Professional Documents

Culture Documents

Simulación Intercambiador

Simulación Intercambiador

Uploaded by

Andrés Torres VivasCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Simulación Intercambiador

Simulación Intercambiador

Uploaded by

Andrés Torres VivasCopyright:

Available Formats

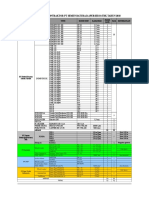

Heat Exchanger Thermal Design

Shell&Tube V7.2.1 CP1Page 1

File: Untitled.edr

Date: 12/12/2014

Time: 02:56:16 p.m.

Basic geometry

Unit Configuration

BEM

Exchanger Type

Hor

Position

1 par

Arrangement

1 ser

Single segmental

Baffle type

Baffle number

Tube passes

Plain

Tube type

in

0,75

Tube pitch

in

0,9375

12,75

Spacing at inlet

in

15,625

Inside Diameter

Shell

6,625

30

Tube pattern

Kettle

Front head

6,657

6,407

Number of nozzles

Tube Side

Inlet

Outlet

Inlet

Outlet

Actual outside diameter

in

1,66

1,66

0,84

0,84

Inside diameter

in

1,38

1,38

0,622

0,622

Height under nozzle

in

0,3928

0,3928

Dome inside diameter

in

Vapor belt inside diameter

in

Vapor belt inside width

in

Vapor belt slot area

Impingement protection

Distance to tubesheet

in

No

No

No

impingement impingement impingement

68

3,75

in

Rear head

6,657

6,407

6,407

Shell Side

Nozzle type

ft

Tube O.D.

in

in

in

Tube length actual

Spacing (center-center)

Outside diameter

31

Tube number (calcs.)

Heat Exchanger Thermal Design

Shell&Tube V7.2.1 CP1Page 2

File: Untitled.edr

Date: 12/12/2014

Time: 02:56:17 p.m.

Tubes

Tubes

Type

Plain

Total number

Number of tubes plugged

31

0

Outside diameter

in

0,75

Inside diameter

in

0,652

Tube length actual

ft

Wall thickness

in

0,049

Tube length effective

ft

5,7917

1,15

Tubesheet thickness

in

1,125

Area ratio Ao/Ai

Pitch

in

0,9375

30

Pattern

Thermal conductivity

External enhancement

Internal enhancement

Low circumferential fins

Low longitudinal fins

Fin density

#/in

Copper

Material

BTU/(ft h F)

Fin number

224,999

Fin height

in

Fin thickness

in

Fin thickness

in

Fin height

in

Tube root diameter

in

Fin spacing

in

Tube wall thickness under fin

in

Cut and twist length

in

Tube inside diameter under fins

in

Heat Exchanger Thermal Design

Shell&Tube V7.2.1 CP1Page 3

File: Untitled.edr

Date: 12/12/2014

Time: 02:56:17 p.m.

Baffles

Baffles

Type

Single segmental

Yes

Tubes in window

Number

Baffle cut: inner / outer / interm

Actual (% diameter)

Nominal (% diameter)

37,33

40

Spacing (center-center)

in

12,75

Actual (% area)

Spacing at inlet

in

15,625

Cut orientation

Spacing at outlet

in

15,625

Thickness

Spacing at central in/out for G,H,I,J shells

in

Tube rows in baffle overlap

Spacing at center of H shell

in

Tube rows in baffle window

2,5

End length at front head

in

16,875

Baffle hole - tube od diam clearance

in

0,0313

End length at rear head

in

16,875

Shell id - baffle od diam clearance

in

0,125

VariableBaffles

Baffle spacing

in

Baffle cut percent, outer

Baffle cut percent, inner

Number of baffle spaces

Baffle region length

Baffle cut area percent, outer

Baffle cut area percent, inner

in

34,04

H

in

0,1875

Heat Exchanger Thermal Design

Shell&Tube V7.2.1 CP1Page 4

File: Untitled.edr

Date: 12/12/2014

Time: 02:56:17 p.m.

Bundle

Frame1

Bundle

Shell ID to center 1st tube row

Tube passes

in

From top

0,3928

Tube pass layout

Ribbon (single band)

From bottom

0,3928

Tube pass orientation

Standard (horizontal)

From right

0,4848

U-bend orientation

From Left

0,4848

Horizontal pass lane width

in

Vertical pass lane width

in

Impingement protection

None

undefined

Impingement distance

in

Interpass tube alignment

Impingement plate diameter

in

Deviation in tubes/pass

Impingement plate width

in

Outer tube limit

in

5,907

Impingement plate length

in

Shell id - bundle otl diam clearance

in

0,5

Impingement plate thickness

in

Tie rod number

Gross surface area per shell

ft

36,5

Tie rod diameter

Effective surface area per shell

ft

35,3

Sealing strips (pairs)

Bare tube area per shell

ft

35,3

Tube to tubesheet joint

Finned area per shell

ft

Tube projection from front tsht

in

0,125

U-bend area per shell

ft

Tube projection from rear tsht

in

0,125

No

0

4

in

0,376

1

Exp.

Heat Exchanger Thermal Design

Shell&Tube V7.2.1 CP1Page 5

File: Untitled.edr

Date: 12/12/2014

Time: 02:56:17 p.m.

Enhancements

Internal enhancements

Tube insert type

None

Twisted tape 360 deg twist pitch

in

Twisted tape thickness

in

hiTRAN part number

Cost/weights

Weights

Shell

lb

Cost data

Dollar(US)

171,1

Labor cost

4332

Front head

10,8

Tube material cost

Rear head

12,8

Material cost (except tubes)

1569

529

Shell cover

Bundle

104,7

Total weight - empty

299,5

Total cost (1 shell)

6431

Total weight - filled with water

374,3

Total cost (all shells)

6431

Heat Exchanger Thermal Design

Shell&Tube V7.2.1 CP1Page 6

File: Untitled.edr

Date: 12/12/2014

Time: 02:56:17 p.m.

Setting Plan

Views on arrow A

A

95,2035 Overall

6,7268

4,875 3,75

64,25

8,875

T2

S1

T1

S1

S2

4,875

10

T1

Pulling Length

14,375

43,25

61

S2

2,0

2,0

Ref

S1

S2

T1

T2

OD

1,66"

1,66"

0,84"

0,84"

Wall

0,14"

0,14"

0,109"

0,109"

Nozzle Data

Standard

150 ANSI Slip on

150 ANSI Slip on

150 ANSI Slip on

150 ANSI Slip on

Notes

Design Data

Design Pressure

Design Temperature

Full Vacuum

Corrosion Allowance

Test Pressure

Number of Passes

Radiography

PWHT

Internal Volume

5,8

1,4375

1,4375

5,8

T2

4,0

4,0

2 Bolts

Fixed

2 Bolts

Sliding

Units

psi

F

Shell

50,

190,

Channel

50,

190,

in

psi

0,

0,

1,2999

0,4098

ft

Intercambiador de Calor Exkova

Aspen Shell & Tube Exchanger

Setting Plan

BEM 6 - 72

Design Codes

ASME Section VIII Div. 1

TEMA R

Drawing Number

Customer Specifications

Empty

299 lb

Weight Summary

Flooded

374 lb

Bundle

105 lb

Revision

Date

12/12/2014

Dwg.

Chk.

App.

Heat Exchanger Thermal Design

Shell&Tube V7.2.1 CP1Page 7

File: Untitled.edr

Date: 12/12/2014

Time: 02:56:17 p.m.

2,44 in

Tube Layout

Shell inside diameter

in

6,407

Front head inside diameter

in

6,407

Outer tube limit

in

2,44 in

Tube number (calcs.)

5,907

31

Tube O.D.

in

Tube pitch

in

0,75

0,9375

Tube pattern

30

Tube passes

Tie rod number

Tie rod diameter

in

Sealing strips (pairs)

0,376

1

Baffle type

Single segmental

Impingement protection

None

Tube length

in

72,

Shell Side Inlet Nozzle Inside Diameter

in

1,38

Shell Side Outlet Nozzle Inside Diameter

in

1,38

Intercambiador de Calor Exkova

Aspen Shell & Tube

Tube Layout

Design Codes

ASME Code Sec VIII Div 1

TEMA R - refinery service

0,75

Drawing Number

31

0,94

Customer Specifications

Revision

Date

12/12/2014

Dwg.

App.

Heat Exchanger Thermal Design

File: Untitled.edr

Ubend details

Shell&Tube V7.2.1 CP1Page 8

Date: 12/12/2014

Time: 02:56:17 p.m.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Assignment Print View 3.7Document6 pagesAssignment Print View 3.7Zach JaapNo ratings yet

- ROI - TCO Calculator v0.4Document29 pagesROI - TCO Calculator v0.4samiransdcNo ratings yet

- R12 - Table/View Changes, Additions: Echnical OcumentDocument97 pagesR12 - Table/View Changes, Additions: Echnical OcumentSameer KulkarniNo ratings yet

- De Moivre TheoremDocument2 pagesDe Moivre TheoremSteve SchouppNo ratings yet

- Ground Floor Plan: General NotesDocument1 pageGround Floor Plan: General NotesChaturbhuj Ikat FabricsNo ratings yet

- Direct Memory AccessDocument16 pagesDirect Memory AccessHerambh DubeyNo ratings yet

- مشروع عبدالرحمن +زيدDocument15 pagesمشروع عبدالرحمن +زيدAbdulrahman AlsalawiNo ratings yet

- Promissory NoteDocument10 pagesPromissory NoteMALKANI DISHA DEEPAKNo ratings yet

- Cylon Voice Changer ProjectDocument4 pagesCylon Voice Changer ProjectBenjamin DoverNo ratings yet

- Ceaser CiperDocument7 pagesCeaser Ciperalhridoy01010No ratings yet

- Elmer TutorialsDocument152 pagesElmer TutorialsfabianoconbrasNo ratings yet

- Completed Unit II 17.7.17Document113 pagesCompleted Unit II 17.7.17Dr.A.R.KavithaNo ratings yet

- Health Insurance in IndiaDocument20 pagesHealth Insurance in IndiaazharscribdNo ratings yet

- Complete Deck of Many ThingsDocument1 pageComplete Deck of Many ThingsErnesto de VegaNo ratings yet

- TL-WR841HP - V5 - Datasheet PDFDocument6 pagesTL-WR841HP - V5 - Datasheet PDFJhair Michele Andree Díaz AranaNo ratings yet

- Airline FinalDocument2 pagesAirline FinalI am ab YesNo ratings yet

- Anthropogoly ReflectionDocument4 pagesAnthropogoly Reflectionapi-300780000No ratings yet

- Slide SPINE Infeksi YudhaDocument25 pagesSlide SPINE Infeksi YudhauntungNo ratings yet

- Populasi Alat Kontraktor PT Semen Baturaja (Persero) TBK Tahun 2018Document1 pagePopulasi Alat Kontraktor PT Semen Baturaja (Persero) TBK Tahun 2018Dwiki KurniawanNo ratings yet

- 3 Assumptions and ApproximationsDocument5 pages3 Assumptions and ApproximationsJack RyderNo ratings yet

- 3bet Pot HeuristicsDocument21 pages3bet Pot HeuristicsJeremiah Bailey-HooverNo ratings yet

- Group I Study Material, Telugu Medium & English Medium, Sakshieducation2Document1 pageGroup I Study Material, Telugu Medium & English Medium, Sakshieducation2Ravi Kumar MogilsettiNo ratings yet

- Chapter 12 BDocument3 pagesChapter 12 Bjuhi993No ratings yet

- Himesh Koul: ExperienceDocument1 pageHimesh Koul: ExperienceTuhin ChakrabortyNo ratings yet

- Cjmo 2023Document2 pagesCjmo 2023ferrousweiNo ratings yet

- Kvaser Usbcan Light User'S GuideDocument16 pagesKvaser Usbcan Light User'S GuidekevreidsNo ratings yet

- Intel 2002 : MicroprocessorsDocument25 pagesIntel 2002 : MicroprocessorsFranch Maverick Arellano LorillaNo ratings yet

- Interfacing RTC DS3231 With 8051 Microcontroller - Codrey ElectronicsDocument19 pagesInterfacing RTC DS3231 With 8051 Microcontroller - Codrey ElectronicsmcamhkNo ratings yet

- An Overview of Deep Learning in Medical Imaging FoDocument45 pagesAn Overview of Deep Learning in Medical Imaging Fofreak showNo ratings yet

- PCS 7 Water Templates V902 enDocument115 pagesPCS 7 Water Templates V902 enABI RAJESH GANESHA RAJANo ratings yet