Professional Documents

Culture Documents

M K Hassanin2015

Uploaded by

NDTInstructorOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

M K Hassanin2015

Uploaded by

NDTInstructorCopyright:

Available Formats

NDT Level 3 Engineer Curriculum vitae

worktown Address: ezdan 31 R26B, Elwakir,Qatar, Cell: +97455112946, m.karim@qcon.com.qa

Hometown Address: 13 El-Khedr Street mohram Baik, Alexandria-Egypt, mohamed.karim85@gmail.com

MOHAMED KARIM RAMY KAMEL HASSANIN

DESIGNATION: Appointed NDT Level 3 , Lead QA/QC Engineer

Education

BSc Production Engineering Department, Alexandria University, July 2009. Graduation Project: Comparative Study of

Welding Codes (API1104, ASME9, AWS D1.1) and Their applications on Procedure qualification Under supervision of Dr.

Ismail A. Abd Allah, Grade: Excellent

Qualfiection Summary :

Certification

PCN Level 3 UT

PCN Level 3 RT

PCN Level 3 MT

PCN Level 3 PT

PCN Level 2 UT

PCN Level 2 RT

PCN Level 2 MT

PCN Level 2 PT

Bas. Safety Rad.

ASNT Level III UT

ASNT Level III RT

ASNT Level III MT

ASNT Level III PT

ASNT Level III VT

API 570

API 510

PCN ID: 326521

Cert. ID.

E014S3335457

E014S3233500

E014S5435474

E014S5538452

E014S9818828

E014S3227824

E014s5426539

E014S5524081

E014S9818828

187350

187350

187350

187350

187350

45933

55984

ASNT ID:187350

Examination Place

Lavender NDT, UK

Lavender NDT, UK

Lavender NDT, UK

Lavender NDT, UK

Lavender NDT, UK

Lavender NDT, UK

Lavender NDT, UK

Lavender NDT, UK

Lavender NDT, UK

Quality Control Egypt

Quality Control Egypt

Quality Control Egypt

Quality Control Egypt

Quality Control Egypt

Prometric-Egypt

Prometric-Qatar

API ID:85552

Professional Experience Summary

Period

Jan 2014 till Now

July 2009 to July 2010

Position

QA/QC Lead Engineer &

Appointed NDT level 3

QA/QC Engineer & NDT

Engineer

QA/QC Junior Engineer

Jan 2007 to June 2009

NDT Technician

August 2010 to Jan 2014

Contract type

Permananet

Permanent

Project

Contract

Part time

Employer

Qatar Engineering and Construction Co.

(Qcon)

Peteroleum Project and Technicanl

Consultation (PetroJet)

ESACO Construction Company

Egyptian Welding Academy

Instructor Experience Summary

Working as freelancer NDT trainer with Egyptian welding Academy from october 2010 to Dec,2013

Page 1 of 4

MOHAMED KARIM MOHAME D RAMY

DESIGNATION: Appointed NDT Level 3 , Lead QA/QC Engineer

PROFESSIONAL EXPERIENCE

Current Employer

January 2014 Present

Qatar Engineering & Construction Co.

Working with Qatar Engineering & Construction Co. W.L.L (Q CON) as a

Appointed NDT Level III

QA/QC Engineer

Responsibilities

prepare, review and Approve Written Practice and NDE procedures in accordance with the

requirements of BS ISO standards ,ASME Code Sections V, VIII, IX and other relevant documents.

Train,qualify,and examine the NDE personnel inaccordance with company written practice.

Conducting performance test for subcontractor NDT technicians.

Audit and Review NDE sub-contractors procedures , written practice and personnel certification

documents to meet Clients/ Company requirements and recommend changes or updates, and

follow up audit shall be done for preventive actions of NCR.

Carrying out NDT Assessment/Audit for Projects for Personnel Qualification and Techniques.

Radiographic film interpretation of weld joints

Reviewing and approving NDT reports, Witnessing NDT activities at site.

Discuss quality, safety and NDT deficiencies, specifications deviations and negative inspection

findings with the clients Personal to develop win solutions.

Ensure safety standards and requirements are observed and bring policy matters to attention of

superiors.

Audit company (NDT SUB CONTRACTOR AND NDT SERVICE PROVIDER).

Interface with management to discuss improvements to NDTprogram.

Monitoring NDT equipments are calibrated periodically in project site.

Attend the client's meeting regarding NDT and take corrective and preventive action for their

complains accordingly.

Ensure that the Safety, Quality&Environment requirements of they are strictly followed

Past Experience

1st:August 2010 to Jan,2014

Company: Petroleum project & technical consultation

(PetroJet)Job:QC/QA Engineer

Projects Involved

1. Construction of New Ethan Propane Maximization - from August 2010 to May 2011

Client : The Egyptian Natural Gas Company (GASCO)

Designer: Engineering for the Petroleum & Process Industries (ENPI)

Page 2 of 4

MOHAMED KARIM MOHAME D RAMY

DESIGNATION: Appointed NDT Level 3 , Lead QA/QC Engineer

Responsibilities

Reviewing WPS/ PQR/ WQT records

Preparing QC Reports.

Check Piping Fitup

Check Visual welded Joints

Monitoring of consumable

Interpretation of radigraphic film of welded joints

2. Construction of hydrotreating naphtha -80,000 inches of piping - from May 2011 to April 2013

Client: Alexandria National Refining and Petrochemicals Company(ANRPC)

Designer: Engineering for the Petroleum & Process

Industries (ENPI)

Responsibilities

Developing welding and NDE control system in the Qcon .

Studying the QCP, ITP, Method of statement and work procedures and schedule the job as per these datas.

Reviewing WPS/ PQR/ WQT records

Co-ordination with client during quality walks through.

Rising of NCR/CAR/TQ.

Preparing QC Reports.

Check Piping Fitup

Check Visual welded Joints

Monitoring of consumable

Interpretation of radigraphic film of welded joints

Preparing Punchlist for Piping loops and systems

3. Construction of 8 spherical tanks (3000 M3), 460,000 T/Y ethylene - from May 2013 to Jan 2014

Client: Egyptian Ethylene and Derivatives Company (Ethydco)

Designer: ENPI&TOYO (JV)

Responsibilities

Studying the QCP, ITP, Method of statement and work procedures and schedule the job as per these datas.

Reviewing WPS/ PQR/ WQT records

Conducting welder qualification test.

Monitoring welding consumables

Preparation and qualification of welding procedure specification.

Preparation and implementation of quality plan &Inspection and test Plane

investigation of preparation of Non-conformance report

Preparation and approval of inspection test plan

Checking fit-up ,dimenstion and releasing for welding

Checking column verticality and sphere roundess.

Performing Ultrasonic Testing on welded Joints

Interpretation radiographic films for welded joints

prepare punchlist for sphereical tank

Page 3 of 4

MOHAMED KARIM MOHAME D RAMY

DESIGNATION: Appointed NDT Level 3 , Lead QA/QC Engineer

2nd July2009 To July 2010

Company: ESACO for Engineering and manufacturing

Job: QA /QC Engineer

Projects Involved

ElSwedy Cement Project, Al-Soukhna, Suez, 6000 TPD (ESCC-line 1)

Client: El-Swedy cement Company

Designer: FLSmidth - Cement Production Consultant (CPC)

Responsibilities

Check dimension of duct and steel work

Check alignment of fans using face and rim method

Visual inspection of welded joints

Witness of welding of clinker rotating furnace using Sumberged Arc Welding

Ultrasonic inspection on cement filter frames,clinker rotating furnace and clinker mill base

3rd Jan,2007 to June 2009 (UnderGraduate Experience)

Company: Egyptian Welding Academy

Position: NDT Technicians (Part Time)

Responsibilities

Demostration for NDT trainees how to setup calibration for Ultrasonic Equipment

Demonstration of NDT trainees how to perform Ultrasonic inspection on welded plates

Demonstate for NDT trainees how to Perform complete MT,PT Testing on forging,casting and

welding

Instructor Experience

Course : Radiographic Testing Level II

Participants Qualifications: Khalda Petroleum Company Engineers

Date: Mar, 2013

Training Conductor: Oil and Gas Skills

Course : Process Piping Fundamental

Participants Qualifications: Petroleum Section Construction Engineers

Date: May, 2013

Training Conductor: Oil and Gas Skills

Training more than 250 trainees with Egyptian welding Academy in MT,RT,VT and UT from

October 2010 till Dec,2013

Personal Information

Nationality: Egyptian

Date of Birth: 29/10/1985

Marital Status: (Married and have one child)

Driving License: Egyptian,Qatari and International Valid Licence

Last Updated at 7th of Jan, 201

Page 4 of 4

You might also like

- PAUT Vs RadiographyDocument1 pagePAUT Vs RadiographyNDTInstructorNo ratings yet

- NigieriaDocument12 pagesNigieriaNDTInstructorNo ratings yet

- TunisiaDocument4 pagesTunisiaNDTInstructorNo ratings yet

- Forging DefectsDocument1 pageForging DefectsNDTInstructor0% (1)

- Color Vision TestDocument1 pageColor Vision TestNDTInstructorNo ratings yet

- Color Vision TestDocument1 pageColor Vision TestNDTInstructorNo ratings yet

- Job Description NDTDocument4 pagesJob Description NDTNDTInstructorNo ratings yet

- A309 Bolting: Appendix F Para. F309 Paragraph 309.1 Para. 309.1 Para. A335.2Document1 pageA309 Bolting: Appendix F Para. F309 Paragraph 309.1 Para. 309.1 Para. A335.2NDTInstructorNo ratings yet

- Piping 4Document1 pagePiping 4NDTInstructorNo ratings yet

- H300 Introduction (Si Units) : Para. 304.3.3Document2 pagesH300 Introduction (Si Units) : Para. 304.3.3NDTInstructorNo ratings yet

- Piping 3Document1 pagePiping 3NDTInstructorNo ratings yet

- (A) Elastic Behavior. The Assumption That DisplaceDocument1 page(A) Elastic Behavior. The Assumption That DisplaceNDTInstructorNo ratings yet

- Piping 4Document1 pagePiping 4NDTInstructorNo ratings yet

- 344.2 Visual Examination: Para. 344.7Document1 page344.2 Visual Examination: Para. 344.7NDTInstructorNo ratings yet

- MTDocument1 pageMTNDTInstructorNo ratings yet

- Non-Destructive Testing: Sample Questions For Conduct of Examinations at Levels 1 and 2Document242 pagesNon-Destructive Testing: Sample Questions For Conduct of Examinations at Levels 1 and 2darqm589% (18)

- Shell Settlement EvaluationDocument1 pageShell Settlement EvaluationNDTInstructorNo ratings yet

- Optimized Performance For Wall Thickness and LiftoffDocument1 pageOptimized Performance For Wall Thickness and LiftoffNDTInstructorNo ratings yet

- Api 580Document1 pageApi 580NDTInstructorNo ratings yet

- General TankDocument2 pagesGeneral TankNDTInstructorNo ratings yet

- Tank Inspection SolutionDocument7 pagesTank Inspection SolutionNDTInstructorNo ratings yet

- Eddify Lyft Presentation DocumentDocument4 pagesEddify Lyft Presentation DocumentBernardo FariasNo ratings yet

- Solutionstainlesssteelweldinspection 170124181624Document13 pagesSolutionstainlesssteelweldinspection 170124181624NDTInstructorNo ratings yet

- Olympus Multiscan Ms 5800 Er1uDocument2 pagesOlympus Multiscan Ms 5800 Er1uNDTInstructorNo ratings yet

- Procedure CFVDocument13 pagesProcedure CFVNDTInstructorNo ratings yet

- Inspections and Audits For Boilers and Pressure VesselsDocument2 pagesInspections and Audits For Boilers and Pressure VesselsNDTInstructorNo ratings yet

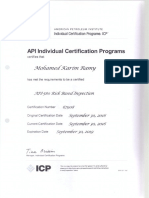

- API Individual Certification Programs: Mohamed Karim RamyDocument1 pageAPI Individual Certification Programs: Mohamed Karim RamyNDTInstructorNo ratings yet

- API Individual Certification Programs: Mohamed Karim RamyDocument1 pageAPI Individual Certification Programs: Mohamed Karim RamyNDTInstructorNo ratings yet

- Job Hazard AnalysisDocument5 pagesJob Hazard AnalysisNDTInstructorNo ratings yet

- Vision CertificateDocument1 pageVision CertificateNDTInstructorNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Quiz 1.1 2021 LectureDocument4 pagesQuiz 1.1 2021 LectureSupia NazmaNo ratings yet

- Fish Smoking ProceduresDocument42 pagesFish Smoking Proceduresanegbe1199100% (1)

- Exer 1 Translocation of MaterialsDocument32 pagesExer 1 Translocation of MaterialsofficialpatdeeNo ratings yet

- Utilization of Natural Polyelectrolytes in Wastewater TreatmentDocument181 pagesUtilization of Natural Polyelectrolytes in Wastewater TreatmentCédric RochatNo ratings yet

- Mark Scheme (Results) January 2022: Pearson Edexcel International GCSE in Chemistry (4CH1) Paper 2CRDocument15 pagesMark Scheme (Results) January 2022: Pearson Edexcel International GCSE in Chemistry (4CH1) Paper 2CRMohamed MuhajireenNo ratings yet

- Ketoconazole: SampleDocument7 pagesKetoconazole: SampleJuan PerezNo ratings yet

- Industrial - Cord Chemicals IncDocument1 pageIndustrial - Cord Chemicals IncEddie Resurreccion Jr.No ratings yet

- Electrodeposition of Cu - SWCNT CompositesDocument14 pagesElectrodeposition of Cu - SWCNT CompositesSorina gNo ratings yet

- ExtrusionDocument9 pagesExtrusionOdebiyi StephenNo ratings yet

- Steel Fence Post & Foundation DetailsDocument2 pagesSteel Fence Post & Foundation Detailsjaouad id boubkerNo ratings yet

- 5 PlasterDocument3 pages5 PlasterMuhammad AgungNo ratings yet

- Lesson 1 Agricultural Crop Production: Use of Farm ToolsDocument25 pagesLesson 1 Agricultural Crop Production: Use of Farm Toolsdee dreamer13No ratings yet

- MitomapDocument1,079 pagesMitomaproymalindoNo ratings yet

- DP1SL Redox UT VCDocument6 pagesDP1SL Redox UT VCmarilee huntNo ratings yet

- Beetroot IA JilleanDocument10 pagesBeetroot IA Jilleanzeen2011No ratings yet

- Modern Saw Welding Guide C5.50 PDFDocument136 pagesModern Saw Welding Guide C5.50 PDFalberto feliciano teixeiraNo ratings yet

- 0620 Chemistry: MARK SCHEME For The May/June 2012 Question Paper For The Guidance of TeachersDocument6 pages0620 Chemistry: MARK SCHEME For The May/June 2012 Question Paper For The Guidance of TeachersmohammadNo ratings yet

- Experimental Techniques For Measuring Sewing Needle TemperatureDocument8 pagesExperimental Techniques For Measuring Sewing Needle TemperatureATLASNo ratings yet

- Biochem Hw1 CellDocument5 pagesBiochem Hw1 Celljazzmin ivy evaNo ratings yet

- Lecture Sheet PDFDocument65 pagesLecture Sheet PDFFaruk abdullahNo ratings yet

- Aldehyde and Ketone Madam GanDocument3 pagesAldehyde and Ketone Madam GannursyahirahNo ratings yet

- Chemical Reactions Unit Plan FinalDocument27 pagesChemical Reactions Unit Plan Finalapi-346594405No ratings yet

- Principles and Practices of Modern Coal Mining - R. D. Singh - Ch2Document49 pagesPrinciples and Practices of Modern Coal Mining - R. D. Singh - Ch2rrathore50% (4)

- Brief Company Profile: Manuli Rubber Industries (MRI)Document36 pagesBrief Company Profile: Manuli Rubber Industries (MRI)Le Anh DangNo ratings yet

- Dividing Wall Technology in Distillation ColumnsDocument5 pagesDividing Wall Technology in Distillation ColumnsAmda AmdaNo ratings yet

- Trisodium CitrateDocument2 pagesTrisodium CitrateAqmar Aqeem Bin AzharNo ratings yet

- Chapter 1 The Scientific Endeavour PDFDocument49 pagesChapter 1 The Scientific Endeavour PDFNadya Chalista Agusthine100% (1)

- HPLC 4Document39 pagesHPLC 4Naveen YaparthiNo ratings yet

- Chemical EquilibriumDocument31 pagesChemical Equilibriumrohan raj100% (1)

- Ecosystems QP Edexcel IalDocument19 pagesEcosystems QP Edexcel IalAyesha TauseefNo ratings yet