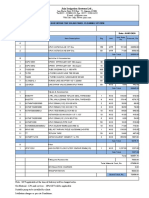

KUOSHENG POOL COOLING PIPE.

BOLTED JOINT 6" WN 150# RF

DESIGN CONDITIONS

0.69

Allowable Stresses

100.00

Flange

Bolting

A-182 F304

Design temp., Sfo

137.00 Design temp., Sb

A-193 B8 Cl 1 Atm. Temp., Sfa

137.90 Atm. Temp., Sa

0.00

No. of bolts

Bolt Nom. Size

Bolt root dia. (a)

FLANGE DIMENSIONS

A=

279.40 B=

154.20 C=

Tentative thickness (t)

25.40 h=

63.50 go

2

GASKET AND FACING DETAILS

Gasket

FLEXITALLIC CG 6" 150#, 4.5 mm

Facing

3

GASKET PARAMETERS

4

LOAD AND BOLT CALCULATIONS

N

13.50 W m2=bGy

2.78E+05 Am=greater of W m2/Sa

1

Design pressure

Design temperature

Flange material

Bolting material

Corrosion allowance

6.55 Hp=2bGmP

b

G

1.68E+04

196.10 H=G2P/4

68.97 W m1=Hp+H

y

m

5

3.00

MOMENT CALCULATIONS

Load

x

Operating

1.30E+04 hD=R+0.5g1

HD=B P/4

2

HG=W m1-H

1.68E+04 hG=0.5(C-G)

8.00E+03 hT=0.5(R+g1+hG)

HT=H-HD

or W m1/Sb

293.80

357.30

8.00

19.05

15.75

3/4" 10 UNC 2A

241.30 R=

7.10 g1=

24.6

18.95

7.79E+02

2.10E+04 Ab

1.56E+03

3.78E+04 W=

4.18E+05 BOLT STRESS =

Lever Arm

267.89

= Moment

34.08 MD=HDhD

22.6 MG=HGhG

4.42E+05

33.08 MT=HThT

Mo

2.65E+05

1.09E+06

3.80E+05

Seating

HG=W

4.18E+05

K AND HUB FACTORS

1.812

1.58

1.88

3.44

3.78

2.67

6

K=A/B

T

Z

Y

U

g1/go

hG=0.5(C-G)

22.6 M'o

h/ho

F (GRAPH APP. XI)

V (GRAPH APP. XI)

f (GRAPH APP. XI)

e=F/ho

d=(U/V)hogo2

9.44E+06

1.92

0.62

0.07

1.00

0.02

9.00E+04

ho = (Bgo)

33.09

STRESS FORMULA FACTORS

7

t

= te+1

= 4/3 te + 1

= /T

= t3/d

= +

25.40

1.48

1.63

0.93

0.18

Bolt spacing

1.12

94.76

56.90

If bolt spacing exceeds 2a+ t , multiply m0 and m G by

bolt spacing

2 a+t

1.29

mo = Mo/B

9.09E+03

mG = Mo/B

7.90E+04

Allowable Stress

Operating

Allowable Stress

Seating

Hub .Longitudin al

Hub .Longitudin al

1.5 Sfo

205.5

S H fmo / g1

22.66 1.5 Sfa

206.85

137.00

Sfo

137.00

Sfo

137.00

S R mo / t 2

Flange . Tangential

S T moY / t 2 ZS R

Greater of 0.5( S H S R )

or 0.5( S H S T )

196.96

Flange .Radial

Flange .Radial

Sfo

S H fmG / g 1

20.62

Sfa

137.90

9.73

Sfa

137.90

S R mG / t 2

Flange . Tangential

S T mG Y / t 2 ZS R

179.20

84.53

Greater of 0.5( S H S R )

21.64

Sfa

137.90

or 0.5( S H S T )

188.08

0.5(SH + SR)

21.64

0.5(SH + SR)

188.08

0.5(SH + ST)

16.19

0.5(SH + ST)

140.75

�Presin (bar)

K (MPa)

k0

da (mm)

dD (mm)

a (mm)

Z (mm3)

FRB (N)

FDV (N)

BRIDA PLANA (Fig. 6 de AD-B8)

CONDICIONES DE DISEO

6.87 Temperatura (C)

20

MATERIAL DE LA BRIDA = St 37-2

235 S

1.5 K20 (MPa)

CARACTERSTICAS DE LA JUNTA

k0 KD

534 k1

995 dt (mm)

826.5 dL (mm)

72.5 v (B8 Fig. 3)

27540

310835.18 FFB (N)

1386545.059 W (mm3)

GEOMETRIA DE LA BRIDA

910 di (mm)

33 s1 (mm)

0.5 d'L (mm)

bD (mm) (B7, Tbl. 1)

47.5

CALCULO DE FRB, FFB, FDB, FSB, FDV (B7)

57745.30 FDB (N)

270966.31 hF (mm)

235

35.6

759

6

16.5

76204.52

43.82

�S'

1.1

SD

1.2

d2 (mm)

ad (mm)

b (mm)

FSB (N)

776

41.75

186

444785.00