DYNA

Power Controls

Product Information

DYNA I Smoke Limit Controller

General

The Barber-Colman DYNA I Controller provides smoke

control on start up for diesel engines using the DYNA 8000

or 8200 electric actuator.(Model DYN1-10695 is used only

with the DYNA 8400 actuator.) These controllers provide

isochronous or droop speed control with both adjustable

start up fuel limit and ramp time.

The controller's electronics are heavily conformal

coated, protecting against moisture and vibrations

associated with engines. It is easy to adjust, having

only SPEED, GAIN and combination INTEGRAL and

DERIVATIVE. The power for the governor is obtained

from the engine's DC starting system, eliminating the

need for mechanical drives and hydraulic lines. Neither the start up fuel limit or ramp need any external

signal for initializing the smoke limit function.

Standard Features

nc

Typical Applications

l

l

o

All electric

All engine compatible diesel and gas

Generator paralleling compatibility

Temperature stable

Remote speed adjustable

High reliability

Mounts in any position

Speed Governing

Generator Sets

Compressors

Power Carts

Pump Sets

r

o

F

on

H

tr

is

i

r

o

ed

l

a

c

Actuator Compatibility

DYNA 8000 and 8200

DYNA 8400 (For use with DYN1-10695 only)

Failsafe

The DYNA Governor has an internal FAILSAFE circuit

that instantly reacts to:

Interruption of the DC power to spring return actuator

to minimum fuel position.

Loss of speed reference signal to remove power from

actuator causing it to spring return to minimum fuel

position.

m

u

c

t

n

e

e

r

e

e

c

n

y

l

n

Speed Sensing

ef

The DYNA all-electric governor requires a frequency

signal to read engine speed. Typically, a hole is drilled

and tapped in the flywheel housing perpendicular to

the crankshaft, and a magnetic pickup is inserted into

it to sense the teeth on the ring gear. Minimum input

signal is 2.5 volt AC RMS.

Input Signal Frequency

Input Signal

Frequency in Hertz =

Engine RPM x Number of Gear

Teeth on Flywheel

60 Seconds

Select controller for the correct input signal frequency

range generated by the magnetic pickup at the maximum

engine operated (RPM) speed, as listed below.

Available Models

Input Signal

Frequency

DYN1-10693-001-0-12/24

DYN1-10693-002-0-12/24*

1200 to 2500 Hz

1200 to 2500 Hz

DYN1-10694-001-0-12/24

DYN1-10694-002-0-12/24*

2500 to 5000 Hz

2500 to 5000 Hz

DYN1-10695-000-0-12*

2500 to 5000 Hz

*

DYNA 129-3

�Control Box Specifications

Smoke Limiting Features

Operating Voltages: 12 or 24 volts, 20%

Barber-Colman's start-up Smoke Limit Controller has

two features for smoke limiting:

Steady State Speed Band Capability: 0.25%

1. Restrictive Fuel Limiting

Ambient Operating Temperature: -40F to +180F

(-40C to +85C)

The start-up fuel limit potentiometer will allow the operator to set a specific fuel limit on start-up. This fuel limit will

be held until the engine obtains 90% of set speed.

Temperature Stability: Better than 0.5% over

temperatures of -40F to +167F (-40C to +75C)

Fuel limit is set by cranking the engine and turning the

fuel limit potentiometer clockwise (CW) until the engine

starts. After engine starts, turn potentiometer an additional 3 to 5% to ensure positive starts.

Mechanical Vibration: Withstands the following

vibration without failure or degraded performance:

0.06 inch double amplitude at 5 to 18 Hz; 1 G at 18

to 30 Hz; 0.02 inch double amplitude at 30 to 48 Hz;

2.5 G's at 48 to 70 Hz.

2. Fuel Ramp

Output Signal: PWM current to 15 amp max

t

n

e

On warm or hot engines, a specific fuel limit setting will

control start-up smoke, but not completely. A warm or

hot engine does not need the same fuel limit to start as

a cold engine does.

Connection: Terminal strip

y

l

n

m

O

u

To reducec

smoke even further on start-up for a warm or

etime can be set. Ramp time

hot engine,

a specific ramp

o

Enclosure: Die cast aluminum

c

canD

be set from 0 to 10 seconds. The ramp time starts

nfailsafe, allowing fuel setting to

from release of the

e

Weight: 1.36 lbs. (.62 kg)

dincrease over the

r selected ramp time.

e

e

l

f

l

e

o

Control Box Adjustments

R

r

t

l

Speed Setting: 20 turn potentiometer n

a

c

o

i

Gain: Single turn potentiometer c

r

n

o

Integral/Derivative: SingleU

turn potentiometer

st

i

Droop: Single turn potentiometer approx.

H 0 to 15%

Start-up Fuel Limit: Single turnr

potentiometer

o

F

Circuit Boards: Heavy conformal coating for moisture

and vibration protection

Ramp Time: Single turn 0 to 10 seconds

Fuel Selection: Diesel or gas

Actuator Selection:

DYNA 8000 and 8200

DYNA 8400 (For use with the DYN1-10695 only)

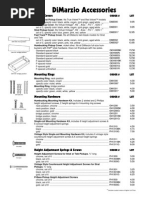

�Installation Dimensions DYN1 10694

(For reference only)

5.56 .2

[.219 .008]

146. 1.0

[5.75 .040]

5.56 .4

[.219 .016]

134.9

[5.312]

0.6 [.024] M

Nameplate

MAX

ON

OFF

S1 S2

MAX

S1 - OFF - DIESEL

S1 - ON - GAS

S2 - OFF - 8000 ACT.

S2 - ON - 8200 ACT.

START-UP

FUEL

RAMP

TIME

101.6

[4.000]

BSC

DROOP

REMOTE

SPEED POT

ROCKFORD, IL. USA

GAIN

ACT

TP1 TP2

SPEED

ILS

1

112.7 1.0

[4.437 .040]

MPU

10

11

White

54.6

[2.15] Max.

Black

Cable A*

Red

Red

5.56 .4

[.219 .016]

Black

Cable C

Twisted Pair

#14 Ga.

Red

t

y

n

AAAA

AAAAA

AAA

l

e

AAAAA

AAAAA

AAAA n

m

O

u

c

e

o

c

D

n

e

d

r

e

e

l

f

l

e

o

R

r

t

l

n

a

c

o

i

c

r

n

o

t

U

is

H

NOTE: Wiring Diagram for CE Controllers on page 4

r

o

F

41.9

[1.65] Max.

Black

4.0 .6

[.160 .024]

INC

4V

8V

Cable B*

DYNT

Magnetic

Pickup

DC Power

Cable C

Twisted Pair

#14 Ga.

CCW

5K **

CW

DYNC

Actuator

Dimensions in mm

Inches in brackets [ ]

Cable A DYNK 44-XX

Cable B E26-22

Cable C DYNZ-70-4

(Specify length)

(90 Connector)

(Specify length)

(Specify length)

1. As shown by the solid line from the wiper of the 5K

potentiometer and then connected to terminal 9 (no

resistor required). Adjustable range is approximately

5% at 1800 RPM.

* Shielded Cable Should be purchased from Barber-Colman or customer should purchase a cable with a wrapped

mylar supported aluminum foil shield with a drain wire.

2. As shown by the dashed line from the wiper of the 5K

potentiometer through resistor "R" and then connected to

terminal 8. Reducing the value of "R" increases the

remote adjustable speed range.

** Remote Speed Potentiometer DYNS 10000

The 5K Remote Speed Potentiometer can be wired two

different ways:

3

�Wiring Diagram For

Controllers

DYN1-10693-002-0-12/24

DYN1-10694-002-0-12/24

DYN1-10695-000-0-12

Failsafe

TP1

TP2

A

AAA

y

l

AAAAAAA

AAAAAA

n

O

um

Battery

Actuator

+8V

Chassis

Gnd

Screw

nc

r

o

F

on

H

tr

is

l

l

o

i

r

o

External

Speed

Adjust

+4V

ed

l

a

c

oc

ef

11

10

ILS

t

n

e

e

r

e

Blk

Wht

Chassis

Gnd

Screw

e

c

n

Magnetic Pick-up

Barber-Colman Company

AEROSPACE & POWER CONTROLS DIVISION

DYNA Product Group

NOTE

Barber-Colman believes that all information provided herein

is correct and reliable and reserves the right to update at

any time. Barber-Colman does not assume any responsibility for its use unless otherwise expressly undertaken.

1354 Clifford Avenue

P.O. Box 2940

Loves Park, IL U.S.A. 61132-2940

In Europe contact: Barber-Colman GmbH

Am neuen Rheinhafen 4, D-6720 Speyer, West Germany

Tel: 06232-1203, Fax: 06232-12155, Telex: 467 627

CAUTION

In Japan contact: Ranco Japan Ltd.

Shiozaki Bldg. 7-1, 2-chome, Hirakawa-Cho, Chiyoda-Ku

Tokyo 102, Japan

Tel: 3261-4293, Fax: 3264-4691, Telex: 0232-2087

As a safety measure, the engine should be equipped with

an independent overspeed shutdown device in the event of

failure which may render the governor inoperative.

DYNA 129-3

Phone: (815) 637-3000

Fax: (815) 877-0150

LITHO IN U.S.A.