Professional Documents

Culture Documents

Design 2 Intro

Design 2 Intro

Uploaded by

Rachel IngramCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design 2 Intro

Design 2 Intro

Uploaded by

Rachel IngramCopyright:

Available Formats

INTRODUCTION

The Building and Construction Authority launched Volume One of the Good Industry

Practices Guide on "Design and Material Selection for Quality" in 2008. The guide

attempted to showcase buildable and constructible designs that facilitate good

workmanship as observed in various projects with high CONQUAS and QM scores.

This includes the use of steel structures, drywall partitions, precast elements,

prefabricated bathrooms and other factory made components for higher productivity,

faster completion time and better build quality. This second volume continues from

where the first volume has left. It now focuses on material selection, primarily the

architectural components, that impacts quality during construction.

Quality often comes at a price. It would be ideal if higher quality can be achieved

without increasing costs. Apart from initial costs, the chosen product must also be

functional, aesthetically pleasing, easy to install and maintain thereafter. Generally,

though not always, the use of higher quality material may incur higher initial cost. This

has to be balanced against possible savings in time (due to ease of installation), better

customer satisfaction (due to better quality workmanship) and lower maintenance

costs during use (due to less defects and durability of the product). Apart from

these, there are other intangible benefits to the developer or builders reputation, if

they consistently deliver high quality projects. These factors need to be considered

and balanced against each other when making a choice of which material to use.

For example, some choices highlighted in this guide, like use of special fillers and

techniques to repair and restore stone and timber are costly and are not intended for

ordinary or widespread use. They are presented in this guide to highlight the availability

of such precision techniques which can be utilised where circumstances permit.

Unlike manufacturing, construction is often carried out in an open environment

subject to unpredictable weather conditions and other environmental factors. This

affects productivity and quality outcomes. Build quality is often dependant on the

skill level of the workmen employed and how trade sub-contractors are managed and

co-ordinated. This can be minimized by shifting much of the work to a manufacturing

or factory environment which is not affected by weather conditions and the

processes are largely automated. Thus the use of precisely made factory products

requiring minimal on-site labour for installation will help to raise productivity levels,

ensure better consistency in workmanship and improve overall build quality. This is

evident from the many materials listed in this guide.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

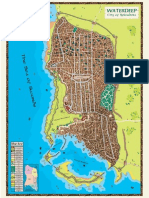

- D&D 3.5 Forgotten Realms - Waterdeep MapDocument1 pageD&D 3.5 Forgotten Realms - Waterdeep MapMarcel Morton100% (5)

- Modern Methods of Construction Full PDFDocument81 pagesModern Methods of Construction Full PDFKenneth PunlaNo ratings yet

- (Sample) - Schedule of FinishesDocument5 pages(Sample) - Schedule of FinishesRachel IngramNo ratings yet

- 168PMixing Tips MortarDocument1 page168PMixing Tips MortarRachel IngramNo ratings yet

- Punch List: University of Delaware-Facilities Design Standards Facilities Planning & Construction CSI: SECTION 17000Document2 pagesPunch List: University of Delaware-Facilities Design Standards Facilities Planning & Construction CSI: SECTION 17000Rachel IngramNo ratings yet

- Proposed 6 Storey Executive Suites With Commercial Space On Lot 3493, Bintulu Town District at Jalan Tun Razak, BintuluDocument3 pagesProposed 6 Storey Executive Suites With Commercial Space On Lot 3493, Bintulu Town District at Jalan Tun Razak, BintuluRachel IngramNo ratings yet

- Subsoil DrainageDocument11 pagesSubsoil DrainageRachel IngramNo ratings yet

- Forwarded Message - From: Joseph Wong Date: 12 December 2012 07:37 Subject: Re: Paling Executive Suites To: Joshua SiaDocument2 pagesForwarded Message - From: Joseph Wong Date: 12 December 2012 07:37 Subject: Re: Paling Executive Suites To: Joshua SiaRachel IngramNo ratings yet

- Book Reviews 10.25.10Document4 pagesBook Reviews 10.25.10Rachel IngramNo ratings yet

- M&E Perunding Dynatech Perunding Elecmec SDN BHD: Type ConsultantDocument21 pagesM&E Perunding Dynatech Perunding Elecmec SDN BHD: Type ConsultantRachel IngramNo ratings yet

- Lot 3493 - InsuranceDocument1 pageLot 3493 - InsuranceRachel IngramNo ratings yet

- Lot3493 Brickwalls (New)Document22 pagesLot3493 Brickwalls (New)Rachel IngramNo ratings yet

- Lot 3493 - Door QtyDocument3 pagesLot 3493 - Door QtyRachel IngramNo ratings yet

- Lot 3493 - Brick Work, ACDocument6 pagesLot 3493 - Brick Work, ACRachel IngramNo ratings yet

- Lot 3493 - Rooms AreaDocument66 pagesLot 3493 - Rooms AreaRachel IngramNo ratings yet

- Building Ordinance SarawakDocument327 pagesBuilding Ordinance SarawakRachel Ingram100% (2)

- Disclosure To Promote The Right To InformationDocument12 pagesDisclosure To Promote The Right To InformationRachel IngramNo ratings yet

- Impregnators For Natural StonesDocument5 pagesImpregnators For Natural StonesRachel IngramNo ratings yet

- Disclosure To Promote The Right To Information: IS 4351 (2003) : Steel Door Frames - (CED 11: Doors, Windows and Shutter)Document14 pagesDisclosure To Promote The Right To Information: IS 4351 (2003) : Steel Door Frames - (CED 11: Doors, Windows and Shutter)Rachel IngramNo ratings yet

- Honeycomb Timber Door and Integrated Architrave FrameDocument6 pagesHoneycomb Timber Door and Integrated Architrave FrameRachel IngramNo ratings yet

- Composite Fibre Plastic MaterialDocument6 pagesComposite Fibre Plastic MaterialRachel IngramNo ratings yet

- Bedding Adhesives For Stones and TilesDocument7 pagesBedding Adhesives For Stones and TilesRachel IngramNo ratings yet

- Lightweight Composite Stone PanelsDocument6 pagesLightweight Composite Stone PanelsRachel IngramNo ratings yet

- Engineered Hardwood FloorDocument8 pagesEngineered Hardwood FloorRachel IngramNo ratings yet

- M&E Fittings and AccessoriesDocument9 pagesM&E Fittings and AccessoriesRachel IngramNo ratings yet

- UGProspectus 2023Document124 pagesUGProspectus 2023yaseennewyaseennewNo ratings yet

- Aws d1.1 WQT ThicknessDocument2 pagesAws d1.1 WQT ThicknessArul Edwin VijayNo ratings yet

- Labsheet 1 (Int)Document3 pagesLabsheet 1 (Int)mail meNo ratings yet

- Chapter 3. Transmission and Switching Techniques PDFDocument63 pagesChapter 3. Transmission and Switching Techniques PDFPhan Vũ KiệtNo ratings yet

- 5MAY HAR-PROD TrabaDocument12 pages5MAY HAR-PROD TrabaGustavo OrceNo ratings yet

- Methods of FishingDocument6 pagesMethods of FishingVictor Ose MosesNo ratings yet

- Dell Client Statement On Intel AMT Advisory (INTEL-SA-00075)Document6 pagesDell Client Statement On Intel AMT Advisory (INTEL-SA-00075)lexanxNo ratings yet

- Release Notes Omnistack 6200Document26 pagesRelease Notes Omnistack 6200ReverieMNo ratings yet

- 21.9L LuvegiDocument3 pages21.9L LuvegiJonathan CastilloNo ratings yet

- CHNN312 FinalDocument26 pagesCHNN312 FinalVALERIANO TRISHANo ratings yet

- Is The Fast Food Indutry Accountable Legally For Obesity?: University of Management and Technology, LahoreDocument10 pagesIs The Fast Food Indutry Accountable Legally For Obesity?: University of Management and Technology, LahoreMuhammad HasnatNo ratings yet

- Rubber Seals PDFDocument11 pagesRubber Seals PDFManjil PuriNo ratings yet

- Abb DB CatlogueDocument18 pagesAbb DB CatlogueSelva KumarNo ratings yet

- Toefl Itp - 2002 - 08Document44 pagesToefl Itp - 2002 - 08marchelita.daffiani.kaligisNo ratings yet

- SIRIM QAS Intl. Corporate ProfileDocument32 pagesSIRIM QAS Intl. Corporate ProfileHakimi BobNo ratings yet

- 10 Insights From Industrial Ecology For The Circular Economy - 2023Document34 pages10 Insights From Industrial Ecology For The Circular Economy - 2023saurabhvij82No ratings yet

- 2 HIE ENG HardwareDocument21 pages2 HIE ENG HardwareBodya StepanovNo ratings yet

- Early Journal Content On JSTOR, Free To Anyone in The WorldDocument3 pagesEarly Journal Content On JSTOR, Free To Anyone in The WorldAshish SinghNo ratings yet

- 1use 4534Document13 pages1use 4534api-286569896No ratings yet

- 前言 ForewordDocument639 pages前言 ForewordOlaf NavaNo ratings yet

- ESI (Tronic) 2.0: Diagnostic SolutionsDocument9 pagesESI (Tronic) 2.0: Diagnostic SolutionsMessi EmetievNo ratings yet

- Fourier Series: Yi Cheng Cal Poly PomonaDocument46 pagesFourier Series: Yi Cheng Cal Poly PomonaJesusSQANo ratings yet

- Doka Calculation Guide PDFDocument70 pagesDoka Calculation Guide PDFboctraian55100% (2)

- Siemens 7SK85 V7.90 Motor PTT User Manual ENUDocument6 pagesSiemens 7SK85 V7.90 Motor PTT User Manual ENURaúlEmirGutiérrezLópezNo ratings yet

- List of Table and ChartsDocument2 pagesList of Table and ChartswilsonNo ratings yet

- A600-40694 - Rev04 EN13000 - A600-1Document40 pagesA600-40694 - Rev04 EN13000 - A600-1suwarjitechnic100% (1)

- Tourism in Cuba and Its Social and Economic EffectsDocument6 pagesTourism in Cuba and Its Social and Economic EffectsSarah MughalNo ratings yet

- Book-Review TadekDocument3 pagesBook-Review Tadekjustyna.owinskaNo ratings yet