0% found this document useful (0 votes)

67 views2 pagesCellulase Production from Soil Bacteria

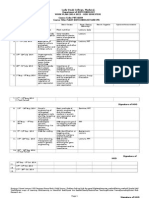

1. Bacteria that produce cellulase enzymes were isolated from soil samples using agar plates containing carboxymethyl cellulose (CMC) to identify colonies with cellulolytic activity. The isolate with the highest cellulase activity was selected for further study.

2. The selected bacterial isolate was identified using morphological and biochemical tests according to Bergey's Manual of Determinative Bacteria.

3. Various process parameters for the production of cellulase enzymes by the selected bacterial isolate were optimized, including pH, temperature, carbon sources, nitrogen sources, and agricultural waste substrates.

Uploaded by

aj_6Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

67 views2 pagesCellulase Production from Soil Bacteria

1. Bacteria that produce cellulase enzymes were isolated from soil samples using agar plates containing carboxymethyl cellulose (CMC) to identify colonies with cellulolytic activity. The isolate with the highest cellulase activity was selected for further study.

2. The selected bacterial isolate was identified using morphological and biochemical tests according to Bergey's Manual of Determinative Bacteria.

3. Various process parameters for the production of cellulase enzymes by the selected bacterial isolate were optimized, including pH, temperature, carbon sources, nitrogen sources, and agricultural waste substrates.

Uploaded by

aj_6Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd