Professional Documents

Culture Documents

1 s2.0 S1877705815022237 Main

1 s2.0 S1877705815022237 Main

Uploaded by

Javier Alejandro RodriguezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 s2.0 S1877705815022237 Main

1 s2.0 S1877705815022237 Main

Uploaded by

Javier Alejandro RodriguezCopyright:

Available Formats

Available online at www.sciencedirect.

com

ScienceDirect

Procedia Engineering 120 (2015) 36 40

EUROSENSORS 2015

Accelerated soak performance of BPDA-PPD polyimide for

implantable MEAs

Elena Tolstosheeva, Volker Biefeld, Walter Lang*

Institute for Microsensors, -Actuators, and -Systems (IMSAS), University of Bremen, P.O. Box 330 440, 28334 Bremen, Germany

Abstract

To mature toward real-world applications biomedical sensors should maintain long-term functionality under relatively harsh invivo conditions. Microelectrode arrays (MEAs) rely on thin films, such as parylene C or polyimide, the water-barrier of which is

crucial for the long-term stability. This work reports on the high water-barrier of BPDA-PPD polyimide. This material was spincoated on interdigitated microstructures and immersed in saline@60C for 170 days. The interdigitated impedance remained

stable, higher than parylene C. Curing was crucial for the water-barrier of this polyimide: only long-cured microelectrode arrays

remained unchanged in their inter-electrode impedances as compared to short-cured devices when soaked in saline@60C for

140 days. Subjecting BPDA-PPD polyimide foils to water-vapour penetration revealed higher performance than parylene C.

These results disclose BPDA-PPD polyimide as a promising insulation for implantable MEAs.

2015

Published

by Elsevier

Ltd. This

is an open access article under the CC BY-NC-ND license

2015The

TheAuthors.

Authors.

Published

by Elsevier

Ltd.

(http://creativecommons.org/licenses/by-nc-nd/4.0/).

Peer-review

under

responsibility

of

the

organizing

committee of EUROSENSORS 2015.

Peer-review under responsibility of the organizing committee of EUROSENSORS 2015

Keywords: BPDA-PPD polyimide, U-Varnish, biomedical, ECoG, parylene C, encapsulation, accelartion soak test, aging, water-barrier, MEA

1. Motivation

Flexible biomedical devices have recently emerged to enable novel methods of signal-acquisition from within the

human body. In this regard, ECoG MEAs only several microns thick can acquire electrical activity of neuronal

populations directly from the cortical surface [1]. Herewith they offer information about cognitive behaviour of high

speed and accuracy for future weakly-invasive BCIs and neuroprosthetics [2]. Nevertheless, exactly the highly

* Corresponding author. Tel.: +49 421-218-62602; fax: +49 421/218-98-62602.

E-mail address: wlang@imsas.uni-bremen.de

1877-7058 2015 The Authors. Published by Elsevier Ltd. This is an open access article under the CC BY-NC-ND license

(http://creativecommons.org/licenses/by-nc-nd/4.0/).

Peer-review under responsibility of the organizing committee of EUROSENSORS 2015

doi:10.1016/j.proeng.2015.08.560

Elena Tolstosheeva et al. / Procedia Engineering 120 (2015) 36 40

miniaturized nature of ECoG MEAs makes them highly susceptible to diffusion of salt water most abundant

medium in-vivo and herewith to the formation of parasitic short-circuits between the electrode traces of the MEAs.

A prerequisite for ECoG devices to enter the market is to guarantee their in-vivo functionality for a span of

several years. Established packaging methods for established medical devices such as heart-pace makers and

cochlear implants cannot be applied because of the highly miniaturized nature of ECoG MEAs. Instead, polymeric

materials, such as parylene C or polyimide have served as thin-film isolation in most ECoG devices. The long-term

in-vitro stability of parylene C has been thoroughly investigated [3]. The BPDA-PPD polyimide has lowest moisture

absorption among the polyimides and was shown to maintain its mechanical properties in-vitro [4].

We used this polyimide for the fabrication of an ECoG MEA [1] and present here the in-vitro performance of a

5m-thick BPDA-PPD polyimide fabricated as: (1) a thin-film coating on interdigitated electrodes and (2) flexible

insulation of an ECoG MEA; (3) thin-foil specimen subjected to water-vapour penetration.

2. Materials and Methods

2.1. Microfabrication

Three samples sets were fabricated: 1). interdigitated electrodes (IDE) coated with short-cured BPDA-PPD

polyimide, long-cured one and parylene C as a reference; 2). MEAs made from short-cured BPDA-PPD polyimide

and long-cured one; 3). thin foils made from long-cured BPDA-PPD polyimide.

1.

IDE samples (see Fig.1): A borosilicate glass wafer was cleaned in Caros acid and sputter-coated with a

20/300nm thick Cr/Au. The Au surface was treated in O2 plasma (500W, 30s) to promote good adhesion and

a 1.8m-thick AZ1518 photoresist was spin-coated, exposed for 2.5s@ 12mW/cm2 and developed in AZ 726

MIF. The photoresist structure was transferred into Au by wet etching it in a Cyanide etch solution. The

resist was stripped in acetone & IPA, and the Au structure was transferred into Cr by wet etching. The wafer

was cleaned in Caros acid and coated by either a 5m-thick parylene C or a U-Varnish-S polyimide film

(BPDA-PPD PI), whereas the polyimide film was either short or long-cured (see Fig.2). A 10m-thick AZ

9260 photoresist was spin coated and structured into contact openings and the parylene/polyimide was

etched in an O2+CF4 RIE-plasma. The resist was stripped in AZ100 (15min@50C). The wafer was diced.

Fig. 1. Microfabrication flow of an IDE sensor with dimensions: 15mm x 15mm IDE-chip and 15m-wide IDE fingers.

Fig. 2. Curing profile of polyimide coating in a Centrotherm oven (short cure in N2) and a wafer-bonding tool (long cure in vacuum ambient).

37

38

Elena Tolstosheeva et al. / Procedia Engineering 120 (2015) 36 40

Fig. 3. Left image: BPDA-PPD polyimide-insulated ECoG MEA; Right image: 5m-thick BPDA-PPD polyimide foil peeled off the wafer.

2.

MEA samples (Fig.3, left) were fabricated as described in [3].

3.

Foil samples (Fig.3, right): 4 Si wafers were cleaned in Caros acid and their native oxides were stripped

with a HF dip. Straight afterwards the organosilane adhesion promoter VM651 was spin-coated for

60s@4000rpm and backed on a hotplate for 120s@120 C. A 5m-thick U-Varnish-S film (BPDA-PPD)

was spin-coated for 40s@3000rpm and soft-backed for 5min@80-120 C & 5min@120 C on a hotplate.

The samples were cured in a Substratbonder SUESS SB6 (long-curing) in a vacuum ambient; (2) chamber

evacuation. After the curing, the wafers were kept for a week in a wafer box. The polyimide films were then

peeled o the wafers as follows: (1) a razor was used to remove the PI residues from the wafer edges, and (2)

a rounded piece of paper to stepwise detach the polyimide foil o its wafer.

2.2. Measurement Test Set-Up

1.

2.

3.

IDE samples (Fig.4): glass cylinders were fixed on top, filled with saline (Fig.1) and kept @60C for 170

days. If water was absorbed by the coating, the impedance was reduced, which was monitored by an

electrochemical impedance spectroscope (EIS).

MEA samples (Fig.5): two MEAs were fabricated from BPDA-PPD PI: a short-cured and a long-cured one.

The electrode openings of the MEAs (circular portion in Fig.3, left) were kept in saline @60C for 140 days.

The impedances between electrode pairs (inter-electrode impedances) were monitored with a multiplexer

linked to an EIS, whereas an impedance decline was associated with water diffusion absorption by the

polyimide and/or lateral creeping along interfaces.

Foil samples: long-cured BPDA-PPD foils were subjected to water-vapour permeation analysis (two

samples). The water-vapour permeation tests were performed externally at PAUL LIPPKE HANDELSGMBH (www.mocon.eu) at 23 C, 85%RH.

Fig. 4. IDE-soak test: (A) schematic of sample cross-section; (B) Assembly of sealing gaskets on IDE-chips; (C) measurement set-up.

Elena Tolstosheeva et al. / Procedia Engineering 120 (2015) 36 40

Fig. 5. Left image: A flex-rigid MEA partially submerged in saline; Right image: The MEA is linked to a PCB to a NI multiplexer and an

IVIUM impedance meter.

3. Results

3.1. IDE samples

Fig.6 shows the impedance data obtained from the IDE samples: short-cured PI, parylene C and long-cured PI.

Polyimide curing is essential for the establishment of a high water-barrier of BPDA-PPD polyimide: short-cured PI

films decreased early in their impedance values (Fig.6, left); parylene C was stable with a slight decline in

impedance (Fig.6, middle), whereas long-cured BPDA-PPD PI remained most stable (Fig.6, right), even superior to

Parylene C.

Fig. 6. Results from in-vitro IDE-tests: short-cured BPDA-PPD polyimide declined quickly in impedance values (left image); Parylene C with

Silane A-174 adhesion promoter remained relatively high impedance values, with a slight decline (middle image); Long-cured BPDA-PPD

polyimide remained with most stable impedance values (right image); min. 3 samples per each polyimide type and 2 samples per parylene C.

3.2. MEA samples

Short-cured MEA declined in its inter-electrode impedance (see Fig.7, left image), whereas the long-cured MEA

maintained its inter-electrode impedance values (see Fig.7, right image).

39

40

Elena Tolstosheeva et al. / Procedia Engineering 120 (2015) 36 40

Fig. 7. Results from MEA soak tests: short-cured BDDA-PPD PI samples declined in inter-impedance values because of parasitic short-circuits

formation due to saline diffusion (left image); long-cured PI MEAs remained stable, with a slight decline in inter-electrode impedances.

3.3. Foil samples

The water-vapour permeation of BPDA-PPD PI foils was measured to be 0.022 gmm/m2day at 23C, 85%RH,

i.e. considerably lower than that of parylene C (0.083 gmm/m2day at 38C, 90%RH [5]).

4. Conclusion

We discovered that BPDA-PPD polyimide provided it is pre-cured suciently long time (long-cured PI

samples) maintains an exceptionally high lateral impedance magnitude measured by IDE-structures, even higher

than that of parylene C. Furthermore, MEA samples encapsulated in long-cured BPDA-PPD polyimide remained

stable in their impedance values despite the fact that saline could enter the device via the electrode openings. Letting

water-vapour permit the long-cured BPDA-PPD PI foils revealed an exceptionally high water-vapour barrier, even

higher than that of parylene C. A possible explanation for the excellent water-barrier properties of this polyimide is

that it is build from polymer chains arranged in a densely-packed poly-crystalline blocks and the water molecules

have difficulty to trespass it on their diusion via the polyimide film.

Acknowledgements

The authors highly appreciate the funding of the Bundesministerium fr Bildung und Forschung (BMBF), Grant

01EZ 0867 (Innovationswettbewerb Medizintechnik) and the German Excellence Initiative via the Creative Unit ISee. The brainstormings with Andreas Kreiter, Sunita Mandon and Victor Godillo-Gonzales contributed a lot to the

outcome of this work.

References

[1] E. Tolstosheeva, et al. (2015): A Multi-Channel, Flex-Rigid ECoG Microelectrode Array for Visual Cortical Interfacing. Sensors 15, 832854.

[2] David Rotermund, et al. (2013): Toward high performance, weakly invasive brain computer interfaces using selective visual attention. The

Journal of Neuroscience, 33(14):60016011.

[3] P.J. Seymour, et al. (2009): The insulation performance of reactive parylene films in implantable electronic devices. Biomaterials 30, 61586167.

[4] B. Rubehn, T. Stieglitz (2010): In vitro evaluation of the long-term stability of polyimide as a material for neural implants. Biomaterials 31,

3449-3458

[5] K. Massey, Permeability properties of plastics and elastomers. William Andrew, 2003.

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Best Practice Guide Compressed AirDocument28 pagesBest Practice Guide Compressed AirGrizz Ly100% (3)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Atlas Copco DIAMEC: 262 Skid VersionDocument4 pagesAtlas Copco DIAMEC: 262 Skid VersionEVCYNo ratings yet

- Munters General Psych ChartDocument2 pagesMunters General Psych CharteselcosacNo ratings yet

- EagleBurgmann DGSDocument8 pagesEagleBurgmann DGSdfNo ratings yet

- Camco KBMM, KBMG, KBUG Side Pocket MandrelDocument4 pagesCamco KBMM, KBMG, KBUG Side Pocket MandrelYovaraj KarunakaranNo ratings yet

- Machine Dowel Pins - Hardened Ground (Metric Series) : Product. For Definitions of Terms Relating To FasDocument6 pagesMachine Dowel Pins - Hardened Ground (Metric Series) : Product. For Definitions of Terms Relating To Fashcsharma1967No ratings yet

- 01the Gujarat Factories Rules 1963Document365 pages01the Gujarat Factories Rules 1963Siddhrajsinh Zala100% (1)

- Ip 287Document5 pagesIp 287Maíra Amaral100% (5)

- Boiler Combustion Theory and EfficiencyDocument84 pagesBoiler Combustion Theory and EfficiencyAhmed Hassan100% (1)

- AutoclaveDocument20 pagesAutoclaveNita Agarwal100% (1)

- Distillation Column DesignDocument120 pagesDistillation Column DesignOmesh Borole71% (7)

- Effect of Cavity Structure On The Risk of Engine Life Limited PartsDocument11 pagesEffect of Cavity Structure On The Risk of Engine Life Limited PartsJavier Alejandro RodriguezNo ratings yet

- Individual-Related Factors and Management-Related Factors in Aviation MaintenanceDocument10 pagesIndividual-Related Factors and Management-Related Factors in Aviation MaintenanceJavier Alejandro RodriguezNo ratings yet

- Turbine Blade Tip Leakage Flow Control by Unsteady Periodic Wakes of Upstream Blade RowDocument14 pagesTurbine Blade Tip Leakage Flow Control by Unsteady Periodic Wakes of Upstream Blade RowJavier Alejandro RodriguezNo ratings yet

- Human-Rating Design of Visual Coding Based On The Airworthiness RequirementsDocument8 pagesHuman-Rating Design of Visual Coding Based On The Airworthiness RequirementsJavier Alejandro RodriguezNo ratings yet

- Surrogate-Based Sensitivity Analysis For Safety Assessment of General Aviation Heavy-Fueled EnginesDocument10 pagesSurrogate-Based Sensitivity Analysis For Safety Assessment of General Aviation Heavy-Fueled EnginesJavier Alejandro RodriguezNo ratings yet

- Advanced Electrochemical in Vitro Detection of Superoxide Radicals With Fully Integrated Microsensor SystemDocument5 pagesAdvanced Electrochemical in Vitro Detection of Superoxide Radicals With Fully Integrated Microsensor SystemJavier Alejandro RodriguezNo ratings yet

- 1 s2.0 S1877705815022286 MainDocument6 pages1 s2.0 S1877705815022286 MainJavier Alejandro RodriguezNo ratings yet

- Vulnerability and Resilience Under Effects of Tsunamis: Case of Industrial PlantsDocument6 pagesVulnerability and Resilience Under Effects of Tsunamis: Case of Industrial PlantsJavier Alejandro RodriguezNo ratings yet

- Research On Ranking Evaluation Models of Safety Risk in Productive Enterprises Based On The Perspective of SupervisionDocument8 pagesResearch On Ranking Evaluation Models of Safety Risk in Productive Enterprises Based On The Perspective of SupervisionJavier Alejandro RodriguezNo ratings yet

- Sopras Sub Jupiter Diaphragm First Stage: Maintenance InstructionsDocument13 pagesSopras Sub Jupiter Diaphragm First Stage: Maintenance InstructionscesarecontoNo ratings yet

- Capitulo I PDFDocument47 pagesCapitulo I PDFJulio CamelNo ratings yet

- How To Identify Failure and Probable Cause: Spicer Driveshaft Components Failure Analysis GuideDocument5 pagesHow To Identify Failure and Probable Cause: Spicer Driveshaft Components Failure Analysis GuidelusthawkNo ratings yet

- Melting Point NotesDocument7 pagesMelting Point Notesdfcgvh gvhbjNo ratings yet

- Product Kemcrete Nov16 PDFDocument2 pagesProduct Kemcrete Nov16 PDFSeifeldin Ali MarzoukNo ratings yet

- Sintex Junction Box Price List 01.01.2021Document1 pageSintex Junction Box Price List 01.01.2021Rajesh Dey100% (1)

- Damage and Fracture of Composite Materials and Structures: September 2012Document7 pagesDamage and Fracture of Composite Materials and Structures: September 2012Komal ChawlaNo ratings yet

- For More Information Please Call 1-800-Belden1Document2 pagesFor More Information Please Call 1-800-Belden1Shah JeeNo ratings yet

- Geotechnical Aspects of Building Design (EN 1997) : Eurocode 2Document55 pagesGeotechnical Aspects of Building Design (EN 1997) : Eurocode 2margitorsiNo ratings yet

- Pentadyne VSS BrochureDocument4 pagesPentadyne VSS BrochureWalid WahyudiNo ratings yet

- Airslide Check List1Document6 pagesAirslide Check List1SANTOSH RATHODNo ratings yet

- Ceramic XrayDocument9 pagesCeramic XrayFandi MarcelloNo ratings yet

- Distillation Columns and Their Process CalculationsDocument6 pagesDistillation Columns and Their Process CalculationsOmer IbrahimNo ratings yet

- Insect Assembly3Document37 pagesInsect Assembly3willbezztNo ratings yet

- HCGHVJ1 - 13Document16 pagesHCGHVJ1 - 13Sahil GrgNo ratings yet

- Lotation: Presents by Group 6Document30 pagesLotation: Presents by Group 6Ricardo KhalidNo ratings yet

- Selection of Optimal Geometrical & Kinematic Variables .: Design of Wind TurbinesDocument32 pagesSelection of Optimal Geometrical & Kinematic Variables .: Design of Wind Turbinesmichaeledem_royalNo ratings yet

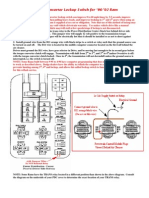

- Torque Converter Lockup SwitchDocument2 pagesTorque Converter Lockup SwitchKenny G Nichol100% (1)

- Maldaner Brochure English PDFDocument4 pagesMaldaner Brochure English PDFSaad KhanNo ratings yet