Professional Documents

Culture Documents

1 s2.0 S187661961400031X Main

Uploaded by

Imam PrabowoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 s2.0 S187661961400031X Main

Uploaded by

Imam PrabowoCopyright:

Available Formats

Available online at www.sciencedirect.

com

ScienceDirect

Procedia Chemistry 9 (2014) 248 256

International Conference and Workshop on Chemical Engineering UNPAR 2013, ICCE UNPAR

2013

Effects of Temperature, Pressure, Preheating Time and Pressing

Time on Rubber Seed Oil Extraction Using Hydraulic Press

Herry Santosoa,*, Iryantoa, Maria Inggrida

a

Chemical Engineering Department, Parahyangan Catholic University, Jalan Ciumbuleuit No.94, Bandung-40141, Indonesia

Abstract

Rubber seeds are side products of rubber trees. Rubber seeds contain 40-50% non-edible oil that can be used as industrial

materials to produce variety of products such as linoleum, lubricant, cutting oil, alkyd resin, biodiesel, etc. To obtain oil from

rubber seeds, there are two common methods that can be used, i.e. solvent extraction and mechanical pressing. Solvent extraction

method uses solvent such as hexane to extract oil from rubber seeds. This method gives a higher yield compared to mechanical

pressing method. However, since solvent is used in this method, it may reduce the quality of the oil. Mechanical pressing method

gives a lower yield but simpler to do and gives a higher quality of oil. One of mechanical pressing machine usually used is

hydraulic press. The objective of this research is to study the effects of temperature, pressure, preheating time and pressing time

on rubber seed oil yield. Rubber seeds that had been cleaned, dehulled, dried, and flaked until the flakes are about 0.5-0.8 mm,

are preheated at 60-80oC for 45-75 minutes. Then, while the rubber seed flakes get further heated, the flakes are pressed for 3090 minutes at 80-120 bar. The effects of temperature, pressure, preheating time, and pressing time on rubber seed oil yield are

then evaluated using a 24 factorial design with 4 center points. The analysis of variance shows that pressure, pressing time and

their interaction have significant effects on rubber seed oil yield. From experiment, the best condition that gives the highest

rubber seed oil yield is at the highest pressure (120 bar) and the longest pressing time (90 minutes) which corresponds to 31.88%

oil yield.

by by

Elsevier

B.V.B.V.

This is an open access article under the CC BY-NC-ND license

2014

2014The

TheAuthors.

Authors.Published

Published

Elsevier

(http://creativecommons.org/licenses/by-nc-nd/3.0/).

Selection and peer-review under responsibility of the Organizing Committee of ICCE UNPAR 2013.

Peer-review under responsibility of the Organizing Committee of ICCE UNPAR 2013

Keywords: Temperature; pressure; preheating time; pressing time; rubber seed oil yield.

* Corresponding author. Tel.: +62-22-2032700; fax: +62-22-2032700.

E-mail address: hsantoso@unpar.ac.id

1876-6196 2014 The Authors. Published by Elsevier B.V. This is an open access article under the CC BY-NC-ND license

(http://creativecommons.org/licenses/by-nc-nd/3.0/).

Peer-review under responsibility of the Organizing Committee of ICCE UNPAR 2013

doi:10.1016/j.proche.2014.05.030

Herry Santoso et al. / Procedia Chemistry 9 (2014) 248 256

1. Introduction

According to Forestry Department of FAO, rubber tree (Hevea brasiliensis) plantation area around the world in

1997 is about 9.6 million ha. The objective of rubber seed cultivation is latex which used as industry main or

secondary materials for production. Beside latex, rubber trees also produce rubber seeds which are usually wasted.

Each rubber tree annually produces about 5 kg rubber seeds [1]. Based on estimated average of 1000 kg rubber seeds

produced per ha annually [2], the rubber seed production worldwide can reach 9.6 million ton rubber seeds every

year.

Rubber seed kernels may contain as high as 68.53% oil and fat and 17.41% protein [2]. In general, rubber seed

kernels contain around 40-50% oil, consisting of 17-22% saturated oil and 17-82% unsaturated oil. Rubber seed oil

has wide potential application. It can be used in latex industry as foaming agent, in the synthesis of alkyd resin used

in paints and coatings, in the production of biodiesel, etc. [3].

There are two methods commonly used for oil extraction from rubber seeds, which are solvent extraction and

mechanical pressing. Solvent extraction method is an oil extraction method using solvent such as n-hexane to help

oil extraction. This method gives a high oil yield from oilseeds. However, the oil extracted using this method has a

low oil quality since the solvent does not only dissolve the oil from oilseeds, but also dissolve other undesirable

components from oilseeds. The other method for oil extraction is mechanical pressing method. This method is the

oldest and the simplest method for oil extraction. Although this method gives a lower oil yield compared to the yield

obtained from solvent extraction method, the advantage of this method is that it does not use any chemical solvent so

that the product may have a higher oil quality. Another advantage of mechanical pressing method is the lower cost of

equipment [4].

There are several types of machine commonly used in mechanical pressing method, i.e. hydraulic press machine

and screw press machine. Hydraulic press machine is classified as batch mechanical pressing machine while screw

press machine is considered as continuous pressing machine [4]. In this research, the rubber seed oil extraction is

carried out using hydraulic press machine.

Some variables have been reported to have effects on rubber seed oil yield when extracted using hydraulic press

machine such as: rubber seed clone type, rubber seed particle size, rubber seed moisture content, pressing

temperature and pressure [3] as well as preheating time before pressing operation [5]. For Pistacia atlantica seed oil

extraction using hydraulic press machine, cake thickness and pressing time have been reported to have significant

effects on Pistacia atlantica seed oil yield [6].

Based on the previous studies, in this research, the effects of temperature, pressure, preheating time, and pressing

time on rubber seed oil yield using hydraulic press machine are investigated. Furthermore, the effects of two factor

interaction between those variables are also examined. The experiment design used in this research is a 24 factorial

design with 4 center points.

2. Materials and Methods

Rubber seeds from Subang, West Java, Indonesia are used for the purpose of this study. Rubber seeds that have

been cleaned, dehulled, dried, and flaked are preheated and then pressed using hydraulic machine. The hydraulic

press metallic cylinder is equipped with a heater, a thermocouple, and a temperature controller installed near the

sample place. The extraction of rubber seed oil using hydraulic press machine is divided into two steps, the

pretreatment step and the pressing operation step.

In the pretreatment step, the rubber seeds are cleaned and the kernels are separated manually from the seeds using

mortar and pestle. The rubber seed kernels are then dried for 12 hours at 70oC [7]. The purpose of the drying process

is to reduce the cyanide and moisture content in the rubber seed kernels so that the kernels are safe to be placed in

the storage [7]. The dried kernels are then flaked until the flakes are about 0.5-0.8 mm in size (mesh no.-20+30). The

smaller the seed particle size, the higher the oil yield can be obtained [5]. The rubber seed flakes are then placed in

the storage and ready to be used in the pressing operation step.

The second step is the pressing operation step. The pressing step begins by placing 17 g rubber seed flakes packed

in cloth into the pressing metallic cylinder. The rubber seed flakes are then preheated inside the metallic cylinder

using a heater at various temperatures (60, 70 and 80oC) and preheating times (45, 60 and 75 minutes). After that,

249

250

Herry Santoso et al. / Procedia Chemistry 9 (2014) 248 256

while the flakes are still heated, the metallic cylinder are pressed using hydraulic press machine at various pressures

(80, 100 and 120 bar) and pressing times (30, 60 and 90 minutes).

After the pressing operation, the rubber seed oil is collected and the yield is determined using the ratio between

the mass of oil extracted and the mass of sample placed inside the metallic cylinder. The effects of temperature,

pressure, preheating time, pressing time, as well as interaction factors between those variables on the yield of rubber

seed oil are investigated using a 24 factorial design with 4 center points.

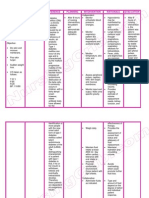

Table 1. Levels of process variables for rubber seed oil extraction using hydraulic press machine

Process Variables

Low (-1)

Center (0)

High (+1)

Temperature ( C)

60

70

80

Pressure (bar)

80

100

120

Preheating time (min)

45

60

75

Pressing time (min)

30

60

90

The physical and chemical properties of rubber seed oil, such as the density, the viscosity, and the free fatty acid

(FFA) content are determined using the oil sample collected from the experiment at the center point operating

conditions. The density is determined using pycnometer. The viscosity is determined at 40oC using Ostwald

viscometer. The free fatty acid (FFA) content is determined by using titration method.

In the titration method for determining the free fatty acid content in the rubber seed oil, the rubber seed oil is

dissolved in isopropyl alcohol (IPA) solution and then titrated using KOH solution. Based on the amount of KOH

solution required to neutralize the rubber seed oil dissolved in IPA solution and the amount of KOH solution

required to neutralize the IPA blank solution, the FFA content can be calculated as follows:

FFA (%) =

(v b ) N MW FFA

100 %

w

(1)

where v is the volume of KOH solution required to neutralizes the rubber seed oil dissolved in IPA solution, b is the

volume of KOH solution required to neutralized the IPA blank solution, N is the normality of KOH solution, MWFFA

is the average molecular weight of the free fatty acids in the rubber seed oil, and w is the weight of rubber seed oil in

the titration sample.

3. Results and Discussion

The experimental results are presented in Table 2. The lowest rubber seed oil yield is from Run 2, using the

following operating conditions: temperature = 60oC, pressure = 80 bar, preheating time = 45 min and pressing time =

30 min, with the oil yield of 19.82%. The highest rubber seed oil yield is from Run 14, using the following operating

conditions: temperature = 60oC, pressure = 120 bar, preheating time = 75 min and pressing time = 90 min, with the

oil yield of 31.88%. From Table 2, it can be seen that the rubber seed oil yields are significantly higher with the

increase of pressure and pressing time. This indicates that these two factors may have a significant effect on the oil

yield.

In order to identify exactly which variables that have significant effects on the rubber seed oil yield in the rubber

seed oil extraction using hydraulic press machine, the Analysis of Variance (ANOVA) is conducted. The ANOVA

result is presented in Table 3.

251

Herry Santoso et al. / Procedia Chemistry 9 (2014) 248 256

Tabel 2. The experimental results for rubber seed oil extraction using hydraulic press machine

Std Order

Run

Temperature (oC)

Pressure (bar)

Preheating time (min)

Pressing time (min)

Yield (%)

60

80

45

30

19.82

80

80

45

30

21.56

11

60

120

45

30

30.47

80

120

45

30

30.64

60

80

75

30

21.88

15

80

80

75

30

23.94

60

120

75

30

30.94

80

120

75

30

29.24

60

80

45

90

30.59

10

12

80

80

45

90

31.12

11

10

60

120

45

90

31.71

12

16

80

120

45

90

30.82

13

60

80

75

90

29.12

14

13

80

80

75

90

28.24

15

14

60

120

75

90

31.88

16

80

120

75

90

31.58

17

17

70

100

60

60

27.00

18

18

70

100

60

60

27.33

19

19

70

100

60

60

29.17

20

20

70

100

60

60

29.82

Table 3. Analysis of Variance

Source

Sum of Squares

DOF

Mean Square

F-value

Model

250.99

15

16.73

8.82

0.0491

A-Temperature

0.033

0.033

0.018

0.9030

B-Pressure

p-value

105.11

105.11

55.38

0.0050

5.06E-04

5.03E-04

2.67E-04

0.9880

D-Pressing time

83.59

83.59

44.03

0.0070

AB

2.38

2.38

1.25

0.3444

0.6962

C-Preheating time

AC

0.35

0.35

0.18

AD

0.91

0.91

0.48

0.5390

BC

5.06E-04

5.06E-04

2.67E-04

0.9880

BD

46.14

46.14

24.31

0.0160

CD

3.00

3.00

1.58

0.2976

ABC

2.26E-03

2.26E-03

1.19E-03

0.9747

ABD

1.26

1.26

0.66

0.4749

ACD

0.033

0.033

0.018

0.9030

BCD

7.09

7.09

3.73

0.1488

ABCD

1.10

1.10

0.58

0.5024

Curvature

9.11-04

9.11E-04

4.80E-04

0.9839

Pure Error

5.69

1.90

Cor Total

256.69

19

Significant

Significant

Significant

Significant

Not Significant

252

Herry Santoso et al. / Procedia Chemistry 9 (2014) 248 256

3.1. Effects of temperature on the rubber seed oil yield

From the ANOVA result, it can be seen that the p-value for Factor A (temperature) is greater than 0.05. This

indicates that temperature does not affect the oil yield significantly. Figure 1 shows the average oil yield at 60, 70,

and 80oC respectively. From Figure 1, it can be seen that the average oil yield remains the same at about 28% as the

temperature increases from 60 to 80oC. This result is slightly different with the result reported in [3], which stated

that the optimum oil yield was obtained at 70oC. The difference is due to the smaller particle size and the higher

operating pressure range used in this study.

Fig. 1. Effects of temperature on the rubber seed oil yield in the oil extraction process using hydraulic press machine

3.2. Effects of pressure on the rubber seed oil yield

The p-value for Factor B (pressure) is less than 0.05. This means the amount of pressure applied in the hydraulic

pressing process does affect the rubber seed oil yield significantly. Figure 2 shows that the average oil yield

increases from 26% to 31% as the operating pressure increases from 80 to 120 bar. This result is in close agreement

with the result in [3], which reported that a higher oil recovery would be obtained at a higher operating pressure.

3.3. Effects of preheating time on the rubber seed oil yield

Fig. 2. Effects of pressure on the rubber seed oil yield in the oil extraction process using hydraulic press machine

Herry Santoso et al. / Procedia Chemistry 9 (2014) 248 256

From the ANOVA result, the p-value for Factor C (preheating time) is greater than 0.05. This indicates that

preheating time does not affect the oil yield significantly. Figure 3 shows that the average rubber seed oil yield

remains relatively the same at about 28% as the preheating time increase from 45 to 74 minutes. This result is

slightly different with the result in [5], which stated that the optimum oil yield is achieved at preheating time about

60 minutes. The difference is due to the fact that in [5], the heating process is carried out only at the beginning

before the rubber seed sample is mechanically pressed, while in this study, the heating process is carried out at the

beginning, during the preheating process, as well as during the pressing process.

3.4. Effects of pressing time on the rubber seed oil yield

Fig. 3. Effects of preheating time on the rubber seed oil yield in the oil extraction process using hydraulic press machine

The p-value for Factor D (pressing time) is less than 0.05. This indicates that pressing time significantly affects

the rubber seed oil yield. From Figure 4, it can be seen that the average oil yield increases from 26% to 31% as the

pressing time increase from 30 to 90 minutes. This result is in close agreement with the result in [6], which found

that the oil yield will increase progressively with the increase of pressing time in Pistacia atlantica oil extraction

using hydraulic press machine.

Fig. 4. Effects of pressing time on the rubber seed oil yield in the oil extraction process using hydraulic press machine

253

254

Herry Santoso et al. / Procedia Chemistry 9 (2014) 248 256

3.5. Effects of interaction between pressure and pressing time on the rubber seed oil yield

The two factor interaction BD (interaction between pressure and pressing time) also has a p-value less than 0.05.

This indicates that the two factor interaction between pressure and pressing time has a significant effect on the

rubber seed oil yield. Other interaction factors have a p-value greater than 0.05, thus it can be concluded that the

other interaction factors do not affect the oil yield significantly. Figure 5 shows that a higher oil yield could be

obtained by using a higher operating pressure or by applying a longer pressing time. Furthermore, the effects of

increasing operating pressure on the oil yield are more significant at shorter pressing time compared to the longer

one.

Fig. 5. Effects of interaction between pressure and pressing time on the rubber seed oil yield in the oil extraction process using

hydraulic press machine

3.6. Effects of curvature on the rubber seed oil yield

From the ANOVA result, it is also shown that the curvature in the oil yield response data has a p-value greater

than 0.05, which indicates that there is no significant curvature in the oil yield response data in the operating

condition ranges selected in the experiment. This means the operating condition ranges selected in the experiment

are not in the optimum operating condition ranges. Thus, the oil yield from this research could still be improved

either by using a higher operating pressure or by applying a longer pressing time.

From this study, the best operating condition that gives the highest rubber seed oil yield so far is obtained at the

highest pressure (120 bar) and the longest pressing time (90 minutes) which corresponds to 31.88% oil yield. Since

temperature and preheating time do not affect the oil yield significantly, it is more economical to use the lowest

temperature (60oC) and the shortest preheating time (45 min) in the pressing process.

3.7. The physical and chemical properties of rubber seed oil

The physical and chemical properties of rubber seed oil extracted at the center point operating conditions are

determined. The properties include the density, the viscosity, and the free fatty acid (FFA) content. The results are

presented at Table 4, along with some results obtained from literatures.

255

Herry Santoso et al. / Procedia Chemistry 9 (2014) 248 256

Table 4. The physical and chemical properties of rubber seed oil

Experiment

Yusup and Khan [8]

Melvin Jose, et al [9]

Density, 25 C (g/cm )

0.92

0.91

0.91

Viscosity, 40oC (mm2/s)

39.58

40.7

66.2

Free Fatty Acid (%)

28.47

22.7

17.08

The rubber seed oil density from this experiment is relatively the same with the rubber seed oil density reported

in [8] and [9]. The kinematic viscosity of the oil is relatively the same with [8] but different with [9]. This is mainly

contributed by the differences in the sources and maybe the clone types of the rubber seeds used in each study. The

differences may affect the composition of the rubber seed oil as well as the kinematic viscosity of the oil. In general,

the more saturated the composition of the oil is, the more viscous the oil will be. This result indicates that the rubber

seed oil in this experiment may have less saturated components in it compared to [9]. The free fatty acid content of

the rubber seed oil in this experiment is higher than [8] and [9]. This indicates that the rubber seeds used in this

experiment may have been stored in a long time period before being used. This may cause the oil to be hydrolyzed

more and as a result increase the free fatty acid content of the oil.

4. Conclusion

From this study, it is found that pressure and pressing time affect the rubber seed oil yield significantly. On the

other hand, temperature and preheating time do not affect the oil yield significantly. The two factor interaction

between pressure and pressing time affects the oil yield significantly, while other interaction factors do not show a

significant effect on the oil yield. Using a higher operating pressure and applying a longer pressing time on the

rubber seed oil extraction process using hydraulic press machine will give a higher oil yield. The effects of

increasing operating pressure on the oil yield are more significant at shorter pressing time compared to the longer

one. There is no significant curvature in the oil yield response data in the operating condition ranges selected in the

experiment. This indicates that the operating condition ranges selected in the experiment are not in the optimum

operating condition ranges. Thus, the oil yield from this research could still be improved. The best operating

condition that gives the highest rubber seed oil yield in this study so far is obtained at the highest pressure (120 bar)

and the longest pressing time (90 minutes) which corresponds to 31.88% oil yield.

Acknowledgements

This research is supported by Direktorat Jendral Pendidikan Tinggi, Kementrian Pendidikan Nasional through

Hibah Penelitian Unggulan Perguruan Tinggi No. 0893/K4/KL/2013.

References

1.

2.

3.

4.

5.

6.

7.

Babatunde, G. M., Pond, W. G. and Peo, E. R., Jr., 1990, Nutritive Value of Rubber Seed (Hevea brasiliensis) Meal: Utilization by

Growing Pigs of Semipurified Diets in which Rubber Seed Meal Partially Replaced Soybean Meal, Journal of Animal Science, 68, pp. 392397.

Eka, H. D., Tajul Aris, Y. and Wan Nadiah, W. A., 2010, Potential Use of Malaysian Rubber (Hevea brasiliensis) Seed as Food, Feed and

Biofuel, International Food Research Journal, 17, pp. 527-534.

Ebewele, R. O., Iyayi, A. F. and Hymore, F. K., 2010, Considerations of the Extraction Process and Potential Technical Applications of

Nigerian Rubber Seed Oil, International Journal of Physical Sciences, 5, pp. 826-831.

Pighinelli, A. L. M. T. and Gambetta, R., 2012, Oil Presses, in Oilseeds, Akpan, U. G., Ed., InTech, available from:

http://www.intechopen.com/books/oilseeds/oil-presses.

Abul Maali, A. R., 1992, Pengaruh Ukuran Partikel dan Lama Pemanasan terhadap Rendemen Minyak Biji Karet, Majalah Dinamika

Penelitian BIPA, 3, pp. 14-24.

Acheheb, H., Aliouane, R. and Ferradji, A., 2012, Optimization of Oil Extraction from Pistacia atlantica Desf. Seeds Using Hydraulic

Press, Asian Journal of Agricultural Research, 6, pp. 73-82.

Iyayi, A. F., Akpaka, P. O. and Ukpeoyibo, U., 2008, Rubber Seed Processing for Value-Added Latex Production in Nigeria, African

Journal of Agricultural Research, 3, pp. 505-509.

256

Herry Santoso et al. / Procedia Chemistry 9 (2014) 248 256

8.

9.

Yusup, S. and Khan, M., 2010, Basic Properties of Crude Rubber Seed Oil and Crude Palm Oil Blend as a Potential Feedstock for Biodiesel

Production with Enhanced Cold Flow Characteristics, Biomass and Bioenergy, 34. pp. 1523-1526.

Melvin Jose, D. F., Edwin Raj, R., Durga Prasad, B., Robert Kennedy, Z. and Mohammed Ibrahim, A., 2011, A Multi-Variant Approach to

Optimize Process Parameters for Biodiesel Extraction from Rubber Seed Oil, Applied Energy, 88, pp. 2056-2063.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- (1908) Mack's Barbers' Guide: A Practical Hand-BookDocument124 pages(1908) Mack's Barbers' Guide: A Practical Hand-BookHerbert Hillary Booker 2nd100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- TSR 9294 DLA3 Dragons RestDocument78 pagesTSR 9294 DLA3 Dragons RestLéo Duarte100% (4)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Heroic Tales Core Rules 1.1.0Document33 pagesHeroic Tales Core Rules 1.1.0Melobajoya MelobajoyaNo ratings yet

- 06 Renr5908 08 01 All PDFDocument108 pages06 Renr5908 08 01 All PDFFrancisco Ospino Arrieta100% (2)

- Play Tennis Manual PDFDocument52 pagesPlay Tennis Manual PDFAnonymous GJuRvp9A5T100% (2)

- Nursing Care Plan Diabetes Mellitus Type 1Document2 pagesNursing Care Plan Diabetes Mellitus Type 1deric85% (46)

- How Plants SurviveDocument16 pagesHow Plants SurviveGilbertNo ratings yet

- 2400 8560 PR 8010 - A1 HSE Management PlanDocument34 pages2400 8560 PR 8010 - A1 HSE Management PlanMohd Musa HashimNo ratings yet

- Emergency Floatation Helicoptero PDFDocument14 pagesEmergency Floatation Helicoptero PDFterrywhizardhotmail.com The Best Of The Best.No ratings yet

- CESC Performance Task Quarter 1Document3 pagesCESC Performance Task Quarter 1MarinaM.CubiaNo ratings yet

- Internet in My LifeDocument4 pagesInternet in My LifeАндріана ПрусNo ratings yet

- Philippines and Singapore Trade Relations and Agreements: 1. What Leads To Said Agreement?Document11 pagesPhilippines and Singapore Trade Relations and Agreements: 1. What Leads To Said Agreement?Ayrah Erica JaimeNo ratings yet

- #5-The Specialities in The Krithis of Muthuswamy DikshitharDocument5 pages#5-The Specialities in The Krithis of Muthuswamy DikshitharAnuradha MaheshNo ratings yet

- Comparison of The EC-GMP Guide Part I With The SFDA-GMP Guideline For Chinese CompaniesDocument7 pagesComparison of The EC-GMP Guide Part I With The SFDA-GMP Guideline For Chinese Companiesrambabukomati472No ratings yet

- Chapter 7 Integration Testing PDFDocument74 pagesChapter 7 Integration Testing PDFebrgsrtNo ratings yet

- Nexus 1500+ Power Quality Meter User Manual - E154713Document362 pagesNexus 1500+ Power Quality Meter User Manual - E154713Antonio BocanegraNo ratings yet

- Media Analysis-GraphicDocument1 pageMedia Analysis-Graphicapi-262266786100% (1)

- Adobe Scan 23-Feb-2024Document4 pagesAdobe Scan 23-Feb-2024muzwalimub4104No ratings yet

- FinancialAccountingTally PDFDocument1 pageFinancialAccountingTally PDFGurjot Singh RihalNo ratings yet

- Declaration of Absence of Conflict of InterestDocument1 pageDeclaration of Absence of Conflict of InterestJvhelcoronacondat CondatNo ratings yet

- Minolta Spotmeter f-1 PDFDocument50 pagesMinolta Spotmeter f-1 PDFmacpator100% (1)

- Module 1 Learning PrinciplesDocument2 pagesModule 1 Learning PrinciplesAngela Agonos100% (1)

- MikroekonomiDocument1 pageMikroekonomiYudhaPrakosoIINo ratings yet

- 热虹吸管相变传热行为CFD模拟 王啸远Document7 pages热虹吸管相变传热行为CFD模拟 王啸远小黄包No ratings yet

- Boomer L2 D - 9851 2586 01Document4 pagesBoomer L2 D - 9851 2586 01Pablo Luis Pérez PostigoNo ratings yet

- Ask NasaDocument68 pagesAsk Nasacavaco2008No ratings yet

- Assignment Brief - Starting A Business and Fundamental of MarketingDocument7 pagesAssignment Brief - Starting A Business and Fundamental of Marketingmd rahimNo ratings yet

- Abbreviations For O&G IndustryDocument38 pagesAbbreviations For O&G IndustryMike George MeyerNo ratings yet

- Wec14 01 Rms 20230112Document23 pagesWec14 01 Rms 20230112Shafay SheikhNo ratings yet

- Class XI-Writing-Job ApplicationDocument13 pagesClass XI-Writing-Job Applicationisnprincipal2020No ratings yet