Professional Documents

Culture Documents

Stojkovic PoF 2003

Uploaded by

Antonio Martín AlcántaraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stojkovic PoF 2003

Uploaded by

Antonio Martín AlcántaraCopyright:

Available Formats

On the new vortex shedding mode past a rotating circular cylinder

D. Stojkovi, P. Schn, M. Breuer, and F. Durst

Citation: Phys. Fluids 15, 1257 (2003); doi: 10.1063/1.1562940

View online: http://dx.doi.org/10.1063/1.1562940

View Table of Contents: http://pof.aip.org/resource/1/PHFLE6/v15/i5

Published by the American Institute of Physics.

Related Articles

Strain-vorticity induced secondary motion in shallow flows

Phys. Fluids 24, 023601 (2012)

Developed quantum turbulence and its decay

Phys. Fluids 24, 011301 (2012)

A fully resolved numerical simulation of turbulent flow past one or several spherical particles

Phys. Fluids 24, 013303 (2012)

Decaying versus stationary turbulence in particle-laden isotropic turbulence: Turbulence modulation mechanism

Phys. Fluids 24, 015106 (2012)

Cavitation inception during the interaction of a pair of counter-rotating vortices

Phys. Fluids 24, 014107 (2012)

Additional information on Phys. Fluids

Journal Homepage: http://pof.aip.org/

Journal Information: http://pof.aip.org/about/about_the_journal

Top downloads: http://pof.aip.org/features/most_downloaded

Information for Authors: http://pof.aip.org/authors

Downloaded 09 Feb 2012 to 130.88.152.176. Redistribution subject to AIP license or copyright; see http://pof.aip.org/about/rights_and_permissions

PHYSICS OF FLUIDS

VOLUME 15, NUMBER 5

MAY 2003

On the new vortex shedding mode past a rotating circular cylinder

D. Stojkovic, P. Schon, M. Breuer,a) and F. Durst

Institute of Fluid Mechanics, FriedrichAlexanderUniversitat ErlangenNurnberg, Cauerstrae 4,

D-91058 Erlangen, Germany

Received 2 December 2002; accepted 31 January 2003; published 3 April 2003

To examine in detail the behavior of a new vortex shedding mode found in a previous investigation

Phys. Fluids 14, 3160 2002, a two-dimensional numerical study on the laminar incompressible

flow past a rotating circular cylinder in the Reynolds number range 60Re200 and at rotational

rates 0 6 was carried out. The results obtained clearly confirm the existence of the second

shedding mode for the entire Reynolds number range investigated. A complete bifurcation diagram

(Re) was compiled defining both kind of shedding modes. The unsteady periodic flow in the

second mode is characterized by a frequency much lower than that known for classical von Karman

vortex shedding of the first mode. The corresponding Strouhal number shows a strong dependence

on the rotational velocity of the cylinder, while only a weak dependence is observed for the

Reynolds number. Furthermore, the amplitudes of the fluctuating lift and drag coefficients are much

larger than those characterizing classical vortex shedding behind nonrotating or slowly rotating

cylinders. Additionally, negative values for the mean drag denoting thrust are found within the

second shedding mode. 2003 American Institute of Physics. DOI: 10.1063/1.1562940

. The total lift coefficient c L is almost independent of Re

and increases linearly with increasing the rotational rate. The

drag coefficient c D has a relatively strong dependence on Re

and . As Re increases, the drag coefficient decreases. As

increases, the pressure drag decreases while the friction drag

increases, resulting in a net decrease in the total drag force.

Stojkovic et al.1 examined the unsteady flow for Re

100 and high rotational rates 0 12. They confirmed

the results of Kang et al.3 about the existence of vortex shedding for Re100 and 0 I(Re)1.8 and its suppression for I . They found that the lift force increases linearly only for lower rotational rates. For 2, the mean lift

coefficient shows a parabolic increase with up to

5.15. Furthermore, on increasing the rotation rate to even

higher values, a second shedding mode was found for a narrow range, II III , where II4.8 and III5.15 at

Re100. In this range of rotational rates the flow field again

shows unsteady behavior. The corresponding Strouhal number was observed to be much lower than that known for the

normal shedding mode. For example, in case of Re100 and

5, St0.022 was found. Furthermore, the amplitudes of

the drag and lift forces were detected to be significantly

larger than those characterizing the first shedding mode at

1.8. The changes in the flow mode and structure behind

the cylinder lead to a kink in the curve for the mean lift

coefficient. For 5.15 the flow was found to be steady

state. The lift coefficient again shows a linear increase, converging asymptotically towards the curve based on the potential flow theory combined with the asymptotic approximation of Moore5 to determine the circulation .

In order to obtain more detailed information about this

phenomenon for a wide parameter range, additional numerical simulations of the two-dimensional unsteady laminar

I. INTRODUCTION

The objective of this brief paper is to present the results

of a detailed numerical study on the laminar unsteady periodic flow motion found in the wake of rotating circular cylinders at high rotational velocities.1 This vortex shedding is

characterized by frequencies much lower than that known for

normal vortex shedding, i.e., the von Karman vortex street.2

The rotating circular cylinder, placed in a free incompressible fluid flow of constant velocity, is considered. This

type of flow is defined by two dimensionless parameters: the

Reynolds number Re(U D)/ and the ratio of the rotational velocity of the cylinder wall to the oncoming flow

velocity (D )/(2 U ), where D is the cylinder diameter, the constant angular velocity of the cylinder rotation,

U the oncoming free-stream velocity and the kinematic

viscosity of the fluid.

Recent numerical investigations for the laminar 2D vortex shedding regime performed by Kang et al.3 for Re

60, 100, and 160 and 0 2.5 showed that vortex shedding exists for I , where I is the critical rotational velocity, which is a nonlinear function of Re. For the same

range of Reynolds numbers and higher rotational rates I

2.5 vortex shedding disappears. It was shown by Kang

et al.3 that the rotation of the cylinder does not significantly

alter the Strouhal number St for the range I . Actually,

St stays nearly constant at lower rotational rates , decreases

slightly as approaches I , and sharply reduces to zero at

I . These results confirmed the assumption of Badr

et al.4 that St is more or less independent of . Furthermore,

Kang et al.3 found that the lift force mostly results from the

pressure force and its contribution increases with increasing

a

Author to whom correspondence should be addressed. Electronic mail:

breuer@lstm.uni-erlangen.de

1070-6631/2003/15(5)/1257/4/$20.00

1257

2003 American Institute of Physics

Downloaded 09 Feb 2012 to 130.88.152.176. Redistribution subject to AIP license or copyright; see http://pof.aip.org/about/rights_and_permissions

1258

Stojkovic et al.

Phys. Fluids, Vol. 15, No. 5, May 2003

flow past a rotating circular cylinder for Re60, 80, 160,

and 200 and 0 6 were performed.

II. COMPUTATIONAL METHODOLOGY

The standard set of partial differential equations, consisting of the continuity and the momentum equations in nondimensional form, was considered. This set of equations has to

be solved for the unknown pressure p, and the two velocities

u i for i1,2 in the x and y directions. The influence of gravity force was excluded from the present considerations. Because the energy equation is decoupled from the system of

other conservation equations, it was not taken into account.

The computations were carried out with the highly efficient flow simulation code LESOCC, based on the finitevolume method for arbitrary nonorthogonal, body-fitted,

nonstaggered grids see Breuer6,7. Convection and diffusion

terms in the momentum equations are approximated by central differencing scheme of second-order accuracy. A lowstorage multistage RungeKutta method three substeps,

second-order accurate in time is applied to integrate the momentum equations in the predictor step. Within the corrector

step the Poisson equation for the pressure correction is

solved implicitly by the incomplete LU decomposition

method of Stone.8

In the present study, an O-type grid was used with an

outer boundary of diameter H and an inner boundary on the

cylinder surface, D/2. The classical far-field boundary conditions were used. The size of the domain for all predictions

was H/D100, which was proved to be sufficiently large by

additional predictions using domain sizes of up to H/D

300. The number of grid points in radial and circumferential direction was 241241 and all other parameters concerning the quality of the grid correspond to those already

used in the calculation of Kang et al.3 Furthermore, this grid

and the LESOCC code were used to confirm the results for

Re100 and 5 reported by Stojkovic et al.1

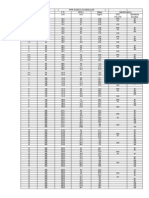

FIG. 1. Stability diagram for different Reynolds numbers 60Re200 and

rotation rates 0 6.

possible to prove nor to disprove this statement. Contrarily,

both curves for II and III decrease with increasing Re.

The variation of the Strouhal number St f D/U for

60Re200 and II III is shown in Fig. 2, where f

denotes the vortex shedding frequency. In order to compare

these St values with the corresponding values of the first

vortex shedding region 0 I , the St data for 1 are

included in the figure. According to these results, the unsteady flow motion found in the second vortex shedding regime see Fig. 1 is characterized by a frequency much lower

III. RESULTS AND DISCUSSION

The numerical results obtained clearly confirm the existence of the second shedding mode in the Reynolds number

range investigated. The interval II III in which the

second vortex shedding mode appears is significantly narrower than that defining the first shedding mode (0

I), as visible in the stability diagram in Fig. 1. The critical rotational speeds defining these two vortex regions for

Re60, 80, 100, 160, and 200 are I1.4, 1.7, 1.8, 1.9, and

1.9, II5.35, 5.0, 4.8, 4.5, and 4.35, and III

5.45, 5.2, 5.1, 4.8, and 4.6, respectively. For each Re

investigated, successive computations with an incrementally

increasing and decreasing rotation rate ( 0.05) were carried out around the critical values leading to the bifurcation

curves in Fig. 1. Using a much finer grid than in the previous

study,1 a slightly different value for III is observed at Re

100. Based on the bifurcation diagram in Fig. 1, it is obvious that I increases monotonically with increasing Re.

Kang et al.3 found a logarithmic increase of I with increasing Re. However, based on the present data, it was neither

FIG. 2. Strouhal number St versus rotation rate at Re

60, 80, 100, 160, and 200. The values in parentheses are the Strouhal

numbers for 1.

Downloaded 09 Feb 2012 to 130.88.152.176. Redistribution subject to AIP license or copyright; see http://pof.aip.org/about/rights_and_permissions

Phys. Fluids, Vol. 15, No. 5, May 2003

The new vortex shedding mode

1259

FIG. 3. Development of the vortex street in the second vortex shedding

mode behind the rotating cylinder for Re160 and 4.7.

FIG. 4. Mean drag coefficient c Da v for Re60, 100, and 200 and 0

6.

than that of the first shedding mode. Furthermore, the Strouhal number dependence on in the second vortex shedding

mode is much stronger than that characterizing the first

mode. With increasing rotation rates, St substantially decreases for each Re investigated. In the case of Re160,

St( III) is approximately three times lower than St(

II). It is worth to mention that the slope of the different

St( ) curves is nearly independent of Re. Due to insufficient

data points it was, however, not possible to find an appropriate fitting curve characterizing the behavior of St with respect to and Re.

The development of the vortex street behind the rotating

cylinder in the second mode is visualized by computed

streaklines shown in Figs. 3a3d exemplarily for Re

160 and 4.7. The cylinder rotating in the clockwise

direction is exposed to free-stream flow coming from the

left. Owing to rotation and strong viscous effects near the

cylinder, an egg-shaped region of closed streaklines see Fig.

3a is formed around the cylinder also visible from streamlines as shown by Stojkovic et al.1. This structure increases

in time. The oncoming fluid flow from the lower part of the

cylinder forces this egg-shaped region to elongate, see Figs.

3b and 3c. After the egg-shaped structure has reached a

certain size, the structure detaches from the cylinder as visible in Fig. 3d, and the entire process starts anew. As is

obvious from Fig. 3, the entire process of vortex formation

and shedding is completely different to that characterizing

the nonrotating cylinder. Only one vortex appears and develops below the cylinder and not two of them which typically

appear behind the nonrotating cylinder developing and detaching from the body in an alternating manner. Furthermore,

the time scales of both shedding motions are completely different. Whereas for the classical shedding mode around

slowly rotating cylinders the ratio of the time periods for one

shedding cycle and a complete revolution of the cylinder is

of the order O(1), the complete cycle for the second shedding mode persists for a multitude of cylinder revolutions,

e.g., about 71 for the case displayed in Fig. 3.

Figure 4 shows the dependence of the mean drag coef-

ficient for Re60, 100, and 200 and 0 6. The results

for low rotational rates and Re60 and 100 are consistent

with the results obtained by Kang et al.3 for I , i.e., in

the first shedding regime. As can be seen in Fig. 4, the behavior of the drag coefficient can be split into three characteristic regions. For II the mean drag coefficient c Da v

decreases with increasing rotation rate. In the vicinity of the

interval for the second vortex shedding mode c Da v starts to

increase see, e.g., Re100) but then abruptly drops, leading

to a kink in the c Da v curve. This phenomenon is pronounced

for Re100 and 200 but not so clearly visible for Re60.

The sudden drop of c Da v results in negative values of the

mean drag coefficient which is equivalent to thrust. With

increasing Re the kink becomes more pronounced and appears for smaller values. This kink in the c Da v curve indicates that the flow mode and structure behind the cylinder

has changed and the second vortex shedding has started.

However, by further increasing the rotational rate to

III , the flow is stable and steady again and c Da v continues to increase smoothly. In spite of this increase of c Da v

within this region, it was shown by Stojkovic et al.1 that the

corresponding flow field is very similar to the structure

known from potential theory. In contrast the flow structure

for I II strongly deviates from the solution of potential theory. Hence it was found that the flow within the region

II III toggles between two characteristic flow structures, one for II where the viscous effects are very important and the other for III where the viscous effects

are mainly restricted to the vicinity of the cylinder and the

rotation dominates the entire flow, leading to a flow structure

very similar to the potential flow field. This explains why for

increasing Re the second vortex shedding mode appears for

smaller values of . Actually, Re could be considered as the

ratio of inertial and viscous forces and with increasing Re the

viscous effects are not so dominant in the flow field and thus

the rotational rates, causing the potential flow field structure,

do not have to be as high as for the case of smaller Re.

Downloaded 09 Feb 2012 to 130.88.152.176. Redistribution subject to AIP license or copyright; see http://pof.aip.org/about/rights_and_permissions

1260

Stojkovic et al.

Phys. Fluids, Vol. 15, No. 5, May 2003

the same Re and within II III . For III the flow

is again stable, showing no kind of shedding motion.

IV. CONCLUSIONS

FIG. 5. Amplitude of the drag coefficient c Dam for Re60, 80, 100,

160, and 200 and 0 6.

Because nonsinusoidal histories of the drag and lift coefficients were observed in the second vortex shedding mode,

the amplitude is defined in a general way by c Dam

1/2(c DmaxcDmin) and corresponding results are presented

in Fig. 5. This figure clearly confirms that the first vortex

shedding mode appears at low rotational rates I and

then completely disappears for I II . The results for

lower rotational rates produced by Kang et al.3 are included

in the figure, coinciding well with the corresponding results

of the present calculation. For I the amplitude of the

drag coefficient c Dam increases almost linearly with increasing and sharply reduces to zero for I . Furthermore,

with increasing Re at const., c Dam increases for the first

shedding mode. The second vortex shedding mode takes

place for II III . The amplitude of the drag signal in

this mode shown in Fig. 5 is up to four times higher than

those characterizing the first shedding mode for the same Re

investigated. It was also observed that the amplitude of the

lift coefficient not shown here is approximately 25% higher

than the corresponding amplitude of the drag coefficient for

It is concluded that for all Reynolds numbers characterizing a two-dimensional laminar unsteady flow, the second

vortex shedding mode exists for the flow around a rotating

cylinder. The second mode appears in the range 4.35

5.45 depending on Re. This vortex shedding mode is characterized by a frequency much lower than that characterizing

the classical von Karman vortex shedding. Furthermore, St is

strongly dependent on the rotational rate and weakly dependent on the Reynolds number: with increasing the frequency of the shedding substantially decreases, whereas an

increasing Re at fixed leads to slightly lower frequencies.

Additionally, the amplitudes of the fluctuating lift and drag

coefficient are much higher for the second shedding mode

than those known for the first mode around a nonrotating or

slowly rotating cylinder. The mean drag coefficient is found

to strongly depend on the rotational rate leading to negative values thrust within the second shedding mode. Furthermore, it was observed that with increasing Re the second

shedding mode appears for smaller values of . This could

be attributed to a smaller influence of the viscous forces

when Re is increased.

1

D. Stojkovic, M. Breuer, and F. Durst, Effect of high rotation rates on the

laminar flow around a circular cylinder, Phys. Fluids 14, 3160 2002.

2

M. M. Zdravkovich, Flow Around Circular Cylinders, Vol. 1: Fundamentals Oxford University Press, New York, 1997.

3

S. Kang, H. Choi, and S. Lee, Laminar flow past a rotating circular

cylinder, Phys. Fluids 11, 3312 1999.

4

H. M. Badr, S. C. R. Dennis, and P. J. S. Young, Steady and unsteady

flow past a rotating cylinder at low Reynolds numbers, Comput. Fluids

17, 579 1989.

5

D. W. Moore, The flow past a rapidly rotating circular cylinder in an

infinite stream, J. Fluid Mech. 2, 541 1957.

6

M. Breuer, Large-eddy simulation of the sub-critical flow past a circular

cylinder: Numerical and modeling aspects, Int. J. Numer. Methods Fluids

28, 1281 1998.

7

M. Breuer, A challenging test case for large-eddy simulation: High Reynolds number circular cylinder flow, Int. J. Heat Fluid Flow 21, 648

2000.

8

H. L. Stone, Iterative solution of implicit approximations of multidimensional partial differential equations, SIAM Soc. Ind. Appl. Math. J.

Numer. Anal. 5, 530 1968.

Downloaded 09 Feb 2012 to 130.88.152.176. Redistribution subject to AIP license or copyright; see http://pof.aip.org/about/rights_and_permissions

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Python For Data ScienceDocument321 pagesPython For Data ScienceAntonio Martín AlcántaraNo ratings yet

- Python For Data ScienceDocument321 pagesPython For Data ScienceAntonio Martín AlcántaraNo ratings yet

- ME2134cheatsheet PDFDocument1 pageME2134cheatsheet PDFbenNo ratings yet

- Proposed Three (3) Storey Apartment: Hydraulic Calculations of Wet Standpipe System and Technical SpecificationsDocument4 pagesProposed Three (3) Storey Apartment: Hydraulic Calculations of Wet Standpipe System and Technical SpecificationsJessica Vargas100% (1)

- Direct numerical simulation of particle detachmentDocument14 pagesDirect numerical simulation of particle detachmentAntonio Martín AlcántaraNo ratings yet

- DynamicTetRemeshing OFW6 PresentationDocument26 pagesDynamicTetRemeshing OFW6 PresentationAntonio Martín AlcántaraNo ratings yet

- Azuma JTheoBiol 1987Document12 pagesAzuma JTheoBiol 1987Antonio Martín AlcántaraNo ratings yet

- Python Data Science Cheat SheetDocument1 pagePython Data Science Cheat SheetMaisarah Mohd PauziNo ratings yet

- 001 - Openfoam SSÇ ÀÚ ÁDocument189 pages001 - Openfoam SSÇ ÀÚ ÁAntonio Martín AlcántaraNo ratings yet

- Diaz 2008Document17 pagesDiaz 2008Antonio Martín AlcántaraNo ratings yet

- Saadat Et Al PRF 2017Document12 pagesSaadat Et Al PRF 2017Antonio Martín AlcántaraNo ratings yet

- Ofw8 Combest Advshm FinalDocument110 pagesOfw8 Combest Advshm FinalAntonio Martín AlcántaraNo ratings yet

- Bruce K. Driver - Lecture Notes - Topology and Functional AnalysisDocument91 pagesBruce K. Driver - Lecture Notes - Topology and Functional AnalysisAndrey FerreiraNo ratings yet

- Euler and Navier Stokes Inverse Problem Studies of Airfoil by Genetic AlgorithmDocument7 pagesEuler and Navier Stokes Inverse Problem Studies of Airfoil by Genetic AlgorithmAntonio Martín AlcántaraNo ratings yet

- Appendix A Complex NumbersDocument3 pagesAppendix A Complex NumbersAntonio Martín AlcántaraNo ratings yet

- Kim JCP 2001Document19 pagesKim JCP 2001Antonio Martín AlcántaraNo ratings yet

- Thrust and Efficiency of Propulsion by Oscillating FoilsDocument6 pagesThrust and Efficiency of Propulsion by Oscillating FoilsAntonio Martín AlcántaraNo ratings yet

- Calderon PF 2014Document16 pagesCalderon PF 2014Antonio Martín AlcántaraNo ratings yet

- Active Vorticity Control in A Shear Flow Using A Flapping FoilDocument21 pagesActive Vorticity Control in A Shear Flow Using A Flapping FoilAntonio Martín AlcántaraNo ratings yet

- 1 s2.0 S0889974613000388 MainDocument24 pages1 s2.0 S0889974613000388 MainAntonio Martín AlcántaraNo ratings yet

- J Exp Biol 2001 SaneDocument21 pagesJ Exp Biol 2001 SaneAntonio Martín AlcántaraNo ratings yet

- Naca Report 567Document9 pagesNaca Report 567Antonio Martín AlcántaraNo ratings yet

- 1 s2.0 S0045794906003865 Main PDFDocument7 pages1 s2.0 S0045794906003865 Main PDFAntonio Martín AlcántaraNo ratings yet

- Guilmineau JFS 2002 PDFDocument22 pagesGuilmineau JFS 2002 PDFAntonio Martín AlcántaraNo ratings yet

- A Study of Two-Dimensional Flow Past An Oscillating CylinderDocument32 pagesA Study of Two-Dimensional Flow Past An Oscillating CylinderAntonio Martín AlcántaraNo ratings yet

- Meshing Tools For Open Source CFD - A Practical Point of ViewDocument25 pagesMeshing Tools For Open Source CFD - A Practical Point of Viewbardock277100% (1)

- PDFDocument28 pagesPDFAntonio Martín AlcántaraNo ratings yet

- S0022112099008071a PDFDocument19 pagesS0022112099008071a PDFAntonio Martín AlcántaraNo ratings yet

- BosDocument236 pagesBosmahzadkhNo ratings yet

- 2010 - Laminar Flow Past An Oscillating Circular Cylinder in Cross FlowDocument8 pages2010 - Laminar Flow Past An Oscillating Circular Cylinder in Cross FlowheloverNo ratings yet

- J Exp Biol-1973-WEIS-FOGH-169-230 PDFDocument62 pagesJ Exp Biol-1973-WEIS-FOGH-169-230 PDFAntonio Martín AlcántaraNo ratings yet

- Hydraulic MachinesDocument11 pagesHydraulic MachinesmaivizhiNo ratings yet

- 345BL Hidr. Schema.Document2 pages345BL Hidr. Schema.Ivan PalominoNo ratings yet

- Guidance of Piping DesignDocument121 pagesGuidance of Piping DesignTapas PalitNo ratings yet

- Barring Gear Causes and PreventionDocument27 pagesBarring Gear Causes and PreventionRamnadh Mandali100% (3)

- Procedure PipeDocument4 pagesProcedure PipejoeknotNo ratings yet

- REYNOLDS NUMBER EXPERIMENT PREDICTS FLUID FLOW TYPESDocument21 pagesREYNOLDS NUMBER EXPERIMENT PREDICTS FLUID FLOW TYPESMervin PerezNo ratings yet

- Refrigerant Piping PDFDocument9 pagesRefrigerant Piping PDFzikhail93No ratings yet

- Lab Report 4Document7 pagesLab Report 4api-300265822100% (1)

- 3 Valvula Modular Serie 01Document42 pages3 Valvula Modular Serie 01Leandro AguiarNo ratings yet

- Pipe Sizes and ScheduleDocument2 pagesPipe Sizes and Schedulechupacid0% (1)

- Static CalculationsDocument1 pageStatic CalculationsAnish BabuNo ratings yet

- Fe-1001 W-HDocument1 pageFe-1001 W-HJan Richardo GultomNo ratings yet

- 330D 336 PDFDocument2 pages330D 336 PDFRICHARDNo ratings yet

- Cooling Tower Package Engineering in Halliburton - Multi Chem Batch PlantDocument3 pagesCooling Tower Package Engineering in Halliburton - Multi Chem Batch PlantragulNo ratings yet

- Illustration 29 07 2017 PDFDocument1 pageIllustration 29 07 2017 PDFGlenn D. KleinNo ratings yet

- Control Valve CharacteristicsDocument5 pagesControl Valve CharacteristicsFarhan HazeeqNo ratings yet

- Offshore Piping Design CriteriaDocument1 pageOffshore Piping Design CriteriaDhakshina K100% (1)

- Surge and swab pressure calculationsDocument2 pagesSurge and swab pressure calculationsSyed IrtazaNo ratings yet

- Unit 09Document3 pagesUnit 09Kin KevinNo ratings yet

- Sun Hydraulics CWEL Technical SpecificationsDocument1 pageSun Hydraulics CWEL Technical SpecificationsJustinNo ratings yet

- Flowmeters: Measuring Flow IndirectlyDocument11 pagesFlowmeters: Measuring Flow IndirectlyNRNiloyNo ratings yet

- Nigeria LNG LTD NLNG Six ProjectDocument13 pagesNigeria LNG LTD NLNG Six ProjectEkundayo JohnNo ratings yet

- Pressure Vessel - LSPDocument4 pagesPressure Vessel - LSPPengelana KehidupanNo ratings yet

- Water Hammer Arrestors and Plumbing Specialties GuideDocument3 pagesWater Hammer Arrestors and Plumbing Specialties GuideMartin Roberto GarciaNo ratings yet

- Centrifugal Pump Selection and SizingDocument50 pagesCentrifugal Pump Selection and SizingmariasofiarossiNo ratings yet

- Data SheetDocument1 pageData SheetGem RNo ratings yet

- Asme Ansi A 13.1Document4 pagesAsme Ansi A 13.1Deniss GálvezNo ratings yet