Professional Documents

Culture Documents

WLDG1009 CEUBasic Shielded Metal Arc Syllabus

Uploaded by

veereshkoutalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WLDG1009 CEUBasic Shielded Metal Arc Syllabus

Uploaded by

veereshkoutalCopyright:

Available Formats

CONTINUING EDUCATION

WLDG 1009: Basic Shielded Metal Arc Welding

SYLLABUS

This course is taught at the following location:

Welding Technology Department

Riverside Campus

Austin Community College

Office: (512) 223-6443

Austin, Texas 78741

For registration and payment information, contact:

Continuing Education Department

5930 Middle Fiskville Road

Austin Community College

Office: (512) 223-7542

Austin, Texas 78752

Course Rationale

This is a 40-clock hour course designed to develop your skills in two basic and important welding

processesshielded metal arc welding and oxy-fuel welding. In addition, you will receive training in oxy-fuel cutting and brazing. The curriculum consists of twenty-eight progressive, competency-based skills projects utilizing individualized training with your instructor. It will require

judicious time management to complete the projects on time, but the reward will be the skill and

confidence of learning these versatile welding and cutting processes.

The skills you will develop are given in detail in the PROJECT LIST which accompanies this syllabus. Following is an overview:

SHIELDED METAL ARC WELDING

Learn

Learn

Learn

Learn

to surface using E-6010 and E-7018 electrodes in the four welding positions

to cut metal for welding by using the manual and track cutting torches

to weld horizontal and vertical tee joints

to weld horizontal lap joints

OXY-FUEL WELDING

Learn

Learn

Learn

Learn

to bead in the four welding positions

to weld the square-groove butt joint

to weld horizontal and vertical lap joints

to weld horizontal and vertical tee joints

OXY-FUEL BRAZING

WLDG 1009: Basic Shielded Metal Arc Welding

Continuing Education

Page 2

Learn to bead in the flat position

Learn to braze flat butt/scarf joints

Learn to braze horizontal lap joints

In addition to tuition, there is a $30 laboratory fee to cover welding electrodes, gases, practice

metal and incidental consumables, and a $3.50 accident insurance fee. This course is approved by

the Texas Higher Education Coordinating Board. To comply with the THECB 40-clock hour

requirement, it will meet within the Austin Community College semester format at the times

published each semester in the ACC Continuing Education Schedule.

Makeup Work

If you must make up work at a class time other than that for which you are scheduled, you must

comply with the following rules:

1. You must sign in using the Attendance Sheet for the Welding Department found in the

white notebook posted on the wall next to the hall door leading into Welding Laboratory 3122. This is a liability insurance requirement.

2. There must be a faculty or staff member on duty at all times when you are working.

You must notify that person when you arrive. You must not work unattended.

3. When you have finished working, you must clean up your work area, sign out, and inform the faculty or staff member on duty that you are leaving.

Safety Regulations

Welding is not inherently dangerous, but it can become very dangerouseven fatalif you are

careless and neglect safety precautions. Most accidents occur when people get in a hurry, so learn

to pace yourself and move cautiously and deliberately. The College endeavors to provide you

with proper training and a safe environment, but you must also do your part by abiding by the

following rules. If you persistently violate these rules, you will be considered a safety risk and

will be withdrawn from class:

1. Wear your safety glasses at all times when you are in the welding labs.

2. Wear your ear plugs in areas of high noise levels.

3. Know the locations and proper use of fire extinguishers. They are located at the exit to every

classroom and laboratory.

4. Do not weld or grind near oxy-fuel tanks, manifold connections, or other potential sources for

gas leaks.

5. Be mindful of proper ventilation in your work area.

6. When using portable grinders, be sure that you direct sparks away from others.

7. When using stationary pedestal grinders, be sure that the tool rest is adjusted as close to the

grinding wheel as possible without touching it. Always wear safety glasses and a face shield

when grinding and wire brushing.

8. Do not handle oxy-fuel equipment with oil or grease on your hands or clothing

9. Do not wear loose or dangling jewelry when welding or handling materials.

10. Be sure that you have the proper shade of filter lens in your welding helmet or face shield.

11. Do not attach your ground lead to water pipes or electrical conduit.

WLDG 1009: Basic Shielded Metal Arc Welding

Continuing Education

Page 3

12. When welding in a booth, keep your door closed. When welding in an open lab, shield your

arc with welding curtains. Always consider the line-of-sight between your arc and the eyes of

bystanders.

13. To avoid burns to others, do not discard hot metal without first quenching it. WriteHOT

on objects too large to bring to the quench tank.

14.Read the appropriate chapters on safety in the Richard Finch, Welders Handbook: A Guide to

Plasma Cutting, Oxyacetylene, ARC, MIG and Tig Welding, current edition, published by the

Penguin Group, mentioned below.

15. Report all accidents to your instructor without delay. If you suspect an unsafe condition or

an equipment malfunction, bring it to your instructor's attention IMMEDIATELY!

Special Warning about Bloodborne Pathogens

A number of very serious Bloodborne Pathogens lurk in todays public environments that can be

devastating to your healtheven fatal:

HIV Human Immunodeficiency Virus

AIDS Acquired Immunodeficiency Syndrome

Hepatitis A, B and C

Tetanus lockjaw

MRSA Methicillin Resistant Staphylococcus Aureus

Necrotizing Fasciitis flesh-eating disease

If you sustain a nick, cut, puncture, abrasion, or any wound in which blood surfaceshowever

minorcease all activity immediately and proceed to a First Aid Kit to apply antiseptic and a

protective bandage. Time is critical in treating Bloodborne Pathogens. Notify your instructor,

who will call Campus Police for further assessment, and if necessary, Austin Emergency Medical

Services will be notified.

You will need to fill out the following forms, as appropriate, to activate your student liability insurance. If your injury requires emergency room treatment, it is much easier to have your forms

with you at the time of admittance. It is infinitely more tedious getting signatures from treating

physicians and hospital personnel days after the occurrence. These forms are attached to the

cabinet doors of the First Aid Kits:

1. Student Accident Liability Form

2. First Aid Log

3. Near-Miss Form

Laboratory Policy

1. You must attend class at the time for which you are enrolled. If you develop a schedule conflict, see your instructor regarding an intradepartmental transfer.

WLDG 1009: Basic Shielded Metal Arc Welding

Continuing Education

Page 4

2. When you complete a project, request approval from your instructor. You will not be credited

for unproved projects.

3. Cleanup time is ten minutes before the end of class. Sweep your immediate work area and return equipment to the tool room. Surrounding work areas must be cleaned with the combined

efforts of all students.

4. Do not waste metal. Cut away practice welds and consolidate pieces. Do not remove metal

from the shop. This will help keep lab fees reasonable in the face of rising costs for steel.

5. If there is an equipment malfunction, inform your instructor immediately so that it can be repaired and returned to service.

6. Smoking and eating are not permitted in the laboratories or classrooms.

Supplies

Required Equipment: The department supplies most equipment, but you will need to purchase

the following personal items:

Safety glasses

Ear plugs

Shirts

Pants

Boots

ANSI-approved with shatter-proof lenses and side shields

Reusable rubber or disposable sponge plugs

Should be made of cotton and have long sleeves

Should be made of cotton and must not have cuffs

High-top shoes also acceptable but fabric shoes not permitted

Gloves

Cap

Locking pliers

Welding hood

Cutting goggles

Chipping hammer

Hand wire brush

Leather gauntlet style to protect from embers and arc burns

Welder's cloth cap with downward bill to protect from sparks

For handling hot metal

For electric arc welding, lens shade #10

For oxyfuel welding, cutting and brazing, lens shade #5

For removing slag

For cleaning metal and welds

These items can be obtained from one of the Austin area welding suppliers:

Airgas Southwest

11,111 North Lamar Blvd.

(512) 835-0202

Austin, Texas

Precision Oxygen

4927 East 5th Street

385-2247

Austin, Texas

On North Lamar between

Kramer and Braker Lanes

On East 5th Street four blocks

east of Springdale Road

Alamo Welding Supply

613 Chicon

(512) 476-9400

Austin, Texas

3-D Welding Supply, Inc.

3016 Highway 123

San Marcos, Texas

(512) 396-3926

Eleven blocks east of I-35

between 6th and 7th Streets

2.5 miles east of I-35

WLDG 1009: Basic Shielded Metal Arc Welding

Continuing Education

Page 5

Praxair Distribution

2801 Montopolis Drive

(512) 389-2323

Austin, Texas

Matheson Tri-Gas

3519 East 5th Street

(512) 385-0611

Austin, Texas

On Montpolis north of Ben White Blvd.

across from the entrance to Sematech

At the corner of East 5th Street

and Springdale Road

Texas Welding Supply

4705 Commercial Park Drive

(512) 272-9353

Austin, Texas

Round Rock Welding Supply

1400 North Industrial Boulevard

(512) 828-3200

Round Rock, Texas

East of Highway 183 off Springdale Road

Highway 79 exit, left under I-35, right at Chisolm, second

street to left, located behind Gattiland

Textbook

Richard Finch, Welders Handbook: A Guide to Plasma Cutting, Oxyacetylene, ARC, MIG and

Tig Welding, current edition, published by Penguin Group, www.penguin.com, ISBN: 978-155788-513-5

"Where do I go from here . . . college credit?"

Welding is fascinating! As the course progresses and you see your skills developing, you may ask

yourself, "Where do I go from here?"

First, we suggest that you take the follow-up Continuing Education Course, WLDG

1043:Intermediate Arc Welding. It will extend your skills by training you in the three major inert

gas processesgas tungsten, gas metal, and flux-cored arc welding.

Next, you may want to receive academic recognition for your skills by converting your two Continuing Education courses into the college-credit course, WLDG 1407: Introduction to Welding

Using Multiple Processes. You can even apply it to one of our Associate of Applied Science degrees in Welding Technology, with specializations in Code Welding or Art Metals.

As you will learn, welding requires a high level of motor skill development. And because it has

always paid above average among the skilled crafts, welding technology can be an excellent career

choice. See your instructor for more information about this intriguing field!

WLDG 1009: Basic Shielded Metal Arc Welding

Continuing Education

Welding Technology Department

Austin Community College

SAFETY AGREEMENT

Office: (512) 223-6443

Austin, Texas 78741

WLDG 1009: Basic Shielded Metal Arc Welding

Continuing Education

Page 6

By signing my name below, I am attesting that my instructor has made me aware that welding is

dangerous if I ignore applicable safety regulations and laboratory policies. I understand that I will

acquire the knowledge of these regulations and policies by (1) reading the course syllabus

attached to this Project List, (2) reading the applicable chapters on safety in my textbook, (3) observing all safety and warning signs posted in the laboratories and classroom, and (4) attending inclass safety demonstrations on equipment and shop practices given by my instructor throughout

the course. I understand that it is my responsibility to attend class regularly, be alert to my

surroundings, and remain constantly vigilant to the risks of working in an industrial environment.

I understand that safe practice is the discretionary interpretation of my instructor, and that if I

fail to adhere to these requirementsincluding the attendance policy outlined in the syllabus

I will be considered a safety risk to myself and others and I will be withdrawn from the course.

Student (signature)__________________________Student (print name)__________________________

Emergency Contact_________________________Emergency cell phone_________________________

Emergency work phone______________________Emergency home phone_______________________

Instructor_________________________________Year_______________________________________

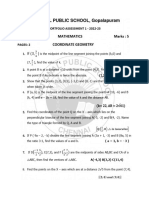

PROJECT LIST

Shielded Metal Arc Welding (SMAW)

Project Number

Skill

Completion Date

Course Completion

Surfacing

1.

2.

3.

4.

5.

6.

7.

8.

Flat..........................E-6010............................................................................................4%

Horizontal................E-6010............................................................................................7%

Vertical....................E-6010..........................................................................................11%

Overhead.................E-6010..........................................................................................14%

Flat..........................E-7018..........................................................................................18%

Horizontal................E-7018..........................................................................................21%

Vertical....................E-7018..........................................................................................25%

Overhead.................E-7018..........................................................................................29%

Oxy-fuel Cutting

9. Manual Torch................................................................................................................32%

10. Track Torch...................................................................................................................36%

Tee Joints

11.

12.

13.

14.

Horizontal (2F)........E-6010..........................................................................................39%

Horizontal (2F)........E-7018..........................................................................................43%

Vertical - up (3F).....E-6010..........................................................................................46%

Vertical - up (3F).....E-7018..........................................................................................50%

WLDG 1009: Basic Shielded Metal Arc Welding

Continuing Education

Page 7

Lap Joints

15. Horizontal (2F)........E-6010..........................................................................................54%

16. Horizontal (2F)........E-7018..........................................................................................57%

Oxy-Fuel Welding (OFW)

Project Number

Skill

Completion Date

Course Completion

Beads

17.

18.

19.

20.

Flat.................................................................................................................................60%

Horizontal......................................................................................................................64%

Vertical..........................................................................................................................68%

Overhead.......................................................................................................................71%

Square-Groove Butt Joint

21. Flat (1G)........................................................................................................................75%

Lap Joints

22. Horizontal (2F)..............................................................................................................79%

23. Vertical - up (3F)...........................................................................................................82%

Tee Joints

24. Horizontal (2F)..............................................................................................................86%

25. Vertical - up (3F)...........................................................................................................89%

Oxy-Fuel Brazing (OFB)

Project Number

Skill

Completion Date

Course Completion

Beads

26. Flat.................................................................................................................................93%

Butt / Scarf Joints

27. Flat.................................................................................................................................96%

Lap Joint

WLDG 1009: Basic Shielded Metal Arc Welding

Continuing Education

Page 8

28. Horizontal (2F)............................................................................................................100%

[End of Document]

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Aggreko Info GuideDocument19 pagesAggreko Info GuideJeongSikYooNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Early Reading 11 - Will Is Ill PDFDocument6 pagesEarly Reading 11 - Will Is Ill PDFKatharina KrawtschenkoNo ratings yet

- Childhood Trauma Questionnaire ScoringDocument2 pagesChildhood Trauma Questionnaire Scoringwoongie yeoNo ratings yet

- Sample OSCE Stations DentalDocument7 pagesSample OSCE Stations DentalEbn Seena90% (10)

- Lesson Plan - HomophonesDocument3 pagesLesson Plan - Homophonesapi-359106978No ratings yet

- 02 eLMS Activity 1 (NSTP)Document1 page02 eLMS Activity 1 (NSTP)Yuki C. ArutaNo ratings yet

- Biometric details document for Chavan familyDocument3 pagesBiometric details document for Chavan familyveereshkoutalNo ratings yet

- One of The Best Industry in The World Is Hotel Industry and The Hotel Industry Is Growing Like Any Thing in The Developing CountryDocument1 pageOne of The Best Industry in The World Is Hotel Industry and The Hotel Industry Is Growing Like Any Thing in The Developing CountryveereshkoutalNo ratings yet

- Tourism Is Travel For RecreationDocument1 pageTourism Is Travel For RecreationveereshkoutalNo ratings yet

- The origins and naming of "BollywoodDocument1 pageThe origins and naming of "BollywoodveereshkoutalNo ratings yet

- 3 Axis Surface Machining (Smgug - C2, DISC 1, Online, Samples)Document429 pages3 Axis Surface Machining (Smgug - C2, DISC 1, Online, Samples)Clode23No ratings yet

- KeyDocument1 pageKeyveereshkoutalNo ratings yet

- Mechanical Tolerance Design Tables & CalculatorsDocument1 pageMechanical Tolerance Design Tables & CalculatorsveereshkoutalNo ratings yet

- Karnataka in India MapDocument6 pagesKarnataka in India MapveereshkoutalNo ratings yet

- 3 Axis Surface Machining (Smgug - C2, DISC 1, Online, Samples)Document429 pages3 Axis Surface Machining (Smgug - C2, DISC 1, Online, Samples)Clode23No ratings yet

- Principle of ManagementDocument2 pagesPrinciple of ManagementveereshkoutalNo ratings yet

- AgniDocument1 pageAgniveereshkoutalNo ratings yet

- Sia ChinDocument1 pageSia ChinveereshkoutalNo ratings yet

- HubliDocument1 pageHubliveereshkoutalNo ratings yet

- ElephentDocument2 pagesElephentveereshkoutalNo ratings yet

- Instructions for Writing Assignments and Internal Assessment Marks DistributionDocument1 pageInstructions for Writing Assignments and Internal Assessment Marks DistributionveereshkoutalNo ratings yet

- This MIG Welding Jig Is Fabricated by Using Stainless Steel BlockDocument1 pageThis MIG Welding Jig Is Fabricated by Using Stainless Steel BlockveereshkoutalNo ratings yet

- WorldDocument1 pageWorldveereshkoutalNo ratings yet

- HAveriDocument2 pagesHAveriveereshkoutalNo ratings yet

- Ethics (Also Moral Philosophy) Is The Branch Of: Philosophy Conduct Ancient Greek Habit Axiology AestheticsDocument1 pageEthics (Also Moral Philosophy) Is The Branch Of: Philosophy Conduct Ancient Greek Habit Axiology AestheticsveereshkoutalNo ratings yet

- Environmental PollutionDocument2 pagesEnvironmental PollutionEdina MohacsanNo ratings yet

- Some Eligible Project Types May IncludeDocument1 pageSome Eligible Project Types May IncludeveereshkoutalNo ratings yet

- ReformsDocument1 pageReformsveereshkoutalNo ratings yet

- SCDL Project GuidelinessDocument12 pagesSCDL Project GuidelinessveereshkoutalNo ratings yet

- AckDocument1 pageAckveereshkoutalNo ratings yet

- LifeDocument2 pagesLifeveereshkoutalNo ratings yet

- Freight & Logistics Project ReportDocument62 pagesFreight & Logistics Project Reportveereshkoutal0% (1)

- This MIG Welding Jig Is Fabricated by Using Stainless Steel BlockDocument1 pageThis MIG Welding Jig Is Fabricated by Using Stainless Steel BlockveereshkoutalNo ratings yet

- White Box Testing Is When The Tester Has Access To The Internal Data Structures and Algorithms Including The Code That Implement TheseDocument1 pageWhite Box Testing Is When The Tester Has Access To The Internal Data Structures and Algorithms Including The Code That Implement TheseveereshkoutalNo ratings yet

- PavanDocument3 pagesPavanveereshkoutalNo ratings yet

- Environmental Management Through Environmental Impact AssessmentDocument26 pagesEnvironmental Management Through Environmental Impact AssessmentSanjana RaviNo ratings yet

- Software Engg. Question Paper - 40 CharacterDocument14 pagesSoftware Engg. Question Paper - 40 Characteranon_572289632No ratings yet

- SteelDocument23 pagesSteelMelinda GordonNo ratings yet

- LP - CELTA TP7 READING - FaziDocument6 pagesLP - CELTA TP7 READING - FaziPin juNo ratings yet

- Erasmus Module CatalogueDocument9 pagesErasmus Module Catalogueelblaco87No ratings yet

- 0452 s18 Ms 12Document14 pages0452 s18 Ms 12Seong Hun LeeNo ratings yet

- Importance of Active ListeningDocument13 pagesImportance of Active ListeningJane Limsan PaglinawanNo ratings yet

- Philosophy BrochureDocument2 pagesPhilosophy Brochureapi-512190037No ratings yet

- Flirt English (2. Staffel): 1. Welcome to BrightonDocument3 pagesFlirt English (2. Staffel): 1. Welcome to BrightonFamilyGangNo ratings yet

- Grade 7 - 10 Class Program Sy 2022 2023Document4 pagesGrade 7 - 10 Class Program Sy 2022 2023Niel Marc TomasNo ratings yet

- The Literature Review Six Steps To SuccessDocument5 pagesThe Literature Review Six Steps To Successafmabbpoksbfdp100% (1)

- Anaswara M G: Neelambari, Thottungal Residential Association, Westyakkara, Palakkad, Kerala, 678014Document3 pagesAnaswara M G: Neelambari, Thottungal Residential Association, Westyakkara, Palakkad, Kerala, 678014AnaswaraNo ratings yet

- Iii-Ii Final PDFDocument44 pagesIii-Ii Final PDFChinsdazz KumarNo ratings yet

- TLE7 Q1 W2 DressmakingDocument18 pagesTLE7 Q1 W2 DressmakingShema Merchs100% (2)

- Six Principles of Special EducationDocument36 pagesSix Principles of Special EducationIsabella Marie GalpoNo ratings yet

- Cooperative Learning Promotes Student SuccessDocument9 pagesCooperative Learning Promotes Student SuccessKalai SelviNo ratings yet

- Advertisements and Their Impacts: A Guide to Common Writing TopicsDocument20 pagesAdvertisements and Their Impacts: A Guide to Common Writing TopicsdumbsimpNo ratings yet

- 4037 w17 Ms 22Document8 pages4037 w17 Ms 22arcanum78No ratings yet

- 50 Habits of Highly Successful PeopleDocument1 page50 Habits of Highly Successful Peoplell_pabilonaNo ratings yet

- QUarter 2 Week 1 MILDocument8 pagesQUarter 2 Week 1 MILSalbich TvNo ratings yet

- Transformacija Vojske Srbije PONOSScreen reader users, click here to turn off Google Instant. WebBooksShoppingVideosImagesMoreSearch tools About 119,000 results (0.37 seconds) Search Results Prokleta avlija - Wikipedia, slobodna enciklopedija ... sh.wikipedia.org/.../Proklet... Translate this pageSerbo‑Croatian Wikipedia U Andrićevoj noveli, Prokleta avlija je naziv poznate carigradske tamnice, u koju je iz neopravdanih razloga dospeo fra-Petar iz Bosne, koga su poslali u ... Radnja - Pripovedanje u prokletoj avliji - Višestruki naratori - Ekranizacija Ivo Andrić - Prokleta avlija prepričano lektira | Lektire.me www.lektire.me/.../ivo-andric-prokleta-avlija_21 Translate this page Pročitajte prepričavanje i detaljnu analizu književnog dela Ivo Andrić - Prokleta avlija. Prepričana lektira: Prokleta avlija - Ivo Andrić - Opušteno opusteno.rs › Diskusije › Književni kutak Translate this page Prepričana lektira: Prokleta avlija - Ivo Andrić Ivo Andrić – Prokleta avlija - kratak sadržajDocument22 pagesTransformacija Vojske Srbije PONOSScreen reader users, click here to turn off Google Instant. WebBooksShoppingVideosImagesMoreSearch tools About 119,000 results (0.37 seconds) Search Results Prokleta avlija - Wikipedia, slobodna enciklopedija ... sh.wikipedia.org/.../Proklet... Translate this pageSerbo‑Croatian Wikipedia U Andrićevoj noveli, Prokleta avlija je naziv poznate carigradske tamnice, u koju je iz neopravdanih razloga dospeo fra-Petar iz Bosne, koga su poslali u ... Radnja - Pripovedanje u prokletoj avliji - Višestruki naratori - Ekranizacija Ivo Andrić - Prokleta avlija prepričano lektira | Lektire.me www.lektire.me/.../ivo-andric-prokleta-avlija_21 Translate this page Pročitajte prepričavanje i detaljnu analizu književnog dela Ivo Andrić - Prokleta avlija. Prepričana lektira: Prokleta avlija - Ivo Andrić - Opušteno opusteno.rs › Diskusije › Književni kutak Translate this page Prepričana lektira: Prokleta avlija - Ivo Andrić Ivo Andrić – Prokleta avlija - kratak sadržajGoran VukadinovicNo ratings yet

- Teaching Reading Skills in A Foreign Language: Christine E Nuttall J. Charles AldersonDocument1 pageTeaching Reading Skills in A Foreign Language: Christine E Nuttall J. Charles AldersonQyQynNo ratings yet

- Lesson Plan Biology 6th ClassDocument4 pagesLesson Plan Biology 6th ClassManju kotturNo ratings yet

- FR QB Vol 1 J23Document473 pagesFR QB Vol 1 J23gopal adhikariNo ratings yet

- G10 - Portfolio Assessment 1 - 2022-2023Document2 pagesG10 - Portfolio Assessment 1 - 2022-2023ayush rajeshNo ratings yet