensile strength Elongation Impact ISO-V(J)

(N/mm

2

) (N/mm

2

) (%) 0C

Required: AWS A5.1 min. 331 min. 414 min. 17 not required

ISO 2560-A min. 380 470-600 min. 20 min. 47

Typical values AW 430 480 26 60

Packaging and available sizes

Diameter (mm) 2.0 2.5 3.2 3.2 4.0 4.0

Length (mm) 300 350 350 450 350 450

Unit: box Pieces / unit 370 250 175 150 110 95

Net weight/unit (kg) 4.2 4.8 5.3 6.2 5.0 5.9

Unit: Linc Pack Pieces / unit 89 54 33 22

Net weight/unit (kg) 1.0 1.0 1.0 1.0

Identification Imprint: 6013-Omnia 46 Tip Color: yellow

Omnia

46: rev. EN 22

76

S

M

A

W

Omnia

46

Materials to be welded

Steel grades/Code Type

General structural steel

EN 10025 S185, S235, S275

Ship plates

ASTM A 131 Grade A, B, D

Cast steel

EN 10213-2 G P 240R

Pipe material

EN 10208-1 L210, L240, L290

EN 10208-2 L240, L290

API 5LX X42, X46

EN 10216-1/ P235, P275

EN 10217-1

Boiler & pressure vessel steel

EN 10028-2 P235, P265, P295

Fine grained steel

EN 10113-2 S275

EN 10113-3 S275

Calculation data

Sizes Current Current Arc time Energy Dep.rate Weight/ Electrodes/ kg Electrodes/

Diam. x length range type - per electrode at max. current - 1000 pcs. kg weldmetal kg weldmetal

(mm) (A) (s)* E(kJ) H(kg/h) (kg) B 1/N

2.0x300 50-60 AC 43 57 0.5 11.4 154 1.68

2.5x350 70-90 AC 68 134 0.6 19.2 84 1.60

3.2x350 90-125 AC 80 220 0.9 30.3 50 1.51

3.2x450 100-135 AC 102 303 0.9 41.3 38 1.56

4.0x350 140-190 AC 74 323 1.5 45.5 33 1.49

4.0x450 150-200 AC 95 456 1.5 62.1 26 1.58

5.0x450 180-240 AC 115 662 1.8 105.5 17 1.75

Welding parameters, optimum fill passes

Welding positions PA/1G PB/2F PC/2G PF/3G up PG/3G down PE/4G PF/5G up PG/5G down

Diameter (mm)

2.0 55A 55A 55A 50A 55 A 50A 55 A

2,5 80A 85A 85A 80A 85A 85A 80A 85A

3,2 110A 115A 115A 110A 115A 110A 110A 115A

4.0 170A 175A 175A 175A 180A 175A 175A 180A

5.0 220A 230A 230 A

77

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Evermotion Archmodels Vol 40 PDFDocument2 pagesEvermotion Archmodels Vol 40 PDFJustinNo ratings yet

- Alternative ADHD TreatmentDocument3 pagesAlternative ADHD TreatmentCindy VanegasNo ratings yet

- Damian C. Brady, P .DDocument9 pagesDamian C. Brady, P .Dapi-27484581No ratings yet

- Ôn HSG - P5-HandoutDocument4 pagesÔn HSG - P5-HandoutMinh ChâuNo ratings yet

- Go Betweens For HitlerDocument402 pagesGo Betweens For HitlerSagyan Regmi Regmi100% (1)

- J.petrauskas ResumeDocument1 pageJ.petrauskas ResumeJPet09No ratings yet

- Nine Principles of Conscious LivingDocument57 pagesNine Principles of Conscious LivingSreeraj Guruvayoor SNo ratings yet

- (Intelligent Systems, Control and Automation_ Science and Engineering 72) B. S. Goh, W. J. Leong, K. L. Teo (Auth.), Honglei Xu, Xiangyu Wang (Eds.)-Optimization and Control Methods in Industrial EngiDocument300 pages(Intelligent Systems, Control and Automation_ Science and Engineering 72) B. S. Goh, W. J. Leong, K. L. Teo (Auth.), Honglei Xu, Xiangyu Wang (Eds.)-Optimization and Control Methods in Industrial EngiVu Duc TruongNo ratings yet

- Sharda dss10 PPT 06Document48 pagesSharda dss10 PPT 06Ragini PNo ratings yet

- National AnthemsDocument6 pagesNational AnthemszhannurazimbaiNo ratings yet

- Conditional Power of One Proportion Tests PDFDocument7 pagesConditional Power of One Proportion Tests PDFscjofyWFawlroa2r06YFVabfbajNo ratings yet

- Aavit 5 ADocument113 pagesAavit 5 AAnonymous ok5UankNo ratings yet

- Expository Essay Rough DraftDocument4 pagesExpository Essay Rough Draftapi-292792461No ratings yet

- Why There Has Been No Brandies Brief in India? Challenges To Socio-Legal Research in IndiaDocument2 pagesWhy There Has Been No Brandies Brief in India? Challenges To Socio-Legal Research in IndiaSubhaprad MohantyNo ratings yet

- Recurrent Neural Processes: Preprint. Under ReviewDocument12 pagesRecurrent Neural Processes: Preprint. Under Reviewgheorghe garduNo ratings yet

- KSS 41 END enDocument702 pagesKSS 41 END enJavier Del Pozo Garcia100% (1)

- BTP ReportDocument27 pagesBTP ReportAayush Ghosh ChoudhuryNo ratings yet

- High School Kids Science Fiction Short StoriesDocument5 pagesHigh School Kids Science Fiction Short StoriesHarshal bhardwaj100% (1)

- Goodrich 6e Ch03 Arrays PDFDocument12 pagesGoodrich 6e Ch03 Arrays PDFArjun SinghNo ratings yet

- Karpagam College of EngineeringDocument6 pagesKarpagam College of EngineeringSuresh VpNo ratings yet

- $RKNVNODDocument8 pages$RKNVNODhoangleeicftNo ratings yet

- Semantics Course BookDocument67 pagesSemantics Course BookJosipa Blažević50% (2)

- A Project Report ON: Admerit IIT & ME, Patna LC Code:-01780Document74 pagesA Project Report ON: Admerit IIT & ME, Patna LC Code:-01780Santosh FranNo ratings yet

- Imp Ob QuestionsDocument2 pagesImp Ob QuestionsPrabhakar RaoNo ratings yet

- Strut & Tie ModelDocument67 pagesStrut & Tie Modelahmed adel100% (9)

- Updating Cd2 School Heads: TradeanDocument2 pagesUpdating Cd2 School Heads: TradeanCarlos GarciaNo ratings yet

- Oracle FLEXCUBE Introduction User Manual PDFDocument166 pagesOracle FLEXCUBE Introduction User Manual PDFriteshNo ratings yet

- Achieving Executive PresenceDocument7 pagesAchieving Executive PresenceSebastián LealNo ratings yet

- Service Manual: Digital Laser Copier/ Digital Multifunctional SystemDocument132 pagesService Manual: Digital Laser Copier/ Digital Multifunctional SystemViktor FehlerNo ratings yet

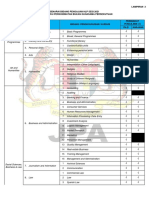

- Bidang Pengajian HLP 2021 - Perkhidmatan Bukan Gunasama PersekutuanDocument4 pagesBidang Pengajian HLP 2021 - Perkhidmatan Bukan Gunasama PersekutuanMasnah Insyirah AnneskiNo ratings yet