RUDDER ALIGNMENT

& INSTALL CHECK

( QUALITY ACCEPTANCE TEST )

PROJECT :

POT 17,500 LTDW

DOC. NO.:

MOS / H7008 / TM

Q02

SHEET

: 1 OF 5

PRODUCT OIL TANKER 17,500 LTDW

COVER SHEET

Document No.

: MOS/H7008/TM Q02

Document Name

: QAT RUDDER ALIGNMENT & INSTALL CHECK

Client Name

: PT. PERTAMINA

Project Name

: PASAMAN

Project No.

: MOS-H7008

MOS/PPC/QAQC

MOS/PPC/QAQC

Established By

Checked By

Date

Date

Classification Society

Owner

Reviewed By

Approved By

Date

Prepared By BNS/PPC/PQE - 2010

Date

�RUDDER ALIGNMENT

& INSTALL CHECK

( QUALITY ACCEPTANCE TEST )

1.

PROJECT :

POT 17,500 LTDW

DOC. NO.:

MOS / H7008 / TM

Q02

SHEET

: 2 OF 5

PURPOSE OF TEST

The Rudder alignment & Install check to ensuring the system performance is in accordance

to the calculation of rudder stock and steering gear system from maker engineering and

comply with requirement of the NK Classification Society.

2. REQUEREMENT

2.1. To Confirm the position of each bush bearing and stock is set on straight line

2.2. The vertically reference line of the position rudder stock to be perpendicular by main

engine propulsion straight line.

3.

PROCEDURE

3.1. The rudder stock is assumed to be aligned in the dock. The line running through

centre of the upper and lower gudgeon bearings are defined as the reference line (0

offset).

3.2. A preliminary alignment of the rudder blade should be carried out in dock. A visual

straight line should be established from the centre of the rudder pintle to the output

of lower rudder bush bearing. The intermediate shaft bearing, the temporary support

and the bearings should be positioned according to the reference line.

3.3. Finish the rudder alignment, installation equipment to be done ie,

3.3.1.Loading and install bushing upper and lower position (complete with

retaining ring)

3.3.2. Loading and install rudder stock complete with sleeve

3.3.3.Loading the rudder blade complete with rudder pintle that already fixed and

positioned according to the reference lanes

3.3.4.Tighten the blade to rudder stock according the maker calculations

3.3.5.Loading the steering gear and tighten to rudder stock as per instruction from

Prepared By BNS/PPC/PQE - 2010

�RUDDER ALIGNMENT

& INSTALL CHECK

( QUALITY ACCEPTANCE TEST )

PROJECT :

POT 17,500 LTDW

DOC. NO.:

MOS / H7008 / TM

Q02

SHEET

: 3 OF 5

maker procedure ie,

Start installation of steering gear when foundation has been build

according to maker foundation plan

To prevent damage and rust, remove the protecting material of

steering gear only just before commissioning

Lift up the steering gear and let it carefully down over the erected

rudder stock

Take care when seal on lower end of rudder carrier slips over the

stainless steel liner

Mounting of cone connection of tiller to rudder stock according to

particulars stated on steering gears final drawing

Set the steering gear down on top of foundation and use aligning

screws, screwed in to cylinder feet, for the adjusting of height

Check clearance of sliding stones by means of a spay for

rectangularity of rudder stack axis to axis of cylinder and ram. Check

at first one side (A and B) and then the other (C and D)

Adjust steering gear until gap x is over whole circle within the

tolerance limit of 0,1 mm

Bore foundation bolt holes. Remove steering gear by turning on

foundation, if necessary

Make steel chocks between carrier unit and foundations top plate

according to the requirements

Fit in chock and ream bolt holes for fitting bolts

Make epoxy resin chocks according to requirements and resin makers

instructions

Weld the cylinder stopper on foundations top plate. Fit stopper keys

and protect them

Prepared By BNS/PPC/PQE - 2010

Fit storage tank and connecting pipe

Make final check before commissioning, if possible under survey of

�RUDDER ALIGNMENT

& INSTALL CHECK

( QUALITY ACCEPTANCE TEST )

PROJECT :

POT 17,500 LTDW

DOC. NO.:

MOS / H7008 / TM

Q02

SHEET

: 4 OF 5

maker service engineer.

3.3.6.Tighten and protect by rams packing or sealing on top of rudder gudgeon

3.3.7. Clearance check of rudder stock by wear fuller gauge. The minimum

clearance to be done is 0,001ds + 1 mm

4. REFERENCE

4.1. Installation instruction of steering gear from Maker

4.2. Arrangement of Rudder stock detail drawing

4.3. NK. Guidelines.

5. EQUIPMENT / TOOLS

5.1.

Fuller gauge

5.2.

Caliper

5.3.

Micro meter

5.4.

Hyd jack min. 0,5 ton

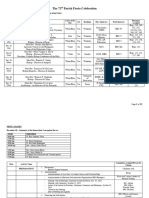

6. TEST RESULT

Description

Allowance ( mm )

Prepared By BNS/PPC/PQE - 2010

"ALIGNMENT DIMANTION"

"CLEARANCE"

0.0 0,30 (mm)

0.0 to 1,50 (mm)

(Reading by fuller gauge)

�PROJECT :

POT 17,500 LTDW

DOC. NO.:

MOS / H7008 / TM

Q02

SHEET

: 5 OF 5

RUDDER ALIGNMENT

& INSTALL CHECK

( QUALITY ACCEPTANCE TEST )

Upper Gudgeon.

0.0

0.0

F

0.0 P

Up

0.0 P

S 0.0

S 0.0

A

0.0

A

0.0

Actual

Up

Lower Gudgeon

0.0

F

0.0

F

0.0 P

0.0 P

Low S 0.0

A

0.0

A

0.0

FP

Low S 0.0

FS

AP

AS

Height/clearance of

steel chocks

TEST KEY :

COMPLETED

DATE :

- Test Performed

X - Test Not Applicable / Waive

S - Satisfactory Result

U - Unsatisfactory Result

WITNESSED BY :

WITNESSED BY :

WITNESSED BY :

_____________________

BUILDERS

REPRESENTATIVE

_____________________

OWNERS

REPRESENTATIVE

_____________________

CLASSS

REPRESENTATIVE

TEST SUPERVISED

BY :

Prepared By BNS/PPC/PQE - 2010